Abstract

Although the aspects that affect the performance and the deterioration of abrasive belt grinding are known, wear prediction of abrasive belts in the robotic arm grinding process is still challenging. Massive wear of coarse grains on the belt surface has a serious impact on the integrity of the tool and it reduces the surface quality of the finished products. Conventional wear status monitoring strategies that use special tools result in the cessation of the manufacturing production process which sometimes takes a long time and is highly dependent on human capabilities. The erratic wear behavior of abrasive belts demands machining processes in the manufacturing industry to be equipped with intelligent decision-making methods. In this study, to maintain a uniform tool movement, an abrasive belt grinding is installed at the end-effector of a robotic arm to grind the surface of a mild steel workpiece. Simultaneously, accelerometers and force sensors are integrated into the system to record its vibration and forces in real-time. The vibration signal responses from the workpiece and the tool reflect the wear level of the grinding belt to monitor the tool’s condition. Intelligent monitoring of abrasive belt grinding conditions using several machine learning algorithms that include K-Nearest Neighbor (KNN), Support Vector Machine (SVM), Multi-Layer Perceptron (MLP), and Decision Tree (DT) are investigated. The machine learning models with the optimized hyperparameters that produce the highest average test accuracy were found using the DT, Random Forest (RF), and XGBoost. Meanwhile, the lowest latency was obtained by DT and RF. A decision-tree-based classifier could be a promising model to tackle the problem of abrasive belt grinding prediction. The application of various algorithms will be a major focus of our research team in future research activities, investigating how we apply the selected methods in real-world industrial environments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

An abrasive belt grinding comprises a belt grinding and a contact control wheel that serves as a machining tool designed to perform grinding, deburring, and finishing operations of any metallic material (Wang et al., 2022a). In the past few years, abrasive belt grinding has gradually developed in high-precision manufacturing industries with advanced equipment (Zhu et al., 2018). In particular, for a turbine blade manufacturing industry for aero-engines and their combustion chambers, even the supporting parts for the combustion chambers such as a bose-hole in Trent 700 combustor, the abrasive belt grinding machining process has shown to be appropriate for complex and curved products due to its capability to adapt to the workpiece surfaces and its low-temperature effect (Caesarendra et al., 2018a). Moreover, supported by the development of advanced scientific technologies including modern control applications and robotic arms with multiple axes, it is possible to work on complex surfaces while maintaining uniform quality (Caesarendra et al., 2018b).

The outcome of a grinding process using an abrasive belt to improve the quality of the workpiece depends on the physical condition of the abrasive belt and the parameters applied during the machining process such as grit roughness size, belt rotation speed, feed rate, compressive force, hardness of the contact wheel to surface of workpiece (Pandiyan et al., 2017). Understanding the five main factors is a challenging factor in the high-precision manufacturing industry because of its high nonlinearity and complexity (Pandiyan et al., 2020a). A worn-out grinding belt greatly affects material removal and the quality of workpiece surface roughness, however, once the workpiece surface material is removed, it will also eventually intensify the wear on the belt surface. Wear causes an abrasive belt to change its original roughness that affects the interaction between the grinding belt and workpiece which in turn seriously reduces grinding performance and surface quality (Chen et al., 2022).

Direct and indirect sensors are two technology clusters for monitoring the condition of systems including the abrasive belt (Kurada & Bradley, 1997). Direct sensing provides an immediate and accurate assessment of the belt grinding condition, but it has limited applications by being out of reach during the machining process. On the other hand, indirect sensors are capable of capturing the occurrence of process parameters such as vibration, force, temperature, etc., calculated and analyzed for belt grinding conditions based on reliable signal characteristics and correlated tool wear conditions. In an automated machining process, monitoring equipment offers a reduction in line production downtime and maintains product quality (Caesarendra et al., 2021). An experiment of online drill bit wear monitoring was carried out to investigate the effect of drill bit wear on cutting force when drilling copper alloy workpieces (Klaic et al., 2018). Meanwhile, the dominance of the average coefficient of cutting force in the tangential direction and flank wear has been investigated by Liang et al., (2022) by combining cutting parameters such as feed per tooth, depth, and cutting speed to analyze milling tool wear. A more sensitive monitoring feature with a residual variation auto-encoder based on multiple sensor signals has been developed to monitor carbide-coated tool wear conditions in impeller machining processes (Ou et al., 2022).

Acoustic Emission (AE) sensors have been applied in surface finishing to capture acoustic waves from the interaction of the abrasive grinding wheel with a workpiece to determine the quality of the polishing process (Wang et al., 2022b). To verify more clearly, Nakai et al., (2015) have calculated the condition of the grinding wheel based on the AE and force sensors which receive signals from the machining process using an intelligent system. Furthermore, Twardowski et al., (2021) have identified the wear of diamond-coated carbide milling tools based on focused acoustic emission signals across the entire vibration frequency spectrum into a classification tree algorithm for the learning process. A series of previous studies have revealed monitoring of tool wear with hard types and rigid grinding using sensor equipment systems and coding algorithms to predict decisions as listed in Table 1. Tool condition monitoring has not been considered the appropriate tool; therefore, the proposed research is to develop suitable abrasive belt condition monitoring to reduce the research gap. Monitoring the condition of belt grinding is a highly appropriate step in ensuring the quality of machining processes. By proactively monitoring, we can identify potential issues or wear on the belt grinding equipment at an earlier stage. This aids in preventing further damage, minimizing downtime, and, of course, maintaining the quality of machining outcomes. Thus, the adage "prevention is better than cure" holds true in this context.

Most of the previous research explored the wear conditions of grinding and cutting tools in the machining process while monitoring tool conditions for grinding belts were still limited to investigations. Machining processes using traditional rigid grinding have been developed into abrasive belt grinding with its advantages including the ability to reach complex workpiece surface geometries (Pandiyan et al., 2020b). Grinding belts are equipped with polymer wheels for contact control and belt placement tracks that cover complex surface areas. Due to the dynamic and interrelated operational parameters, the grinding process with abrasive belts is non-linear and non-uniform (Pandiyan & Tjahjowidodo, 2017).

