Abstract

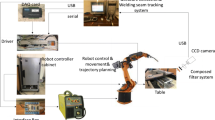

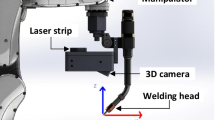

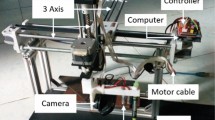

Autonomous acquisition of seam coordinates is a key technology for developing advanced welding robot. This paper describes a position-based visual servo system for robotic seam tracking, which is able to autonomously acquire the seam coordinates of the planar butt joint in the robot base frame and plan the optimal camera angle before welding. A six-axis industrial robot is used in this system, which has an interface for communicating with the master computer. The developed visual sensor device is briefly presented that allows the charge-coupled device (CCD) cameras to rotate about the torch. A set of robust image processing algorithms are proposed so that no special requirements of light source are needed in this system. The feedback errors of this servo system are defined according to the characteristics of the seam image, and the robust tracking controller is developed. Both the image processing program and tracking control program run on the master computer. The experimental results on straight line seam and curve seam show that the accuracy of the seam coordinates acquired with this method is more adequate for high quality welding process.

Similar content being viewed by others

References

Bae, K.Y.: An optical sensing system for seam tracking and weld pool control in gas metal arc welding of steel pipe. J. Mater. Process. Technol. 120, 458–465 (2002)

Yamane, S., Kaneko, Y., Kitahara, N., Ohshima, K., Yamamoto, M.: Neural network and fuzzy control of weld pool with welding robot. Ind. Appl. Soc. Annu. Meet.: Conf. Rec. 1993 IEEE 3, 2175–2180 (1993)

Kim, J.S.: A robust method for vision-based seam tracking in robotic arc welding. IEEE International Symposium on Intelligent Control – Proceeding, pp. 363–368 (1995)

Smith, J.S., Lucas, J.: Vision-based seam tracker for butt-plate TIG welding. J. Phys. E: Sci. Instrum. 22(9), 739–744 (1989)

Luo, H.: Robotic welding, intelligence and automation, laser visual sensing and process control in robotic arc welding of titanium alloys. LNCIS 299, 110–122 (2004)

Kuo, H.C., Wu, L.J.: An image tracking system for welded seams using fuzzy logic. J. Mater. Process. Technol. 120(1–3), 169–185 (2002)

Chen, S.B., Chen, X.Z., Qiu, T., Li, J.Q.: Acquisition of weld seam dimensional position information for arc welding robot based on vision computing. J. Intell. Robot. Syst. 43, 77–97 (2005)

Hutchinson, S.: Tutorial on visual servo control. IEEE Trans. Robot. Autom. 12(5), 651–670 (1996)

Amin-Nejad, S., Smith, J.S., Lucas, J.: A visual servoing system for edge trimming of fabric embroideries by laser. Mechatronics 13(6), 533–551 (2003)

Lam, L.: Thinning methodologies – A comprehensive survey. IEEE Trans. Pattern Anal. Mach. Intell. 14(9), 869–885 (1992)

Yang, S.Y.: VC++ Programming on Image Processing. Tsinghua University Press, Beijing (2003)

Jain, R.: Machine Vision. McGraw-Hill, New York (1995)

Corke, P.I.: Controller design for high performance visual servoing. Proc IFAC 12th World Congress Sydney, pp. 9-395–9-398. (1993)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, L., Lin, T. & Chen, S.B. Autonomous Acquisition of Seam Coordinates for Arc Welding Robot Based on Visual Servoing. J Intell Robot Syst 47, 239–255 (2006). https://doi.org/10.1007/s10846-006-9078-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10846-006-9078-9