Abstract

The introduction of the rotary quern into the Iberian Peninsula during the Iron Age represents a great technological innovation with regard to processing cereals. These mechanisms arrived several centuries later in the Canarian archipelago with the first North African colonists. Contacts with the African continent appear to have either been cut off or minimised a short time later, obliging the colonists to subsist autonomously and adapt to the features of the new territory. Moreover, the archipelago's volcanic character does not offer minerals that could be transformed into metals obliging the new populations to resort to stone tools, an adaptation evidenced by the manufacture of rotary querns. Currently few technological studies of these querns have combined experimental work with hypotheses stemming from archaeological evidence. This article presents two experimental programs that have attempted to reconstruct the operational sequence (chaîne opératoire) of the two main types of rocks exploited for querns in the Canary Islands: volcanic tuff and vesicular basalt.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The introduction of cylindrical hand-driven rotary querns and larger, more complex millstones in Europe in the Iron Age is a highly relevant technological innovation. The oldest mechanisms of this type are recorded in the Western Mediterranean between the sixth and fifth centuries BC in the framework of pre-Roman Iberian communities (Alonso, 2002, 2015; Alonso et al., 2011). Early finds in areas distant to the Mediterranean Basin such as Great Britain or Germany also evidence an advanced adoption of this mechanism by native pre-Roman populations (Picavet, 2019; Wefers, 2011). It was nonetheless the Romans who promoted its expansion throughout the Empire mainly from the turn of the era. Moreover, it is thought that each Roman contubernium (group of eight soldiers and two assistants) transported one of these rotary querns to grind their cereals (Déry, 1997). The efficiency of this mechanism explains that it survived well into the twentieth century in Europe, North Africa (Alonso, 2019), and of particular interest to this study, in the Canary Islands.

Various historical, ethnographic and ethnoarchaeological studies have delved into the role played over time by this mill in production processes. Research has focused on the type of materials that were processed and on the variety of products, as well as on their impact on economic strategies in various historical and cultural contexts (Alonso, 2019; Bustamante et al., 2014). A key line of research has centred on defining the raw materials serving for their manufacture and their spatial distribution with the aim of identifying their commercial routes and cultural influences during Antiquity and the Middle Ages (Anderson et al., 2003; Antonelli & Lazzarini, 2010; Jodry et al., 2011; Peacock, 1980, 2013; Williams-Thorpe, 1988; Williams-Thorpe & Thorpe, 1993). However, less research has been devoted to technological aspects linked to the processes of procuring raw materials and subsequent manufacture of querns. Among these studies stand out those dedicated to quern and millstone quarries which at times have included reconstructions of the extractive techniques based, fundamentally, on the observation of extraction tool marks, hollows (negatives), roughouts and blanks, and waste (Anderson et al., 2003; Anderson, 2016; Jaccottey et al., 2019; Naranjo et al., 2019).

Yet there are very few publications offering an experimental or ethnoarchaeological approach to making querns that serve to verify the hypotheses deriving from the analyses of quarries and their potential workshops that are at times be located at a certain distance from the points of extraction (Anderson et al., 2003; Jaccottey, 2014). In our opinion, one of the most valuable contributions along this line is the ethnoarchaeological study of metate manufacture by the Highland Maya in the 1980s (Hayden, 1987). Although a very different spatial, cultural and chronological context, and a type of grinding implement far from that of rotary mills, the study shares many points with the current analysis. Thus, a key stage of the operational sequence of metate was carried out with stone picks, tools that bear an astonishing resemblance with the pre-Hispanic implements in the archipelago serving to fashion the rotary hand mills. In fact, the only moment when the Guatemalan stone picks gave place to metal hammers and chisels was when detaching the rough blocks from the bedrock (Nelson, 1987).

This article thus aims to address this specific line of research so as to complement previous work on pre-European rotary quern manufacture in quarries and workshops in the Canary Islands (Rodríguez-Rodríguez et al., 2010; Rodríguez-Rodríguez & Francisco, 2012; Naranjo & Rodríguez-Rodríguez, 2016; Naranjo et al., 2019; Arnay et al. 2016, 2019). It also intends to contribute to the discussion on how cultural transmission takes place in a framework of isolation, with special attention placed on the interaction between the availability of resources and technological knowledge.

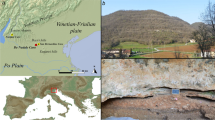

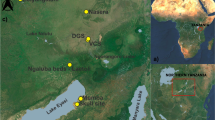

The Canary Islands are particularly appropriate for this objective as they are the only archipelago in the mid-Atlantic to have been populated prior to the late medieval Iberian expansion (Fig. 2). When the early Castilian navigators arrived, they encountered isolated populations living in an astonishing manner, far from their conceptions of culture. Archaeological evidence points to the turn of the era as the most probable date of the initial colonisation from North Africa (Velasco et al., 2020). However, the motives driving the migratory enterprise of the North Africans to settle the islands remain unclear (Fregel et al., 2019). There is evidence that Romanised sailors had temporarily set foot early after the turn of the Era on the Islet of Lobos to exploit the sea snail Stramonita aemastoma for its precious purple dye (del Arco et al., 2017). In any case, the subsequent permanent North African settlers bore a Berber cultural substrate, a notion bolstered by epigraphic and linguistic evidence such Libyco-Berber inscriptions and numerous place names (Springer, 2019; Mora, 2021). The North African settlers brought with them their economy based on agriculture and livestock. They cultivated Mediterranean species, notably wheat and barley as well as legumes, and their domestic animals consisted of pigs, goats, and sheep. The evidence indicates productive practices clearly adapted to the territory, which led to a moderate population growth experiencing by ups and downs. There is also evidence of changes in agricultural practices subsequent to the tenth-eleventh century AD with a preference for barley coupled with a decrease, even the disappearance, of other crops. The most spectacular case is what appears to be an extinction of agriculture on the Island of La Palma (Morales et al., 2014, 2017).

Various studies have delved into the question of island population dynamics over time. The first centuries of the archipelago's colonisation, according to genetic studies of human and plant evidence, must have seen contacts between the different islands, (Fregel et al., 2019; Hagenblad & Morales, 2020). Apart from the brief Roman occupation of the Islet of Lobos, Roman finds have also been brought to light in indigenous settlements on Lanzarote, the easternmost island (Atoche Peña & Arco Aguilar, 2021). However, there is no clear recording in the remaining islands that certifies other contacts during the period of Roman hegemony. The indigenous populations in fact only possessed a few artefacts that reveal a Roman influence on their North African ancestors. One of these artefacts is the object of the current study: rotary querns (Serra & Diego, 1950).

Leaving aside the imported Roman elements detected in Lanzarote, it is possible to observe that all the islands shared a material culture with a common substratum that nonetheless began in a short time to acquire individual specificities. No foreign element is clearly recorded after the third and fourth centuries AD. It is since this time that it is possible to distinguish individual island traits, especially by means of material culture. Pottery forms and decors lend themselves best in revealing these changes (Navarro Mederos, 1997). Ceramological research has in fact yielded observations as to the diachronic evolution on the islands of La Palma, Tenerife and Gran Canaria (Navarro Mederos, 1999; del Pino & Rodríguez-Rodríguez, 2017). A unique evolution of funeral rites has likewise been detected in Gran Canaria (Alberto et al., 2019).

Worth highlighting among the diverse expressions of the material culture of the Canarian native populations is the lithic industry, notably the rotary querns, the focus of this article. Given the absence of metal ores on the islands, these querns had to be produced resorting to a variety of volcanic rocks according to each island's geological substrate. The techniques of knapping, abrasion and polishing were applied depending on the type of artefact. The research carried out to date reveals a remarkable continuity among each island's strategies of manufacture. This phenomenon suggests that the settlers still retained the earlier traditional extraction and fashioning strategies in spite of being immersed in Iron Age traditions. Thus after settling in the new territories and becoming aware of the potential lithic resources, they adapted their strategies to the local lithological characteristics. Although there is no evidence of change among their way of working, diachronic variations can be observed as to a preference for certain raw materials or types of blank (flakes, pebbles, blocks…) on certain islands such as La Palma and Tenerife (Hernández Gómez & Galván, 2008; Rodríguez-Rodríguez, 1993). The use of specialised tools stands out in certain contexts of Gran Canaria such as in the obsidian mines or quern quarries (Rodríguez-Rodríguez & Hernández Gómez, 2006; Rodríguez-Rodríguez & Francisco Ortega, 2012). It is precisely the study of the extractive tasks and the fashioning of the cylindrical hand querns that has given rise to the experimental programs presented in this article.

