Abstract

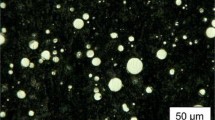

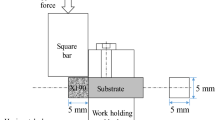

The success of semi-solid metal processing mostly depends on the formation of suitable starting microstructure, which must consist of solid metal spheroids in a liquid matrix. Various methods of obtaining this structure have been established; they include recrystallisation and partial melting (RAP), strain-induced melt-activated (SIMA), or simple mechanical stirring, to name a few. These methods, as widely discussed, have mostly been applied with light alloys, mainly aluminium based. This article discusses solid–liquid structural break-up in M2 tool steel subjected to a direct re-melting procedure from the as-annealed condition. The role of carbide dissolution in the grain boundary liquation of the steel is described. This leads to the production of near spheroidal solid grains in a liquid matrix, a microstructure suitable for the thixoforming process. Microstructural examination revealed that carbide particles contained in bands at 1220 °C slowly disappeared with temperature. At 1300 °C, the solid grains seemed to be free from carbides. Most of the carbides had now re-precipitated at the grain boundaries. Thixoforming carried out at 1340 and 1360 °C revealed the thixotropic properties of the semi-solid metal slurries. The results indicate a widening of the range of potential routes to thixoformable microstructures.

Similar content being viewed by others

References

Spencer DB, Mehrabian R, Flemings MC (1972) Metall Mater Trans 3A:1925

Flemings MC (1991) Metall Trans A 22A:957

Kirkwood DH (1994) Int Mater Rev 39(5):173

Fan Z (2002) Int Mater Rev 47(2):49

Legoretta EC, Atkinson HV, Jones H (2008) J Mater Sci 43:5456. doi:https://doi.org/10.1007/s10853-008-2829-1

Nohn B, Morjan U, Hartmann D (2000) In: Proceedings of the 6th international conference on semi-solid processing of alloys and composites, Turin, Italy. Edimet Spa, Brescia, pp 265–272

Omar MZ, Atkinson HV, Palmiere EJ, Howe AA, Kapranos P (2004) Steel Res Int 75(8/9):552

Omar MZ, Palmiere EJ, Howe AA, Atkinson HV, Kapranos P (2005) Mater Sci Eng A 395:53

Puttgen W, Bleck W, Hirt G, Shimahara H (2007) Adv Eng Mater 9(4):231

Kapranos P, Kirkwood DH, Sellars CM (1993) J Phys IV Colloque C7, Suppl J Phys III 3:835

Kapranos P, Kirkwood DH, Sellars CM (1996) In: Proceedings of the 4th international conference on semi-solid processing of alloys and composites, The University of Sheffield, Sheffield, UK, pp 306–311

Kapranos P, Ward PJ, Atkinson HV, Kirkwood DH (2000) Mater Des 21:387

American Society for Testing and Materials (1996) ASTM E 112-96

American Society for Testing and Materials (1999) ASTM E 562-99

Roberts GA, Hamaker JC Jr, Johnson AR (1971) Tool steels, 3rd edn. American Society for Metals, Metals Park

Omar MZ, Palmiere EJ, Howe AA, Atkinson HV, Kapranos P (2004) In: Proceedings of the 8th international conference on semi-solid processing of alloys and composites, Limassol, Cyprus. North American Die Casting Association, Wheeling

Honeycombe RWK, Bhadeshia HKDH (1995) Steels: microstructure and properties. Edward Arnold, UK

Meuser H, Bleck W (2001) Steel Res Int 72(7):271

Meuser H, Bleck W (2002) In: 7th International conference on semisolid processing of alloys and composites, Tsukuba, Japan, pp 349–354

Dienes GJ, Klemm HF (1946) J Appl Phys 17:458

Acknowledgements

The authors wish to thank Universiti Kebangsaan Malaysia (a.k.a National University of Malaysia), Malaysia, for financial assistance, and the University of Sheffield, UK, for the provision of laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omar, M.Z., Atkinson, H.V., Howe, A.A. et al. Solid–liquid structural break-up in M2 tool steel for semi-solid metal processing. J Mater Sci 44, 869–874 (2009). https://doi.org/10.1007/s10853-008-3181-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3181-1