Abstract

Archaeologists have explored a wide range of topics regarding archaeological stone tools and their connection to past human lifeways through experimentation. Controlled experimentation systematically quantifies the empirical relationships among different flaking variables under a controlled and reproducible setting. This approach offers a platform to generate and test hypotheses about the technological decisions of past knappers from the perspective of basic flaking mechanics. Over the past decade, Harold Dibble and colleagues conducted a set of controlled flaking experiments to better understand flake variability using mechanical flaking apparatuses and standardized cores. Results of their studies underscore the dominant impact of exterior platform angle and platform depth on flake size and shape and have led to the synthesis of a flake formation model, namely the EPA-PD model. However, the results also illustrate the complexity of the flake formation process through the influence of other parameters such as core surface morphology and force application. Here we review the work of Dibble and colleagues on controlled flaking experiments by summarizing their findings to date. Our goal is to synthesize what was learned about flake variability from these controlled experiments to better understand the flake formation process. With this paper, we are including all of the data produced by these prior experiments and an explanation of the data in the Supplementary Information.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

From the 1980s until his death in 2018, Harold Dibble built and ran an experimental lab in his department at the University of Pennsylvania designed to better understand stone tool production through controlled experimentation. This effort resulted in the construction of two flaking apparatuses, nicknamed Igor and Super Igor, that represented a culmination of his experimental interests dating back to his dissertation work in the 1970s when he built a drop tower apparatus to generate insights that he then applied to the Tabun lithic assemblages housed at the University of Arizona (Dibble, 1981). He maintained interest in the approach over the subsequent years, eventually partnering with his graduate student Andy Pelcin to restart the drop tower experiments in the 1990s (Dibble & Pelcin, 1995; Pelcin, 1996, 1997a, b). Dibble was assured that controlled experimentation, where individual variables could be isolated and systematically manipulated, was superior to the more common replication experiments that characterize lithic studies. The renewed drop tower experiments with Pelcin also convinced Dibble of the need to upgrade the experimental design, and this led to a difficult but ultimately successful effort to obtain National Science Foundation funding (BCS-0649673 and BCS-1153192) to build a new lab. This upgrade was largely motivated by an experimental desire to test more variables than the drop tower setup allowed and to produce flakes that more closely resemble the archaeological record (Rezek et al., 2016). This latter point meant that the new design could perhaps convince more archaeologists of the validity of the approach and of the results for understanding the decisions and actions of past flintknappers. For Dibble, the validity of the empirical models derived from the previous drop tower experiments for the archaeological record was never in doubt; in fact, the scraper reduction model for which his early career is best known was a direct result of this work. However, he also well understood that the burin spall-like flakes produced in those early experiments from plate glass inhibited a greater appreciation of the underlying, general process of flake production they were revealing.

The Dibble and colleagues experiments (hereafter called the Dibble experiments) produced a series of papers examining many aspects of flake production (Dibble & Rezek, 2009; Dogandžić et al., 2020; Leader et al., 2017; Magnani et al., 2014; Rezek et al., 2011). However, while there is continuity in these papers, a coherent flaking model did not emerge, making it difficult to take stock of where this line of research currently stands. At the time of his passing, it was Dibble’s intention to produce a paper pulling together and summarizing the results to date, and here we do our best to fulfill his wish in his absence. In addition to integrating his papers, we also discuss some of the limitations of the experimental design and highlight areas and approaches that could be constructively explored in subsequent experiments. With this summary, we also include a complete database coming from these experiments (see the Supplementary Information for field descriptions).

A Brief Review of the History of Experimentation in Lithic Studies

Because the physical properties of stone and the ways in which they fracture are uniformitarian and invariant across time and space, we can assume that processes associated with stone fracture observed today also operated in the past (Eren et al., 2016; Lin et al., 2018). Based on this premise, archaeologists verify hypotheses and develop inferences about past lithic technology by replicating the forms of stone artifacts observed in the archaeological record.

Systematic documentation of the experimental approach in lithic research appeared as early as the late nineteenth century. These early efforts mainly focused on reproducing “primitive” tools with “primitive methods” and were not considered a major component in archaeological research (Johnson et al., 1978). From the 1960s onwards, the flintknapping work of Bordes, Crabtree, Tixier, and others began to draw more attention to the use of replicative flintknapping to investigate past knapping procedures (Bordes, 1969; Crabtree, 1970; Frison, 1979; Shea et al., 2001; Sheets & Muto, 1972). Lithic experiments flourished in the following decades as researchers increasingly used flintknapping as an experimental means to examine different questions concerning stone tool production, including the effect of different percussion techniques, reduction sequences, and raw material types (Dogandžić et al., 2020; Eren & Lycett, 2012; Eren et al., 2011a, b; Magnani et al., 2014; Moore & Perston, 2016; Tabarev, 1997). Today, experiment is arguably a core aspect of stone tool research that is routinely employed to examine a wide variety of issues surrounding the technological and functional nature of past stone tools (Eren et al., 2016; Lin et al., 2013, 2018; Marreiros et al., 2020a, b; Režek et al., 2018), as well as broader socio-cultural, biomechanical, and cognitive domains associated with lithic technology (Moore & Perston, 2016; Pargeter et al., 2019; Stout et al., 2015).

Philosophy Behind Experimentation in Lithic Studies

The inferential power of lithic experiments for explaining past hominin behavior depends on the validity of the experimental design. The inferential validity of an experiment has been discussed in the form of “internal” and “external” validity (Eren et al., 2016; Lin et al., 2018). Internal validity refers to the quality of the causal relationships between the independent variables and the experimental outcome within an experimental framework (Eren et al., 2016; Lin et al., 2018). External validity refers to the ability to apply the experimental conclusions to settings beyond the condition in which the experiment was conducted (Lin et al., 2018). The inferential validity of an experiment is governed by hypothesis construction and variable control (Lin et al., 2018). Like in any other science, experimentation in archaeology should be guided with clear and testable hypotheses (Eren et al., 2016). A good hypothesis should finely balance the relationship between its underlying uniformitarian assumptions and how these assumptions are treated to avoid being non-testable or un-falsifiable (Lin et al., 2018). Once a hypothesis is formulated, it is realized through a concrete experimental design that allows control over independent variables relevant for testing the hypothesis. This is to avoid possible confounding factors that may complicate the interaction between these independent variables, thus ensuring the internal validity of an experiment (Lin et al., 2018).

With these concepts of validity in mind, we can categorize lithic experiments into two groups: replicative and controlled. Lithic experimentation has traditionally centered around replication. Specifically, in replicative experiments, human knappers use what is believed to be the actual methods and materials to replicate forms of stone artifacts discovered in the archaeological record (Flenniken, 1978; Franklin & Simek, 2008; Johnson et al., 1978; Scerri et al., 2016). This type of lithic experimentation allows researchers to look beyond the form of the artifacts and explore the dynamic ways past people made and used different forms of stone tools under settings that highly resemble the past knapping conditions (Johnson et al., 1978). Replicative lithic experiments allow archaeologists to explore a wide range of topics in lithic studies under a highly realistic knapping framework, including manufacturing techniques (Boëda, 1982; Bordes, 1969; Callahan, 1979, 1985; Clark, 1982, 2012; Crabtree, 1966, 1968, 1970; Hayden & Hutchings, 1989; Pelegrin, 2012), function (Iovita et al., 2014; Schoville et al., 2016; Shea et al., 2001; Shea et al., 2002; Sisk & Shea, 2009; Tringham et al., 1974; Villa et al., 2009), morphological characteristics (Boldurian & Hoffman, 2009; Bradbury & Carr, 1995; Bradley & Sampson, 1986; Buchanan et al., 2016; Dibble et al., 2005; Eren & Bradley, 2009; Karavanić & Šokec, 2003), curation, and use life (Andrefsky, 2006; Clarkson & Hiscock, 2011; Eren et al., 2008; Shott, 2020; Shott & Sillitoe, 2005; Shott et al., 2000) of stone tools, as well as the cognitive and technological capabilities of the prehistoric knappers (Bril et al., 2010; Eren et al., 2011a, b; Harlacker, 2003; Nonaka et al., 2010; Pelegrin, 1993; Rein et al., 2013; Rugg & Mullane, 2001; Stout et al., 2014; Toth & Schick, 2019). Moreover, replicative experiments offer a broader context for investigating changes in flake attributes at each stage of the knapping process (Bradbury & Carr, 1999; Braun et al., 2008b; Marwick, 2008). Today, replicative experimentation plays a central role in the technological approach of lithic artifact analysis (Bordes, 1953, 1969, 1971; Brenet et al., 2009; Callahan, 1979, 1985; Crabtree, 1970; Frison, 1979; Geneste, 1985, 1988; Pelegrin, 1990; Roussel et al., 2009; Shea et al., 2001), with a particular focus on reconstructing the sequences and techniques of past stone tool production.