Although rotary querns are recorded throughout all the islands of the archipelago, systematic research has only been carried out on the isles of Tenerife and Gran Canaria. The typology of this mechanism is very regular and reveals few changes over time. Although they can vary in diameter, most range from 30 and 35 cm. The grinding surfaces of both the lower immobile (meta) and upper active stone (catillus) are relatively flat. Each bear central perforations in order to fix a spindle serving to tether and stabilise the upper stone during rotation. The eye of the upper stone is at times surrounded by a raised collar serving as a sort of hopper which facilitated feeding the grains. One or more sockets cut vertically into the top of the upper stone served to insert a wooden handle to drive the mill (Fig. 1).

Example of a rotary quern of volcanic tuff (max. diameter: 35.6 cm) discovered in situ at floor level in a dwelling dated between AD 340–771 (El Pajar, Arguineguín, Gran Canaria). The collar around the eye, not present on all models, probably served as a hopper. This piece is also decorated with several knobs. © El Museo Canario

The work about rotary querns began early on Tenerife, an island where querns were fashioned in situ in quarries consisting of naturally detached blocks and boulders. It focused on typological aspects and advanced hypotheses on their strategies of manufacture and use. In this sense, the authors interested in the subject were able as late as the 1940-1950s to observe the daily use of rotary querns as well as witness craftsmen carving these hand mills with metal tools. Although the early studies by Serra and Diego (1950) and Diego (1953) recognised that these types of querns were potentially linked to Roman influences, it is only in the present century that systematic quern research projects have focused on the processes of procurement, transformation, and use of different materials in the area of Las Cañadas in the Teide National Park (three quarry/workshops). Archaeological research in Gran Canaria, in turn, has identified several true extractive quarries of volcanic tuff or ash (7) and vesicular basalt (2) (Fig. 2). A workshop specialised in finishing rotary querns was also identified in the vicinity of one of the quarries (Cardones). Research in both islands has focused on technological and typological aspects as well as delved into petrographic and geochemical characterisations intended to identify distribution networks (Mangas et al., 2008; Rodríguez-Rodríguez et al., 2007, 2010; Naranjo et al., 2016, 2019; Naranjo & Rodríguez-Rodríguez, 2016; Arnay et al., 2019).

The archaeological evidence consists mainly of circular extraction hollows on true extractive quarry faces, cylindrical roughouts (or blanks) in various stages of manufacture and working waste. Tools serving to produce them were likewise recorded. The nature of these tools is exceptional as they are exclusively of stone. Indeed, the volcanic archipelago possesses no minerals that can be transformed into metal tools. Hence the ancient inhabitants of the islands had to make do with the geological resources at hand. The types of tools serving to extract and fashion querns were for the most part massive picks of great technical complexity designed to carry out different tasks and to withstand repair and resharpening, actions that were repeated given the high frequency of accidents (Francisco, 2016; Rodríguez-Rodríguez & Francisco, 2012). This aspect contrasts greatly with quern and millstone production undertaken with metal tools in other cultural and spatial contexts (Anderson, 2016; Colfer, 2019; Guillier et al., 2005; Jaccottey et al., 2014, 2019).

The current study therefore offers a series of findings gleaned from two experimental programs aimed at reconstructing the operational sequence of the extraction and the fashioning with lithic tools of rotary querns. The strategies reveal an exceptional case of adaptation to insular environments with little or no contact with the outside world. The study therefore pursues the following specific objectives: 1) to compare through experimentation the technological strategies applied to the production of rotary querns in the Canary Islands from the initial extraction of cylindrical blanks from bedrock to their fashioning into finished objects; 2) to record the qualities and use-wear of the different tools serving for the experimentation; 3) to establish the different categories of waste stemming from each phase of manufacture and describe the types of traces left on the surfaces of the querns that render it possible to identify the knapping, pecking, pounding and abrasion techniques. A fourth objective is to attempt to shed light on how technological knowledge is transmitted and adapted in an isolated environment devoid of certain resources to create artefacts, in this case querns, whose design stems from a setting distant in space and time.

Archaeological Evidence of the Exploitation of Rotary Querns in Gran Canaria and Tenerife

The systematic study of a total thirteen rotary quern quarries and workshops on the islands of Gran Canaria and Tenerife has led to hypotheses on the operational sequence of the production of these mechanisms from both vesicular basalt and volcanic tuff (Rodríguez-Rodríguez et al., 2007, 2010; Naranjo et al., 2016, 2019; Arnay et al., 2019) (Fig. 3 and 4). This section will briefly describe the different procedures, which can be broken down into four theoretical phases whose boundaries remain, at times, unclear. The first of the phases, direct extraction from bedrock, is only recorded in archaeological contexts of Gran Canaria. We will then describe the tools which are clearly associated with these workplaces.

The raw materials serving for their manufacture were mainly vesicular basalts, exploited throughout the archipelago, and volcanic tuff, only recorded in Gran Canaria. Both basalt and volcanic tuff can vary in composition from place to place according to different magmatic processes. All are characterised by very irregular surfaces rendering them very abrasive. Their isotropy facilitated a relative control over the processes of cylinder extraction. There is no doubt that the disposition and geological nature of these rocks conditioned certain extraction strategies such as the possibility of hewn cylinders from bedrock on both vertical and horizontal planes. However, observations in the field indicate that the rotary quern makers in both Tenerife and Gran Canaria shared a number of technological procedures regardless of the differences in the properties of the raw materials.

The suitability of vesicular basalt for rotary querns is well known. It combines the key properties of abrasion and bite as its vacuoles naturally trap the grains. Hence the grinding surfaces did not necessarily require dressing. This rock appears in the form of extensive flows or, in conditions of erosion, as detached surface blocks, often in ravine beds. The second rock type, volcanic tuff, is extracted extensively in true extractive quarries of varying size. It is a pyroclastic rock specifically taking on the form of compact lapilli (volcanic ash). It is associated with the Strombolian cones of the Post-Roque Nublo cycle (Rodríguez-Rodríguez et al., 2006; Mangas et al., 2008; Schmincke & Sumita, 2010) characterised by aggregates with irregular and abrasive surfaces and heterogeneous grains and vesicles. Despite its hardness, it is easy to work, responding well to both percussion and friction.

The tools identified in the quarries and workshops consisted mainly of basalt picks, which display slight morphological differences between each of the two islands. Those from Gran Canaria, in fact are characterised by more variety than those of Tenerife. They were fashioned through direct percussion with a hard hammerstone. Their morphology, mostly triangular, was designed to present one or two active bevelled or trihedral points, interconnected by crests. This allowed them to be reworked after suffering an accident or extensive wear (Rodríguez-Rodríguez & Francisco, 2012). These tools in fact served also to work other materials in mines, quarries, artificial caves and to manufacture construction elements such as building blocks. They are practically the only types of knapped tools recorded in mines and quarries (Martín et al., 2001; Rodríguez-Rodríguez et al., 2005, 2006, 2007, 2010). In domestic or storage contexts, in turn, they appear alongside other tools (Rodríguez-Rodríguez, 2009; Naranjo & Rodríguez-Rodríguez, 2016).

The study of the archaeological picks recovered in the rotary quern quarries of Gran Canaria distinguished different phases of manufacture and three models or types. Type 1 bears a roughly inverted isosceles triangular shape with two active points joined by an arris or crest corresponding to the longest side of the triangle. Type 2 correlates to tools with two active points that through successive reshaping take on the form of a scalene triangle. Type 3 has the form of an isosceles triangle with a single active point opposite a relatively flat base (Fig. 5). The three types reveal an average length of 16.6 cm and weight of 1566 g while certain cases surpass two kilos and 20 cm in length (Rodríguez-Rodríguez & Francisco, 2012). The archaeological finds from Tenerife are exclusively of Type 3. They are smaller and notably lighter than their Gran Canarian counterparts, with averages of 14.5 cm in length and 571 g in weight.

Other tools recovered in a much smaller proportions consist of stone hammers and abraders. The first served to fashion the rotary querns and sharpen the basalt picks, while the second served to finish the quern surfaces.

Phase 1: Direct Cylinder Extraction from the Quarry Face

The initial phase of direct extraction of rotary querns from the tuff or basalt quarries, recorded only in Gran Canaria, was to cut a very deep circular trench or channel around the future cylinder into a vertical or horizontal rock mass face. These trenches reveal, in fact, a succession of very clear impacts carried out with the trihedral and dihedral pick points. The subsequent splitting of the cylinder from the rock mass was carried out by successive blows along one of the cylinder's edges as evidenced by marks left on the quarry face adjacent to the circular negatives (Naranjo et al., 2019). Furthermore, it cannot be ruled out that isolated detached surface blocks were also exploited, especially in the case of vesicular basalt.

