Abstract

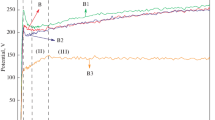

Titanium oxide (TiO2) coatings were formed on titanium substrates in a sodium silicate (Na2SiO3) aqueous solution, using plasma electrolytic oxidation method. The effects of duty ratio, frequency, and positive/negative pulse proportion on the microstructure and phase compositions of the coatings were investigated. The coatings were mainly composed of anatase TiO2 plus a little amount of rutile TiO2. The coatings obtained at the frequency range 900–2700 Hz, under a duty ratio of 20%, and a positive/negative pulse proportion of 3, showed the best quality in terms of density and adhesion. The effect of positive/negative pulse proportion was relatively small. However, continuous coating could not be obtained using the positive/negative pulse proportion of 1. Compared with that of bare titanium, the property of resistance to corrosion was obviously improved for the titanium with TiO2 coating. The corrosion potential rose about 0.13 V and the corrosion current density decreased about one order of magnitude.

Similar content being viewed by others

References

Brewer WD, Bird RK, Wallace TA (1998) Mater Sci Eng A 243:299

Tjong SC, Mai YW (2008) Compos Sci Technol 68:583

Yamashita Y, Takayama I, Fujii H, Yamazai T (2002) Nippon Steel Tech Rep 85:11

Cannillo V, Colmenares-Angulo J, Lusvarghi L, Pierli F, Sampath S (2009) J Eur Ceram Soc 29:1665

Matykina E, Arrabal R, Skeldon P, Thompson GE (2009) Acta Biomater 5:1356

Geetha M, Singh AK, Asokamani R, Gogia AK (2009) Prog Mater Sci 54:397

Schutz RW, Watkins HB (1998) Mater Sci Eng A 243:305

Rahman M, Wang ZG, Wong YS (2006) JSME Int J Ser C 49:11

Wang YM, Jia DC, Guo LX, Lei TQ, Jiang BL (2005) Mater Chem Phys 90:128

Moskalewicz T, Smeacetto F, Czyrska-Filemonowicz A (2009) Surf Coat Technol 203:2249

Kalita VI, Gnedovets AG (2005) Plasma Process Polym 2:485

Cammarota GP, Casagrande A, Poli G, Veronesi P (2009) Surf Coat Technol 203:1429

Yang W, Hsu M, Lin M, Chen Z, Chen L, Huang H (2009) J Alloys Compd 479:642

Teng S, Liang W, Li Z, Ma X (2008) J Alloys Compd 464:452

Zhang XJ, Gao YH, Ren BY, Tsubaki N (2010) J Mater Sci 45:1622. doi:10.1007/s10853-009-4138-8

Fritsche A, Haenle M, Zietz C, Mittelmeier W, Neumann H, Heidenau F, Finke B, Bader R (2009) J Mater Sci 44:5544. doi:10.1007/s10853-009-3776-1

Gong S, Xu H, Yu Q, Zhou C (2000) Surf Coat Technol 130:128

Yerokhin AL, Nie X, Leyland A, Matthews A, Dowey SJ (1999) Surf Coat Technol 122:73

Parfenov EV, Yerokhin AL, Matthews A (2007) Thin Solid Films 516:428

Zhao Z, Chen X, Chen A, Huo G, Li H (2009) J Mater Sci 44:6310. doi:10.1007/s10853-009-3869-x

Xue W, Deng Z, Chen R, Zhang T (2000) Thin Solid Films 372:114

Yerokhin AL, Nie X, Leyland A, Matthews A (2000) Surf Coat Technol 130:195

Xue W, Wang C, Deng Z, Zhang T (2002) ISIJ Int 42:651

Han Y, Hong SH, Xu KW (2002) Surf Coat Technol 154:314

Matykina E, Skeldon P, Thompson GE (2007) Surf Eng 23:412

Birss V, Xia S, Yue R, Rateick RG Jr (2004) J Electrochem Soc 151:B1

Han Y, Hong S, Xu K (2003) Surf Coat Technol 168:249

Yao Z, Cui R, Jiang Z, Wang F (2007) Appl Surf Sci 253:6778

Rudnev VS, Yarovaya TP, Lysenko AE, Nedosorov PM, Dushina NE (2008) Prot Met 44:715

Klapkiv MD (1995) Mater Sci 31:494

Gu WC, Lv GH, Chen H, Chen GL, Feng WR, Yang SZ (2007) Mater Sci Eng A 447:158

Teh TH, Berkani A, Mato S, Skeldon P, Thompson GE, Habazaki H, Shimizu K (2003) Corros Sci 45:2757

Guan Y, Xia Y, Li G (2008) Surf Coat Technol 202:4602

Colmenares-Angulo JR, Cannillo V, Lusvarghi L, Sola A, Sampath S (2009) J Mater Sci 44:2276. doi:10.1007/s10853-008-3044-9

Lu SW, Harris C, Walck S, Arbab M (2009) J Mater Sci 44:541. doi:10.1007/s10853-008-3086-z

Erokhine A, Voevodin AA, Schmertzler RD (1998) US Patent 5,720,866

Acknowledgements

The authors acknowledge the financial support from the Canadian National Program on Generation IV Energy Technologies. The authors would like to thank Tom Vanderhoek for the preparation of metallic substrates.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, C., Hui, R., Qu, W. et al. Effects of processing parameters on microstructures of TiO2 coatings formed on titanium by plasma electrolytic oxidation. J Mater Sci 45, 6235–6241 (2010). https://doi.org/10.1007/s10853-010-4718-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4718-7