However, a major issue surrounding replicative experimentation is its heavy reliance on the subjective observation and experience of the modern knapper. Knapping is a skill that involves the coordination of multiple bodily movements (Bril et al., 2012; Geribàs et al., 2010; Rein et al., 2013; Vernooij et al., 2012). Yet, mastering the knapping process with the ability to consistently produce a desirable flaking outcome does not necessarily imply that the knapper is fully aware of the variables at work and their respective effects (Dibble & Rezek, 2009). In fact, while experienced knappers can often predict the flaking result of different knapping actions with a relatively high degree of accuracy (Bril et al., 2010; Nonaka et al., 2010), it is still extremely difficult to isolate and quantify the exact effect of a particular variable during the flaking process (Dibble & Rezek, 2009). Moreover, when a knapper makes changes to one flaking variable, other factors may change at the same time. For example, a knapper may unconsciously adjust their hammer striking angle and position when switching between soft and hard hammers, thus causing the influence of these various parameters to be systematically confounded in the experimental outcome (Lin et al., 2018). As a result, it can be difficult to determine the exact effect of any single one of the confounded variables on the experimental outcome. In addition, because of confounded factors, it is challenging for replicative experiments to reproduce exactly the flaking process used in separate knapping instances. Even when carried out by the same knapper, aspects of the experimental knapping process are bound to differ in varying degrees, including core morphology, body posture, hand grip, hammer striking angle and location, and percussion force. The inability to reproduce the result of individual flintknapping experiments means that experimental observations cannot be easily verified, an issue that inevitably reduces the internal validity of the experimental outcome. To improve the level of variable control and isolation in replicative experimentation, recent studies have argued that a greater amount of attention needs to be paid to the design of replicative experiments, particularly as a tool for hypothesis testing and model building (Eren et al., 2016; Lin et al., 2018).

In contrast to replicative flintknapping, a number of studies in the 1970s and ‘80 s began to employ mechanical flaking apparatuses to investigate the underlying mechanics of flake formation under a more controlled experimental setting (Bonnichsen, 1977; Cotterell & Kamminga, 1987, 1992; Cotterell et al., 1985; Faulkner, 1972, 1973; Speth, 1974, 1975, 1981). The primary focus of the controlled experimental approach is on isolating the impact of different knapping parameters on flake attributes through variable control. By maintaining all of the relevant test variables in an experiment while varying only the one in question, a controlled experimental setting can best guarantee the internal validity of its outcome. This means that researchers can have greater confidence in the causal relationships between the tested variables (i.e., independent variables) and the flaking outcome examined within the scope of an experiment (Eren et al., 2016; Lin et al., 2018).

The early controlled experiments focused on testing ideas drawn from fracture mechanics (Cotterell & Kamminga, 1992; Cotterell et al., 1985; Speth, 1972, 1974, 1975, 1981). While they provided some in-depth discussions on flake initiation, formation, and termination, the results of these studies did not gain much traction in mainstream lithic research because it was difficult to apply them to the interpretation of archaeological assemblages. This lack of traction stemmed in part from the fact that variables examined in these fracture mechanics-based experiments were difficult, if not impossible, to measure on lithic artifacts (e.g., mechanical properties and size of the hammerstone, contact time of the hammer strike). Starting from the work of Dibble and Whittaker (1981), Dibble and colleagues made an explicit shift away from fracture mechanics to investigate instead variables under the direct control of knappers (e.g. platform configurations) (Dibble & Pelcin, 1995; Dibble & Rezek, 2009; Dogandžić et al., 2020; Leader et al., 2017; Magnani et al., 2014; Rezek et al., 2011). These knapper-based controlled experiments are guided by knappers’ observations of what they think matters in flake production. By directly testing variables that knappers can manipulate, this approach arguably touches more directly on stone knapping as a technological process than experiments that focus explicitly on how fracture mechanics work. Moreover, this focus on knapper control also meant that Dibble’s experiments were largely driven by the attributes he observed in the archaeological lithics that he primarily studied in his field research, namely Middle Paleolithic and Middle Stone Age flakes from Europe, southwest Asia, and northern Africa. At the same time, though he built experiments around what knappers thought was important, it is worth noting that Dibble himself was quite skeptical of the validity of some apparent truisms derived from modern knapper experience. He questioned, for instance, the relative importance that knappers typically place on core surface morphology and on hammer type to determine flaking outcomes. Thus, an implicit goal of the Dibble experiments was to systematically test what could be described as modern knapper “folk wisdom”.

The effort to exert experimental control necessarily requires breaking down the stone knapping process into individual parameters that can then be controlled and manipulated during the experimental process. Controlled flaking experiments often feature a highly artificial setup, such as the drop tower, and flaking products that can have limited resemblance to actual archaeological flakes (Rezek et al., 2016). This lack of “realism” is one of the main critiques that have been leveled against a controlled experimental approach, leading to questions about the external validity of the study outcomes (i.e., the degree to which the experimental findings can be applied to real-world settings). As an effort to address this realism critique, Dibble and colleagues developed a new experimental design to increase the external validity of the experiments by adopting a more realistic core design and hammer delivery process (Dibble & Rezek, 2009; Dogandžić et al., 2020). We will discuss these changes made in the new experimental design in detail in the next section. In addition, it has been argued that the ability to generalize experimental findings to archaeological settings does not necessarily depend on the realism of the experimental design but rather on the ability to confidently determine the causal effects of fundamental parameters (i.e., high in internal validity) (Lin et al., 2018; Magnani et al., 2014). From this perspective, if we can confidently establish the cause-and-effect of key knapping variables such as platform shape and hammer hardness on flake attributes, we should expect the same cause-and-effect from these key variables to operate in lithic fracture irrespective of where, when, or how these flakes were made (Magnani et al., 2014).

Strategies of the Dibble Experiments

As mentioned above, many of the earlier controlled experiments employed a drop tower setup where a steel ball bearing is dropped onto the edge of a piece of plate glass to produce flakes. The resulting flakes have a morphology similar to a burin spall. In order to make more “realistic” flakes, Dibble and Rezek (2009) introduced a new experimental design with two primary changes. First, instead of using plate glass with angular shapes, soda-lime glass cores were molded to have a curved flaking surface with a lateral and longitudinal convexity (Fig. 1). This core geometry, which was referred to as a “semispherical” core in the Dibble experiments, produced flakes that, in terms of both size and shape, looked similar to archaeological flakes. In later experiments, other core shapes were molded or cut to test the effect of core surface morphology on flaking outcomes. Glass was chosen as the core material because it fractures conchoidally and is easily molded to standardized shapes. To these standardized core shapes, different platform morphologies were achieved by using saws and grinding wheels. A purpose-built core mount allowed the core to be flexibly positioned for different hammer striking conditions.