It therefore appears that in Gran Canaria both tuff and basalt were extracted with picks of the three types cited above, devoid of handles, mainly through direct percussion and to a lesser extent through indirect percussion in conjunction with wooden billets.

The quarries/workshops of Tenerife, contrary to those of Gran Canaria, are characterised by surface blocks detached by geological and erosive processes. These elements bear traces of knapping intended to eliminate the irregularities of their edges or reduce their size by giving them a shape in line with the dimensions of rotary querns. Trenching was also at times carried out on larger blocks as evidenced by the negatives of the points of picks (Serra & Diego, 1950; Arnay et al., 2016). The vesicular blocks of Tenerife were thus presumably initially roughed out with compact basalt pebbles. Type 3 picks could have also served for this task through direct and/or indirect percussion.

Phase 2. Fashioning the Cylindrical Roughouts

In spite of the fact that cylindrical roughouts bearing knapping scars have been identified among the ancient true extractive tuff quarries of Gran Canaria, it is more common that they bear traces of pecking or pounding (described in Phase 3). It has been noted that a regularisation of the surface of querns takes place during their extraction, a procedure that indicates the cylinders were an advanced state after they are split from the rock face. Vesicular basalt flaking scars reveal centripetal thinning of the quern upper and lower faces. Their contours are likewise already well delineated during trenching. These scars could stem from indirect percussion with picks, a technique suited to more inclined and precise blows.

Querns hewn from naturally detached vesicular blocks of Tenerife, in turn, were presumably initially roughed out with compact basalt pebbles. Type 3 picks without handles were also most likely used by means of direct and/or indirect percussion. Cylinders of irregular thickness and coarse surfaces with knapping scars are likewise recorded. Certain of these scars were initiated from the peripheral edges towards the centre of the two circular surfaces following a convergent orientation. Others, usually parallel, are oriented in the opposite direction generating the cylindrical edge joining the two faces. Trenching was also at times applied in quarries to split blocks into smaller element (Serra & Diego, 1950; Arnay, et al., 2016).

Therefore, it is our belief that the shaping into the final form of the vesicular basalt roughouts required a more precise knapping technique than direct percussion by designing adequate convexities of surfaces to remove flakes. This likewise required shaping the appropriate striking platforms. Certain of the scars clearly indicate that the flakes were long and large (at times exceeded more than half of the total surface), yet with very thin sections. Convexities could also be pecked and abraded to correct irregularities. The angle of percussion had to be quite low, tangent to the surface, suggesting that indirect was probably more suitable than direct percussion. The combination of knapping and pecking of the same surfaces is evidenced by archaeological finds (Naranjo et al., 2016). Hence it is noteworthy that the strategies serving to achieve the desired thickness the cylinder consisted of a combination of knapping flakes by indirect percussion with other less invasive techniques such as pecking and pounding.

Phase 3. Regularisation of the Quern Surfaces

Both the vesicular basalt and tuff quern roughouts in this phase required a final surface thinning and regularisation. Consequently, flaking scars are no longer visible as the arrises or irregularities were erased by pecking, pounding and/or abrasion. The traces of pecking consist of rectilinear marks (up to 2 cm in length) with V sections of variable depth corresponding to picks with dihedral points. Other smaller irregular tool marks of varying depth (potentially linked to trihedral points) are also visible (Naranjo et al., 2016). Shallow oval or circular marks presumably produced by pounding likewise appear albeit to a lesser extent. Small rounded and irregular shaped stones bearing wear and percussion marks have in fact been brought to light. These could have produced this type of wear while reviving and reshaping the points of picks through direct percussion. Finally, the traces linked to abrading are described below in Phase 4.

Phase 4. Finishing the quern (Fashioning the eye and Handle Holes, Abrading the Non-active Surfaces and eventually dressing the Active Surfaces)

There are very few cases among the archaeological vesicular querns of both Tenerife and Gran Canaria indicating that accidents or fractures occurred while fashioning the eye. The little evidence suggests that this phase was carried out either by pecking or drilling (abrasive motion) initiated from each surface of the quern yielding perforations with biconical or cylindrical profiles. The inner surfaces of the eyes mostly reveal traces of abrasion.

The traces of abrasion on the outer and inner surfaces of the querns suggest they could have been carried out with irregularly shaped sandstones or vesicular stone abraders (at times bearing clear linear traces), objects that appear in workshops and quarries. In Gran Canaria, there are also some picks with smoothed arrises, which can be related to this final treatment. However, the most significant finds related to this phase of the process of quern making consist of quern fragments, which served as abraders as they bear flutes of different widths marked by linear traces or striae. These objects apparently served to regularise the edges of the querns, which are usually convex and not flat (Naranjo et al., 2016).

The sites in Tenerife are characterised by Type 3 picks bearing signs of wear not only on their points but on most of the arrises/crests that join their different faces. These consist of linear traces perpendicular to the arrises, characteristic of a semi-rotary abrasive motion. Other vesicular rock blanks bearing similar wear along the arrises are also recorded. These objects are labelled ‘drills’ as they are devoid of traces indicating that they served for either direct or indirect percussion. The friction they underwent was so intense that they ended up taking on a conical shape, presumably, from our viewpoint, because they served exclusively as drills. Consequently, it is very likely that the converging arrises of the points of the picks served for abrasion by means of semi-rotary, back and forth movements. Other less standardised artefacts could have likewise been narrow enough to pierce the eyes of the querns.

The holes or sockets serving to lodge a wooden vertical handle to manually drive the quern are on the top, non-active surface of the upper stones (Fig. 1). Although varying in diameter and depth, they are always smaller than the eye and never totally perforate the quern. Their manufacture is identical to that of the eye.

Finally, no tool has been identified among the materials recovered at either the quarries or surface block workshops that could have exclusively served to dress the active surfaces of the querns to enhance their ‘bite’. Traces of dressing have been identified on finished querns unearthed in both domestic or storage settings. It is also possible that this action was carried out either at the end of the manufacturing process, prior to delivery, or later during the life of the quern. This could be the case of those from Montaña Cruz de Tea in Tenerife. In any case, the dressing consisted of shallow random peckings, and in certain cases in Tenerife, to more complex patterns of radial grooves.

The Experimental Program: Materials and Methods

The earlier archaeological research presented in Sect. 2 led to advance a series of initial hypotheses as to the strategies of extraction and fashioning of rotary querns. The experimental program served to verify them, as the intention was to reproduce as faithfully as possible the different variables intervening in the production process.

Selecting the Materials for the Rotary Quern Experimentation

The experiments were carried out with two main rock types: volcanic tuff and vesicular eruptive materials (mainly basalts and trachybasalts).

The first experimental program took place at the volcanic tuff quarry of Montaña de Cuatro Puertas (Telde, Gran Canaria), an exploitation serving until the 1970s to extract construction materials located a short distance from a pre-Hispanic true extractive rotary quern quarry (Rodríguez-Rodríguez et al., 2006) (Fig. 3a). Its tuff consists of consolidated heterometric pyroclasts, notably brown centimetric megacrystals of augite that protrude due to surface alteration. Geochemically the rock lines up with basanites bearing an average of 42% SiO2, 4% Na2O + K2O and < 5.2% of volatiles, and maximum values of Cr (552 ppm) and Ni (455 ppm) when compared to samples from the other quarries under study (Mangas et al., 2008).

The second experimental program took place in the Island of Tenerife aimed at reconstructing the operational sequence of working vesicular materials, rocks likewise present on the Island of Gran Canaria. The blocks selected for this work are from an area of Tenerife near the ancient quern workshops of Las Cañadas del Teide (La Orotava). The work was carried out on detached blocks in the vicinity of two sites studied in the Teide National Park, notably around the Los Corrales Mountain and the volcanic zone around the Cruz de Tea and Lomo de Chío Mountains (Fig. 4). The volcanic slags from Los Corrales correspond to benmoreites/tephrites while those of Cruz de Tea/Chío are basanites/tephrites. Although each bear similar proportions of Si and Al, they reveal notable differences of Rb/Ca and Rb/Fe correlations in the form of higher levels of Ca, Mn, Fe and Ti at Cruz de Tea and higher Rb levels at Los Corrales. This is perhaps due to the presence of plagioclase rich in Ca at Los Corrales and a dominance of clinopyroxenes at Cruz de Tea (Arnay et al., 2019).

