Abstract

The effect of (Sc,Ta) doping on the properties of Bi3TiNbO9-based ceramics was investigated. The (Sc,Ta) modification greatly improves the piezoelectric activity of Bi3TiNbO9-based ceramics and significantly decreases the dielectric dissipation. The d33 of Bi3(Ti0.96Sc0.02Ta0.02)NbO9 was found to be 12 pC/N, the highest value among the Bi3TiNbO9-based ceramics and almost 2 times as much as the reported d33 values of the pure BTNO ceramics (~6pC/N). The high TC (higher than 900 °C) and stable piezoelectric and dielectric properties, demonstrating that the (Sc,Ta) modified Bi3Ti1−xScx/2Tax/2NbO9-based material a candidate for ultrahigh temperature applications. The new (ScTa) modification has an important typical significance, the way should be used for reference in constructing the new high performance materials.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Bismuth layer-structured ferroelectrics (BLSFs) ceramics are potential candidate lead-free materials in piezoelectric device application, especially at high temperatures and high frequencies application. In addition to their high Curie temperatures, they exhibit correspondingly low temperature coefficients of dielectric and piezoelectric properties, low aging rate, strong anisotropic electromechanical coupling factors and low temperature coefficient of resonant frequency, making them suitable for pressure sensors, trapped energy filters, etc [1, 2].

In recent years, BLSFs have been given more attention. BLSFs, such as SrBi2Na2O9 (SBN), SrBi4Ti4O15 (SBTi), SrBi2Ta2O9 (SBT), La0.75Bi3.25Ti3O12 (BLT) etc. have been found to be excellent materials for nonvolatile ferroelectric random access memory (FRAM), owing to their fatigue free polarization behavior [3–7]. The general formula of BLSF is (Bi2O2)2+(Am−1BmO3m+1)2−, where A is a mono-, di- or trivalent element (or a combination of them) allowing dodecahedral coordination and B is a transition element with octahedral coordination, e.g., Ti4+, Nb5+, Fe3+, W6+ or Ta5+; m is the number of octahedral layers in the perovskite slab, which varies from 1 to 6 [4, 8]. The poling of the BLSF ceramics requires relatively high electric field because of their high coercive fields and the two-dimensional orientation restriction of rotation of the spontaneous polarization.

Bismuth titanate niobate (Bi3TiNbO9, hereinafter called BTNO) (m = 2), which is made up of (Bi2O2)2+ layers between which (BiTiNbO7)2− layers are inserted [9], is promising for high temperature piezoelectric sensors because of its very high Tc (914 °C) [8]. However, the piezoactivity of pure BTNO ceramics is quite low (d 33 < 7 pC/N) [10] for high temperature applications. The A-site substitution or/and B-site substitution have been shown to be effective in modifying the structure and polarization process [11–23]. Only a few works have addressed the properties of cation-modified BTNO-based ceramics. For La- and Ti/W-substituted BTNO[24] and Bi2K1/6Bi5/6TiNb2/3W1/3O9 [25] compounds, only a few properties (e.g., lattice parameters and Tc) have been mentioned, and no detailed structural and electrical properties have been studied. To modify BTNO structure for improving its piezoelectricity, the ScTa co-substitution into B-site of BTNO was conducted.

The only valence of Sc is 3 and the only valence of Ta is 5, so the average valence of (ScTa) is 4 which is equal to the only valence of Ti4+. The radius of Sc3+ is 0.073 nm, and the radius of Ta5+ is 0.068 nm. They are almost the same as the radius of Ti4+ (r Ti 4+ =0.068 nm). More than that, Sc, Ta, Ti and Nb in the BLSF structure have the same favorable coordinate number which is 6. All of those can assure the (Sc3+Ta5+) co-substitute Ti4+ into B-site of BTNO. Because the valence of Nb is 5 which is different from the average valence of (ScTa), and the law of conservation of electric, the ScTa will not co-substitute Nb. In addition, the samples will be prepared according the formula Bi3Ti1−x(ScTa)x/2NbO9, so there is not lack of Nb which will lead Nb to stay at the original position without being substituted .

2 Experiment

The starting raw materials were high purity Bi2O3 (99.8 %), TiO2 (99.8 %), Nb2O5 (99.5 %), Sc2O3 (99.27 %), Ta2O5(99.5 %). The samples were prepared according the formula Bi3Ti1−x(ScTa)x/2NbO9 (x = 0.00, 0.02, 0.04, 0.06). The chemicals were weighed according to the composition, and then mixed using ball milling, dried and calcined at 808 °C for 3 h. After calcination, the ball-milled ground powders were pressed into disks with 13 mm in diameter and 2 mm in thickness. Densification was achieved by sintering the disks at 1080 °C for 2 h in a sealed crucible to prevent volatilization.