Illustration of a semispherical glass core redrawn from Dibble and Rezek (2009)

The second important change in these experiments was the use of a pneumatic cylinder to apply a direct compressive load on the core to initiate flake fracture. The use of a steel ball bearing in the drop tower experiments meant that the ball “hammer” inevitably bounces back after coming into contact with the core, a phenomenon that is the opposite of the common practice among modern flintknappers of “following through” with a hammer blow after the initial impact (Whittaker, 1994). With the new Dibble experimental machine (“Igor”), hammers of different materials and shapes are mounted to the piston of the cylinder. Upon activation, the cylinder extends the hammer downward over a fixed distance to strike the core underneath, thereby simulating a hammer blow with “follow through” upon impact. A load cell is positioned between the hammer and the cylinder to record the amount of force exerted for each flake removal (Dibble & Rezek, 2009). The experiments from 2009 to 2017 used a pneumatic cylinder that allowed for forces up to 1,500 lbf (Dibble & Rezek, 2009; Leader et al., 2017; Magnani et al., 2014; Rezek et al., 2011). In 2017, a second machine (“Super Igor”) with a more powerful servo-hydraulic press (Fig. 2) was built to increase the amount of force up to 20,000 lbs. This new machine allowed raw materials other than glass to be tested (Dogandžić et al., 2020). Compared to the previous drop tower setup, the new design allowed for a finer control over the hammer percussion process, with the ability to manipulate force application parameters such as the displacement speed and travel distance of the hammer. The hammer displacement speed on the second machine is adjusted by the controllers attached to the servo-hydraulic testing press (Dibble & Rezek, 2009; Dogandžić et al., 2020).

The Super Igor machine. This experimental setup was used in Dogandžić et al. (2020). The device marked by the orange square was used to hold the core during the flake removal process. This same device was used in previous experiments conducted with the Igor machine (Dibble & Rezek, 2009; Leader et al., 2017; Magnani et al., 2014; Rezek et al., 2011)

Using the new experimental design, Dibble and colleagues examined a range of fundamental aspects of flaking by summarizing the empirical relationships among test variables using regression models (Dibble & Rezek, 2009; McPherron et al., 2020; Rezek et al., 2016). With this approach, Dibble’s research group studied the effect of a number of flaking variables, including platform attributes such as platform depth and exterior platform angle, core surface morphology, the application of force (i.e., hammer type, angle of blow, location of hammer strike), and raw materials (Dibble & Rezek, 2009; Dogandžić et al., 2020; Leader et al., 2017; Magnani et al., 2014; Rezek et al., 2011). Results from these experiments demonstrate the complexity of the flake formation process, which involves simultaneous interactions of different variables that are difficult to understand in isolation. More importantly, these experimental results led to the synthesis of a flake formation model, which we term the EPA-PD model, that predicts the flaking outcome based on key platform variables. In the following sections, we will review in detail the experimental variables that were controlled as independent variables in the Dibble experiments and how they contribute to variability in flaking outcomes, as well as the EPA-PD model and its application to archaeological assemblages.

Experimental Variables

Exterior Platform Angle and Platform Depth Are the Primary Factors Driving Flake Size

The exterior platform angle (EPA) is the angle between the platform surface and the exterior surface of the core. Platform depth (PD, also sometimes referred to as platform thickness) is the distance from the point of percussion to the core edge (Fig. 1). Prior to the Dibble experiments, drop tower experiments repeatedly demonstrated the importance of these two platform parameters in determining flake size and shape (Dibble, 1997; Dibble & Pelcin, 1995; Dibble & Whittaker, 1981; Pelcin, 1996, 1997a, b) (see also Fig. 3). Increasing either or both exterior platform angle and platform depth results in larger and heavier flakes. The first paper from the Dibble experiments (Dibble & Rezek, 2009) replicated this finding by showing a clear positive correlation between EPA-PD and flake mass. Thus, with a given exterior platform angle, greater platform depths result in heavier flakes. Likewise, the slope of the relationship between platform depth and flake mass increases with exterior platform angle such that higher exterior platform angles result in increasingly heavier flakes for the same platform depth (Fig. 4) (Dibble & Rezek, 2009). The flake shape is impacted by exterior platform angle but not by platform depth. For a given platform depth, a higher exterior platform angle produces flakes that are relatively thinner (i.e., higher surface area to thickness ratio) and more elongated (i.e., higher length to width ratio) than those produced with a lower exterior platform angle (Dibble & Rezek, 2009; Lin et al., 2013).

Schematic illustration of the relationship between EPA-PD and flake size in profile view (redrawn from Dibble & Pelcin, 1995). The dotted lines represent the flaking outcome. a When the exterior platform angle (EPA) is held at a constant, increasing platform depth will result in larger flakes. b When platform depth (PD) is held at a constant, increasing exterior platform angle will result in larger flakes

Relationship between platform depth and flake mass grouped by exterior platform angle. The cube root of flake mass is used here to standardize its dimension with platform depth (Dibble & Rezek, 2009)

One of the most important findings of the Dibble experiments is that in comparison to other knapping variables such as core morphology, hammer type, and platform configuration, the effect of EPA-PD on flake size and shape is by far the strongest and the most consistent (Dibble & Rezek, 2009; Dibble & Whittaker, 1981; Dogandžić et al., 2020; Leader et al., 2017; Magnani et al., 2014; Rezek et al., 2011). This relationship has also been demonstrated in actual flake collections, though in each case the strength of the relationship is less strong than in the controlled experiments (Braun et al., 2019; Davis & Shea, 1998; Dibble, 1997; Dogandžić et al., 2020; Lin et al., 2013; Režek et al., 2018; Shott et al., 2000).

Force Does Not Have a Significant Effect on the Flaking Outcome

Some of the more counter-intuitive and perhaps controversial findings of the Dibble experiments involve force. Here, the striking force refers to the push of the hammer when it hits the core to remove a flake. In the Dibble experiments, the striking force is measured by a load cell attached to the hammer. In the drop tower setup, the striking force is controlled by changes in hammer mass and/or speed (i.e., drop height). It is a common conception among modern knappers that a harder blow, meaning a greater striking force, will generate a bigger flake. In this respect, however, previous controlled experiments have produced equivocal outcomes. Some showed that changes in striking force result in variation in flake dimensions and termination types (Dibble & Whittaker, 1981; Speth, 1974), while others showed that changing the striking force does not exert any sizable impact on the detached flakes (Dibble & Pelcin, 1995; Pelcin, 1996). For example, Dibble and Whittaker (1981) varied striking force by changing the mass of the steel ball bearings used in their drop tower experiment. The results show that, while increasing the size of the ball bearing does allow larger flakes to be made, force operates as a threshold variable—that is, for a given force, flake size is dependent on the combined effect of exterior platform angle and platform depth. Or stated alternatively, given a particular platform configuration, a certain level of force is required to remove a flake, and exceeding this level of force does not change the resulting flake in terms of size or shape.

It is worth noting that these earlier drop tower experiments varied striking force in different ways. Speth (1974), for instance, varied the drop height of the ball bearing, which in turn changed the travel distance/time of the hammer and hence speed at contact while holding hammer mass and morphology constant. On the other hand, Dibble and Whittaker (1981) held speed constant but changed the size of the ball bearing, which in turn altered the mass and size (i.e., diameter) of the hammer. Importantly, it is not clear whether these alternative approaches to changing force are experimentally equivalent. It is known, for instance, that hammer size impacts Hertzian cone characteristics (Fischer-Cripps, 2007; Frank & Lawn, 1967; Roesler, 1956), but how these characteristics may change flaking outcomes is still not well understood.

Direct Percussion and Pressure Flaking Produce Equivalent Flakes

From an experimental perspective, one way to think about the speed component of force in stone knapping is to consider two extremes in the distinction between static and dynamic loading. The former represents a process whereby the pressure mounts slowly (slow hammer speed), such as in pressure flaking, while the latter represents a quick delivery (fast hammer speed) of pressure in direct hammer percussion. It is commonly noted in replicative flintknapping that flakes produced through direct hammer percussion versus pressure flaking share distinct differences in shape, such that pressure flaked flakes are said to be thinner, more elongated, and more evenly shaped (e.g., Mourre et al., 2010). However, direct percussion and pressure flaking are typically applied in very different contexts in flintknapping, and these actualistic experiments leave many important variables, especially ones that are related to platform preparation, uncontrolled.