The experimental picks from Gran Canaria were fashioned from basalt. The only exception was one of phonolite, which served to compare how this rock reacted to the work. They followed the size of their archaeological counterparts and likewise were not equipped with handle. Three types saw use in the quarries (Fig. 6a-b; Fig. 7). In turn, the experimental picks used in Tenerife, all exclusively of Type 3, likewise were based on local archaeological finds. Although also of basalt, they are smaller than those of Gran Canaria (Fig. 8).

Experimental picks serving to produce volcanic tuff rotary querns: a.1) Type 1 with two active points; a.2) detail of the left bevelled point and use-wear traces; a.3) detail of the right trihedral point with use-wear and reshaping traces; b.1) Type 2 with two active points; b.2) detail of the right highly worn trihedral point; b.3) detail of the worn and reshaped left trihedral point (photos: S. Méndez Pérez)

Experimental pick serving to fashion rotary querns with volcanic tuff: a.1) Type 3 with a single active point opposite a flat base; a.2) Detail of the highly worn trihedral point; a.3) detail of the base bearing traces of indirect percussion and residue left by the wooden hammer or billet (photos: S. Méndez Pérez)

Experimental picks serving to fashion vesicular basalt rotary querns: a.1) Type 3; a.2) detail of the active highly worn bevelled point; a.3) detail of the base of the pick opposite the active point with percussion wear and residue left by a wooden billet; b.1) Type 3; b.2) detail of the active worn and reshaped trihedral point; b.3) detail of the base opposite the active point with residue of a wooden billet (photos: S. Méndez Pérez)

The experimental fashioning of querns also resorted to direct percussion using rounded basalt stones or pebbles of two calibers. The first were massive, large and heavy (≥ 500 g) serving to knapp flakes, whereas the second (≤ 300 g) were intended to pound the surfaces.

Wooden billets or mallets serving to strike the picks through indirect percussion also formed part of the set of tools used to produce the experimental querns. The choice of this organic material for this element stems from the fact that it was the only raw material available in pre-Hispanic Canary Islands contexts combining the density and elasticity needed for the task. There were in fact in ancient times no large mammals on the archipelago whose bones could have served for such tools. These experimental billets were thus fashioned from species of autochthonous laurisilva and the monteverde forests such as heather (Erica arborea L.), juniper (Juniperus turbinata) and wild olive (Ilex canariensis) (Arechavaleta et al., 2010) due to their high density, weight and resistance to wear. Although most were used green, some were hardened by heat. They had different typometry and weight (between 1.4 kg and 380 g) and were designed to adapt to the characteristics of the type of percussion (intensity and orientation of the blows).

Based on evidence collected in archaeological workshops, fragments of broken querns and other vesicular and abrasive rocks, as well as the stone picks themselves, served as abraders to regularise quern surfaces. The experimental work thus likewise resorted to these types of tools.

The Conception behind the Experimental Work

The intention of the experimental work was to reproduce and test the operational sequence inferred from the different analyses carried out at both archaeological quern quarries and workshops (Rodríguez-Rodríguez et al., 2006, 2010; Rodríguez-Rodríguez & Francisco, 2012; Naranjo et al., 2019; Arnay et al., 2016, 2019). This led to establishing two distinct programs intended to grasp the differences deriving from working two different types of raw materials: vesicular basalt and volcanic tuff.

The experimental sessions, which took place over several days, were preceded by knapping a stock of picks. The subsequent steps were registered by video and photography. Records were kept of the type and actions carried out with each tool (Table 1). The waste associated with each phase of the reproduction of both picks and querns (accidents, resharpening) was likewise collected. Notable among the waste were knapping flakes of vesicular basalt and volcanic tuff. These elements appearing in large proportions in the quarries and workshops are in fact excellent indicators of the procedures and gestes (actions) of the quern makers. They were then studied and described according to the conventions of knapped conchoidal fracture rock research, notably the orientation of the negatives on the dorsal face, the striking platforms, the bulbs, waves, etc. (Inizan et al., 1999). However, the different actions (pounding, pecking and abrasion) yielded a great amount of irregular waste, which defies systematic classification. In these cases, the study limited itself to recording their proportions among the different assemblages.

Results

The results of the experimentation can be broken down according to the four phases noted in Sect. 2. They consist of a description followed by a record of the working waste. These findings are also presented in the form of four tables which the working process data, distinguishing between vesicular basalt and volcanic tuff and the features and accidents suffered by the picks (Tables 2, 3, 4 and 5). A final assessment will then be advanced as to both the suitably of the approach and if it is possible to identify markers of certain of the technical procedures.

Phase 1. Direct Cylinder Extraction from the Quarry Face

The experimental extraction of querns of volcanic tuff, a rock type exclusive to the Island of Gran Canaria, began by the carving directly into the vertical quarry face of a circular trench around the future cylinder. This was undertaken by the three types of pick (without handles) through direct percussion following different angles (Fig. 9a-b). Indirect percussion with wooden billets combined with the picks was rarely attempted (Fig. 9c).

Phases of the experimentation with volcanic tuff: a) Phase 1: cutting the circular trench by means of direct percussion; b) Ph. 1: detail of the trench; c) Ph. 1: cutting the trench by indirect percussion; d) Ph. 1: creation of the recess serving to split the cylindrical roughout; e) Ph 1: splitting the cylinder by indirect percussion with picks serving as wedges; f) Ph 1: unwanted fracture during splitting; g) Ph. 4: cutting the eye by pecking with indirect percussion; h) Ph. 4: drilling the eye by semi-rotary abrasion (photos: I. Francisco and A. Rodríguez-Rodríguez)

Cutting the trench required several hours of intense continuous work, alternating between different individuals. One sector of the trench was cut wider, as it was from this point that the cylinder was to be split from the rock face (Fig. 9d). As the work advanced, the trench had to be widened for the point of the pick to be able to attain the base. This phase of the operation also saw the shaping of the outer face of the future quern by applying the same technique of percussion, albeit more delicately to avoid an accident.

A series of strategies were adopted upon completing the circular trench to split the cylinder. The first splitting attempt, unsuccessful, was carried out by pounding one of the sides of the cylinder with large rounded pebbles. The next attempt was carried out with Type 1 picks serving as wedges (adapting the crest joining its two active points as the active edge) (Fig. 9e) struck with stone hammers and wooden mallets, a technique that succeeded in separating the cylinder from the face. Yet in two cases, the action was not entirely successful, as the cylinders did not split across the totality of their base due to a microfissure running through the rock face (Fig. 9f). In any case, the roughout extracted at this point possessed a form that was cylindrical enough to serve for the following phases of quern manufacture.

Production of volcanic tuff querns generated a great number of fragments of angular and irregular shape, gravel and dust. The characteristic debris of this true extractive phase, apart from broken roughouts (or blanks), are flakes and fragments preserving traces of the trench that for the most part correspond to the regularisation of the quarry face for subsequent cylinder extraction. The other waste elements cannot be distinguished from those of other work phases.

The points of the experimental picks suffered from the percussion impacts (Figs. 6 and 7). As this wear occurred over a short period of time, the points required frequent resharpening. In fact, the point of the phonolite pick, a rock less resistant than basalt, accidentally broke during the process yielding a pyramidal-shaped fragment. Basalt flakes were also generated during the resharpening of the picks, with striking platforms and dorsal faces bearing traces of the earlier wear. It is noteworthy that these pieces deriving from accidents and the reshaping of points are identical to certain finds discovered in archaeological quarries (Francisco, 2016; Rodríguez-Rodríguez & Francisco, 2012). Wear linked to hammer and billet percussion is also visible on the surfaces of picks that served as punches.

Direct percussion with picks to cut the trenches in the case of volcanic tuff proved to be very effective. Although requiring a great amount of energy, the task was not complex from the technical standpoint. The greatest difficulty was splitting the cylinder from the quarry face. Resorting to the long side of Type 1 picks as wedges appears to be the most practical splitting method. Although a recess was designed to immobilise the tool and facilitate striking it, the method was not very effective, as it required the experimenters to stabilise the wedges with their hands putting them at risk of receiving a blow. In any case, the archaeological quarries reveal numerous examples of failures corresponding to this phase. Moreover, it is not possible to distinguish this phase from the next through the waste, except for the failed cylindrical extractions themselves or large stone fragments bearing traces of trenching. In the case of picks, only the presence or absence of marks of blows on their non-active areas allow distinguishing between those having served for direct or indirect percussion.

Phase 2. Fashioning the Cylindrical Roughouts

The experiment undertaken with vesicular basalt blocks on the Island of Tenerife resorted to naturally detached surface blocks. These were first hewn into shape through direct percussion with hand-sized basalt pebbles (Fig. 10a-b) and then through indirect percussion combining Type 3 picks with wooden mallets. In fact, determining the plausibility of indirect percussion technique, that is a pick serving as a punch stuck by another tool, is one of the main objectives of the experiment.

