Abstract

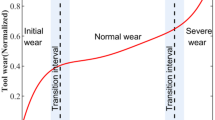

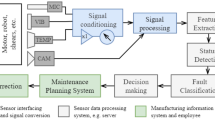

The integrity of machining tools is important to maintain a high level of surface quality. The wear of the tool can lead to poor surface quality of the workpiece and even to damage of the machine. Furthermore, in some applications such as aeronautics and precision engineering, it is preferable to change the tool earlier rather than to loose the workpiece because of its high price compared to the tool’s one. Thus, to maintain a high quality of the manufactured pieces, it is necessary to assess and predict the level of wear of the cutting tool. This can be done by using condition monitoring and prognostics. The aim is then to estimate and predict the amount of wear and calculate the remaining useful life (RUL) of the cutting tool. This paper presents a method for tool condition assessment and life prediction. The method is based on nonlinear feature reduction and support vector regression. The number of original features extracted from the monitoring signals is first reduced. These features are then used to learn nonlinear regression models to estimate and predict the level of wear. The method is applied on experimental data taken from a set of cuttings and simulation results are given. These results show that the proposed method is suitable for assessing the wear evolution of the cutting tools and predicting their RUL. This information can then be used by the operators to take appropriate maintenance actions.

Similar content being viewed by others

References

AFNOR. (2005). Condition monitoring and diagnostics of machines–Prognostics: Part 1: General guidelines. NF ISO 13381-1.

Akansu, A. N., Serdijn, W. A., & Selesnick, I. W. (2010). Emerging applications of wavelets: A review. Physical Communication, 3(1), 1–18.

Aliustaoglu, C., Ertunc, H. M., & Ocak, H. (2009). Tool wear condition monitoring using a sensor fusion model based on fuzzy inference system. Mechanical Systems and Signal Processing, 23, 539–546.

Alonso, F., & Salgado, R. (2008). Analysis of the structure of vibration signals for tool wear detection. Mechanical Systems and Signal Processing, 22, 735–748.

Bhattacharyya, P., Sengupta, D., Mukhopadhyay, S., & Chattopadhyay, A. B. (2008). Online tool condition monitoring in face milling using current and power signals. International Journal of Production Research, 46(4), 1187–1201.

Brezak, D., Majetic, D., Udiljak, T., & Kasac, J. (2012). Tool wear estimation using an analytic fuzzy classifier and support vector machines. Journal of Intelligent Manufacturing, 23, 797–809.

Chelidze, D., & Cusumano, J. (2004). A dynamical systems approach to failure prognosis. Journal of Vibration and Acoustics, 126, 2–8.

Chen, X., & Li, B. (2007). Acoustic emission method for tool condition monitoring based on wavelet analysis. International Journal of Advanced Manufacturing Technology, 33, 968–976.

Dong, M., & He, D. (2007). A segmental hidden semi-Markov model (HSMM)-based diagnostics and prognostics framework and methodology. Mechanical Systems and Signal Processing, 21, 2248–2266.

Gajate, A., Haber, R., Del Toro, R., Vega, P., & Bustillo, A. (2012). Tool wear monitoring using neuro-fuzzy techniques: A comparative study in a turning process. Journal of Intelligent Manufacturing, 23, 869–882.

He, D., Li, R., & Bechhoefer, E. (2012). Stochastic modeling of damage physics for mechanical component prognostics using condition indicators. Journal of Intelligent Manufacturing, 23, 221–226.

Heng, A., Tan, A. C., Mathew, J., Montgomery, N., Banjevic, D., & Jardine, A. K. (2009). Intelligent condition-based prediction of machinery reliability. Mechanical Systems and Signal Processing, 23(5), 1600–1614.

Heng, A., Zhang, S., Tan, A. C. C., & Mathew, J. (2009). Rotating machinery prognostics: State of the art, challenges and opportunities. Mechanical Systems and Signal Processing, 23(3), 724–739.

Jardine, A. K., Lin, D., & Banjevic, D. (2006). A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mechanical Systems and Signal Processing, 20(7), 1483–1510.

Jemielniak, K., & Arrazola, P. (2008). Application of ae and cutting force signals in tool condition monitoring in micro-milling. CIRP Journal of Manufacturing Science and Technology, 1, 97–102.

Kilundu, B., Dehombreux, P., & Chiementin, X. (2011). Tool wear monitoring by machine learning techniques and singular spectrum analysis. Mechanical Systems and Signal Processing, 25, 400–415.

Kunpeng, Z., San, W. Y., & Soon, H. G. (2009). Wavelet analysis of sensor signals for tool condition monitoring: A review and some new results. International Journal of Machine Tools and Manufacture, 49, 537–553.