In the context of the grinding process with abrasive belts, non-linearity refers to the fact that the relationship between the input parameters (such as belt speed, pressure, and grit size) and the output parameters (such as surface roughness, material removal rate, and grinding force) is not linear. This means that a change in one input parameter does not result in a proportional change in the output parameter. Instead, the relationship between the input and output parameters is complex and can be influenced by other factors such as the properties of the workpiece material and the abrasive belt. On the other hand, non-uniformity refers to the fact that the grinding process with abrasive belts is not uniform across the entire surface of the workpiece. This means that different parts of the workpiece may experience different levels of material removal, surface roughness, and other output parameters. The non-uniformity can be caused by various factors such as the wear of the abrasive belt, the unevenness of the workpiece surface, and the non-uniform distribution of the abrasive particles on the belt (Pandiyan et al., 2020a).

Abrasive belt grinding has three main components, i.e., a force control wheel, an abrasive-coated belt, and a prime mover wheel. Depending on the application, a belt grinding is selected based on its grit size and it is used continuously until it reaches its wear limit before it is replaced by the new one. The performance of the belt grinding process is influenced by the feed rate, depth of feed, compressive force, direction, and feeding angle (Zhang et al., 2005). Although the factors affecting the performance of abrasive coated belts have been detected, compared to other types of tools, belt grinding tools exhibit apparent difficulties in managing wear during their operating time. Belt wear causes degradation of the abrasive grains that result in decreasing grinding performance and the workpiece surface becomes defective (Pandiyan et al., 2016).

Belt grain wear could occur massively, and it has a serious impact on tool integrity for surface smoothing, therefore, Pandiyan et al. (2019) detected sensor parameter data during the milling process and then analyzed it with a decision algorithm from Machine Learning (ML) to monitor belt condition. Belt grinding that loses its integrity can greatly differ the mechanism of contact between an abrasive grain and workpiece surface, whereby as wear of the grains grows, the function of grinding abrasive changes from cutting ability to only shearing and plowing (Pandiyan & Tjahjowidodo, 2019). The common strategy for monitoring tool wear status is by practicing a conventional method, namely checking directly by interrupting the process relying on the capability of employee operators. The entire production process might come to a complete halt due to measurement activities and assessing the eligibility of the tool to maintain workpiece quality, especially if it requires unloading and loading back to its original position with difficult reference settings. The erratic challenge of belt wear demands manufacturing machinery to be equipped with intelligent decision methods. This research is proposed to reveal monitoring of abrasive belt grinding using ML which analyzes the vibration signal of the accelerometer and force sensors.

Manufacturing process automation embedded with artificial intelligence might be a breakthrough to address the challenges of abrasive belt grinding, increasing productivity and reducing human intervention. In recent years, intelligent tool monitoring, especially in abrasive belt grinding, has attracted many researchers to reveal how to ensure tool life, as Pandiyan et al. (2018) have explained the evolution of degradation by classifying Genetic Algorithm (GA) and Support Vector Machine (SVM) from the accelerometer and compressive force data in the belt grinding process installed on the robotic arm. During surface finishing by abrasive belt grinding, Discrete Wavelet Decomposition (DWD) and Fast Fourier Transform (FFT) decomposed the raw signal simultaneously captured from an omnidirectional capacitance microphone. Moreover, the condition of the belt based on the response of the extracted sound signal is modeled using Optimally Pruned Extreme Learning Machine (OP-ELM) to predict the wear factor of belt grains (Zhang et al., 2018). Numerous researchers have employed acoustic emission installed in research objects, for instance, an application of sound signals to detect grinding belt wear has been reported by Zhang et al. (2015) by building a regression model with classification in SVM to predict belt condition utilizing OP-ELM. Cheng et al. (2020) demonstrated that the integration of sound and current signals on the abrasive belt significantly enhances the accuracy of tool wear prediction. They constructed a Bayesian network through sensor fusion and compared it with 315 experimental data. Their findings revealed that Random Forest (RF) models can generate more precise predictions. Similarly, Wu et al. (2017) implemented a strategy involving various ML techniques, including Support Vector Regression (SVR), Artificial Neural Network (ANN), Random Forests (RF), and feed-forward back propagation.

Despite significant advancements in recent decades, particularly in robotic belt grinding of superalloys, there remains a scarcity of advanced techniques and methods to achieve precision profile finishing and desired properties (Ren et al., 2023). Li et al. (2017) introduced a novel approach for modelling and controlling automatic grinding processes with belt grinding tools; however, its trajectory accuracy and rigidity pose challenges, limiting its implementation for accurate grinding. While industrial robots offer flexibility, accuracy, and consistency in machining operations, their implementation encounters various limitations, including material and tool diversity, low adaptability to environmental changes, flexibility issues, complex tool path preparation processes, and quality control challenges (Makulavičius et al., 2023). A prominent restriction in robot-based machining tasks is inadequate rigidity at the tool center point (TCP), impacting machining accuracy (Verl et al., 2019). Despite a comprehensive review of calibration and measurement techniques, trajectory planning, force control, and surface integrity analysis by Zhu et al. (2020), issues persist regarding grinding accuracy and poor surface quality.

In this paper, an abrasive belt grinding system integrated into a robot arm equipped with an accelerometer is established, based on vibration signal response experiments carried out to determine the prediction of belt grain wear. The purpose of this study is to monitor the condition of the abrasive belt grinding predicted using ML codes from correlation data of vibration and force sensors in the three directions and to study the potential to incorporate it in an online monitoring system in the future. The paper is structured as follows: Section "Introduction" provides a literature review on a brief development of tool monitoring methods which focused on monitoring abrasive belt grinding using the ML method, while Section "Machine learning models" reveals several ML methods used in this study including K-Neural Networks (KNN), Support Vector Machine (SVM), Multi-layer Perceptron (MLP), and Decision Tree (DT), while the data captured by sensors discussed in Section "Materials and methods", and processed into ML method is discussed in Section "Experimental Settings and Discussion". Furthermore, Section "Conclusions" presents the conclusions of this study.