Phases of the experimentation with vesicular basalt: a) Phase 2: direct percussion with a hard rounded hammer with the block on the ground; b) Ph. 2: direct percussion with a hard rounded hammer with the block on the lap; c) Ph. 2: indirect perpendicular percussion with the block on the ground; d) Ph. 2: indirect parallel percussion with the block on the lap; e) Ph. 3: pecking with rolled hand-sized pounder; f) Ph. 3: abrading the surface of a quern with a another quern; g) Ph. 4: cutting the eye through direct percussion; h) Ph. 4: drilling the eye with semi-rotary abrasion (photos: S. Méndez Pérez)

Indirect percussion involved two angles of strike that, although linked to two successive undertakings, could, at times, alternate. In the initial stages of quern shaping, the inclination of the pick tended to be perpendicular or highly inclined with respect to the working surface. Roughouts were stabilised either on the lap or, if large and heavy, on the ground. As work progressed, the angle of the pick changed to being tangent to the surface (Fig. 10c-d). This difference, due to the special characteristics of the vesicular material, can be broken down into two knapping strategies. The first consisted of simple strikes obtained by a single blow to a specific percussion platform. The second, in turn, consisted of a series of consecutive impacts delimiting a trench to highlight a portion of the rough surface. This trench received a blow detaching a flake that, on occasions, preserved part of that intentional fluting on its dorsal face. This indirect percussion was complemented by pecking and pounding to correctly define the convexity of the cases that required reduction of their thickness. This roughing out phase was generally brief (15–30 min), depending on the original form of the blocks and how they responded to the work.

The waste produced by this work consisted of irregular fragments, gravel, dust and, especially, flakes. The dorsal faces and striking platforms of the vesicular basalt flakes are characterised by particular features such as traces of fluting described above and negatives of pecking, pounding and abrasion. Tool marks indicative of indirect percussion are visible in areas of the ventral face adjacent to the striking platforms. These marks, termed indirect percussion negatives, correspond to impacts of the point of the pick. They can bear different morphologies: hemispheric, conical, domed and cubic (Fig. 11a-d). These characteristic indirect percussion marks indicate the quern maker did not always manage to remove the flake with a single accurate strike. The action at times required multiple blows and created a depression for the point of the pick to fit. The point thus served as a sort of wedge, and through an action termed ‘wedging’ (Cotterell & Kaminga 1987), detached the flake by levering. These types of marks are observed among the archaeological material, even among the flakes of volcanic tuff.

The points of picks during this phase also suffered heavy wear (Fig. 8). The impacts of wooden billets left minute cupolas and cracks on the platforms. The arrises of these bases also revealed signs of smoothing. Knapping accidents resulting in a fracture of the point (thus requiring reshaping) were not very frequent (only two during all the indirect percussion sessions). Although the point of contact of the wooden percussion tool also suffered a high degree of wear, in no case did any break during the experimentation. Moreover, the experiment revealed no differences between the various wood species serving for these tools.

The technique of direct percussion for the initial roughing out of cylinders of naturally detached vesicular blocks has several limitations. The size of the blocks combined with the weight of the hammers render it difficult to hew them into shape. The technique also fails to accurately transmit the energy of the impact. Furthermore, this phase of work is very difficult to control leading to accidents and fractures that often rendered the blocks useless. This technique is therefore presumably only suitable in the initial stages of rough hewing querns from detached blocks to test the suitability of the material.

Direct percussion is not efficient when applied to vesicular blocks characterised by large and abundant vesicles as it destroys the percussion platforms without detaching flakes. These type of rocks, in turn, responds very well to pecking and abrasion during the more advanced stages of quern making. By contrast, the vesicular rocks with denser surfaces (smaller vesicles) react better to knapping as they lend themselves to conchoid fracture while remaining very resistant to pecking and abrasion. These features are constant throughout all phases of the experimental work. Furthermore, the great density of these rocks means that they often had to be struck repeatedly to remove flakes. It is for this reason that the striking platforms of certain flakes bear depressions and indentations that, on occasion, accurately reflect the shape of the active edge of the pick. The intensity of the blow also favours irregular fragments, which betray a lower level of precision of the technique. All cases generated a great amount of gravel and dust with a greater proportion among the larger blocks with smaller vesicles. It is noteworthy that this variability is also reflected by the archaeological record.

Indirect percussion in the case of vesicular rocks is undoubtedly much more efficient than direct percussion as it is more precise and requires less effort. The technique likewise leads to less accidents and unwanted fractures. This strategy is therefore more efficient in the final stages of quern fashioning. Moreover, although the wear of the tools is more intense, they suffer less accidents, prolonging their life.

Phase 2 was indistinguishable from Phase 1 in volcanic tuff flakes detached in the experimental text.

Phase 3. Regularisation of the Quern Surfaces

Type 3 picks with bevelled and trihedral points served to peck the quern surfaces. This phase of the experimentation focused on lighter tools than those used in previous phases. They applied direct and indirect percussion on roughouts of both volcanic tuff and vesicular rocks. The angle of the impact in each of these cases was rather high, almost perpendicular to the surface.

Pounding was carried out by applying a kinematic similar to that of pecking. Both pebbles and other stones with flat surfaces, including the faces of certain picks, served to strike the larger areas (Fig. 10e). The querns during this phase were stabilised either on the ground or on the lap of the quern maker. Although repetitive and physically intense, the task was relatively easy to execute. Abrasion was, at times, combined with the previous techniques.

The waste generated in Phase 3 consisted mainly of gravel and dust. Moreover, the wear on the picks during this technique is very intense and swift, and cannot be distinguished from that of other types of percussion (Fig. 12). The wear on the rounded hammerstones present the same characteristics as when they served for knapping. The wear on the stones with flat surfaces used for these tasks likewise present the same attributes as the other hammerstones. These consist mainly by small irregular cupolas and depressions, linear traces of differing density and orientation, as well as small fissures and star-shaped microfractures.

Use-wear linked to the volcanic tuff experimental and archaeological picks: a) Exp. 303: abraded, levelled area with linear orientation. Volcanic tuff residues; b) Exp. 303: smooth zones, domed bright spots, striae; c) Exp. 302: combination of smooth and abraded zones, flat polish with oriented striae and micropits; d) Exp. 301: flat polish with crossed striae, combined with abrasion. Surface impregnated with a reddish thin layer of volcanic tuff; e) MQ 762: abraded, levelled area, rounded edge, some domed bright spots; f) MQ 2084: abraded area, oriented striae, rounded edge. Volcanic tuff residues; g) MQ 762: domed, grainy polish in high topography with striae and pits; h) MQ 2084: smoothed, bright surface in high topography, phenocryst with fractures. Observation by Nikon Labophot 2 microscope (100X-200X magnifications); photographs were taken with a Nikon D5 Fi 1 and arranged with the software Helicon Focus. Exp. number: reference number of the experimental tool; MQ number: inventory number of archaeological artefacts from the Montaña Quemada quarry. (photos: A. Rodríguez-Rodríguez)

The pecking, pounding and abrasion of Phase 3 are complementary strategies. They present no great difficulty at the technical level and the risk of roughout fracture is practically non-existent. Marks stemming from these actions were only be identified among unfinished quern fragments.

Phase 4. Finishing the Quern

The experimental cutting of the eyes and handle holes of the querns was initiated by a light direct or indirect percussion (to avoid fracture) with the points of Type 3 picks at variable angles (Fig. 9g; Fig. 10g). The holes were then deepened by means of a semi-rotary abrasive drilling with Type 3 picks and conical fragments of other vesicular rocks (Fig. 9h; Fig. 10g-h).

The abrasion of the non-working surfaces was carried out in a bidirectional manner with fragments and flakes of vesicular rock. The experiment also used a quern (that was being made at the same time) as an abrader with excellent results as the action simultaneously regularised the two products (Fig. 10f). The flat faces of the picks also served as abraders for the surfaces of the volcanic tuff querns. Although the means of stabilising the querns during this phase varied, the most common method was to set them on the ground and work while squatting or kneeling, a posture which increases the force exerted by the arms.

The shallow pecking to dress the active faces (to enhance the grinding qualities) was carried out with the same tools through both direct and indirect percussion.

The actions of this phase only yielded gravel and (more often) dust. The abraders reveal wear spreading across and rounding off their arrises, as well as perpendicular linear marks and fields of wear.

