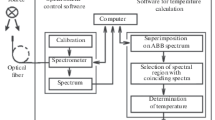

The prospects for thermal imaging and spectral technology in organizing the monitoring of laser technology processes for high-temperature modification of structural materials are analyzed. It is shown that the use of thermal imaging technology is appropriate during setup of these processes. For continuous monitoring it is more promising to use small-sized spectral technology. Solutions are proposed in which it can be used to conduct continuous monitoring based on the determination of two parameters: the effective heating temperature of the treated surface in the interaction region of the laser radiation and a parameter associated with the effective heating area. The prospects for introducing small-sized spectral devices for continuous monitoring into the feedback loop of the control system for laser systems are demonstrated.

Similar content being viewed by others

References

J. Dowden, The Theory of Laser Materials Processing, Springer Series in Materials Sciences, vol. 119, Springer, New York (2009), pp. 23–75.

H. Kyogoku and T. Ikeshoji, Mech. Eng. Rev., 7, No. 1, 1–19 (2020), https://doi.org/10.1299/mer.19-00182.

H. Helvajian, J. Laser Micro/Nanoengineering, 4, No. 1, 1–6 (2009), https://doi.org/10.1299/mer.19-00182.

W. Xizhao, D. Jun, J. Ming, K. Shanhao, W. Baoye, and Z. Xiaoyan, Int. J. Adv. Manuf. Technol., 92, 4571–4581 (2017), https://doi.org/10.1007/s00170-017-0413-z.

F. Calignano, M. Galati, and L. Iuliano, Machines, 7, No. 4, 72–93 (2019), https://doi.org/10.3390/machines7040072.

M. Skalon, B. Meier, A. Gruberbauer, and S. Amancio-Filho, Materials, 13, No. 3, 808–824 (2020), https://doi.org/10.3390/ma13030808.

H. Wang, W. Liu, Z. Tang, Y. Wang, X. Mei, K. M. Saleheen, Z. Wang, and H. Zhang, Opt. Eng., 59, No. 7, 070901(1–18) (2020), https://doi.org/10.1117/1.OE.59.7.070901.

S. Everton, M. Hirsch, P. Stravroulakis, R. Leach, and A. N. Clare, Mater. Design, 95, No. 5, 431–445 (2016), https://doi.org/10.1016/j.matdes.2016.01.099.

I. Eriksson, Optical Monitoring and Analysis of Laser Welding, Universitetstryckeriet, Luleе University of Technology (2011), pp. 1–82.

X. He, and T. Deb Roy, J. Appl. Phys., 94, No. 10, 6949–6958 (2003), https://doi.org/10.1063/1.1622118.

A. N. Cherepanov and V. P. Shapeev, Teplofi z. Aéromekh., 20, No. 2, 239–253 (2013).

V. I. Bogdanovich, M. G. Georbelidze, A. V. Sotov, N. D. Pronichev, V. G. Smelov, and A. V. Afapovichev, Izv. Samarskogo Nauch. Tsentra Ross. AN, 19, No. 4, 105–114 (2017).

T. Sibillano, A. Ancona, V. Berardi, and P. Lugara, Sensors, 9, No. 5, 3376–3385 (2009), https://doi.org/10.3390/s90503376.

Y. Saadlaoui, J. Sijobert, M. Doubenskaia, F. Bertrand, E. Feulvarch, and J. M. Bergheau, Crystals, 10, No. 4, 246 (2020), https://doi.org/10.3390/cryst10040246.

D. You, X. Gao, and S. Katayama, Science and Technology of Welding and Joining, 19, No. 3, 81–201 (2014), https://doi.org/10.1179/1362171813Y.0000000180.

J. Stavridis, A. Papacharalampopoulos, and P. Stavropoulos, Int. J. Adv. Manuf. Technol., 94, 1825–1847 (2017), https://doi.org/10.1007/s00170-017-0461-4.

Q. Pengyuan, W. Gang, G. Zhen, L. Xianghua, and W. Liu, Materials, 12, No. 20, 3322–3333 (2019), https://doi.org/10.3390/ma12203322.

G. Repossini, V. Laguzza, G. Marco, and B. Colosima, Additive Manuf., 16, 35–48 (2017), https://doi.org/10.1016/j.addma.2017.05.004.

I. Zhirnov, D. Kotoban, and A. Gusarov, Appl. Phys. A, 124, No. 2, 157–166 (2018), https://doi.org/10.1007/s00339-017-1532-y.

I. Zhirnov, C. Protasov, D. Kotoban, and A. Gusarov, J. Thermal Spray Technol., 26, No. 4, 648–660 (2017), https://doi.org/10.1007/s11666-017-0523-z.

D. Dagel, G. Grossetete, and O. Danny, Measurement of Laser Weld Temperatures for 3D Model Input, Sandia National Laboratories, New Mexico, US (2016), pp. 4–28.

D. Qu, J. Berry, N. Calta, M. Crumb, G. Guss, and M. J. Mathews, Phys. Rev. Appl., 14, 014031–014043 (2020), https://doi.org/10.1103/PhysRevApplied.14.014031.

L. Jacquemetton, M. Piltch, and D. Beckett, Thermal Calibration of Commercial Melt Pool Monitoring Sensors on a Laser Powder Bed Fusion System, Natl. Inst. Stand. Technol. Adv. Man. Ser., 100–35 (2020), p. 1–20, https://doi.org/10.6028/NIST.AMS.100-35.

W. Wójcik, V. Firago, A. Smolarz, I. Shedreyeva, and D. Yeraliyeva, Sensors, 22, 742–764 (2022), https://doi.org/10.3390/s22030742.

V. Firago and W. Wojcik, Przegląd Elektrotech., 91, No. 2, 208–214 (2015).

V. A. Firago, Digital Thermographys [in Russian], BGU, Minsk (2019), pp. 195, 236.

IMEC. Hyperspectral Imaging. Sensors. Available online at: https://www.imecint.com/en/hyper–spectral imaging (accessed on Sept. 17, 2018)

A. N. Magunov, Spectral Pyrometry [in Russian], Fizmatlit, Moscow (2012), pp. 23–38.

V. A. Firago, W. Wojcik, and M. S. Dzhunisbekov, Russ. Metallurgy (Metally), 11, 1224–1230 (2019), https://doi.org/10.1134/S0036029519110053.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Zhurnal Prikladnoi Spektroskopii, Vol. 89, No. 4, pp. 568–579, July–August, 2022. https://doi.org/10.47612/0514-7506-2022-89-4-568-579.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Firago, V.A., Devoino, O.G., Lapkovsky, A.S. et al. Monitoring of Laser Processing of Structural Materials Using Thermal Imaging and Spectral Technology. J Appl Spectrosc 89, 731–741 (2022). https://doi.org/10.1007/s10812-022-01418-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10812-022-01418-1