Machine learning models

The present investigation used the following machine learning classification and prediction algorithms:

K-nearest neighbors (KNN)

KNN, a common classification algorithm for non-parametric behavior patterns like tool conditions, predicts data groups by calculating distances between tested and training points. Selecting K points close to the tested data, it computes probabilities for the training data group, choosing the group with the highest score (Junior et al., 2018).

The default distance metric of the nearest neighbour algorithm is the Euclidean distance, the so-called L2 distance, which calculates the distance between two points, x[a] and x[b] that can be written as follows:

In constructing a classification, the simple embodiment of the KNN method tries to predict a target class label as the class label most frequently represented among the K training examples closest to the specified query point.

Support Vector Machine (SVM)

It is an aggregate of supervised learning methods as a robust classification, outliers’ detection, and an efficiency regression technique that maximizes model prediction accuracy.

All data are separated linearly, hyperplane f(x) = 0 can be written as,

where the w component is an n-dimensional vector, and the b component is a scalar number that determines the optimal separation hyper-plane that renounces the maximum margin of both classes. Kernel tricks are utilized in non-linear classification data problems where they transform the incoming data into a larger dimensional feature space to build the possibility of applying linear separation. The non-linear nature of kernel functions is used in the SVM method ϕ: X → F converts data from the input data space X to features space F. In space F, the discriminant function can be written as follows:

SVM with non-linear data can be derived by classifying it to be a linear partition by mapping correctly the input data x (in matrix form) into the features space and training SVM for mapped features ϕ(x). From the training examples, linear combinations can articulate weight vectors, i.e., \({\text{w}}=\sum_{i=1}^{n}{\alpha }_{i}{{\text{x}}}_{{\text{i}}}\) accordingly Eq. 3 takes the form as the following formula:

In the features space, F this expression takes the formula as follows:

Afterward, nonlinear SVM can be trained by exchanging the results of Eq. 2 with kernel analogues K (xi, xj).

Furthermore, the resulting classifier for non-linear SVM is represented by the kernel function as follows:

Multi-layer perceptron (MLP)

Each neuron k at layer l for the input x can be derived using Eq. 8. The weight vector learned at each mini-batch is denoted as W while the bias for each neuron is denoted as b. Each input value will be passed to the non-linear activation function denoted as g, which is in our case, the ReLU activation function.

The training process will be undertaken by using an optimization technique called gradient descent (Agarap, 2018) which processes the score from the loss function. The learning mechanism for parameter w is based on the gradient of the loss function L that is shown in Eq. 9. The time for updating the parameter is denoted by t while the learning rate that controls the influence from the gradient is denoted by α. The biased learning also proceeds with a similar process by taking the gradient from the loss function L.

Decision Tree (DT)

There are several algorithms that can be employed to construct the decision tree including ID3 (Goodfellow et al., 2016), C4.5 (Quinlan, 1985), and Classification and Regression Trees (CART) (Quinlan, 1993). The Scikit-Learn library (Berk, 2020) that uses the CART algorithm which constructs the binary tree to form a predictor was implemented in the present study.

The lower score shows the purest selection of the node leading to higher performance. The Gini impurity is calculated using Eq. 10.

where H is the loss function. The data at node m of the tree is denoted by Qm. The k denotes the index of the labels of the samples and Pmk denotes the prediction probability at node m.

Materials and methods

In order to predict the belt abrasive wear which affects the surface polishing quality of machining workpieces, two types of sensors, i.e. three-axis accelerometer and three-axis dynamometer are utilized in this research. The research methodology including the experiment preparation and the data acquisition process is detailed in the following sub-sections.

Sensor devices and experimental setup in the polishing process

An abrasive belt grinder is attached to the end-effector of the multi-axis robotic arm to experiment with the grinding of mild steel workpieces as shown in Fig. 1. To deliver the direction movement in the grinding, we use the multi-axis ABB 6660–205-193 robotic arm, while the workpiece grinding process employs a belt grinder with electric power which rotates at 11,000 rpm in no-load conditions. Generally, abrasive belts are used for surface reduction or grinding and surface smoothing or polishing processes with a belt size of about 19.05 to 203.2 mm in width and about 457.2 mm in length.

The abrasive belt is fed with a compressive force controlled by an ATI Industrial automation (Omega 160) force sensor at three Cartesian coordinates (x, y, and z) wrapped around a closed metal box. By adding a custom-made mount, the belt-grinding abrasive is affixed to a force sensor installed on the end-effector of ABB's robot arm. A multi-axis force transducer, i.e., the ATI force sensor, provides uniform control of the force input in the Z direction/normal direction. Force sensor from the normal direction facilitates the operation of the belt grinding to measure the compressive force constantly on the workpiece during material removal, while this research applies a fixed 20 N abrasive belt grinding force. Table 2 lists the parameters of other research conditions comprehensively.

Pre-research by carrying out the grinding process on the workpiece has obtained four classifications of abrasive belt conditions for different surface wear and was used as a basis for belt grouping during the experiment as described in Table 3. Four groups representing different abrasive belt wear levels corresponding to the usage time were observed on a few workpieces as output variable values during the study. Meanwhile, the applied input parameters such as grinding speed, force control, and feed rate are controlled at a fixed value as written in Table 2.

Vibration signals due to mechanical contact between the abrasive belt grinding and workpiece during this experiment were captured by the accelerometer from Kistler 8763B500, a triaxial type vibration sensor, where the sensor is mounted on the belt tension control rod arm as shown in Fig. 1. Kistler 9254 dynamometer is placed at the bottom of the mild steel workpiece holder. The force sensor has a physical form with a very low overall height of 32 mm and a large measurement range of up to ± 10 kN. This dynamometer is equipped with a cover plate measuring 95 × 105 mm, used to measure three components of the resultant force vector and three components of the resultant moment vector. The analog vibration signal generated from the grinding process is converted into the digital signal format by NI DAQ, a data acquisition module with 2 kHz for sampling frequency, meanwhile, communication with the computer utilizes the LabVIEW software platform and saves the vibration data into an Excel file. DEWESoft platform is utilized to support the performance of the NI DAQ device in capturing force signals from dynamometers that travel in normal and tangential directions. The signals captured by an accelerometer and force sensors are synchronized offline respecting the time duration.

