Abstract

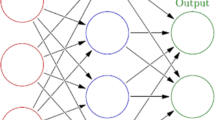

In industrial settings, it is inevitable to encounter abnormal patterns monitoring a process. These patterns point out manufacturing faults that can lead to significant internal and external failure costs unless treated promptly. Thus, detecting such abnormalities is of utmost importance. Machine learning algorithms have been widely applied to this problem. Nevertheless, the existing control chart pattern recognition (CCPR) method can only deal with a fixed input size rather than dealing with different input sizes according to the actual production needs. In order to tackle this problem, an original CCPR method relying on convolutional neural network (CNN) named as VIS-CNN is proposed. Signal resizing is performed using resampling methods, then CNN is used to extract the abnormal patterns in the dataset. Five different input sizes are generated for model training and testing. The optimal hyperparameters, as well as the best structure of the used CNN are obtained using Bayesian Optimization. Simulation results show that the correct recognition rate of the VIS-CNN is 99.78%, based on different window size control charts. Furthermore, we address the issue of the mixed CCP and provide a modified scheme to achieve high recognition ratio for 8 mixed patterns on top of 6 standard patterns. The modified scheme includes wavelet noise reduction and Adaptive Boosting. A case study on metal galvanization process is presented to show that the method has potential applications in the industrial environment.

Similar content being viewed by others

References

Addeh, A., Khormali, A., & Golilarz, N. A. (2018). Control chart pattern recognition using RBF neural network with new training algorithm and practical features. ISA Transactions, 79, 202–216. https://doi.org/10.1016/j.isatra.2018.04.020

Antoniou, A. (2016). Digital signal processing. McGraw-Hill.

Azizkalteh, A., & Babouei, S. (2020). Control chart patterns recognition using ANFIS with new training algorithm and intelligent utilization of shape and statistical features. ISA Transactions, 102, 12–22. https://doi.org/10.1016/j.isatra.2019.12.001

Brochu, E., Cora, V. M., & De Freitas, N. (2010). A tutorial on Bayesian optimization of expensive cost functions, with application to active user modeling and hierarchical reinforcement learning. arXiv preprint arXiv:1012.2599.

Costantino, F., Di Gravio, G., Shaban, A., & Tronci, M. (2015). SPC forecasting system to mitigate the bullwhip effect and inventory variance in supply chains. Expert Systems with Applications, 42(3), 1773–1787. https://doi.org/10.1016/j.eswa.2014.09.039

Fuqua, D., & Razzaghi, T. (2020). A cost-sensitive convolution neural network learning for control chart pattern recognition. Expert Systems with Applications, 150, 113275. https://doi.org/10.1016/j.eswa.2020.113275

Hachicha, W., & Ghorbel, A. (2012). A survey of control-chart pattern-recognition literature (1991–2010) based on a new conceptual classification scheme. Computers & Industrial Engineering, 63(1), 204–222. https://doi.org/10.1016/j.cie.2012.03.002

Hemanth, D. J., & Balas, V. E. (2019). Telemedicine technologies: Big data. Academic Press.

Jang, J. S. (1993). ANFIS: adaptive-network-based fuzzy inference system. IEEE Transactions on Systems, Man, and Cybernetics, 23(3), 665–685.

Johnstone, I. M., & Silverman, B. W. (2004). Needles and straw in haystacks: Empirical Bayes estimates of possibly sparse sequences. The Annals of Statistics, 32(4), 1594–1649.

Kadakadiyavar, S., Ramrao, N., & Singh, M. K. (2020). Efficient mixture control chart pattern recognition using adaptive RBF neural network. International Journal of Information Technology, 12(4), 1271–1280. https://doi.org/10.1007/s41870-019-00381-z

Kao, L.-J., Lee, T.-S., & Lu, C.-J. (2016). A multi-stage control chart pattern recognition scheme based on independent component analysis and support vector machine. Journal of Intelligent Manufacturing, 27(3), 653–664.

Khan, S. H., Hayat, M., Bennamoun, M., Sohel, F. A., & Togneri, R. (2017). Cost-sensitive learning of deep feature representations from imbalanced data. IEEE Transactions on Neural Networks and Learning Systems, 29(8), 3573–3587.

Khormali, A., & Addeh, J. (2016). A novel approach for recognition of control chart patterns: Type-2 fuzzy clustering optimized support vector machine. ISA Transactions, 63, 256–264. https://doi.org/10.1016/j.isatra.2016.03.004

Lévesque, L. (2014). Nyquist sampling theorem: Understanding the illusion of a spinning wheel captured with a video camera. Physics Education, 49(6), 697.

