Abstract

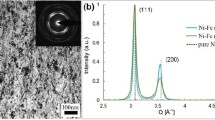

The tensile behaviors of FCC Ni–Fe alloys were investigated within three grain size regimes: >100 nm, 15–100 nm, and <15 nm. The results show that the nanocrystalline metals demonstrated large strain hardening rates, which increase with decreasing the grain size. With the similar grain size, lowing the stacking-fault energy (SFE) by addition of alloying element increases the yield strength and strain hardening ability. The “low” tensile elongation of nanocrystalline metals is due to the basic tradeoff between the strength and tensile elongation, i.e. nanostructured metals are not inherently brittle. Both the tensile results and fracture surface observations suggest that the tensile ductility increases with increasing the grain size. Furthermore, within the large grain size regime, the fracture surface exhibited the real void structure; while the fracture surface showed the concave and convex features when the grain size is less than the critical value.

Similar content being viewed by others

References

Kumar KS, Suresh S, Chisholm MF, Horton JA, Wang P (2003) Acta Mater 51:387

Embury JD, Hirth JP (1994) Acta Metall Mater 42:2051

Dieter GE (1986) Mechanical metallurgy. McGraw-Hill, New York, p 168

Yamakov V, Wolf D, Phillpot SR, Mukherjee AK, Gleiter H (2004) Nat Mater 3:43

Schiøtz J, Di Tolla FD, Jacobsen KW (1998) Nature 391:561

Van Swygenhoven H (2002) Science 296:66

Schiøtz J, Jacobsen KW (2003) Science 301:1357

Yamakov V, Wolf D, Phillpot SR, Mukherjee AK, Gleiter H (2003) Phil Mag Lett 83:385

Liao XZ, Zhao YH, Zhu YT, Valiev RZ, Gunderov DV (2004) J Appl Phys 96:636

Nieh TG, Wadsworth J (1991) Scripta Met Mater 25:955

Cheung C, Palumbo G, Erb U (1994) Scripta Met Mater 31:735

Li H, Ebrahimi F (2003) Mater Sci Eng A 347:93

Wang N, Wang Z, Aust KT, Erb U (1997) Mater Sci Eng A 237:150

Ebrahimi F, Bourne GR, Kelly MS, Matthews TE (1999) NanoStruct Mater 11:343

Legros M, Elliott BR, Rittner MN, Weertman JR, Hemker KJ (2000) Philos Mag A 80:1017

Matlock DK, Zia-Ebrahimi F, Krauss G (1984) In: Krauss G (ed) Deformation, processing and structure. ASM Publication, Metals Park, Ohio, p. 47

Valiev RZ, Alexandrov IV, Zhu YT, Lowe TC (2002) J Mater Res 17:5

McCrea JL, Palumbo G, Hibbard GD, Erb U (2003) Rev Adv Mater Sci 5:252

Zhang K, Weertman JR, Eastman JA (2005) Appl Phys Lett 87:061921

Yip S (2004) Nature Mater 3:11

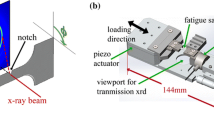

Budrovic Z, Van Swygenhoven H, Derlet PM, Van Petegem S, Schmitt B (2004) Science 304:273

Ebrahimi F, Ahmed Z, Morgan KL (2001) MRS Symp Proc 634:B2.7.1

Mitra R, Ungar T, Morita T, Sanders PG, Weertman JR (1999) In: Chung Y-W, Dund DC, Liaw PK, Olsen GB (eds) The 1999 J.R. Weertman Symposium. TMS, Warrendale, PA, p 553

Hasnaoui A, Van Swygenhoven H, Derlet PM (2003) Science 300:1550

Acknowledgements

This work was supported by the National Science Foundation (NSF) under the grant # DMR-9980213 at Materials Science and Engineering Department of the University of Florida and DMR-0231320 at Materials Science and Engineering Department of the University of Tennessee.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, H., Ebrahimi, F., Choo, H. et al. Grain size dependence of tensile behavior in nanocrystalline Ni–Fe alloys. J Mater Sci 41, 7636–7642 (2006). https://doi.org/10.1007/s10853-006-0856-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0856-3