Planning and configuring belt grinding lines were carried out using the built-in software of ABB's robotic studio. Figure 2 illustrates the abrasive belt path planning for the linear paths carried out in this work having five distinct zones from point A to point E. In order to achieve the required in feed force, the abrasive belt grinding is set at points B-C, and then it continues to move to the point C-D position where the feeding force on the surface of the workpiece is completely controlled during the study. After surface feeding, the abrasive belt leaves the workpiece as shown in the D-E point positions. The entire range of grinding processes works in dry and unlubricated conditions.

Data acquisition and collection

Triggered vibration signals and forces generated by performing grinding on mild steel workpieces using the abrasive belt with four distinct conditions, namely new belt, after 5 min usage time, after 15 min usage time, and in a completely worn-out state. Specifically, the new grain belt is operated to grind the surface of the mild steel workpiece for 5 min continuously, then the condition of the belt and workpiece is observed and recorded, while the vibration and force signals have been documented automatically in an Excel file on the computer. After that, the belt grinding was operated again for 15 min continuously, while the conditions of the belt and workpiece were observed again as before. In the final process, the abrasive belt is re-operated until worn-out for about 30 min and observing the condition the belt and workpiece are in worn-out condition.

This research has applied an ML method, which is utilized to predict wear on abrasive belt grinding by installing a 3-axis dynamometer and a 3-axis accelerometer sensor as operational data. The accelerometer and force features are captured and displayed via the LabVIEW platform and stored in an Excel file, which therefore serves as the raw training data for the ML model. However, the raw data extracted and injected into the ML algorithm does not guarantee the convergence of the solution, it must be searched by trying several ML methods. Therefore, several types of ML algorithms were investigated in this study including KNN, SVM, MLP, and DT methods to identify three axes of vibration and force sensors in order to obtain relevant axes representing the wear condition of belt grains. A sample of the raw signal from the accelerometer and compressive force sensor in the x-axis direction for different durations of abrasive belt operation is presented in Fig. 3a for vibration signals and (b) for compressive forces signal. The picture order from top to bottom in Fig. 3 represents the vibration and force signal signals for a brand-new belt, 5 min usage time, 15 min usage time, and worn-out belt.

Machining contact between an abrasive belt grinding and a workpiece generates a frequency of around 2 kHz in a period of 3.5 s and produces a raw dataset in the form of vibration and force signals reaching seven thousand points as illustrated in Fig. 3. Segmentation of raw data groups into smaller data groups is prepared before completing the convolution. The data has been grouped up to 200 s, although there is an overlap of about 10%, thus every 0.1-s reading of sample data from the belt grinding process, there are 200 data points that describe the dynamic characteristics of the grinding cycle (Pandiyan et al., 2018).

The assessment of tool state relies on scrutinizing diverse sensor data properties. This study involves the identification of various time-domain and frequency-domain features crucial for real-time differentiation among four distinct tool life cycles. The research methodology employs the Welch spectral density extraction approach to extract information from a signal, including position and peak frequency values. Additionally, the computation of signal energy distribution features within the specified frequency band is conducted using a periodogram. The selection of signal attributes is guided by a priori knowledge concerning the anticipated characteristics of the signals to be categorized. For prognosticating tool belt status monitoring, a comprehensive set of 27 unique features is derived from both the time and frequency domains of each sensor channel. The data, sourced from six channels encompassing AE sensors, 3-axis accelerometers, and 2-axis dynamometers, expands the feature space to 162 variables, with each channel contributing 27 variables. This detailed analysis enhances the understanding of tool conditions through an intricate exploration of sensor data, providing a robust foundation for real-time monitoring and forecasting of tool life cycles.

Experimental settings and discussion

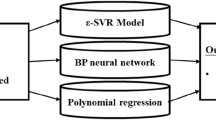

Various ML models have been applied to analyze the wear level of belt grains such as KNN, SVM, MLP, and DT from vibration and force signals generated by mechanical contact between the abrasive belt grinding and workpiece (Pedregosa et al., 2011). The objective is to examine these popular ML methods in the application of abrasive belt grinding intelligence condition monitoring. To provide an objective comparison analysis, the ML methods undergo similar stages presented in Fig. 4.

Prior to comparing the algorithms, the vibration data was split into data training and data testing. The strategy of splitting the dataset into two groups consists of training and testing sets, where 80% and 20% of the raw dataset are for training and testing, respectively. The certainty for each partition leads to a balanced data set that applies to all algorithms in the ML method in which each built class has a similar number of samples. This separation process with a balanced set embodied in the implementation is critical in assessing machine learning models because accuracy metrics in unbalanced data sets do not represent true performance (Brodersen et al., 2010). The detailed procedure can be seen in Fig. 5.

The selected ML methods were tuned in advance to get their peak performance, except for the LR method as it does not require crucial parameters to be tuned. Each hyperparameter in the ML model except the LR method was tuned by enumerating each possible set of choices. Then, the accuracy and latency analysis as presented in Fig. 4 were compared based on K-fold cross-validation. To measure the latency the model was run ten times. Each algorithm has been compared using accuracy metrics in two different evaluations: 10-fold cross-validation (10-fold CV) and standardized performance in test sets. A 10-fold CV is used in the training set to compare each algorithm and to determine good hyperparameters. Due to the small number of samples in the raw data, the 10-fold CV will avoid bias in terms of comparative analysis. For the test set, the model has been trained with all data points in the training set and utilizes the model to be evaluated in the test set.

In terms of scale, the scale for accuracy is a real number in [0, 1]. The value of 0 shows faulty performance while 1 shows flawless performance. In other words, this score can be transformed into a percentage where 0 is 0% while 1 is 100%. For the latency, we use the seconds as the scale.

This study used three common set separations i.e., the training set, validation set, and testing set. In the first stage, the dataset was divided into two parts: the training set and the testing set. The validation set was taken from the training set through K-fold cross-validation. This will assess the performance of the model with different elements of the train and validation set that potentially reveal its true performance.