The X-ray diffraction (XRD) patterns for the ceramic powers were obtained with an X-ray diffractometer (PGeneral XD-3) patterns using Cu Kα radiation. For room temperature electrical and dielectric properties measurement, platinum electrodes (1 cm2) are fixed on both surfaces of the sintered pellets and fired at 800 °C for 20 min in air. Samples were poled in silicone oil at 200 °C under a dc electric field from 100 kV to 150 kV/cm for 60–120 min. The piezoelectric coefficient d 33 was measured using a quasi-static d 33 meter (Institute of Acoustics, Academia Sinica, ZJ-2). The temperature dependence of the resistivity ρ was determined using a high resistance meter (Shanghai ZC43) with an applied voltage of 20 Volts. The planar coupling k p and the thickness coupling k t were determined by the resonance-antiresonance method by using an Impedance Analyzer (Agilent 4294A). The dielectric behavior was also measured using an Impedance Analyzer (Agilent 4294A) at 1000 kHz as a function of temperature.

3 Results and discussion

Figure 1 presents the SEM micrographs of the BTNO-based ceramics. As shown, the BTNO (x = 0.00) ceramic exhibits the smallest grain size when compared to the (ScTa) modified counterparts, indicating that the addition of (ScTa) enhanced the grain growth of the ceramics.

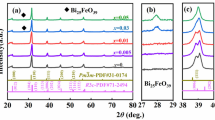

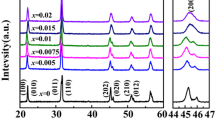

Figure 2 shows the XRD patterns of Bi3Ti1−x(ScTa)x/2NbO9 (x = 0.00, 0.02, 0.04, 0.06) ceramics scanned in the range 2θ of 20–60 degree. Compared with the pattern of pure Bi3TiNbO9 ceramics, the Bi3Ti1−x(ScTa)x/2NbO9 (0.02, 0.04, 0.06) ceramics are also bismuth layer-structured ferroelectrics with m = 2. From Fig. 2, the ceramics possess a pure phase of layer-structured structure and no second phases were found, which is believed that Sc3+ and Ta5+ diffuse into the lattices to form solid solutions.

Figure 3 shows the dielectric permittivity (ε/ε 0) and dielectric loss (tanδ) measured at 1000 kHz as a function of temperature for the Bi3Ti1−x(ScTa)x/2NbO9-based ceramics. As expected, the dielectric maxima occurred over 900 °C, which corresponding to the Curie temperatures (T C ). T C of the ceramics in this work gradually decreased from 913 °C to 901 °C with the diffusion of (ScTa)1/2 instead of Ti (r Ti 4+ =0.068 nm, r Sc 3+ =0.073 nm, r Ta 5+ =0.068 nm) into the lattices. The temperature dependence of dielectric behavior in the temperature range of 30–600 °C was found to be very low \( \left(\frac{\partial \epsilon }{\partial T}=0.09/{}^{\circ} C\right) \) and the dielectric loss at 600 °C and 1000 kHz was found to be less than 7 %, exhibiting the Bi3Ti0.96Sc0.02Ta0.02NbO9 ceramics possess high stability of the dielectric properties.

Figure 4 presents piezoelectric constant d 33 as a function of temperature for Bi3Ti0.96Sc0.02Ta0.02NbO9 ceramic, in which one can see the two-layer BTNO orthorhombic structured materials is very stable to thermal annealing. The d 33 of samples are measured after annealing for 1 h, and all the samples are short-circuit during the annealing. After the d 33 measurement, The same samples are put in the oven to be annealed again for the next d 33 measurement. Among the ScTa co-substituted BTNO, one composition, Bi3Ti0.96Sc0.02Ta0.02NbO9 with a quite high piezoelectric constant d 33 of 12 pC/N and an ultrahigh T C of 905 °C have been obtained recently by using ordinary sintering process. The value of piezoelectric constant d 33 of the piezoelectric ceramics was found to be relative temperature independent to 800 °C and drop to zero when the temperature over 905 °C, related to the de-poling temperature, which is useful for high temperature applications.

Figure 5 shows the temperature dependence of the resistivity ρ for the Bi3Ti0.96Sc0.02Ta0.02NbO9 material. The high temperature resisitivity is important for high temperature piezoelectric applications and the ability to achieve high electric field poling at high temperature. The resistivity of the Bi3Ti0.96Sc0.02Ta0.02NbO9 sample is still higher than 105Ω · cm at 550 °C. That is important for its use in high-temperature piezoelectric devices. The activation energy E a was calculated according to Arrhenius law:

which was found to be 1.02 eV for Bi3Ti0.96Sc0.02Ta0.02NbO9. This prove the main charge carriers of the material are oxygen vacancies.

Frequency constants N p (planar frequency constant) and N t (thickness frequency constant) for BTNO-x = 0.04 material were found to decrease with increasing temperature, indicating that the materials become softer, as shown in Fig. 6. The reduction is very small, where N p decreases by 5.0 % of its room temperature value when at 620 °C, while the change for N t was found to be only 1.6 %, exhibiting very low temperature coefficient of resonant frequency.

Figure 7 presents electromechanical coupling factors as a function of temperature for Bi3Ti0.96Sc0.02Ta0.02NbO9 material, in which one can see the planar coupling k p is about 5 % at room temperature, much lower than the value of thickness coupling k t (~ 19 %), exhibiting a strong anisotropic behavior. Both the coupling factors k p and k t were found to be relative temperature independent to 840 °C and drop to zero when the temperature over 890 °C, related to the de-poling temperature, which is useful for high temperature applications.

