Abstract

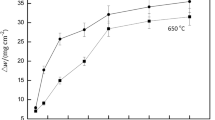

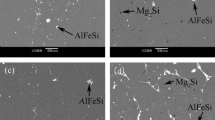

Weight loss test in 4% sulfuric acid aqueous solution bath and salt spray test with 5% NaCl aqueous solution were used to evaluate the corrosion resistance of Al–11.7 wt%Si alloys with no modification, sodium modification, or strontium modification. SEM and optical microscopy were used to, respectively, observe the surface and depth corrosion morphologies of the alloys. The results showed that the corrosion-resistance of the alloy with no modification was the best, followed by the Sr-modified alloy, with the Na-modified alloy showing the worst results. Up to 360 h duration in 4% sulfuric acid aqueous solution bath, all the three alloys showed uniform corrosion characteristics. However, after 360 h duration, pitting corrosion became the typical characteristic of the modified alloys and it resulted in a considerable increase in percentage weight loss. After 480 h, the depth of the pitting holes in the Sr-modified alloy was larger than that in the Na-modified alloy, but the transverse corrosion channels in the former were far less than those in the latter. After this duration, the well-developed transverse corrosion channels in the Na-modified alloy became interconnected inch by inch, which led to severe exfoliation corrosion, so the percentage weight loss of the Na-modified alloy rose abruptly.

Similar content being viewed by others

References

Chien CW, Lee SL, Lin JC, Jahn MT (2002) Mater Lett 52(4–5):334

Edwards WM, Thomson RC, Barnes SJ, Barnes SI (2002) Mater Sci Forum 396–402(2):625

Liu L, Samuel AM, Samuel FH, Doty HW, Valtierra S (2004) J Mater Sci 39(1):215

Nogita K, McDonald SD, Dahle AK (2003) Mater Trans 44(4):692

Liao H, Sun G (2004) Mater Sci Technol 20(4):521

Liao H, Sun Yu, Sun G (2002) Mater Sci Eng A 335(1–2):62

Liao H, Ding Yi, Sun G (2002) Acta Metall Sinica 38(3):245

Bereket G, Yurt A (2001) Corros Sci 43(6):1179

Sankaran KK, Perez R, Jata KV (2001) Mater Sci Eng A 297(1–2):223

Long X-Q, Jin W-H (2001) J Civil Aviat Univ China 19(3):55

Voevodinb N, Jeffcoatec C, Simonb L, Khobaibb M, Donleya M (2001) Surf Coat Technol 140(1):29

Lu G, Guang S, Chen H, Lin D (2005) Chinese J Nonferrous Met 15(5):734

Aballe A, Bethencourt M, Botana FJ, Cano MJ, Marcos M (2001) Corros Sci 43(9):1657

Wang H, Wu J, Wang J, Wang H, Fang Z (2003) Electrochemistry 9(1):60

Zhang L, Zhou H (2002) Aluminium Fabrication 25(2):38

Mondolf LF (1988) In Aluminum alloys, structure and properties. Metallurgy Industry Press, Beijing, p 317 (in Chinese)

Acknowledgement

The authors would like to thank Pan Ye for valuable discussions. This work is supported by the Jiangsu Province Natural Science Foundation (BK2004069) and the Southeast University Early-Research Foundation (XJ0612238).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liao, H., Dong, G. & Sun, G. Investigation on influence of sodium- or strontium-modification on corrosion-resistance of Al–11.7%Si alloy. J Mater Sci 42, 5175–5181 (2007). https://doi.org/10.1007/s10853-006-0545-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0545-2