Ten number of K was suggested for a small number of datasets as suggested in previous studies (Aguilera et al., 2010; Marcot & Hanea, 2021). Using K = 10, the evaluation will take 10% of the training set (204 samples) as the validation set which results in roughly 20 samples per validation. A high number of K will provide less bias for comparison during parameter/hyper-parameter selection. For observing its capability, a comparison of each method using a test set containing roughly 52 samples was conducted.

Hyperparameter optimization

Before analyzing the performance of several ML methods, each algorithm was optimized to determine its peak performance in terms of accuracy and efficiency. Bayesian Optimization (BO) (Shahriari et al., 2016) is employed to find the optimal hyperparameter. The BO method is an efficient algorithm for finding the optimal hyperparameter that works based on a surrogate model and acquisition function. The objective function is designed to search the hyperparameters that maximize the accuracy while minimizing the latency of the model’s prediction which is shown in Eq. 11 with the search space for each machine learning model that is defined in Table 4.

In the objective function defined in Eq. 11, we aid the BO to search the hyperparameter for each model such that the models balancing the accuracy performance with the latency. The BO will maximize the function by finding the maximum cross validation through function \(KFoldCV(.)\) and minimizing the mean latency through maximizing the inverse of the function \(meanLatency(.)\). The mean latency was calculated by recording the running time ten times using the test set. The model itself is denoted as f.

Results and discussions

The score of the performance of optimized models is detailed in Table 5. Bold style text shows the best of its criteria. Starting from the objective score obtained from BO, the highest performance was achieved by RF which contributed to the highest 10-fold CV score. The objective score indicates the tradeoff between accuracy and latency which shows higher performance than DT and other models. The lowest objective score was obtained by SVM which was slightly lower than KNN and MLP. SVM, KNN, and MLP are not a suitable approach to handling our problem. On the other hand, tree-based models yielded high performance which are DT, RF, and XGBoost.

In test accuracy, all samples in the train set were included the validation set during 10-Fold CV which provided flawless performance for a tree-based decision model of 100% accuracy. These models are DT, RF, and XGBoost. Although the RF produced the highest accuracy with 10-fold CV, it still has equivalent accuracy with DT and XGBoost. Furthermore, DT has less complexity than RF as it utilizes merely one decision tree which becomes competitive with the RF model. On the other hand, KNN, SVM, and MLP yielded the lowest performance which was below 30% of test accuracy. From these results, it observed that DT, RF, and XGBoost is a potential and an effective approaches to tackling abrasive belt grinding problems.

For the efficient models, DT and XGBoost produced the lowest latency compared to other models. Both models achieved a computational time of roughly 0.004 s for running the test set. Meanwhile, XGBoost provided the highest latency with approximately 0.02 s which becomes the lowest performance among all models. Other models like KNN, SVM, and MLP yielded a latency of about 0.01 s but with low test accuracy.

Identifying the most appropriate model for addressing a given problem necessitates thorough consideration and is dependent upon different factors. In addition, it observed that DT, RF, and XGBoost are the best candidates compared to KNN, SVM, and MLP. In a tree-based model, all approaches could achieve 100% of test accuracy. Hence, accounting for the accuracy of the model alone, DT, RF, and XGBoost can be considered as a good preference. Furthermore, considering the latency that may be suitable in embedded devices, DT and RF are the most preferable choices as they can yield the lowest latency. However, since RF employs a different decision tree, it may provide a slightly lower performance than DT which provides more stable results in terms of latency.

It is imperative to acknowledge that the efficacy of the model under discussion is contingent upon the dataset used for training. Hence, different datasets may yield disparate results, thereby necessitating a reevaluation of the model. This paper provides insight into the potential baseline models that have to be assessed in other datasets with similar tasks/problems, namely DT, RF, and XGBoost.

A DT visualization from the optimal hyperparameter is depicted in Fig. 6. The left arrow appointing the left node of the tree in the figure represents the right or true condition of the parent node while the right arrow manifests the opposite (wrong or false condition). Traversing from the root of the tree, the main condition is at the position 137 ≤ 0.117. For the true condition, the conditional execution from the expression 143 ≤ 705.725 resulted in classification for class worn-out and used (both with 51 samples). Meanwhile, for the right child node from the root, the same position 137 will be assessed through condition ≤ 0.156. The true condition from this node resulted in 48 samples classified as new. If the condition is not satisfied, the node will traverse the next child node from condition 48 ≤ 407500. The true condition from this node classified the 51 samples as brand new while the other 3 samples from the false condition were classified as New. In DT method, “new” and “used” label refer to “5 minutes” and “15 minutes” usage time, respectively.

Creating a decision tree visualization with only two features considered (137 and 143) allows us to understand the importance of these features in the context of the grinding problem. Feature 137 and 143 might represent specific measurements or characteristics observed during the grinding process. For example, feature 137 could represent the vibration level detected during grinding, while feature 143 might represent the temperature of the grinding tool. These two features are crucial because they provide valuable insights into the condition and performance of the grinding process.

In the grinding problem, the timeline is likely a critical factor influencing the values of features 137 and 143. As the grinding process progresses over time, the vibration level (137) and temperature (143) of the grinding tool may change accordingly. For instance, at the beginning of the grinding process, the vibration level might be relatively low, and the temperature might be stable. However, as the grinding continues, the vibration level could increase due to wear and tear on the grinding tool, while the temperature might also rise due to friction generated during the process. Therefore, these features capture dynamic changes over time, making them essential for monitoring and controlling the grinding process effectively.

The constructed decisions, such as "137 <= 0.117" and "143 <= 706," represent the splitting criteria used by the decision tree to partition the data into different branches. These decisions are based on the values of features 137 and 143. For example, "137 <= 0.117" means that if the value of feature 137 is less than or equal to 0.117, the data point will follow one branch of the tree, while if it is greater than 0.117, it will follow another branch. Similarly, "143 <= 706" indicates that the data point will be split based on whether the value of feature 143 is less than or equal to 706 or not.

