Abstract

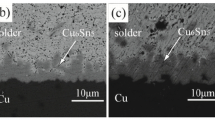

In this work preliminary results are reported on the characterization of Pb-free joints produced by using a diffusion soldering method at a process temperature of 700 °C during 20 min. The solder alloy is a metallic paste involving Ga and Al and Ni powder, and the substrates are Cu and Ni. The dissolution and diffusion-reaction processes, which take place at the interfaces of the interconnection zone, have been investigated by means of SEM and EPMA. A solid solution and intermetallic compounds (IMCs) with high melting point form as layers almost free from defect, allowing service temperatures about 500 °C higher than the process temperature. The phase stability sequence starting from the Ni to the Cu interface is the following: α′-Ni3Ga, γ-Cu9Ga4, β-Cu3Ga and (Cu) solid solution of the Ga–Cu system. The relative reaction front displacement of the layers and the implications of the present findings for the applicability of the diffusion-soldering method are also discussed.

Similar content being viewed by others

References

Directive 2002/95/Ec of The European Parliament and of the Council of 27 January 2003 on the restriction of the use of certain hazardous substances in electrical and electronic equipment, pp L 37/19–23

Directive 2002/96/Ec of the European Parliament and of the Council of 27 January 2003 on waste electrical and electronic equipment (WEEE) Official Journal of the European Union, 13.2.2003, pp L 37/24–38

Glazer J (1995) Inter Mater Rev 40:65

Abtew M, Selvaduray G (2000) Mater Sci Eng R 27:95

Suganuma K (2001) Curr Opin Solid State Mater Sci 5:55

Zeng K, Tu KN (2002) Mater Sci Eng R 38:55

Kattner UR (2002) J Mater 54 (12):45

Cui Y, Liu XJ, Ohnuma I, Kainuma R, Ohtani H, Ishida K (2001) J Alloys Compd 320:234

Kaufman L (1991) In: Doyama M, Suzuki T, Kihara J, Yamamoto R (eds) Computer aided innovation of new materials. Elsevier, Amsterdam, p 773

Frear DR, Jones WR, Kinsman KR (1991) Solder mechanics—a state of the art assessment. The Mineral, Metals & Materials Socienty, Warrandale, PA

Schwartz GC, Srikrishnan KV, Bross A (1998) Handbook of semiconductor interconnection technology. Marcel Dekker Inc, New York

Zhou Y, Gale WF, North TH (1995) Int Mater Rev 40:181

MacDonald WD, Eager TW (1992) Annu Rev Mater Sci 22:23

Sinclair CW (1999) J Phase Equilib 20:36 1

Humpston G, Jacobson DM (1993) Principles of soldering and brazing. ASM International, Materials Park, OH, p 128

Nishimoto K, Saida K, Kim D, Nakao Y (1995) ISIJ Int 35:1298

Nakao Y, Nishimoto K, Shinozaki K, Kang CY (eds) (1990) In: North TH (ed) Joining of advanced materials, Chapman Hall, New York, p 129

Yeh MS, Chuang TH (1997) Weld J 76(12):517

Hansen M (eds) (1990) Constitution of binary alloys. McGraw-Hill Book Co, New York

Smith DL, Caul HJ (1956) J Am Dent Assoc 53:315

Bhattacharya SK, Baldwin DF (2000) Adv Packaging 9(8):61

Gale WF, Totenmeier TC (2004) Smithells metals reference book. Elsevier & ASM, New York

Massalski TB (1990) Binary alloy diagrams. ASM International, Materials Prk, OH

Chen KI, Lin KL (2002) J Electron Mater 31(8):861

Christian JW (1975) The theory of transformation in metals and alloys. Pergamon Press, Oxford

Porter DA, Easterling KE (1981) Phase transformations in metals and alloys. Van Nostrand Reinhold Co Ltd, Oxford

Dybkov VI (1998) Growth kinetics of chemical compound layers. Cambridge Int Sci Publ, Cambridge

Schmalzried H (1995) Chemical kinetics of solids. VCH Weinheim, Germany

Acknowledgements

This research was partially supported by the National Scientific and Research Council of Argentina (CONICET) through the PIP 02612 and Res. No. 1273/04 grants.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sommadossi, S., Troiani, H.E. & Fernández Guillermet, A. Diffusion soldering using a Gallium metallic paste as solder alloy: study of the phase formation systematics. J Mater Sci 42, 9707–9712 (2007). https://doi.org/10.1007/s10853-007-1940-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1940-z