Abstract

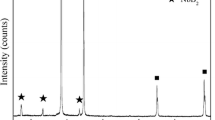

AM60B alloy has been refined by SiC particles and the corresponding refining mechanism has been mainly discussed. The results indicate that the addition of 0.2 wt% SiC particles in form of mixture with Mg powder decreases the grain size from 317 μm of the not refined alloy to 46 μm. The decrease of β phase and formation of Mg2Si and Al4C3 phases well demonstrate that the reactions of 3SiC + 4Al = Al4C3 + 3Si and 2Si + Mg = Mg2Si occur during refining treatment. In addition, the crystal nuclei are composed of two kinds of elements, Al and C. All of these imply that the formed Al4C3 particles are the actual heterogeneous nucleation substrates.

Similar content being viewed by others

References

Eliezer D, Aghion E, Froes FH (1998) Adv Perform Mater 5:201

Wang YX, Zeng XQ, Ding WJ, Luo AA, Sachdev AL (2007) Metall Mater Trans A38:1358

Chen TJ, Lu GX, Ma Y, Li YD, Hao Y (2009) J Alloys Compd 486:124

Chen B, Lin DL, Zeng XQ, Lu C (2010) J Mater Sci 45:2510. doi:10.1007/s10853-010-4223-z

Shepelev D, Bamberger M, Katsman A (2009) J Mater Sci 44:5627. doi:10.1007/s10853-009-3793-0

Cao P, Qian M, StJohn DH (2007) Scripta Mater 56:633

Motegi T (2005) Mater Sci Eng A 413–414:408

Cao P, Qian M, St John DH (2006) Scripta Mater 54:1853

Dahle AK, Lee YC, Nave MD, Schaffer PL, St John DH (2001) J Light Met 1:61

Cao P, Qian M, St John DH (2004) Scripta Mater 51:125

Kim YM, Wang L, You BS (2009) J Alloys Compd. doi:10.1016/j.jallcom.2009.10.141

Liu S, Zhang Y, Han H (2009) J Alloys Compd. doi:10.1016/j.jallcom.2009.10.161

Wang SC, Chou CP (2008) J Mater Proc Technol 197:116

Wang Y, Zeng X, Ding W (2006) Scripta Mater 54:269

Yang M, Pan F, Cheng R, Tang A (2008) J Alloys Compd 461:298

Ma G, Han G, Liu X (2009) J Alloys Compd. doi:10.1016/j.jallcom.2009.10.221

Suresh M, Srinivasan A, Ravi KR, Pillai UTS, Pai BC (2009) Mater Sci Eng A525:207

Fu HM, Qiu D, Zhang MX, Wang H, Kelly PM, Taylor JA (2008) J Alloys Compd 456:390

Gunther R, Hartig C, Bormann R (2006) Acta Mater 54:5591

Easton MA, Schiffl A, Yao J-Y, Kaufmann H (2006) Scripta Mater 55:379

Lu L, Dahle AK, St John DH (2005) Scripta Mater 53:517

Qian M, Cao P (2005) Scripta Mater 52:7415

He YB, Pan QL, Qin YJ, Liu XY, Li WB (2010) J Mater Sci 45:1655. doi:10.1007/s10853-009-4143-y

Figueiredo RB, Langdon TG (2009) J Mater Sci 44:4758. doi:10.1007/s10853-009-3725-z

Hou LF, Wei YH, Liu BS, Xu BS (2008) J Mater Sci 43:4658. doi:10.1007/s10853-008-2668-0

Park J, Kim M, Yoon U, Kim WJ (2009) J Mater Sci 44:47. doi:10.1007/s10853-008-3130-z

Liu S, Chen Y, Han H (2009) J Alloys Compd. doi:10.1016/j.jallcom.2009.12.064

Jin QL, Eom J-P, Lim S-G, Park W-W, You B-S (2005) Scripta Mater 52:421

Pan Y, Liu X, Yang H (2005) Mater Charact 55:241

Jiang QC, Wang HY, Wang Y, Ma BX, Wang JG (2005) Mater Sci Eng A392:130

Hadian R, Emamy M, Campbell J (2009) Metall Mater Trans B. doi:10.1007/s11663-009-9251-1

Li C, Wu Y, Li H, Liu X (2009) J Alloys Compd 477:212

Liu YH, Liu XF, Bian XF (2004) Mater Lett 58:1282

Sritharan T, Chan LS, Tan LK, Hung NP (2001) Mater Charact 47:75

Lee J-C, Byun J-Y, Park S-B (1998) Acta Mater 46:1771

Zhang MX, Kelley PM, Qian M, Taylor JA (2005) Acta Mater 53:3261

Acknowledgements

This work was supported by the National Basic Research Program of China (grant No. G2007CB613706), the Development Program for Outstanding Young Teachers in Lanzhou University of Technology and the Opening Foundation of Key Laboratory of Gansu Advanced Non-ferrous Materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, T.J., Ma, Y., Lv, W.B. et al. Grain refinement of AM60B magnesium alloy by SiC particles. J Mater Sci 45, 6732–6738 (2010). https://doi.org/10.1007/s10853-010-4767-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4767-y