Abstract

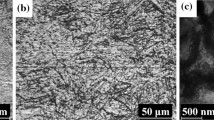

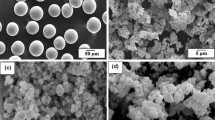

Wear-resistant titanium materials with high hardness and strength can be manufactured by introducing very fine titanium silicides and carbides into an ultrafine-grained titanium matrix. Nanocrystalline titanium particles with fine and homogeneous distributed carbon and silicon were generated by high energy ball milling of titanium with silicon powder or additions of the organic fluid hexamethyldisilane (HMDS). Spark Plasma Sintering (SPS) was chosen to compact the granules to prevent grain coarsening during sintering. Additionally, the Ti5Si3 and TiC x dispersoids limited grain coarsening. After sintering, the novel materials exhibited high hardness and strength, and excellent wear resistance. The electrochemical behaviour (comparable to that of commercially pure titanium) was also tested and showed the excellent suitability as an implant material.

Similar content being viewed by others

References

Breme HJ (1996) In: Peters M, Leyens C, Kumpfert J (eds) Titan und Titanlegierungen. DGM Informationsgesellschaft mbH

Wintermantel E, Ha S-W (1998) Biokompatible Werkstoffe und Bauweisen, 2., vollst. neubearb. Aufl. Springer, Heidelberg

Sauer C, Weißgärber T, Dehm G, Mayer J, Püsche W, Kieback B (1998) Z Metallkd 89:119

Tokita M (1999) Mater Sci Forum 308–311:83

Handtrack D, Sauer C, Kieback B (2004) Proc PM2004 World Congr, Vienna 419

Handtrack D, Despang F, Sauer C, Kieback B, Reinfried N, Grin Y (2006) Mat Sci Eng A 437:423

Handtrack D (2006) Dissertation, Technische Universitaet Dresden (submitted in Sept. 2006)

Boukamp BA (1993) Equivalent Circuit, Version 4.51, University of Twente

Pan J, Leygraf C, Thierry D, Ektessabi AM (1997) J Biomed Mater Res 35:309

Schubert-Bischoff P, Bloeck U, personal communication

Koch CC, Youssef KM, Scattergood RO, Murty KL (2005) Adv Eng Mater 7(9):787

Han BQ, Lavernia EJ (2005) Adv Eng Mater 7(6):457

Wang Y, Chen M, Zhou F, Ma E (2002) Nature 419:912

Eisenbarth E, Meyle J, Nachtigall W, Breme J (1996) Biomat 17:1399

Spyrou P, Papaioannou S, Hampson G, Brady K, Palmer RM, McDonald F (2002) Clin Oral Impl Res 13:623

Scharnweber D, Beutner R, Roeßler S, Worch H (2002) J Mater Sci: Mater Med 13:1215

Thull R (1998) In: Helsen JA, Breme HJ (eds) Metals as Biomaterials. John Wiley, New York, p 289

Scharnweber D (1998) In: Helsen JA, Breme HJ (eds) Metals as Biomaterials. John Wiley, New York, p 101

Velten D, Biehl V, Aubertin F, Valeske B, Possart W, Breme J (2002) J Biomed Mater Res 59:18

Schmidt H, Exner HE (1999) Z Metallkd 90:594

Zwicker U (1974) Titan und Titanlegierungen. Springer Verlag, Berlin

Khan MA, Williams RL, Williams DF (1996) Biomat 17:2117

Acknowledgements

The authors would like to thank Y. Grin, N. Reinfried (MPI Dresden), G. Walther (IFAM Dresden), T. Gemming (IFW Dresden) and K. Peters (Mainz University) for the technical support and fruitful discussions. The financial support by the Deutsche Forschungsgemeinschaft (Schwerpunktprogramm 1100) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Handtrack, D., Sauer, C. & Kieback, B. Microstructure and properties of ultrafine-grained and dispersion-strengthened titanium materials for implants. J Mater Sci 43, 671–679 (2008). https://doi.org/10.1007/s10853-007-2160-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2160-2