These decisions are constructed based on the algorithm's optimization process to maximize the information gain at each split, leading to more homogeneous subsets of data. In the context of the grinding problem, these decisions could represent critical thresholds for controlling the process. For example, if the vibration level (feature 137) exceeds a certain threshold, it might indicate an abnormal condition that requires intervention to prevent damage to the grinding tool or the workpiece. Similarly, if the temperature (feature 143) exceeds a certain threshold, it could signal overheating, which may affect the quality of the finished product. Therefore, the decision tree provides a systematic approach to decision-making based on these important features, helping to ensure the efficiency and effectiveness of the grinding process.

Conclusions

Monitoring the condition of the abrasive belt grinding, belt surface wear has been affected by the workpiece (geometry and material hardness) and tool conditions (type and nature of the abrasive material, belt speed and tension, tool compression force, in-feed speed, and tool quality). During the grinding process, the surface layer is peeled off, and the grains are micro- and macro-grinded resulting in a rough-sized surface topography of the abrasive belt. The dynamic features and interrelated changes have resulted in the workpiece grinding process being un-linear and non-uniform.

In principle, this study has examined the effect of vibration and force on the surface grinding process of mild steel on the wear of the grain coating of belts using various machine learning algorithm predictions. This new strategy has been proposed to assess belt grinding surface wear with machine learning utilities that complement each other and facilitate the interpretation of belt surface wear parameters.

Based on experimental activities and analytical discussions on the grinding process using abrasive belts presented in this paper, the following statements have concluded:

-

Each algorithm has been compared using the tenfold CV accuracy metric as a training set to compare each algorithm and determine good hyperparameters.

-

Tree-based models, Decision Tree (DT), Random Forest (RF), and XGBoost method generate the highest average accuracy compared to Multi-Layer Perceptron (MLP), Support Vector Machine (SVM), and K-Nearest Neighbor (KNN).

-

Decision Tree (DT) and Random Forest (RF) yielded high performance with low latency merely about 0.004 s in evaluating the test set.

The findings of this research offer crucial insights for effective process management. By implementing these research findings, it can enhance operational efficiency, reduce downtime, and improve equipment reliability. The challenge may lie in integrating changes without disrupting production. Lean practices can serve as a solution by targeting waste elimination and continuous process improvement. Thoughtful implementation can have a significant positive impact on overall performance.

Future works will study the possibility of direct sensing for online applications which consist of two main stages: (1) the integration of the prediction models through ensemble learning; and (2) and the application of Internet of Thing (IoT) based machine learning cloud system for online prediction. The ensemble learning combines the predictions of multiple models to improve overall performance and robustness. In the context of online applications for the grinding process, ensemble learning can enhance decision-making by leveraging both the predictions form machine learning models and real-time sensor data. A preliminary study on an online machine learning prediction to predict a chamfer length of deburring process in the aerospace industry based IoT which employed the Amazon Web Services Machine Learning (AML) platform has been conducted and presented in Caesarendra et al., (2018a). This will give an insight regarding the possibility of the online application of the intelligent manufacturing of either workpiece or tool condition monitoring.

References

Agarap, A.F. (2018). Deep learning using rectified linear units (ReLU). ArXiv 2018, abs/1803.08375. https://doi.org/10.48550/arXiv.1803.08375

Aguilera, P. A., Fernández, A., Reche, F., & Rumí, R. (2010). Hybrid Bayesian network classifiers: Application to species distribution models. Environmental Modelling & Software, 25, 1630–1639. https://doi.org/10.1016/j.envsoft.2010.04.016

Berk, R. A. (2020). Statistical Learning from a Regression Perspective. 3rd ed., In: Allen, G., Veaux, R.D., Nugent, R. (eds.) Springer Cham. https://doi.org/10.1007/978-3-030-40189-4.

Brodersen, K. H., Ong, C. S., Stephan, K. E., Buhmann, & J. M. (2010). The balanced accuracy and its posterior distribution. 2010 20th International Conference on Pattern Recognition, IEEE, 2010. Istanbul, Turkey, 23–26 August 2010. https://doi.org/10.1109/ICPR.2010.764.

Caesarendra, W., Pappachan, B. K., Wijaya, T., Lee, D., Tjahjowidodo, T., Then, D., & Manyar, O. M. (2018a). An AWS machine learning-based indirect monitoring method for deburring in aerospace industries towards industry 4.0. Applied Sciences, 8(11), 2165. https://doi.org/10.3390/app8112165

Caesarendra, W., Triwiyanto, T., Pandiyan, V., Glowacz, A., Permana, S. D. H., & Tjahjowidodo, T. (2021). A CNN prediction method for belt grinding tool wear in a polishing process utilizing 3-axes force and vibration data. Electronics, 10, 1429. https://doi.org/10.3390/electronics10121429

Caesarendra, W., Wijaya, T., Tjahjowidodo, T., Pappachan, B. K., Wee, A., & Roslan, M. I. (2018b). Adaptive neuro-fuzzy inference system for deburring stage classification and prediction for indirect quality monitoring. Applied Soft Computing, 72, 565–578. https://doi.org/10.1016/j.asoc.2018.01.008

Cao, K., Han, J., Xu, L., Shi, T., Liao, G., & Liu, Z. (2022). Real-time tool condition monitoring method based on in situ temperature measurement and artificial neural network in turning. Frontiers of Mechanical Engineering, 17, 5. https://doi.org/10.1007/s11465-021-0661-3

Chen, G., Caudill, J., Chen, S., & Jawahir, I. S. (2022). Machining-induced surface integrity in titanium alloy Ti-6Al-4V: An investigation of cutting edge radius and cooling/lubricating strategies. Journal of Manufacturing Processes, 74, 353–364. https://doi.org/10.1016/j.jmapro.2021.12.016

Cheng, C., Li, J., Liu, Y., Nie, M., & Wang, W. (2020). An online belt wear monitoring method for abrasive belt grinding under varying grinding parameters. Journal of Manufacturing Processes, 50, 80–89. https://doi.org/10.1016/j.jmapro.2019.12.034

Goodfellow, I., Bengio, Y., Courville, A. (2016). Deep Learning. The MIT Press. https://mitpress.mit.edu/9780262035613/deep-learning/. Accessed 31 Jan 2024

Junior, P., D’Addona, D. M., Aguiar, P., & Teti, R. (2018). Dressing tool condition monitoring through impedance-based sensors: Part 2-neural networks and k-nearest neighbor classifier approach. Sensors, 18, 4453. https://doi.org/10.3390/s18124453