Abrasion, combined with pecking and pounding the quern, although requiring a great physical effort, is not technically difficult. To minimise the risk of unwanted breaks, pecking was only applied in the initial stages and followed by abrasion, a technique that required a greater investment in time.

Discussion and Conclusions

Rotary querns are mechanisms, due to their high efficiency, that experienced few morphological alterations over time and space. In the Canary Islands, they hardly went through any transformations from pre-Hispanic times to the twentieth century. The main difference is that the earlier models of the centuries prior to the conquest of the archipelago were produced with stone tools, due to the absence on the islands of metals. It is also relevant that both vesicular eruptive rocks and volcanic tuffs served to make querns. The second was nonetheless abandoned with the arrival of the Europeans in medieval times.

The existence, especially in Gran Canaria, of rotary mill quarries bearing great similarities with those recorded in Europe and North Africa clearly reveals the origin of their technological tradition. However, the quern makers of the archipelago came against a major problem when attempting to faithfully reproduce the different actions involved in quern extraction and fashioning. Iron tools, after an undefined period of time, could no longer be procured for the work due to the break down of connections between the islands and the mainland. According to archaeological data, the population that remained in the archipelago after the third century AD acquired a new identity thus leading to an amalgam of ancestral traditions with new survival strategies. Research reveals that they adopted ways of life fully adapted to the new volcanic landscapes. These ways of life were marked by well-established agricultural and livestock practices and material cultures sufficiently original to allow identifying particularities of each island. The populations were initially faced with a scarcity followed by a total absence of metal working tools that would have facilitated tasks as key as tilling the land and working stone. This article explores aspects of a specific know-how, while likewise offering information serving to reflect on how to reconcile the necessity to produce models dictated by centuries of tradition with different available materials and technological resources.

Despite the abundance of archaeological finds evidencing the processes of procuring and manufacturing rotary querns, no experimental program has ever attempted to test these hypotheses. This is thus one of the specific objectives of the current experimentation, which has shed light on the differences and similarities of transforming volcanic tuff and vesicular rocks into rotary querns. Moreover, it renders possible to identify strategies that require greater technical knowledge as well as others that are more basic and adopted with less preparation.

Valuable data was obtained from B. Hayden's, (1987) detailed descriptions of the processes of metate manufacture in Guatemala. The photographs and drawings he presents, the comments of the interviewee, Ramón Ramos, and even the terminology are essential to grasping certain aspects. However, it must be noted that the experimental program in the Canarian archipelago was conceived exclusively from observations garnered during the study of the quarries and workshops. The data deriving from the project in Guatemala, cited in the following lines, when relevant, served to enrich the discussion.

The true extractive experimental work on volcanic tuff was undertaken by several individuals who, replacing each other, maintained the same level intensity in their objective of extracting the cylinders from the vertical quarry face. The repetitive actions required precise direct percussion so as to complete the task relatively quickly. The trenching and regularisation of the external surface of querns, identical to those of the archaeological quarry faces, were relatively simple tasks, albeit time and effort consuming. The splitting of the cylinder from the quarry face, in turn, was not bereft of difficulty. The experimenters attempted several strategies demanding great precision and physical strength. The results were not optimal as the two splitting attempts were not successful. The subsequent work was also relatively simple as volcanic tuff is easy to peck, pound and abrade and does not require much knapping. As this island comprised vesicular basalt quarries identical to those of volcanic tuff, the same type of specialisation was required to accomplish phase 1. This specific aspect of phase 1 cannot be compared to the work carried out by Ramón Ramos, as the blocks in Guatemala where split with metal chisels and hammers (Nelson, 1987: 123).

Working vesicular basalt in phase 2 required greater specialisation. Large flakes had to be knapped to give the block the necessary flat/convex surfaces. Acquiring the dexterity required for this phase was a limitation for the experimental quern maker as this individual's experience was limited to non-vesicular volcanic rocks. Achieving correct results thus required a number of experimental sessions. The greater investment in time dedicated to acquiring the skills yielded better results. This methodological requirement contrasts with the fact that phase 2 of the experimental making of querns certainly did not require a great amount of time. On the other hand, the simple and repetitive actions involved in pecking, pounding and abrading, significantly prolong a task that can require more than a day, especially in the case of vesicular rocks.

Direct and indirect percussion required, when compared to the other techniques, specialised knowledge of knapping stone (mechanics of fracture of each stone type, mastery of actions and postures, modulating the force of striking with hammers and punches …). The experiment highlights that the indirect percussion technique requires greater efforts of preparation and training. It is a complex strategy applied for the first time to this context of production without access to ethnographic or published references, and guided exclusively by archaeological evidence.

At this point, it is necessary to delve into why picks were used as chisels in indirect percussion. In this sense, the hypothesis stems from the percussion marks observed on the faces opposite to the active points of the picks. Ramón Ramos in Guatemala, by contrast, never used his tools in this manner but always by means of direct percussion. For this he selected large, heavy (between 2–3 kilos), triangular shaped pieces clutched with both hands (Hayden, 1987:42–43). This tool type is not recorded in the workshops of the two island where the picks are lighter (average 1.56 kilos in Gran Canaria and 0.57 kilos in Tenerife) and could be used, if necessary, with a single hand. The lighter type 3 picks resemble more in shape and weight those used by Ramos with one hand during the final tasks.

The results of the experimental work confirm most of the hypotheses. The experimentation appears to support, for example, the idea of applying indirect percussion at various stages in the process of making vesicular basalt and volcanic tuff querns. This technique, compared to direct percussion yielding a large number of fractures, appears to be a more efficient in controlling the size and shape of the extractions. Another convergence, this time with the ethnoarchaeological study, was the solution adopted to remove the more prominent areas in the middle of the working faces. This consisted of cutting a ledge along one edge by removing small flakes, which yielded an abrupt face serving as a striking platform to remove the protuberance (Hayden, 1987: 28). Here it is also compelling to note the use of the edges and faces of one-handed picks together other specific stones in the smoothing process.

A highly significant aspect of the experiment is that it led to identifying characteristic traces of quern making among the archaeological material that have to date never been understood. These include traces adjacent to the striking platforms on the ventral face of the flakes of varied shape, that appear to be linked to the type of point of the tools serving to shape the quern.

The absence of specific references to studies on the production of rotary querns without metal tools led to other ethnoarchaeological frameworks such as the production of polished axes and adzes. Particularly illustrative is the case superbly described by Pétrequin & Pétrequin, (1993) based on finds from Irian Jaya (Indonesia). Here the knapping of the blanks required great skill while the subsequent polishing could be carried out by the lesser trained. The authors also stressed that investing in creating good blanks facilitated and shortened the subsequent abrasion required to finish the pieces. On the contrary, it was not possible in the case of the Guatemala metate production, resorting to stone picks to identify a correlation between the time necessary for phases 2 and 3 of the shaping and regularising of the surfaces and the last phase of abrasion. Indeed, the morphology of these tools differ greatly. Time in the case of the metates had to be devoted to the fashion their feet and in the case of rotary querns to cutting the central eye and the handle holes. Hayden in fact estimated that roughing out a metate blank required 3 h and 50 min and the reduction and smoothing of the preform 10 h and 12 min (Hayden, 1987: 34–43). Our experimentation revealed differences between volcanic tuff and vesicular basalt. The first of these rock demanded more time for phase 1, for example 7 h and 6 min in one case, four hours and one minute in the other, whereas phase 3 and 4, in turn, required between 3 h and five minutes and 2 h and 20 min (see Table 2). Vesicular basalt demanded less time for phase 2 (between 65 and 15 min) than for phases 3 and 4 (between 5 h 30 min and 3 h 15 min) (see Table 3). Working the vesicular basalt thus reassembled more the Guatemalan experience due to the similarities of the raw material.

The results gleaned from the experimentation therefore have served to better interpret the archaeological evidence recovered in sites throughout the Canary Islands, and have assisted in reconstructing the operational sequence of rotary quern making. In addition, the experimentation yielded very specific data as to working a type of raw material of very irregular granulometry that hardly responds to conchoid mechanical fracture.

The populations that settled the Canary Islands after the turn of the Era with roots in the Amazighe/Berber culture remain poorly understood. They had experienced in the first millennium BC continuous contacts with various Mediterranean civilisations (Phoenicians, Punics, Greeks, and Romans) and merged cultural elements from each with their ancestral traditions. The hand operated rotary quern was an innovation that had widely accepted and currently still serves in houses and tents throughout the Maghreb (Alonso, 2019). There were also rotary quern quarries in North Africa, certain exploited until the twentieth century, in locations as emblematic as the Grotte d'Hercule along Cape Achakkar (Morocco). The colonists brought this knowledge to the archipelago. They nevertheless had to adapt it to very different types of raw materials radically different from their original sedimentary and metamorphic outcrops. Vesicular basalt and tuff were suitable materials to produce the querns. They nonetheless had to face the problem of how to exploit them subsequent to loss of access to the metal tools they originally brought with them. It cannot be ruled out that even in their land of origin not everyone had an easy access to these tools due to economic or availability reasons. A current example is the study cited above by Hayden on the last Mayan metate manufacturers working as recently as the 1980s.

