Abstract

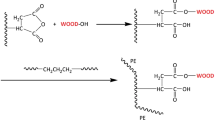

This study evaluated some physical and mechanical properties of injection-moulded polypropylene (PP) composites reinforced with various mixtures of the wood flour (WF) and the olive mill sludge (OMS). Water resistance of the composites improved by the increasing OMS flour content. However, the flexural properties of the composites decreased with increasing OMS flour content. The addition of a coupling agent improved the compatibility between the lignocellulosic material and PP through esterification and thus reduced the water absorption and improved the stability and mechanical properties. The findings obtained in the study showed that the OMS was capable of serving as new reinforcing filler in the manufacturing of thermoplastic polymer composites.

Similar content being viewed by others

References

Alburquerque JA, Gonzalvez J, Garcia D, Cegarra J (2004) Bioresource Technol 91:195

IOR, Olive oil technology, Institute of Olive Researches. http://www.zae.gov.tr/zeytinyagi/7.asp. Accessed on August 2009

Fornes F, Fuente RG, Belda RM, Abad M (2009) Bioresource Technol 100:3982

Vlyssides AG, Loizidou M, Gimouhopoulos K, Zorpas A (1998) Fresenious Environ Bull 7:308

Hytiris N, Kapellakis IE, de Roij RL, Tsagarakis KP (2004) Resour Conserv Recy 40:129

Varol M (2006) Combustion and co-combustion of olive pomace and coal in a fluidized bed. MSc Thesis, Middle East Technical University, 175 pp

Varol M, Atimtay AT (2007) Fuel 86:1430

Ashori A (2008) Bioresource Technol 99:4661

Ashori A, Nourbakhsh A (2009) Waste Manage 29:1291

Georgopoulos ST, Tarantili PA, Avgerinos E, Andreopoulos AG, Koukios EG (2005) Polym Degrad Stabil 90:303

Liu H, Wua Q, Zhang Q (2009) Bioresource Technol 100:6088

Panthapulakkal S, Zereshkian A, Sain M (2006) Bioresource Technol 97:265

Mustapa MSE, Hassan A, Rahmat AR (2005) Symposium polimer kebangsaan KeV hotel residence, 23–24 August 2005, pp 185–191

Talavera FJF, Guzman JAS, Richter HG, Duenas RS, Quirarte JR (2007) Indus Crops Prod 26:1

Son J, Yang HS, Kim HJ (2004) J Thermoplast Compos 17:509

Balasubramanian M, Paglicawan MA, Zhang ZX, Lee SH, Xin ZZ, Kim JK (2008) J Thermoplast Compos 21:51

Ramaraj B (2007) J Appl Polym Sci 103:3827

Kim HS, Yang HS, Kim HJ, Park HJ (2004) J Therm Anal Calorim 76:395

ASTM D 570-05 (2005) Annual book of ASTM standards. 8.01. Standard test method for water absorption of plastics. American Society Testing Materials, Conshohocken, PA

ASTM D 790-03 (2003) Annual book of ASTM standards. 8.01. Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. American Society Testing Materials, Conshohocken, PA

ASTM D 618-08 (2008) Annual book of ASTM standards. 8.01. Practice for conditioning plastics for testing. American Society Testing Materials, Conshohocken, PA

ANSI/AHA A135.4 (2004) Basic hardboard. American Hardboard Association, Palatine, IL

Wood handbook (1999) Wood as an engineering material. United States Department of Agriculture Forest Service, Forest Products Laboratory, Madison WI, 463 pp

Ayrilmis N (2000) The effect of tree species on technological properties of MDF. MSc Thesis, Institute of Natural Sciences, Istanbul University, 227 pp

Stokke DD, Gardner DJ (2003) J Vinyl Addit Techn 9:96

Adhikary KB, Pang S, Staiger MP (2008) Composites B 39:807

Stark N (2001) J Thermoplast Compos 14:421

Matuana LM, Balatinecz JJ, Sodhi RNS, Park CB (2001) Wood Sci Technol 35:191

Walker J (2004) Primary wood processing: principles and practice, 2nd edn. Springer, Dordrecht, 596 pp

Acknowledgement

The authors gratefully acknowledge Research Fund of Istanbul University for the laboratory equitment used in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ayrilmis, N., Buyuksari, U. Utilization of olive mill sludge in manufacture of lignocellulosic/polypropylene composite. J Mater Sci 45, 1336–1342 (2010). https://doi.org/10.1007/s10853-009-4087-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-4087-2