Klaic, M., Murat, Z., Staroveski, T., & Brezak, D. (2018). Tool wear monitoring in rock drilling applications using vibration signals. Wear, 408–409, 22–227. https://doi.org/10.1016/j.wear.2018.05.012

Kurada, S., & Bradley, C. (1997). A review of machine vision sensors for tool condition monitoring. Computers in Industry, 34, 55–72. https://doi.org/10.1016/S0166-3615(96)00075-9

Kurek, J., Krupa, A., Antoniuk, I., Akhmet, A., Abdiomar, U., Bukowski, M., & Szymanowski, K. (2023). Improved drill state recognition during milling process using artificial intelligence. Sensors, 23, 448. https://doi.org/10.3390/s23010448

Li, M., Gao, Y., Dong, W., Du, Z. (2017). Design and modeling of belt grinding tool for industrial robot application. In: 2017 IEEE International Conference on Unmanned Systems (ICUS), Beijing, China, 2017, 260–265. https://doi.org/10.1109/ICUS.2017.8278351

Li, Y., Liu, Y., Tian, Y., Wang, Y., & Wang, J. (2022). Application of improved fireworks algorithm in grinding surface roughness online monitoring. Journal of Manufacturing Processes, 74, 400–412. https://doi.org/10.1016/j.jmapro.2021.12.046

Liang, J., Gao, H., Xiang, S., Chen, L., Chen, L., You, Z., & Lei, Y. (2022). Research on tool wear morphology and mechanism during turning nickel-based alloy GH4169 with PVD-TiAlN coated carbide tool. Wear, 508–509, 204468. https://doi.org/10.1016/j.wear.2022.204468

Liu, C., Meerten, Y., Declercq, K., & Gryllias, K. (2022). Vibration-based gear continuous generating grinding fault classification and interpretation with deep convolutional neural networks. Journal of Manufacturing Process, 79, 688–704. https://doi.org/10.1016/j.jmapro.2022.04.068

Makulavičius, M., Petkevičius, S., Rožėnė, J., Dzedzickis, A., & Bučinskas, V. (2023). Industrial robots in mechanical machining: Perspectives and limitations. Robotics, 12, 160. https://doi.org/10.3390/robotics12060160

Marcot, B. G., & Hanea, A. M. (2021). What is an optimal value of k in k-fold cross-validation in discrete Bayesian network analysis? Computational Statistics, 36, 2009–2031. https://doi.org/10.1007/s00180-020-00999-9

Nakai, M. E., Aguiar, P. R., Guillardi, H., Jr., Bianchi, E. C., Spatti, D. H., & A’Addona, D. M. (2015). Evaluation of neural models applied to the estimation of tool wear in the grinding of advanced ceramics. Expert Systems with Applications, 42, 7026–7035. https://doi.org/10.1016/j.eswa.2015.05.008

Ou, J., Li, H., Liu, B., & Peng, D. (2022). Deep transfer residual variational autoencoder with multi-sensors fusion for tool condition monitoring in impeller machining. Measurement, 204, 112028. https://doi.org/10.1016/j.measurement.2022.112028

Pandiyan, V., Caesarendra, W., Glowacz, A., & Tjahjowidodo, T. (2020a). Modelling of material removal in abrasive belt grinding process: A regression approach. Symmetry, 12, 99. https://doi.org/10.3390/sym12010099

Pandiyan, V., Caesarendra, W., Tjahjowidodo, T., & Praven, G. (2017). Predictive modelling and analysis of process parameters on material removal characteristics in abrasive belt grinding process. Applied Sciences, 7, 363. https://doi.org/10.3390/app7040363

Pandiyan, V., Caesarendra, W., Tjahjowidodo, T., & Tan, H. H. (2018). In-process tool condition monitoring in compliant abrasive belt grinding process using support vector machine and genetic algorithm. Journal of Manufacturing Processes, 31, 199–213. https://doi.org/10.1016/j.jmapro.2017.11.014

Pandiyan, V., Murugan, P., Tjahjowidodo, T., Caesarendra, W., Manyar, O. M., & Then, D. J. H. (2019). In-process virtual verification of weld seam removal in robotic abrasive belt grinding process using deep learning. Robotics and Computer Integrated Manufacturing, 57, 477–487. https://doi.org/10.1016/j.rcim.2019.01.006

Pandiyan, V., Shevchik, S., Wasmer, K., Castagne, S., & Tjahjowidodo, T. (2020b). Modelling and monitoring of abrasive finishing processes using artificial intelligence techniques: A review. Journal of Manufacturing Processes, 57, 114–135. https://doi.org/10.1016/j.jmapro.2020.06.013

Pandiyan, V., & Tjahjowidodo, T. (2017). In-process endpoint detection of weld seam removal in robotic abrasive belt grinding process. The International Joiurnal of Advanced Manufacturing Technology, 93, 1699–1714. https://doi.org/10.1007/s00170-017-0646-x

Pandiyan, V., & Tjahjowidodo, T. (2019). Use of Acoustic Emissions to detect change in contact mechanisms caused by tool wear in abrasive belt grinding process. Wear, 436–437, 203047. https://doi.org/10.1016/j.wear.2019.203047

Pandiyan, V., Tjahjowidodo, T., & Samy, M. P. (2016). In-process surface roughness estimation model for compliant abrasive belt machining process. Procedia CIRP, 46, 254–257. https://doi.org/10.1016/j.procir.2016.03.126

Patange, A. D., Pardeshi, S. S., Jegadeeshwaran, R., Zarkar, A., & Verma, K. (2022). Augmentation of decision tree model through hyper-parameters tuning for monitoring of cutting tool faults based on vibration signatures. Journal of Vibration Engineering & Technologies, 11, 3759–3777. https://doi.org/10.1007/s42417-022-00781-9

Pedregosa, F., Varoquaux, G., Gramfort, A., Michel, V., Thirion, B., Grisel, O., Blondel, M., Prettenhofer, P., Weiss, R., Dubourg, V., Vanderplas, J., Passos, A., Cournapeau, D., Brucher, M., & Duchesnay, E. (2011). Scikit-learn: Machine learning in python. Journal of Machine Learning Research, 12, 2825–2830.