This point, namely whether and how percussive and pressure flakes vary, is essential to the Dibble experimental setup and understanding the applicability of the conclusions drawn from it. Dibble was convinced that, for the variables he examined, the difference between static (pressure) and dynamic (percussive) loads was minimal, if not irrelevant. This conviction was based on three sets of data. First, the Dibble and Pelcin drop tower experiments showed that force does not seem to matter beyond achieving the threshold force for flake initiation (Dibble & Pelcin, 1995). Second, the flakes from the new controlled experiments (static loading) showed the same patterns previously observed in the drop tower experiments (dynamic loading). Third, in two studies using the new experimental setup with varying hammer displacement speeds (0.01, 0.05, 650, 10000 inches per minute), Dibble and colleagues observed no discernable variation in flake mass and dimension (Dibble & Rezek, 2009; Magnani et al., 2014). Note that the upper value, 10000 inches per minute or approximately 4.3 m per second, is roughly equivalent to the speed at which knappers strike a core (Bril et al., 2010), although the delivery is static rather than dynamic.

Hitting the Core Harder Does Not Matter Because the Force Required to Remove a Flake Is a Function of Its Mass and Flake Mass Is a Function of EPA-PD

Using the new mechanical flaking apparatus, the Dibble experiments revisited this issue of percussive force by using a load cell to record the exact amount of force necessary to remove a flake. Importantly, the high-resolution load cell data shows a picture in line with what was previously proposed by Dibble and Whittaker (1981) based on the drop tower experiments. Specifically, the load cell data show that force increases to the level required for flake detachment and then declines immediately once the flake is removed. Moreover, the force recorded by the load cell correlates tightly with flake mass irrespective of variation in other variables such as exterior platform angle, platform depth, angle of blow, and core surface morphology (Fig. 5). Thus, the minimum amount of force required to remove a flake is determined by the mass of the flake, which itself is a function of platform depth and exterior platform angle. Based on this observation, applying less than the minimally required force for a given combination of exterior platform angle and platform depth will not result in a successful flake removal. Likewise, exerting more force by hitting the core harder will not change the flake mass (Dibble & Pelcin, 1995). However, first, Van Peer (2021) used data from the Dibble experiments conducted with the machine Igor to argue that flake mass starts to increase at a slower rate relative to the striking force once the force surpasses a certain threshold. Second, we note that this particular conclusion, that the application of excessive force does not make a difference in the flaking outcome, is based more on the drop tower experiments than on the new experimental design because with the use of cylinder compressive loading, it was not possible to apply forces in excess of what was minimally required to remove a flake.

Relationship between flake mass and striking force. The minimum force required to remove a flake with a certain mass is tightly related to its mass (Dibble & Rezek, 2009). Force is expressed as a function of flake mass

Raw Material Type Affects the Force Required but not the Flaking Outcome

One of the main critiques of the controlled flaking experiments to date is the sole reliance on glass as the flaking medium. While the new experimental design introduced by Dibble and Rezek (2009) has greatly improved the resemblance of the experimental flakes to actual lithic artifacts, the use of glass cores still raises concerns regarding the applicability of the experimental results to flakes made of different raw material types, especially because glass is an amorphous solid, whereas other materials, such as chert, are primarily made of crystalline quartz. Raw material variability features prominently in explanations of archaeological stone tool variability, especially in relation to discussions of lithic technological organization in terms of the quality and supply of raw materials in a given region (Andrefsky, 1994). Thus, the sole reliance on glass among controlled experiments inhibits further considerations of cost–benefit analyses in stone flake production based on raw material variability. However, a number of replicative flintknapping studies have indicated that raw material differences, at least among relatively fine-grained stone types, have minimal to no effect on the general morphology of the detached flakes (Clarkson & Hiscock, 2011; Eren et al., 2014; Kimura, 2002). Thus, how various raw materials respond to the knapping process under controlled conditions was important to evaluate.

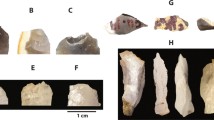

To address this, Dogandžić et al. (2020) compared the glass results to flakes made on three other raw material types (basalt, flint, obsidian). All cores were made to an identical form that features a central ridge and longitudinal convexity. The results show that, in nearly every comparison of flake volume and linear dimensions, the flakes show no discernable variation among the four raw material types. Instead, the experimental flakes exhibit the same EPA-PD relationship whereby increasing either platform parameter causes flake size to rise in almost identical ways (Dogandžić et al., 2020) (see also Fig. 6). The only measurable difference among the flaking outcomes of different raw material types is in the amount of force required for successful flake detachment—more force is required to remove flakes from flint and basalt cores than from the glass or obsidian cores. The results demonstrate that the general flaking patterns observed in glass can indeed be extended to some raw materials that were commonly used in the past (Dogandžić et al., 2020). Of course, there are likely many other raw material types that may respond differently to fracture than those tested in this study, especially those that are more heterogeneous, such as, for example, porphyry (Namen et al., 2022). However, given the consistency in flake formation across multiple stone types as shown in Dogandžić et al. (2020), it is more reasonable to assert that the same fundamental fracture patterns also apply to less amorphous raw materials, though the relationship may be more varied or “noisy” due to heterogeneities such as flaws and inclusions.

Relationship between platform depth, exterior platform angle, and flake mass (cube root) for flakes made of four different types of raw material (Dogandžić et al., 2020)

The Effect of Platform Beveling on the EPA-PD Relationship Remains Poorly Understood

At the ontset of the new experimental program, Dibble already knew that the combination of EPA-PD was a strong determining factor in flaking, an observation that was later confirmed and strengthened with subsequent experimental outcomes. At the same time, however, Dibble also knew that, while the EPA-PD model worked well on plane, symmetrical, unobstructed, and unmodified platforms, platform preparation (e.g., trimming behind the platform, faceting the platform surface, isolating the platform, etc.) altered the EPA-PD model in ways that were not all understood. For instance, previous controlled experiments (Pelcin, 1996) on plate glass tested the influence of different platform bevels (material removed from behind or from the sides of the platform) and found that flakes with beveled platforms are generally longer than those made with unbeveled platforms while showing no clear difference in mass. In these earlier experiments, the bevel morphologies also changed the bulb thickness. To explain this finding, Pelcin (1996) proposed that platform beveling likely causes flake mass to be redistributed across the core morphology to produce longer flakes without changing the overall flake mass.

Given that one of the guiding principles of the Dibble experiments was to understand the ways in which knappers can control flaking outcomes (as opposed to creating a general model of fracture mechanics) and given that platform preparation is an important aspect of flake variability in the archaeological record, an experiment was designed to investigate the effect of platform beveling on the EPA-PD model’s ability to predict flake mass (Leader et al., 2017). In this experiment, the platform surface was beveled in three ways: flat exterior bevel, concave exterior bevel, and lateral bevel (Fig. 7). The flat bevel was thought to simulate trimming or thinning the core’s exploitation surface from the platform (Fig. 7a). The concave bevel represented striking a flake from a core immediately behind a previously struck flake, meaning that the platform surface curves inward from the scar of the previous flake (Fig. 7b). The lateral bevel, on the other hand, was meant to represent uneven (i.e. not flat) platform surfaces, including the faceted types where the point of percussion is intentionally raised and isolated by removing material from either side (Fig. 7c–e). For this bevel type, three different cuts were used at angles of 30, 45, and 60° (see Fig. 7c–e). Each of these bevel types is found in the archaeological record and is thought to represent techniques used to control the flaking outcome. The impact of beveling could be compared across bevel types and to the same cores without bevels.