The detailed properties of the Bi3TiNbO9-based materials were characterized at room temperature and listed in Table 1. The T C was found to be 913 °C for Bi3TiNbO9 (x = 0.00) sample and gradually decrease with the modification of ScTa. The mechanical quality factor Q of the Bi3Ti0.96Sc0.02Ta0.02NbO9 ceramic were found to be higher than that of the other ceramics. The dielectric loss (tanδ) of Bi3TiNbO9-based materials increase with modification, where the tanδ of Bi3Ti0.96Sc0.02Ta0.02NbO9 (x = 0.04) was found to be only 0.21 %. The piezoelectricity of the pure BTNO was improved due to the lattice distortion caused by the ScTa co-substitution into B-site, the d 33 of Bi3Ti0.96Sc0.02Ta0.02NbO9 was found to be 12 pC/N, the highest value among the Bi3TiNbO9-based ceramics, also almost 2 times as much as the d 33 values of the pure BTNO ceramics (~6pC/N).

4 Conclusion

In summary, Bi3TiNbO9-based materials were synthesized using conventional solid state processing. The dielectric and piezoelectric properties of Bi3Ti0.96Sc0.02Ta0.02NbO9-based ceramics exhibiting a very stable temperature behavior, together with its high T C ~905 °C, excellent piezoelectric coefficient ~12 pC/N and very low temperature coefficient of resonant frequency, making the (ScTa) modified Bi3TiNbO9-based ceramics a candidate for ultra-high temperature applications. The new (ScTa) modification of Bi3TiNbO9-based materials resulted in the obvious improvement of the piezoelectric activity, having an important typical significance. The way should be used for reference in constructing the new high performance materials.

References

E.C. Subbarao, J. Phys. Chem. Solids. 23, 665 (1962)

T. Takenaka, K. Sakata, J. Appl. Phys. 55, 1092 (1984)

A. Ando, M. Kimura, Y. Sakabe, Jpn. J. Appl. Phys. 42, 520 (2003)

R.Z. Hou, X.M. Chen, J. Mater. Res. 20, 2354 (2005)

R.Z. Hou, X.M. Chen, Solid State Commun. 130, 469 (2004)

Y. Noguchi, I. Miwa, Y. Goshima, M. Miyayama, Jpn. J. Appl. Phys. 39, L1259 (2000)

Y. Yao, C. Song, P. Bao, D. Su, X. Lu, J. Appl. Phys. 95, 3126 (2004)

Z. Zhang, H. Yan, X. Dong, Y. Wang, Mater. Res. Bull. 38, 241 (2003)

R.W. Wolfe, R.E. Newnham, D.K. Smith, Ferroelectrics 3, 11971 (2004)

A. Moure, L. Pardo, C. Alemany, J. Eur. Ceram. Soc. 21, 1399 (2001)

Z.Y. Zhou, X.L. Dong, H. Chen, H.X. Yan, J. Am. Ceram. Soc. 89, 1756 (2006)

T. Takenaka, K. Sakata, Jpn. J. Appl. Phys. 24, 730 (1985)

Z.X. Cheng, X.L. Wang, Appl. Phys. Lett. 90, 222902 (2007)

R. Aoyagi, H. Takeda, S. Okamura, T. Shiosaki, Mater. Res. Bull. 38, 25 (2003)

H.X. Yan, C.G. Li, J.G. Zhou, Jpn. J. Appl. Phys. 40, 6501 (2001)

Z.X. Cheng, X.L. Wang, Appl. Phys. Lett. 89, 2221918 (2006)

Z.G. Gai, J.F. Wang, Appl. Phys. Lett. 90, 052911 (2007)

S.J. Zhang, Solid State Commun. 140, 154 (2006)

Z.X. Cheng, X.L. Wang, J. Phys. D. Appl. Phys. 43, 242001 (2010)

M. Matsushita, R. Aoyagi, H. Takeda, Jpn. J. Appl. Phys. 43, 7164 (2004)

R. Aoyagi, S. Inai, Y. Hiruma, T. Takenaka, Jpn. J. Appl. Phys. 44, 7055 (2005)

Z.X. Cheng, X.L. Wang, J. Appl. Phys. 107, 084105 (2010)

S.J. Zhang, F.P. Yu, J. Am. Chem. Soc. 94, 3153 (2011)

J.P. Mercurio, A. Souirti, M. Manier, Mater. Res. Bull. 27, 123 (1992)

L.V. Korzunova, L.A. Shebanov, Ferroelectrics 93, 111 (1989)

Acknowledgments

This work supported by the National Natural Science Foundation of China under the Grant Nos. 51002087, 51002097, 51202132 and 51172129, China Postdoctoral Science Foundation under Grant No. 20100471500.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Gai, ZG., Zhao, ML., Su, WB. et al. Influences of ScTa co-substitution on the properties of Ultra-high temperature Bi3TiNbO9-based piezoelectric ceramics. J Electroceram 31, 143–147 (2013). https://doi.org/10.1007/s10832-013-9833-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-013-9833-9