Abstract

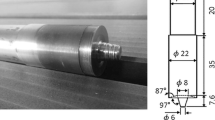

Micro-indentation technique was employed to study the hardness and elastic modulus for different positions along the thickness of weld nugget zone (WNZ) in friction stir welded aluminum alloy thick plate joints and base material (BM). Experimental results showed that maximum hardness and elastic modulus 2.11 and 81.6 GPa were obtained in the top of WNZ, minimum values 0.79 and 74.9 GPa present in the BM, respectively. For different positions, both of them were as follows: BM < bottom < middle < top. Meanwhile, the hardness decreased with the increase in grain size or the load. The rod-like shape precipitates presented in the BM and the round particles of top was smaller than that of middle and bottom, and the top of WNZ presents the higher dislocation density.

Similar content being viewed by others

References

Zhang TY, Xu WH, Zhao MH (2004) Acta Mater 52:57

Uzun O, Kolemen U, Celebi S, Guclu N (2005) J Eur Ceram Soc 25:969

Culha O, Toparlia M, Sahinb S, Aksoy T (2008) J Mater Process Technol 206:231

Yang M, Akiyama Y, Sasaki T (2004) J Mater Process Technol 151:232

Thomas WM, Nicholas ED, Needham JC, Murch MG, Temple-Smith P, Dawes CJ (1995) International Patent No. PCT/GB92/02203; GB Patent No. 9,125,978.8, 1991; US Patent No. 5,460,317, 1995

Xu WF, Liu JH, Luan GH, Dong CL (2009) Mater Design 30:1886

Zhang Z (2008) J Mater Sci 43:5867. doi:10.1007/s10853-008-2865-x

Venkateswaran P, Xu ZH, Li XD, Reynolds AP (2009) J Mater Sci 44:4140. doi:10.1007/s10853-009-3607-4

Ghosh S, Pal TK, Mukherjee S, Das G, Ghosh S (2008) J Mater Sci 43:5474. doi:10.1007/s10853-008-2840-6

Dwyer-Joyce RS, Ushijima Y, Murakami Y, Shibuta R (1998) Tribol Int 31:525

Oliver WC, Pharr GM (1992) J Mater Res 7:1564

Zeng K, Chiu CH (2001) Acta Mater 49:3539

Nix WD, Gao H (1998) J Mech Phys Solids 46:411

Xu WF, Liu JH, Luan GH, Dong CL (2008) Acta Metall Sin 44:1404

Su JQ, Nelson TW, Mishra R, Mahoney M (2003) Acta Mater 51:713

Safarkhanian MA, Goodarzi M, Boutorabi SMA (2009) J Mater Sci 44:5452. doi:10.1007/s10853-009-3735-x

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, W., Liu, J. & Zhu, H. A study on the hardness and elastic modulus of friction stir welded aluminum alloy thick plate joints using micro-indentation. J Mater Sci 46, 1161–1166 (2011). https://doi.org/10.1007/s10853-010-4886-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4886-5