The three types of beveled flakes examined in Leader et al. (2017). a Shows a flat-beveled flake, the angle between the beveled surface and the platform is 90°; b shows a concave-beveled flake, the angle between the beveled surface and the platform is 90°; c shows a laterally-beveled flake, the angle between the platform surface and the lateral bevel surface is 30°; d shows a laterally-beveled flake, the angle between the platform surface and the lateral bevel surface is 45°; e shows a laterally-beveled flake, the angle between the platform surface and the lateral bevel surface is 60°

The results show that beveling significantly changes the EPA-PD model. For instance, flat- and concave-beveled cores produced larger flakes in their linear dimensions and are heavier than those made from the laterally-beveled and unbeveled cores (Fig. 8). However, if instead of using the actual platform depth of these flakes in the EPA-PD model, the platform depth is calculated from the original edge of the core (prior to the bevel), the relationship between EPA-PD and flake mass remains the same across most of the bevel types. The study concluded that platform beveling changes the relationship between platform depth and flake attributes through the geometry of the platform surface configuration, such that the influence of platform beveling on flake variation changes depending on the position, curvature, angle, and depth of the bevel (Leader et al., 2017). For instance, for flakes with concave platform beveling, the depth of the bevel significantly affects the resulting flake mass—a deeper bevel depth leads to greater flake mass relative to the actual platform depth.

Relationships between different flake attributes and platform depth for beveled and unbeveled flakes (Leader et al., 2017). Both the flat and concave bevels were cut at a 6 mm depth from the original flake exterior surface, and the lateral bevels were cut at 45° relative to the platform surface. a Shows the relationship between the cube root of flake mass and platform depth, b shows the relationship between flake length and platform depth, c shows the relationship between flake width and platform depth, and d shows the relationship between platform width and platform depth

One possible explanation for why the EPA-PD model is skewed by platform beveling is that the relationship between platform depth and platform width is changed. Leader et al. (2017) found that all three types of platform beveling have some influence over platform width. When the platform surface is unbeveled, the resulting platform width of the flake is simply a function of platform depth (see also McPherron et al., 2020). Platform beveling changes this simple linear relationship between platform width and platform depth. For instance, among the flakes made on a concave-beveled platform, a deeper bevel resulted in significantly wider platforms for a given value of platform depth. Similarly, flakes made with laterally beveled platforms show a greater platform width when compared to their unbeveled counterparts of the same platform depth (as shown in Fig. 8d). However, we note that on these laterally-beveled flakes, the platform width was measured as the distance between the points where the flake’s interior and exterior surfaces meet (Leader et al., 2017). In other words, if the crack that formed the flake extended onto the lateral bevels, then these surfaces were included in the flake’s platform width (rather than measuring only the isolated and raised portion of the platform as platform width). In any case, these changes in platform width caused by platform beveling cannot be conveniently translated into a refined EPA-PD model to produce a consistent outcome. While both flat- and concave-beveled platforms result in larger and heavier flakes (Fig. 8a–c), the laterally-beveled platform actually causes the flakes to become relatively shorter than the unbeveled flakes (Fig. 8b) (Leader et al., 2017).

Combined with the results of the prior drop tower experiment (Pelcin, 1996), the Leader et al. (2017) platform beveling experiment showed that the EPA-PD model only applies to a certain class of flakes (such as those without platform modifications) and pointed to platform depth as the weaker part of the model (because platform depth varies by bevel type). In addition, the experimental findings indicate that some of the flake variability unexplainable by the EPA-PD model may be attributable to platform beveling. For instance, typically in the analysis of archaeological flakes, all of the flakes shown in Fig. 8a would be considered together as one group in an EPA-PD model to predict mass, the result would therefore have much more variation compared to the unbeveled flakes alone.

Core Surface Morphology Has an Impact on Flake Shape and Size

Core surface morphology has long been considered an important factor in constraining flake initiation, propagation, and termination, as well as the size and morphology of the produced flake (Cotterell & Kamminga, 1987; Pelcin, 1997a; Rezek et al., 2011). The Rezek et al. (2011) experiment tested the effect of core surface morphology on flake variation by modifying the exterior surface of the original semispherical design. Four designs were used: a center ridge form (resembling a blade core), a parallel form (resembling a prismatic blade core), a convergent form (resembling a Levallois point core), and a divergent form (see Rezek et al., 2011). The experimental results show that core morphologies do affect, but not always, flake size and shape (Fig. 9) (Van Peer, 2021). For example, independently of EPA-PD, flake elongation (the length to width ratio) shows variation among some of the core morphologies but not others (Fig. 9b). A geometric morphometric analysis on the two-dimensional outline of the flakes shows that, while core morphology does exert some effect on flake morphology, much of the variation in flake shape, especially elongation, is in fact controlled by the EPA-PD relationship. Because of this relationship, flakes from distinct core forms can, in some instances, share a very similar size and shape, while flakes from the same core type can vary considerably due to platform configurations alone. This set of results led Rezek et al. (2011) to conclude that core surface morphology is not as important of a factor in affecting flake variation, especially when compared to the effect of EPA-PD, such that the shape of a flake cannot be predicted solely by the geometry of the core. This conclusion, while in agreement with that of Pelcin (1997a), highlights the complexity of the interaction between core morphological variation and platform attributes in flake variation. Probably a better way of expressing this is that core morphology has a smaller effect on flake morphology than EPA-PD does and that the addition of core morphology to the EPA-PD model would help explain additional variability in flake size and shape, which is suggested in Fig. 9b.

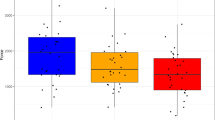

a The relationship between platform depth and flake mass for different core morphologies when exterior platform angle is 65°. b Flake elongation (length/width) grouped by core morphology for different core morphologies (Rezek et al., 2011)

Hammer Type and Shape Affect Several Flake Attributes

Soft Hammers Produce Platform Lipping and Impact Flake Shape. Hard Hammers Can Also Produce Platform Lipping

Replicative knapping experiments have shown that hard versus soft hammers can affect various flake attributes, including flake mass, linear flake dimensions, platform attributes, flake initiation, and flake termination (Bradbury & Carr, 1995; Buchanan et al., 2016; Damlien, 2015; Driscoll & García-Rojas, 2014; Schindler & Koch, 2012). These differences in flaking outcomes are often attributed to differences in force propagation mechanisms. For hard hammer percussion, it is often said that a conchoidal fracture takes place where the force propagates directly from the point of percussion to the termination (Cotterell & Kamminga, 1987). This process results in a clear point of initiation and a well-formed bulb of percussion. On the other hand, a bending fracture is often said to take place with soft hammer percussion (Cotterell & Kamminga, 1987), where the fracture initiates some distance away from the point of hammer contact, leading to flakes having a more diffused bulb, a smaller platform surface and a pronounced “lip” on the interior platform edge. In fact, platform lipping in particular is often used as an indicator of soft hammer percussion in the analysis of archaeological stone tools (Hayden & Hutchings, 1989; Sharon & Goren-Inbar, 1999; Sullivan & Rozen, 1985). However, prior controlled experiments by Bonnichsen (1977) and Pelcin (1997b) showed no clear differences in the occurrence of platform lipping between hard and soft hammer percussion. Pelcin (1997b) postulated that this discrepancy could be because human knappers tend to change percussion techniques, either consciously or unconsciously, when switching between hard and soft hammers (Hayden & Hutchings, 1989). As such, the presence of flake features such as platform lipping may be related to knapping factors other than hammer type.

To test this proposition, the Magnani et al. (2014) experiment examined the effect of three different hammer materials: steel, copper, and synthetic bone. To ensure consistency, these hammers were milled to an identical ball bearing shape the same size as the tip of the mechanical indenter normally used in the experiments. These hammers were then used to strike the platform surface at varying platform depths and exterior platform angles. The results showed that flakes produced by the synthetic bone hammer have smaller bulbs and are longer and thinner than flakes produced by the steel and copper hammers. This outcome is consistent with Pelcin’s (1997b) earlier observation.