Qazani, M. R. C., Pourmostaghimi, V., Moayyedian, M., & Pedrammehr, S. (2022). Estimation of tool-chip contact length using optimized machine learning in orthogonal cutting. Engineering Applications of Artificial Intelligence, 114, 105118. https://doi.org/10.1016/j.engappai.2022.105118

Quinlan, J. R. (1985). Induction of decision trees. Machine Learning, 1, 81–106. https://doi.org/10.1007/BF00116251

Quinlan, J. R. (1993). C4.5: Programs for machine learning. Morgan Kaufmann Publishers Inc.

Rabiee, A. H., Tahmasbi, V., & Qasemi, M. (2023). Experimental evaluation, modeling and sensitivity analysis of temperature and cutting force in bone micro-milling using support vector regression and EFAST. Engineering Applications of Artificial Intelligence, 120, 105874. https://doi.org/10.1016/j.engappai.2023.105874

Ren, X., Huang, X., Gao, K., Xu, L., Li, L., Feng, H., Zhang, X., Chen, H., Chai, Z., & Chen, X. (2023). A review of recent advances in robotic belt grinding of superalloys. The International Journal of Advanced Manufacturing Technology, 127, 1447–1482. https://doi.org/10.1007/s00170-023-11574-z

Shahriari, B., Swersky, K., Wang, Z., Adams, R. P., & de Freitas, N. (2016). Taking the human out of the loop: A Review of Bayesian optimization. In Proceedings of the IEEE, 104, 148–175. https://doi.org/10.1109/JPROC.2015.2494218

Twardowski, P., Tabaszewski, M., & Pikula, M. W. (2021). Identification of tool wear using acoustic emission signal and machine learning methods. Precision Engineering, 72, 738–744. https://doi.org/10.1016/j.precisioneng.2021.07.019

Verl, A., Valente, A., Melkote, S., Brecher, C., Ozturk, E., & Tunc, L. T. (2019). Robots in machining. CIRP Annals, 68, 799–822. https://doi.org/10.1016/j.cirp.2019.05.009

Wan, B. S., Lu, M. C., & Chiou, S. J. (2022). Analysis of spindle AE signals and development of AE-based tool wear monitoring system in micro-milling. Journal of Manufacturing and Material Processing, 6, 42. https://doi.org/10.3390/jmmp6020042

Wang, N., Zhang, G., Ren, L., & Yang, Z. (2022a). Analysis of abrasive grain size effect of abrasive belt on material removal performance of GCr15 bearing steel. Tribology International, 171, 107536. https://doi.org/10.1016/j.triboint.2022.107536

Wang, S., Zhao, Q., & Wu, T. (2022b). An investigation of monitoring the damage mechanism in ultra-precision grinding of monocrystalline silicon based on AE signals processing. Journal of Manufacturing Processes, 81, 945–961. https://doi.org/10.1016/j.jmapro.2022.07.055

Wu, D., Jennings, C., Terpenny, J., Gao, R. X., & Kumara, S. (2017). A comparative study on machine learning algorithms for smart manufacturing: Tool wear prediction using random forests. Journal of Manufacturing Science and Engineering, 139, 071018. https://doi.org/10.1115/1.4036350

Xiao, Z., Ma, H., Lu, Y., Zhang, G., Liu, Z., & Song, Q. (2023). Real-Time milling tool breakage monitoring based on multiscale standard deviation diversity entropy. International Journal of Mechanical Sciences, 240, 107929. https://doi.org/10.1016/j.ijmecsci.2022.107929

Zhang, K. F., Yuan, H. Q., & Nie, P. (2015). A method for tool condition monitoring based on sensor fusion. Journal of Intelligent Manufacturing, 26, 1011–1026. https://doi.org/10.1007/s10845-015-1112-y

Zhang, P., Gao, D., Lu, Y., Ma, Z., Wang, X., & Song, X. (2022). Cutting tool wear monitoring based on a smart toolholder with embedded force and vibration sensors and an improved residual network. Measurement, 199, 111520. https://doi.org/10.1016/j.measurement.2022.111520

Zhang, X., Chen, H., Xu, J., Song, X., Wang, J., & Chen, X. (2018). A novel sound-based belt condition monitoring method for robotic grinding using optimally pruned extreme learning machine. Journal of Material Processing Technology, 260, 9–19. https://doi.org/10.1016/j.jmatprotec.2018.05.013

Zhang, X., Kuhlenkötter, B., & Kneupner, K. (2005). An efficient method for solving the Signorini problem in the simulation of free-form surfaces produced by belt grinding. International Journal of Machine Tools and Manufacture, 45, 641–648. https://doi.org/10.1016/j.ijmachtools.2004.10.006

Zhu, D., Feng, X., Xu, X., Yang, Z., Li, W., Yan, S., & Ding, H. (2020). Robotic grinding of complex components: A step towards efficient and intelligent machining-challenges, solutions, and applications. Robotics and Computer-Integrated Manufacturing, 65, 101908. https://doi.org/10.1016/j.rcim.2019.101908

Zhu, D., Xu, X., Yang, Z., Zhuang, K., Yan, S., & Ding, H. (2018). Analysis and assessment of robotic belt grinding mechanisms by force modeling and force control experiments. Tribology International, 120, 93–98. https://doi.org/10.1016/j.triboint.2017.12.043

Acknowledgements

The Authors would like to thank Dr. Vigneashwara Pandiyan for the support in the experimental work and data acquisition.

Funding

This research was funded by Universiti Brunei Darussalam, grant number UBD/RSCH/1.3/FICBF(b)/2019/007. The authors also acknowledge the Polish National Agency for Academic Exchange (NAWA) No. BPN/ULM/2022/1/00139/U/00001 for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Surindra, M.D., Alfarisy, G.A.F., Caesarendra, W. et al. Use of machine learning models in condition monitoring of abrasive belt in robotic arm grinding process. J Intell Manuf (2024). https://doi.org/10.1007/s10845-024-02410-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10845-024-02410-6