Their lack of economic resources in their land of origin thus led them to resort or keep alive ancestral techniques to replace the tools that were difficult to obtain. It is perhaps this situation that also facilitated retaining the knowledge of lithic technology by the first settlers of the islands. The stone tools they made met the optimal conditions to carry out these tasks. They were large and heavy, suited to working the new rock types. They also bore a design not only adapted to more than one stage of the operational sequence, but that facilitated their reconditioning when they suffered unwanted accidents. There is no evidence as to the lithic prototypes in the Maghreb when there was no access to metal tools. It is nonetheless astounding that the tools of the Mayan artisans of Guatemala bore a great resemblance to those of the Canary Islands. There is in fact a convergence of various aspects, notably knowledge of the qualities and mechanical responses of different rock types, centuries of technological tradition, and strategies of adaptation to new geological environments.

This study therefore represents more than a specific contribution to the knowledge of the ways of life of the pre-Hispanic period of the Canarian archipelago. It sheds new light on the variability of technological strategies among two highly differentiated contexts producing a specific types of mills. This study likewise records the specificities of working stone without metal tools, and how to obtain a universal artefact, the rotary quern, which was key to the processing of daily bread, and particularly gofio (roasted flour), the staple of the archipelago's ancient inhabitants.

Data Availability

All data needed to elaborate this work and its conclusions are present in the paper. Additional data related to this paper may be requested from the authors.

References

Alberto Barroso, V., Delgado Darias, T., Moreno Benítez, M., & Velasco Vázquez, J. (2019). La dimensión temporal y el fenómeno sepulcral entre los antiguos canarios. Zephyrvs, 84, 139–160. https://doi.org/10.14201/zephyrus201984139160

Alonso, N. (2002). Le moulin rotatif manuel au nord-est de la Péninsule Ibérique: une innovation technique dans le contexte domestique de la mouture de céréales, In: H. Procopiou, R. Treuil (dir.), Moudre et broyer : l'interprétation fonctionnelle de l'outillage de mouture et de broyage dans la Préhistoire et l'Antiquité, Actes de la Table Ronde internationale (Clermont-Ferrand, 30 nov.-2 déc. 1995), CNRS, Université Paris I, Éd. du CTHS, 2 tomes: 111–127.

Alonso, N., Aulinas, M., Garcia, M. T., Martín, F., Prats, G., & Vila, S. (2011). Manufacturing rotary querns in the 4th century BC fortified settlement of Els Vilars (Arbeca, Catalonia, Spain). In D. F. Williams, & D. Peacock (Eds.), Bread for the people: The archaeology of mills and milling: Proceedings of a colloquium held in the British School at Rome, 4th-7th November 2009 (pp. 55–65). Oxford: Archaeopress.

Alonso, N. (2015). Moliendo en ibero, moliendo en griego: aculturación y resistencia tecnológica en el Mediterráneo occidental durante la Edad del Hierro. Vegueta: Anuario de la Facultad deGeografía e Historia, 15, 23–36

Alonso, N. (2019). A first approach to women, tools and operational sequences in traditional manual cereal grinding. Archaeological and Anthropological Sciences, 11(8), 4307–4324. https://doi.org/10.1007/S12520-019-00791-X

Anderson, T. J., Agustoni, C., Duvauchelle, Vincent Serneels, V., & Castella, D. (2003). Des artisans à la campagne: carrière de meules, forge et voie gallo-romaines à Châbles (FR) Academic Press, Archéologie Fribourgeoise, Vol. 19, Fribourg.

Anderson, T. (2016). Turning Stone to Bread: A Diachronic Study of Millstone Making in Southern Spain. The Highfield Press.

Antonelli, F., & Lazzarini, L. (2010). Mediterranean trade of the most widespread Roman volcanic millstones from Italy and petrochemical markers of their raw materials. Journal of Archaeological Science, 37, 2081–2092. https://doi.org/10.1016/j.jas.2010.02.008

Arechavaleta, M., Rodríguez, S., Zurita, N., & García, A. (2010). Lista de especies silvestres de Canarias. Hongos, plantas y animales terrestres. 2009. Gobierno de Canarias.

Arnay de la Rosa, M, García Ávila, J. C., Marrero Salas, E., Abreu Hernández, I., & González Reimers, E. (2016). Canteras taller en las Cañadas del Teide. Estudios preliminares sobre la producción de elementos de molturación guanche. In: XXII Coloquio de Historia Canario-Americana (2016). XXII - 133. Canarias (España), 1–15. https://revistas.grancanaria.com/index.php/CHCA/article/view/10070/9569

Arnay de la Rosa, M., González Reimers, E., Marrero Salas, E., García Ávila, J. C., Criado Hernández, C., Lacave Hernández, A., González Fernández, R., & Abreu Hernández, I. (2019). Identification of prehispanic rotary quern productions areas in Las Cañadas del Teide (Tenerife, Canary Islands, Spain). Journal of Archaeological Science Reports, 28, 102048. https://doi.org/10.1016/j.jasrep.2019.102048

Atoche Peña, P., & del Arco Aguilar, M. D. C. (2021). Las Islas Canarias en el contexto del Mediterráneo antiguo. In Abantos. Homenaje a Paloma Cabrera Bonet (pp. 39–50). Edición Ministerio de Cultura y Deporte.

Bustamante Álvarez, M., Salido Domínguez, J., & Gijón Gabriel, E. (2014). La panificación en la Hispania romana. In: D. Bernal Casasola (Ed.), Artífices idóneos: artesanos, talleres y manufacturas en Hispania (pp. 333–369). Editorial CSIC Consejo Superior de Investigaciones Científicas. http://hdl.handle.net/10261/239261

Colfer, N. (2019). Turning Stone into Bread: The Millstone Quarries of Medieval and Post-medieval Ireland. Industrial Archaeology Review, 41(1), 65–72. https://doi.org/10.1080/03090728.2019.1594063

Cotterell, B., & Kamminga, J. (1987). The formation of flakes. American Antiquity, 52(4), 675–708.

del Arco-Aguilar, M. C., del Arco-Aguilar, M. M., Benito-Mateo, C., & Rosario-Adrián, M. C. (2017). Un taller romano de púrpura en los límites de la Ecumene: Lobos 1. Santa Cruz de Tenerife: Cabildo de Tenerife.

del Pino Curbelo, M., & Rodriguez Rodriguez, A. (2017). Proposal for the classification of ceramic materials of aboriginal tradition in the island of Gran Canaria (Canary islands). Lucentum, 36, 9–31.

Déry, C. A. (1997). Food and the Roman army: Travel, transport and transmission (with particular reference to the province of Britannia). In: H. Walker (Ed.), Food on the move: Proceedings of the Oxford symposium on food and cookery, 1996 (pp. 84–96). Prospect Books.

Diego Cuscoy, L. (1953). Nuevas excavaciones arqueológicas en las Canarias Occidentales.Yacimientos de Tenerife y La Gomera (1947–1951). Informes y Memorias 28. Madrid.

Francisco Ortega, I. (2016). Estudio de los procesos de obtención, fabricación distribución de las industrias líticas talladas prehispánicas de la isla de Gran Canaria. Universidad de La Laguna.

Fregel Lorenzo, R., Calderón, Ordóñez A., Santana, Cabrera J., Vicente Cabrera, M., Velasco, Vázquez. J., Alberto Barroso, V., & Bustamante, C. (2019). Mitogenomes illuminate the origin and migration patterns of the indigenous people of the Canary Islands. PLoS ONE, 14(3), e0209125. https://doi.org/10.1371/journal.pone.0209125

Guillier, G., Biard, M., & Cherel, A. F. (2005). Un atelier augustéen de taille de meules en poudingue au “Clos des Forges” à Avrilly (Eure). Revue archéologique de l´Ouest, 22, 199–220. https://doi.org/10.3406/rao.2005.1123

Hagenblad, J., & Morales Mateos, J. (2020). An Evolutionary Approach to the History of Barley (Hordeum vulgare) Cultivation in the Canary Islands. The African Archaeological Review, 37(4), 579–595. https://doi.org/10.1007/s10437-020-09415-5

Hayden, B. (Ed.). (1987). Lithic studies among the contemporary Highland Maya. University of Arizona Press.