Results of the Magnani et al. (2014) experiment showed that platform lipping is much more prevalent (over 95%) among the flakes produced by soft hammer percussion than those made with the steel (under 40%) and copper hammers (under 60%). This finding suggests that the use of a softer hammer material increases the chance of platform lipping. In the case of lipped flakes made by harder hammers, the angle of blow and where the platform was struck affected the outcome. A negative angle of blow (hitting “inward” to the core) or striking the platform on its edge (as opposed to the surface) increases the chance of lip formation. Thus Magnani et al., (2014:40) concluded that “the presence or absence of lipping in general has little or no predictive value regarding the kind of hammer that was used.” While this statement is true on a flake-by-flake basis, it is also clear that at the assemblage level an elevated percentage of lipped flakes can indicate the use of soft hammer given that negative angles of blow are likely to be relatively uncommon knapping strategies. Further, the ability to infer the hammer type on a flake-by-flake basis could be improved if the angle of blow or where the platform was struck can be measured on an archaeological flake.

The Magnani et al. (2014) experiment also showed an important trade-off in knapping success with the use of a soft hammer. When the exterior platform angle of the core is greater, the synthetic bone hammer had a higher chance of failing during the experiment as the hammer tip was not able to sustain the impact pressure and instead crushed against the platform surface. Magnani et al. (2014) thus suggested that the common co-occurrence of other knapping techniques, such as on-edge strikes with soft hammers, may reflect strategies for mitigating the heightened probability of unsuccessful flake detachment with soft hammer percussion when striking directly on platform surfaces.

According to Magnani et al. (2014), the correlation between platform depth and flake mass of a given exterior platform angle is weaker for flakes with platform lipping than for flakes without platform lipping. This outcome might be caused by the bending fracture process associated with the formation of platform lipping. Specifically, because fracture appears to have initiated some distance away from the point of percussion on these flakes, there is likely noise in the platform depth to flake mass relationship because the actual platform depth could not be measured from the point of percussion.

Hammer Shape and Size Do Not Affect Flake Size and Shape

In addition to hammer material, Magnani et al. (2014) also tested the influence of hammer size and shape by adopting five different steel hammer designs that varied in their tip shape and diameter. They concluded that when other variables are held constant, neither the size nor shape of the hammer shows an effect on flake morphology. Although according to the fracture mechanics theory of conchoidal (Hertzian) fracture, the size of the Hertzian cone is related to several variables such as the mechanical properties of both the hammer and the core, the size of the hammer, and the striking force (Frank & Lawn, 1967; Lawn, 1967; Lawn et al., 1974). However, one, the relationship between Hertzian cone size and flake size is poorly understood, and, two, it is possible that the range of hammer sizes used in the Dibble experiments might not have been large enough to measurably impact the overall size and shape of the flakes produced.

The Angle of Blow Affects Flake Size

The Zero or Positive Angle of Blow Affects the Size but not the Overall Shape of the Flake

The angle of blow is the angle at which the hammer comes into contact with the platform surface. Dibble and Rezek (2009) measured this angle between the hammer impact trajectory and the perpendicular of the platform. A perpendicular hammer impact has an angle of blow of zero, a positive angle indicates an oblique blow striking “outward” towards the core surface, and a negative angle of blow describes a strike directed “inward” to the core volume (Fig. 10). Speth (1972) argued that the angle of blow affects the size of the bulb of percussion, whereby a greater angle of blow (a more oblique impact) results in a less prominent bulb. In a later study, Speth (1975) also showed that flakes produced with a large angle of blow were slightly shorter than those produced with a smaller angle of blow. According to Speth (1972, 1975), higher angles of blow limit the stress applied on the platform, thus resulting in a more reduced flake length and a less prominent bulb under otherwise identical striking conditions. To the contrary, Dibble and Whittaker (1981) found limited variation among flake attributes in relation to the angle of blow. They explained the discrepancy between their work and Speth (1975)’s in two ways. The first is that the range of variation in the angle of blow was set at 25° in Dibble and Whittaker (1981), which is considerably smaller than the 45-degree interval used in Speth (1975). As such, the 25-degree range of variation may not have been sufficient to observe the effect of angle of blow on flake dimension. The second reason is that the effect of the angle of blow could have been overshadowed by the more dominant impact of platform depth and exterior platform angle. It could also be the case that the response to the angle of blow is not linear across all possible angles, and thus, the range of tested angles may impact the results. In a later study, Pelcin (1996) went further to argue that the angle of blow does not exert any direct influence on flake attribute, though he did not provide further detailed discussion of this perspective.

The initial Dibble and Rezek (2009) experiment explored the influence of the angle of blow at intervals up to 50°. The results showed that the angle of blow has a negative effect on flake mass (standardized by platform depth). Put simply, for a particular EPA and PD, a more perpendicular blow produces a heavier flake than a more oblique strike (Fig. 11a). This may be because the percussive force applied to the platform surface is more concentrated when the hammer blow is more perpendicular (Dibble & Rezek, 2009). Later, Magnani et al. (2014) showed that a more perpendicular angle of blow also produces flakes that are longer, wider, and thicker (when both platform depth and exterior platform angle are held constant), as was reported in Speth (1975). In addition, Van Peer (2021) showed that changes in the combination of the angle of blow and exterior platform angle could also affect flake morphology. However, the angle of blow does not influence the overall shape in terms of the length and width ratio of the detached flake (Fig. 11b), nor does it alter the minimum force required for successful flake removals (Dibble & Rezek, 2009; Magnani et al., 2014).

So while the angle of blow has been shown to have an impact on various flake attributes in several controlled experiments (Dibble & Rezek, 2009; Magnani et al., 2014; Speth, 1975), it is not included in the current EPA-PD model derived from the Dibble experiments. This is because the angle of blow has mostly remained an unmeasurable knapping variable up to now (but see below and Li et al., 2022).

Negative Angles of Blow May Change Flake Size

The Magnani et al. (2014) experiment revisited the angle of blow in the context of force application and examined the effect of negative angles of blow (i.e., striking “inward” into the core, as in biface thinning, see also Fig. 10c). Looking only at platform surface-struck flakes, the experimental findings are largely consistent with those reported in the prior study of Dibble and Rezek (2009), where the angle of blow has a negative effect on flake size (as measured by mass). That is, flakes made on lower angles of blow, including those with negative impact angles (Fig. 10c), are consistently heavier than those made on more oblique angles. Interestingly, when negative angle of blow flakes are included, the experimental results show that the angle of blow has a significant influence on both the mass and linear dimensions such as the length and width of flakes. Specifically, flakes made with negative angles of blow are consistently heavier and larger (in both length and width) than the flakes made with positive angles of blow when holding EPA and PD constant (Magnani et al., 2014). This finding, however, needs to be interpreted with caution due to possible confounding variables. To be specific, because decreasing the angle of blow also increases the relative occurrence of platform lipping and hence bending fracture (Magnani et al., 2014), it is currently unclear whether the greater flake length and width associated with negative angle of blows actually reflect the greater propensity of bending fracture when the hammer is struck “inward” into the core.

Striking on the Platform Edge Changes the Flake Shape

The Magnani et al. (2014) experiment also explored the influence of different hammer strike locations on the resulting flake variability in the context of their force application experiment. They produced flakes by having the hammer strike either on the platform surface some distance away from the core exterior surface (platform strikes) or directly on the exterior platform edge (on-edge strikes). The latter simulates the common knapping technique used in biface thinning, often in association with the use of a soft hammer. Interestingly, the experimenters found that for on-edge strikes they had to lightly abrade the platform edge to reduce the chance of the core edge shattering upon hammer impact, especially when a steel hammer was used. This observation is consistent with the common flintknapping practice of edge abrasion in biface thinning, which is thought to make the edge more resistant to on-edge hammer impact (Sheets, 1973).

The Magnani et al. (2014) experiment showed that edge-struck flakes tend to be longer and wider compared to flakes made from platform strikes. This difference is particularly pronounced when the angle of blow is negative. Put simply, for a given platform depth, flakes made by striking the core edge at an inward angle (a negative angle of blow) are substantially longer and wider than those made by striking the platform surface at an outward angle (a positive angle of blow). However, as with angle of blow and hammer type discussed earlier, on-edge strikes also increase the occurrence of platform lipping and, hence bending fracture. It is thus unclear whether on-edge strikes directly increase the dimensions of the detached flakes or whether the increase in flake length and width is associated with the occurrence of bending fracture that is more prevalent with on-edge percussion.