Lu, Z., Wang, M., & Dai, W. (2020). A condition monitoring approach for machining process based on control chart pattern recognition with dynamically-sized observation windows. Computers & Industrial Engineering, 142, 106360. https://doi.org/10.1016/j.cie.2020.106360

Maged, A., Haridy, S., Khoo, M. B. C., & Shamsuzzaman, M. (2021). Time between events monitoring for imperfect maintained systems with application to a robotic system. Journal of Statistical Computation and Simulation. https://doi.org/10.1080/00949655.2021.1993224

Mehmood, R., Lee, M. H., Hussain, S., & Riaz, M. (2019). On efficient construction and evaluation of runs rules–based control chart for known and unknown parameters under different distributions. Quality and Reliability Engineering International, 35(2), 582–599. https://doi.org/10.1002/qre.2423

Miao, Z., & Yang, M. (2019). Control chart pattern recognition based on convolution neural network. Paper presented at the smart innovations in communication and computational sciences, Singapore.

Ranaee, V., & Ebrahimzadeh, A. (2011). Control chart pattern recognition using a novel hybrid intelligent method. Applied Soft Computing, 11(2), 2676–2686. https://doi.org/10.1016/j.asoc.2010.10.016

Ranaee, V., & Ebrahimzadeh, A. (2013). Control chart pattern recognition using neural networks and efficient features: A comparative study. Pattern Analysis and Applications, 16(3), 321–332. https://doi.org/10.1007/s10044-011-0246-6

Rasmussen, C. E., & Nickisch, H. (2010). Gaussian processes for machine learning (GPML) toolbox. The Journal of Machine Learning Research, 11, 3011–3015.

Santiago, E., & Smith, J. (2013). Control charts based on the exponential distribution: Adapting runs rules for the t chart. Quality Engineering, 25(2), 85–96.

Shongwe, S. C. (2020). On the design of nonparametric runs-rules schemes using the Markov chain approach. Quality and Reliability Engineering International, 36(5), 1604–1621. https://doi.org/10.1002/qre.2648

Snoek, J., Larochelle, H., & Adams, R. P. (2012). Practical bayesian optimization of machine learning algorithms. Paper presented at the advances in neural information processing systems.

Victoria, A. H., & Maragatham, G. (2020). Automatic tuning of hyperparameters using Bayesian optimization. Evolving Systems. https://doi.org/10.1007/s12530-020-09345-2

Xia, M., Li, T., Xu, L., Liu, L., & Silva, C. W. D. (2018). Fault Diagnosis for Rotating Machinery Using Multiple Sensors and Convolutional Neural Networks. IEEE/ASME Transactions on Mechatronics, 23(1), 101–110. https://doi.org/10.1109/TMECH.2017.2728371

Yager, R. R., & Filev, D. P. (1994). Generation of fuzzy rules by mountain clustering. Journal of Intelligent & Fuzzy Systems, 2(3), 209–219.

Zaman, M., & Hassan, A. (2019). Improved statistical features-based control chart patterns recognition using ANFIS with fuzzy clustering. Neural Computing and Applications, 31(10), 5935–5949. https://doi.org/10.1007/s00521-018-3388-2

Zan, T., Liu, Z., Su, Z., Wang, M., Gao, X., & Chen, D. (2020a). Statistical process control with intelligence based on the deep learning model. Applied Sciences, 10(1), 308.

Zan, T., Liu, Z., Wang, H., Wang, M., & Gao, X. (2020b). Control chart pattern recognition using the convolutional neural network. Journal of Intelligent Manufacturing, 31(3), 703–716.

Zhang, M., & Cheng, W. (2015). Recognition of mixture control chart pattern using multiclass support vector machine and genetic algorithm based on statistical and shape features. Mathematical Problems in Engineering.

Zhang, Y., Shang, Y., Gao, N., & Wang, Q. (2017). Monitoring prespecified changes in linear profiles using control charts with supplementary runs rules. Communications in Statistics - Simulation and Computation, 46(9), 7249–7263. https://doi.org/10.1080/03610918.2016.1235190

Zhou, X., Jiang, P., & Wang, X. (2018). Recognition of control chart patterns using fuzzy SVM with a hybrid kernel function. Journal of Intelligent Manufacturing, 29(1), 51–67. https://doi.org/10.1007/s10845-015-1089-6

Acknowledgements

The authors would like to thank the reviewers and the editor for their constructive comments on an earlier version of the paper. This work is supported by National Natural Science Foundation of China (71971181 and 72032005) and by Research Grant Council of Hong Kong (11203519, 11200621). It is also funded by Hong Kong Innovation and Technology Commission (InnoHK Project CIMDA) and Hong Kong Institute of Data Science (Project 9360163).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maged, A., Xie, M. Recognition of abnormal patterns in industrial processes with variable window size via convolutional neural networks and AdaBoost. J Intell Manuf 34, 1941–1963 (2023). https://doi.org/10.1007/s10845-021-01907-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-021-01907-8