Hernández Gómez, C. M., & Galván Santos, B. (2008). Estudio geoquímico de dos centros de producción de obsidianas en la Prehistoria de Tenerife: El Tabonal de los Guanches (Icod de los Vinos) y el Tabonal Negro (Las Cañadas). Trabajos De Prehistoria, 65(2), 151–168. https://doi.org/10.3989/tp.2008.0800

Inizan, M.L., Reduron-Ballinger, M., Roche, H., & Tixier, J. (1999). Technology and Terminology of Knapped Stone. Préhistoire de la Pierre taillée. Tome 5. Ed. Cercle de Recherches et d'Etudes Préhistoriques. Nanterre.

Jaccottey, L. (2014). Expériences de fabrication de meules à partir des recherches menées dans l’est de France : Buts et procédés. Revista D’arqueologia De Ponent, 24, 113–136.

Jaccottey, L., Buchsenschutz, O., Hamon, C., Fronteau, G., Jodry, F., Lepareux-Couturier, S., & Robin, B. (2014). Methodology of millstone study in France: Neolithic to the Middle Ages. In L. Selsing (Ed.), Seen through a millstone (pp. 133–148). AmS-Skrifter 24, Museum of Archaeology, Stavanger University.

Jaccottey, L., Farget, V., Fronteau, G., Beuchot, S., Boyer, F., & Cherot, C. (2019). The quern and millstone quarries of Bibracte and Autun: The case of Saint-Andeux (Côte-d’Or, Burgondy, France). In N. Alonso & T. Anderson (Eds.), Tilting at Mills: The Archaeology and Geology of Mills and Milling, Revista d’Arqueologia de Ponent, Número Extra 4 (pp. 81–100). https://doi.org/10.21001/rap.2019.extra-4.5

Jodry, F., Jaccottey, L., Robin, B., Picavet, P., & Chaussat, A. G. (2011). Typologie et fonctionnement des manchons des moulins rotatifs manuels durant le deuxième âge du fer et le Haut-Empire. Évolution typologique et technique des meules du Néolithique à l’an mille, Actes des IIIe Rencontres Archéologiques de l’Archéosite gaulois, Bordeaux, Éd. de la Fédération Aquitania, 299–317.

Mangas Viñuela, J., Rodríguez-Rodríguez, A. C., Martín Rodríguez, E., & Francisco Ortega, I. (2008). Canteras aborígenes de molinos de mano en la isla de Gran Canaria (España). caracterización petrológica de tobas de lapilli". Geo-Temas, 10, 1301–1304.

Martín Rodríguez, E., Rodríguez-Rodríguez, A. C., Velasco Vázquez, J., Alberto Barroso, V., & Morales Mateos, J. (2001). Montaña de Hogarzales: Un centro de producción de obsidiana, un lugar para la reproducción social. Tabona, 10, 127–166.

Mora Aguiar, I. (2021). La dispersión de la escritura libico-bereber desde Numidia hasta Canarias. In Moncunill Martí, N. & Ramírez-Sánchez, M. (eds) Aprender la escritura olvidar la escritura. Nuevas perspectivas sobre la historia de la escritura en el occidente romano. Veleia. Anejos Series Minor, 39, 39–65.

Morales Mateos, J., Rodríguez Rodríguez, A., & Marrero, Á. (2014). Prehistoric plant use on La Palma Island (Canary Islands, Spain): an example of disappearance of agriculture in an isolated environment. In C. J. Stevens, S. Nixon, M. A. Murray, & D. Fuller (Eds.), Archaeology of African plant use (pp. 195–204). Institute of Archaeology Publications 61, UCL.

Morales Mateos, J., Rodríguez Rodríguez, A., & Henríquez-Valido, P. (2017). Agricultura y recolección vegetal en la arqueología prehispánica de las Islas Canarias (siglos III-XV d.C.): la contribución de los estudios carpológicos. In: J. Fernández Eraso. J.A. Mujika Alustiza, Á. Arrizabalaga Valbuena, M. García Diez (coord.): Miscelánea en homenaje a Lydia Zapata Peña (1965–2015), Ed. Universidad del País Vasco, 180–218.

Naranjo Mayor, Y., Francisco Ortega, I., & Rodríguez-Rodríguez, A. (2016). The quarry and workshop of Barranco Cardones (Gran Canaria, Canary Islands), Basalt quern production using stone tools. Journal of Lithic Studies, 3(2). https://doi.org/10.2218/jls.v3i2.1779

Naranjo Mayor, Y., & Rodríguez Rodríguez, A. (2016). Propuesta de clasificación de los instrumentos de molienda y otro utillaje lítico no tallado de los antiguos canarios. Hacia una tipología morfo-funcional. XXI Coloquio de Historia Canario Americana, 843–852. https://revistas.grancanaria.com/index.php/CHCA/article/view/9557/9057

Naranjo Mayor, Y., Rodríguez Rodríguez, A., & Francisco Ortega, I: (2019). The quern quarry of La Calera (Agaete, Gran Canaria, Spain), Working volcanic tuff with stone tools). In:N. Alonso & T. Anderson (eds), Tilting at Mills: The Archaeology and Geology of Mills and Milling Revista d’Arqueologia de Ponent Número Extra, 4, 119–126. https://doi.org/10.21001/rap.2019.extra-4.7.

Navarro Mederos, J. F. (1997). Arqueología de las islas Canarias. Espacio, Tiempo y Forma. Serie i. Prehistoria y Arqueología, 10, 447–478.

Navarro Mederos, J. F. (1999). El viaje de las loceras. La transmisión de tradiciones cerámicas prehistóricas e históricas de África a Canarias y su reproducción en las islas. Anuario De Estudios Atlánticos, 45, 61–118.

Nelson, M. (1987). Site content and structure: Quarries and workshops in the Maya Highlands. In: B. Hayden (Ed.), Lithic Studies among the Contemporary Highland Maya (pp. 120–147). The University of Arizona Press Tucson.

Peacock, D. P. S. (1980). The Roman Millstone Trade: A Petrological Sketch. World Archaeology, 12(1), 43–53.

Peacock, D. P. S. (2013). The stone of life. Querns, mills and flour production in Europe up to C. AD 500. The Highfield Press (Southampton Monographs in Archaeology New Series,1).

Pétrequin, P., & Pétrequin, A. M. (1993). Écologie d’un outil: la hache de pierre en Irian Jaya (Indonésie) (Vol. 12). CNRS.

Picavet, P. (2019). Les meules rotatives de la fin de l’Âge du Fer au Haut Moyen Âge entre la Seine et le Rhin. Université de Lille.

Rodriguez-Rodriguez, A.C. (1993).La industria lítica de la isla de La Palma. Cuevas de San Juan, un modelo de referencia. Tesis Doctoral (1990), Edición Secretariado de Publicaciones de la Universidad de La Laguna.

Rodríguez-Rodríguez, A.C., Martín Rodríguez, E., Mangas Viñuela, J., & Melián Aguiar, J. (2005). La gestión de los recursos obsidiánicos en el centro de producción de La Montaña de Hogarzales. El ejemplo de la mina 38. Tabona XIV, 213- 238.

Rodríguez-Rodríguez, A.C., Martín Rodríguez, E., Mangas Viñuela, J., González Marrero, M.C., & Buxeda i Garrigós, J. (2006). La explotación de los recursos líticos en la isla de Gran Canaria. Hacia la reconstrucción de las relaciones sociales de producción en época preeuropea y colonial. In: G. Martínez, A. Morgado; J.A. Afonso (coords), Sociedades prehistóricas, recursos abióticos y territorio. Fundación Ubn al-Jatib de Estudios de Cooperación Cultural, Granada, 367–391.

Rodríguez-Rodríguez, A.C. & Hernández Gómez, C (2006).“Lágrimas negras”. L’exploitation de l’obsidienne aux Îles Canaries: de la simplicité des systèmes de taille à la spécialisation artisanale. En: L. Astruc, F. Bon, V. Léa, P-Y. Milcent et S. Philibert dir.: Normes techniques et practiques sciales. De la simplicité des outillages pré- et protohistoriques. Éditions APDCA, Antibes (France), 391–401.

Rodríguez-Rodríguez, A. C., Martín Rodríguez, E., Mangas Viñuela, J., & Francisco Ortega, I. (2007). Las canteras de molinos de mano de Gran Canaria. Anatomía de unos Centros de Producción singulares. Tabona, 15, 115–142.