A Flake Formation Model Generated from the Dibble Experiments

The Dibble experiments show that a number of variables, such as exterior platform angle, platform depth, angle of blow, core surface morphology, hammer material, hammer strike position, and platform beveling all play a role in determining the flake size and shape. However, among these variables, the strong effect of exterior platform angle and platform depth on flakes were repeatedly highlighted (Dibble & Rezek, 2009; Dogandžić et al., 2020; Leader et al., 2017; Magnani et al., 2014; Rezek et al., 2011). This outcome lends support to Dibble’s earlier observations concerning the dominant influence of the two platform attributes on the size and shape of flakes under conchoidal flaking. Specifically, the previous drop tower experiments by Dibble and colleagues (Dibble & Pelcin, 1995; Dibble & Whittaker, 1981) led to the development of a general model stating that flake mass is primarily determined by platform attributes, namely platform depth and exterior platform angle. Since the initial development of this general model, which we term the EPA-PD model, the prominent influence of platform depth and exterior platform angle in accounting for flake variability was verified by not only the updated Dibble experiments as summarized above but also studies of flintknapped and archaeological assemblages (Dibble, 1997; Dibble & Pelcin, 1995; Dibble & Rezek, 2009; Dibble & Whittaker, 1981; Dogandžić et al., 2015, 2020; Lin et al., 2013; McPherron et al., 2020; Režek et al., 2018). The EPA-PD model thus arguably captures a fundamental relationship between platform geometry and flake morphology in the flake formation process, though it is important to note that there is still a considerable amount of flake variability that cannot be explained by the model, especially when other factors (for instance, platform beveling and the angle of blow) are included in the experimental setting. We will elaborate more on these limitations of the model below.

Applications of the EPA-PD Model

Since its initial development, the EPA-PD model has been modified and applied in different forms by various researchers to interpret variation in archaeological assemblages for different purposes (Archer et al., 2018; Braun et al., 2019, 2008a; Clarkson & Hiscock, 2011; Dibble, 1997; Dogandžić et al., 2015, 2020; Lin et al., 2013; Režek et al., 2018; Shott et al., 2000; Shott & Seeman, 2017). At its core, the model uses key platform and flake attributes to predict the original blank size through linear regression analysis. One important application of the EPA-PD model is quantifying mass loss via retouch on retouched artifacts by predicting the original flake mass from platform attributes (and sometimes other flake variables). Being able to accurately estimate the mass loss of lithic artifacts at different stages of reduction is important for gauging technological curation and use-life management (Clarkson & Hiscock, 2011; Shott, 1996; Shott et al., 2000). To this end, studies have expanded upon the general EPA-ED model with the aim of accurately and reliably reconstructing the original blank size by using different platform and flake attributes (Archer et al., 2018; Clarkson & Hiscock, 2011; Davis & Shea, 1998; Dibble, 1997; Dogandžić et al., 2015, 2020; Hiscock & Tabrett, 2010; Shott et al., 2000; Shott & Seeman, 2017).

Another important application of the EPA-PD model is for understanding how knappers managed the EPA-PD relationship during knapping to achieve different flaking outcomes. The Dibble experiments demonstrated that the exterior platform angle and platform depth play a dominant role in determining not only the mass of a flake but also its shape. As such, variation between the two platform attributes directly impacts morphological features (such elongation and relative thickness) that dictate the economy of flake utility, especially in terms of cutting edge length and retouchable volume (Lin et al., 2013). Comparing the exterior platform angle and platform depth values among archaeological assemblages thus provides an effective means to identify patterns in the ways past knappers controlled the striking platform in order to manipulate and manage the production of cutting edge (Lin et al., 2013; Režek et al., 2018). Moreover, because both the exterior platform angle and platform depth can be directly measured on archaeological flakes, this application of the EPA-PD model allows disparate lithic assemblages to be compared on an objective and continuous scale of flake variability. With this approach, researchers can track the evolution of hominins’ knapping strategies across large spans of time and space using large datasets (Braun et al., 2019; Lin et al., 2013; Režek et al., 2018).

The EPA-PD Model Only Works Well in a Highly Controlled Setting

As mentioned already, a primary application of the EPA-PD model has been on estimating the original mass of flake blanks. Based on their plate glass experiments, Dibble and Pelcin (1995) and Pelcin (1996, 1998) published a series of linear regression models for predicting original flake mass based on platform depth and exterior platform angle. However, subsequent studies that applied these equations to flintknapped flakes have reported mixed results (Davis & Shea, 1998; Shott et al., 2000). This outcome is not entirely surprising, given that these equations were developed using the burin spall-like flakes that are arguably very different to flintknapped flakes. As Shott et al., (2000: 882) remarked, these equations “point the way but do not yet accurately estimate original size of knapped flakes.” Instead, researchers are encouraged to empirically define models for each assemblage in question (Dibble, 1998; Pelcin, 1998). Yet, while empirical models repeatedly show a considerable significant relationship between EPA-PD and flake size attributes (e.g., mass, surface area), these models have limited predictive value due to considerable error in the estimates, where the degree of over- or under-estimation can span an order of magnitude (Shott et al., 2000).

Some of these uncertainties in the EPA-PD model performance may be related to measurement error in linear measurements and angle values, as well as the crude approximation of platform area using linear dimensions (Dibble, 1998; Shott et al., 2000). Indeed, recent studies have shown that using 3D digitizing technologies to more accurately measure the size and shape of flake attributes can improve the performance of the EPA-PD model in explaining the flake mass variation (Archer et al., 2018; Clarkson & Hiscock, 2011). However, as mentioned earlier, even in cases where the EPA-PD model delivers strong predictive power with respect to flake mass, there is typically a notable amount of unaccounted-for variability when the model is applied to flintknapped or archaeological flakes (Braun et al., 2008a; Dogandžić et al., 2015). In comparison, the model performs very well under a strictly controlled setting, especially with flakes made by hard-hammer percussion on the platform surface and from cores with no platform beveling or core edge asymmetry (Dibble & Rezek, 2009; Leader et al., 2017; Magnani et al., 2014; Rezek et al., 2011). As discussed in the previous section, any change made to the striking condition that deviates from the “standardized” setting described in Dibble and Rezek (2009) has the potential to skew the EPA-PD model.

Based on the Dibble experiments summarized above, we identify here four major factors that can explain the decreased performance of the EPA-PD model when applied to flintknapped or archaeological flakes (i.e., factors that can cause the EPA-PD model to “break”). The first factor is the angle of blow. The Dibble and Rezek (2009) experiment showed that flakes become lighter as the angle of blow increases, even when exterior platform angle is held at a constant. The Magnani et al. (2014) experiment also found that negative angles of blow affect the EPA-PD relationship with flake mass. As such, the angle of blow represents an important source of variation in flake size/mass that is not captured by the EPA-PD model.

The second factor is platform beveling. As shown by Leader et al. (2017), the addition of platform beveling appears to change the EPA-PD relationship with flake mass, particularly with respect to platform depth. For instance, the platform depth of flakes made with a concave-beveled platform tends to be much smaller than the platform depth of a similar sized flake made with an unbeveled platform (Leader et al., 2017; McPherron et al., 2020). Similar observations regarding the effect of platform shape on flake size were made by Clarkson and Hiscock (2011). These findings indicate that the applicability of the EPA-PD model in part depends on the platform surface shape of the flakes in question.

