Abstract

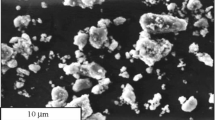

Tetragonal ZrO2 polycrystalline (TZP) ceramics with varying yttria and ceria content (2–3 mol%) and distribution (coated or co-precipitated), and varying second phase content Al2O3 were prepared and investigated by means of microstructural analysis, mechanical properties, and hydrothermal stability, and ZrO2-based composites with 35–60 vol% of electrical conductive TiN particles were developed. The effects of stabilizer content and means of addition, powder preparation, sintering conditions, and grain size have been systematically investigated. Fully dense Y-TZP ceramics, stabilized with 2–3 mol% Y2O3, 2 wt% Al2O3 can be achieved by hot pressing at 1,450 °C for 1 h. The hydrothermal stability increased with increasing overall yttria content. The jet-milled TiN powder was used to investigate the ZrO2–TiN composites as function of the TiN content. The experimental work revealed that fully dense ZrO2–TiN composites, stabilized with 1.75 mol% Y2O3, 0.75 wt% Al2O3, and a jet-milled TiN content ranging from 35 to 60 vol% could be achieved by hot pressing at 1,550 °C for 1 h. Transformation toughening was found as the primary toughening mechanism. The decreasing hardness and strength could be attributed to an increasing TiN grain size with increasing TiN content, whereas the decreasing toughness might be due to the decreasing contribution of transformation toughening from the tetragonal to monoclinic ZrO2 phase transformation. The E modulus increases linearly with increasing TiN content, whereas the hydrothermal stability increases with addition of TiN content.

Similar content being viewed by others

References

Gremillard L, Chevalier J, Epicier T, Fantozzi G (2002) J Am Ceram Soc 85(2):401

Basu B, Vleugels J, Biest OV (2004) Mater Sci Eng A366:338

Mudali UK, Sridhar TM, Raj B (2003) Sadhana 28:601

Hannink RHJ, Swain MV (1994) Annu Rev Mater Sci 24:359

Chevalier J, Cales B, Drouin JM (1999) J Am Ceram Soc 82(8):2150

Fang P, Gu H, Wang P, Landuyt JV, Vleugels J, Biest OV (2005) J Am Ceram Soc 88:1929

Vleugels J, Zhao C, Biest OV (2005) Mater Sci Forum 492–493:699

Basu B, Vleugels J, Biest OV (2004) J Eur Ceram Soc 24:2031

Vleugels J, Yuan ZX, Biest OV (2002) J Eur Ceram Soc 22:873

Chevalier J (2006) Biomaterials 27:535

Hraguchi K et al (2001) J Bone Joint Surg 83-B:996

Vleugels J, Biest OV (1999) J Am Ceram Soc 82(10):2717

Salehi S, Biest OV, Vleugels J (2005) J Eur Ceram Soc 5873:1

Huang SG, Vleugels J, Li L, Biest OV, Wang PL (2005) J Eur Ceram Soc 25:3109

Lawson S, Gill C, Smith GP, Egerton TA, Mccolgan P (1993) Third Euro-Ceramics V.3:507

Singh R, Gill C, Lawson S, Dransfield GP (1996) J Mater Sci 31:6055

Lawson S (1995) J Eur Ceram Soc 15:485

Acknowledgements

M. Arin would like to thank International Coordination of Istanbul Technical University and Kathoieke Univesiteit Leuven for giving an opportunity to study in the framework of Erasmus exchange programme. M. Arin also thanks to the laboratory technician H. H. Sezer and Research Assistant V. Ezirmik in Istanbul Technical University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arin, M., Goller, G., Vleugels, J. et al. Production and characterization of ZrO2 ceramics and composites to be used for hip prosthesis. J Mater Sci 43, 1599–1611 (2008). https://doi.org/10.1007/s10853-007-2343-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2343-x