Lebold, M., & Thurston, M. (2001). Open standards for condition-based maintenance and prognostic systems. In Proceedings of the 5th maintenance and reliability conference (MARCON).

Luo, J., Pattipati, K. R., Qiao, L., & Chigusa, S. (2003). Model-based prognostic techniques applied to a suspension system. Transactions on Systems, Man, and Cybernetics, 38, 1156–1168.

Medjaher, K., Tobon-Mejia, D. A., & Zerhouni, N. (2012). Remaining useful life estimation of critical components with application to bearings. IEEE Transactions on Reliability, 61(2), 292–302.

Oraby, S., & Hayhurst, D. (2004). Cutting tool condition monitoring using surface texture via neural network. International Journal of Mathematical and Computational Tools Manufacturing, 44, 1261–1269.

Pal, S., Heyns, P. S., Freyer, B. H., Theron, N. J., & Pal, S. K. (2011). Tool wear monitoring and selection of optimum cutting conditions with progressive tool wear effect and input uncertainties. Journal of Intelligent Manufacturing, 22, 491–504.

PHM Society. (2010). PHM data chalelnge 2010. https://www.phmsociety.org/competition/phm/10.

Purushothaman, S. (2010). Tool wear monitoring using artificial neural network based on extended Kalman filter weight updation with transformed input patterns. Journal of Intelligent Manufacturing, 21, 717–730.

Rehorn, A., Jiang, J., & Orban, P. (2005). State of the art methods and results in tool condition monitoring: A review. International Journal of Advance Manufacturing Technology, 26, 693–710.

Roweis, T., & Saul, L. (2000). Nonlinear dimensionality reduction by locally linear embedding. Science, 290, 2323–2326.

Saxena, A., Celaya, J., Saha, B., Saha, S., & Goebel, K. (2010). Metrics for offline evaluation of prognostic performance. International Journal of Prognostics and Health Management, 1(1), 20.

Schölkopf, B., & Smola, A. (2002). Learning with kernels. Cambridge: MIT Press.

Shi, D., & Gindy, N. N. (2007). Tool wear predictive model based on least squares support vector machines. Mechanical Systems and Signal Processing, 21(4), 1799–1814.

Sikorska, J., Hodkiewicz, M., & Ma, L. (2011). Prognostic modelling options for remaining useful life estimation by industry. Mechanical Systems and Signal Processing, 25(5), 1803–1836.

Sun, J., Hong, G., Rahman, M., & Wong, Y. (2004). The application of nonstandard support vector machine in tool condition monitoring system. In Second IEEE international workshop on electronic design, test and applications (DELTA 2004, pp. 295–300.

Tenenbaum, J., Silva, V. D., & Langford, J. C. (2000). A global geometric framework for nonlinear dimensionality reduction. Science, 290, 2319–2323.

Tobon-Mejia, D. A., Medjaher, K., & Zerhouni, N. (2012). Cnc machine tool’s wear diagnostic and prognostic by using dynamic bayesian networks. Mechanical Systems and Signal Processing, 28, 167–182.

Vachtsevanos, G., Lewis, F. L., Roemer, M., Hess, A., & Wu, B. (2006). Intelligent fault diagnosis and prognosis for engineering systems. New York: Wiley.

Van Der Maaten, L. J. P., Postma, E. O., & Van Den Herik, H. J. (2009). Dimensionality reduction: A comparative review. Tech. report, Tilburg University. TiCC-TR 2009-005.

Vapnik, V. (1995). The nature of statistical learning theory. New York: Springer.

Vapnik, V., Golowich, S., & Smola, A. (1997). Support vector method for function approximation, regression estimation, and signal processing. Advances in Neural Information Processing Systems, 9, 281–287.

Yan, J. H., & Lee, J. (2005). Degradation assessment and fault modes classification using logistic regression. Journal of Manufacturing Science and Engineering Transactions of the ASME, 127(4), 912–914.

Yan, W., Qiu, H., & Iyer, N. (2008). Feature extraction for bearing prognostics and health management (PHM)—A survey. Technical report. Air Force Research Laboratory.

Yeo, S. H., Khoo, L. P., & Neo, S. S. (2000). Tool condition monitoring using reflectance of chip surface and neural network. Journal of Intelligent Manufacturing, 11, 507–514.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benkedjouh, T., Medjaher, K., Zerhouni, N. et al. Health assessment and life prediction of cutting tools based on support vector regression. J Intell Manuf 26, 213–223 (2015). https://doi.org/10.1007/s10845-013-0774-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-013-0774-6