The third factor is the hammer strike location. Results from the Magnani et al. (2014) experiment showed that the EPA-PD model does not work well in predicting flake mass when applied to flakes produced from on-edge strikes. This outcome is likely related to the heightened occurrence of bending fracture and platform lipping among flakes made from on-edge hammer strikes. As Magnani et al., (2014: 41) noted, given that in bending flakes the fractures begin some distance away from the point of hammer impact, there would be a certain amount of additional noise, or error, in the relationship between platform depth and flake size. Related to this, the fourth factor that complicates the EPA-PD model is the use of soft hammers. Studies have noted that the EPA-PD model performs better for hard-hammer flakes than soft-hammer flakes (Shott et al., 2000). Echoing these earlier observations, data from the Magnani et al. (2014) experiment show that the explanatory power of the EPA-PD model is lower for flakes made with the synthetic bone hammer compared to flakes made with the steel hammer. Both soft hammer percussion and on-edge strike tend to produce a higher frequency of non-conchoidally fractured flakes (i.e., bending flakes). Given that the EPA-PD model is developed exclusively using conchoidal flakes, it makes sense that the use of different hammer materials can reduce the accuracy of the EPA-PD model in reconstructing the original flake size.

Improving the EPA-PD Model

In a recent study, McPherron et al. (2020) examined the Dibble experimental dataset and observed that the fracture propagating from the point of percussion out towards the exterior core surface tends to occur at a more or less constant angle. This angle, which they termed the platform surface interior angle (or PSIA), is likely related to the Hertzian cone angle (which is a constant that varies with raw material type). The authors showed that, instead of the actual platform depth measured from the platform surface, estimating platform depth based on the PSIA and platform width can lead to much more accurate predictions of flake mass, particularly among flakes with beveled platforms. This finding indicates that the actual platform depth on flakes is an imperfect proxy for how far into the core a flake is struck, and it may be possible to improve the EPA-PD model and its performance by incorporating the PSIA (McPherron et al., 2020).

Another important step in refining the EPA-PD model is to integrate proxies for the angle of blow into the model. As mentioned already, the Dibble experiments have demonstrated the importance of the angle of blow in determining flake size. Where the angle of blow is known in the Dibble experimental dataset, adding the variable into the EPA-PD regression model (which we term the EPA-PD-AOB model) increases the model’s adjusted R-square from 0.80 to 0.91. The improvement in the model performance can be seen in Fig. 12, where the predicted flake mass from the updated EPA-PD-AOB model plots more tightly against the actual flake mass. Thus, efforts to explain flake variation need to consider the effect of the angle of blow. In a recent study, Li et al. (2022) introduced a proxy for the angle of blow, what they termed the bulb angle, that can be directly measured on the flake’s bulb of percussion. The authors showed that including the bulb angle into the EPA-PD model improved considerably the model’s performance in predicting flake mass in their study sample (adjusted R-square increased from 0.56 to 0.76 or 0.72 depending on how the bulb angle is measured). The bulb angle thus represents a useful attribute to incorporate into the EPA-PD model. However, it is important to note that there remain uncertainties regarding the bulb angle measurement and its comparability among raw material types. Because the Hertzian cone angle varies by material type, it is likely that the same angle of blow would result in different bulb angle values among different raw materials. More studies are thus needed to better integrate new variables such as the bulb angle and the PSIA into the EPA-PD model to improve its performance.

Limitations of the Dibble Experiments To Date

A major departure of the Dibble experiments from the earlier controlled flaking experiments (e.g., Cotterell et al., 1985; Cotterell & Kamminga, 1987; Speth, 1972, 1974, 1975) is their explicit shift away from fracture mechanics. Rather, the Dibble experiments were designed to test the empirical effects of various knapper-controlled variables on flake variability. As discussed in the section above, this approach has allowed the researchers to effectively evaluate the cause-and-effect of different knapping factors. While some of the results from the Dibble experiments support conventional views shared among replicative flintknappers, many findings illustrate a more nuanced and complex picture of the knapping process, where flake attributes are simultaneously influenced by multiple knapping variables at varying levels. Clarifying the complex relationships of these variables remains a challenging task for future research.

The knapper controlled variables that the Dibble experiments examined also broadly fall into two categories: those that are directly observable and measurable on flakes and cores and those that are not. For instance, Dibble focused on exterior platform angle and platform depth because these variables are measurable on actual flakes. So too are platform preparations and to an extent core surface morphology. However, variables like hammer hardness, strike force, and angle of blow cannot be easily derived from flakes up to now. Dibble’s hope was that the measurable attributes would have the largest impact on flaking outcomes and that the unmeasurable attributes would play at best only a minor role. If the opposite were true, then the whole set of experimental results and its applicability to the archaeological record would be questionable. The results summarized here seem to suggest that a mix of variables is at work. On the one hand, the EPA-PD model stands out as a clear finding. Knappers can alter their flaking outcomes by manipulating these two variables. It is also clear that measurable platform modifications like trimming and shaping are also impacting flaking outcomes, but it is unclear how they can be incorporated into the EPA-PD model to clearly quantify their impact on flake size and shape. The fact that the angle of blow also clearly has an impact on the EPA-PD relationship but remains unmeasurable on archaeological flakes makes it even more difficult to quantify the relationship between different variables. These two aspects together likely to a large extent account for the limits of the EPA-PD model in predicting flake size in archaeological collections.

In the following section, we consider this and some of the other limitations of the Dibble experiments, and we follow this by considering some future directions for experimentation.

The Collinearity and Equifinality of the Experimental Variables Should be Taken into Consideration in the Data Analysis

The Dibble experiments are specifically designed to control and isolate knapping variables so that only one of them is tested at a time. This ideally will allow researchers to record only the interactions between the tested independent variables and the dependent variables of interest. However, interactions among the various independent and dependent variables are far more complex and difficult to disentangle.

The interaction between platform width and platform depth on beveled flakes is an example of collinearity of the experimental variables. Platform beveling has been shown to cause the current EPA-PD model to underestimate flake mass on beveled flakes by changing the simple linear relationship between platform width and platform depth (Leader et al., 2017; McPherron et al., 2020). Although adding PSIA helps correct the EPA-PD model, it is still unclear whether platform width is acting independently or under the influence of platform depth (Lin et al., 2022). Equifinality is another commonly encountered issue when analyzing experimental variables. In the Magnani et al. (2014) experiment, factors such as hammer material, strike location, and the angle of blow are all found to possibly contribute to the variability in the EPA-PD model. In addition, Magnani et al. (2014) suggested that platform lipping may also introduce noise to the EPA-PD model because lipped flakes are generated from bending fracture, which is different from the conchoidal fracture that the EPA-PD model is built on. However, the presence of platform lipping can be influenced by changes in hammer material, strike location, and the angle of blow. It is thus difficult to identify the actual variable(s) responsible for lowering the correlation between EPA-PD and flake mass. These findings highlight the issue of equifinality in flake formation and caution against attempts to unambiguously infer a particular knapping technique on the basis of particular flaking attributes.

Up to now, most of the analyses in the Dibble experiments were done to examine the effect of individual variables on different flake attributes. These analyses are usually done in the form of linear correlations of the experimental variables and the various flake attributes, leading to the current EPA-PD model (Dibble & Rezek, 2009; Dogandžić et al., 2020; Leader et al., 2017; Magnani et al., 2014; Rezek et al., 2011). Although this approach shows that EPA-PD can account for a large portion of flake variability (Braun et al., 2019; Dibble, 1997; Dogandžić et al., 2020; Lin et al., 2013; Režek et al., 2018), the effect of many other variables that were examined in the Dibble experiments is left unexplained. For instance, variables such as core surface morphology, platform width, hammer material, the angle of blow, hammer strike location, and raw material type are all found to influence the flake size and/or shape, but they are not included in the EPA-PD model because (1) the effect of these variables is overshadowed by EPA-PD and (2) it is difficult to quantify the effect of some variables in the form of linear regression. Multivariate approaches such as general linear modeling (as conducted in Dogandžić et al., 2015) and principal component analysis (as conducted in Rezek et al., 2011) should be applied more to the Dibble experimental dataset to better understand the influence of the various experimental variables and to create a more comprehensive model of flake formation.

The Current Experimental Design Does Not Allow Certain Flaking Variables to be Examined as Independent Variables