Abstract

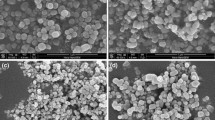

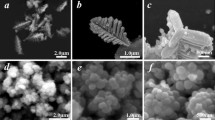

Spherical barium titanate particles with cubic phase were synthesized by a low-temperature hydrothermal reaction. Firstly, The method of hydrolysis of titanium tetrachloride was used for producing spherical TiO2 particles (0.45–1.5 μ m) with various concentrations of TiCl4(0.05–0.2 M) and volume ratios of acetone to water solutions (RH = 0–4). These TiO2 particles were converted to barium titanate by a hydrothermal conversion in a barium hydroxide solution. The size and morphology of the TiO2 particles was controlled by the volume ratio of acetone to water (RH ratio) in the mixed solvent. At the RH ratio of 3, the morphology of TiO2 particles was very uniform and discrete. These TiO2 particles were in the anatase phase and were converted to the rutile phase when the calcination temperature increased to 700∘C and above. Uniform and spherical barium titanate particles were successfully synthesized from the as-prepared TiO2 particles by using a hydrothermal reaction in a barium hydroxide solution. The Ba/Ti ratios, reaction temperature, and reaction time did not influence the size and morphology of BaTiO3 particles, but increased the concentration of unfavorable salts such as Ba(OH)2 and BaCO3. The high purity BaTiO3 particles could be obtained by washing with formic acid to remove the unfavorable salts. The size and morphology of the BaTiO3 particles remained the same as those of the TiO2 particles, confirming the in-situ transformation mechanism for the conversion of TiO2 to BaTiO3. The as-synthesized particles were cubic phase and transformed to tetragonal phase after calcinations at 1150∘C for 1 h. The mean density of the pellets sintered at 1300∘C for 2 h was 5.86 g/cm3 and accounted for 97.34% of the theoretical density.

Similar content being viewed by others

References

M. Z.-C. Hu, G. A. Miller, E. A. Payzant and C. J. Rawn, J. Mater. Sci. 35 (2000) 2927.

G. J. Choi, S. K. Lee, K. J. Woo, K. K. Koo and Y. S. Cho, Chem. Mater. 10 (1998) 4104.

S. Wada, T. Suzuki and T. Noma, J. Ceram. Soc. Jpn. 103 (1995) 1027.

B. Huybrechts, K. Ishizaki and M. Takata, J. Mater. Sci. 30 (1995) 2463.

Y. Suyama and M. Nagasawa, J. Am. Ceram. Soc. 77 (1994) 603.

A. Beauger, J. C. Mutin and J. C. Niepce, J. Mater. Sci. 18 (1983) 3543.

A. Amin, M. A. Spears and B. M. Kulwicky, J. Am. Ceram. Soc. 66 (1983) 733.

H. S. Potdar, S. B. Deshpande and S. K. Date, Mater. Chem. Phys. 58 (1999) 121.

S. G. Kim, M. H. Lee, T. Y. Noh and C. Lee, J. Mater. Sci. 31 (1996) 3643.

H. Shimooka and M. Kuwabara, J. Am. Ceram. Soc. 78 (1995) 2849.

F. Chaput and J.-P. Boilot, J. Am. Ceram. Soc. 73 (1990) 942.

P. K. Dutta, R. Asiaie, S. A. Akbar and W. Zhu, Chem. Mater. 6 (1994) 1542.

K. Kumazawa, T. Kagimoto and A. Kuwabara, J. Mater. Sci. 31 (1996) 2599.

L. M. Gan, L. H. Zhang, C. H. Chew and B. H. Loo, J. Mater. Sci. 31 (1996) 1071.

P. Gherardi and E. Matijevic, Colloids Surf. 32 (1988) 257.

T. Ogihara, N. Mizutani and M. Koto, Ceram. Int. 13 (1987) 35.

C. Sanchez, J. Livage, M. Henry and F. Babonneau, J. Non-Cryst. Solids 100 (1988) 65.

H. T. Harris and C. H. Byers, J. Non-Cryst. Solids 103 (1988) 49.

H. K. Park, Y. T. Moon, D. K. Kim and C. H. Kim, J. Am. Ceram. Soc. 79 (1996) 2727.

A. Kato, Y. Takeshita and Y. Katatae, Mater. Res. Soc. Symp. Proc. 155 (1989) 13.

Y. T. Moon, H. K. Park, D. K. Kim, I. S. Seog and C. H. Kim, J. Am. Ceram. Soc. 78 (1995) 2690.

M. Z.-C. Hw, V. Kurian, E. A. Payzant, C. J. Rawn and R. D. Hunt, Powder Technol. 110 (2000) 2.

K. Y. Chen and Y. W. Chen, Powder Technol. 141 (2004) 69.

F. Franks, “Water-A Comprehensive Treatise,” (Plenum Press, New York, 1973) Vol. 2, p. 405.

L. Meites, “Handbook of Analytical Chemistry,” (McGraw-Hill Press, New York, 1982) p. 1–49.

J. O. Eckert Jr, C. C. Hung-Houston, B. L. Gersten, M. M. Lencka and R. E. Riman, J. Am. Ceram. Soc. 79 (1996) 2929.

W. Hert, J. Am. Ceram. Soc. 71 (1988) 879.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

CHEN, KY., CHEN, YW. Preparation of monodispersed spherical barium titanate particles. J Mater Sci 40, 991–998 (2005). https://doi.org/10.1007/s10853-005-6518-z

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-6518-z