Abstract

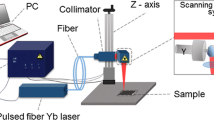

The principles of monitoring the laser processing of metals are considered; the design and the main parameters of the spectrophotometer designed on the base of an optical-fiber AvaSpec 2048 spectrometer with the spectral range 380–1050 nm are presented. The technique of its calibration is discussed and the obtained spectral sensitivity is reported. The measured spectra of optical and near IR radiation that forms in the contact region of CO2 laser radiation (wavelength 10.2 μm, power 1 kW) with the steel surface are presented. The problems of selecting the spectral portion in which the uncertainty of measuring temperature during contactless technological monitoring of high-temperature laser processes using thermographic devices will be minimal are discussed.

Similar content being viewed by others

REFERENCES

J. Dowden, The Theory of Laser Materials Processing (Springer Series in Materials Sciences, 2009), Vol. 119.

C. Meier, R. Penny, Y. Zoua, J. Gibbs, et al., “Thermophysical phenomena in metal additive manufacturing by selective laser melting: fundamentals, modeling, simulation and experimentation,” Ann. Rev. Heat Trans. (2018). https://doi.org/10.1615/AnnualRevHeattransfer.2018019042

H. Helvajian, “Laser material processing in the micro and nanometer domains: past, present and possibly the future,” J. Laser Micro/Nanoengineering 4 (1), 1–6 (2009).

M. Zain-ul-abdein, D. Nelias, J. Jullien, and D. Deloison, “”Prediction of laser beam welding-induced distortions and residual stresses by numerical simulation for aeronautic application,” J. Mater. Proc. Technol. 209, 2907–2917 (2009).

S. Ostuni, P. Leo, G. Gasalino, “FEM simulation of dissimilar aluminum titanium fiber laser welding using 2D and 3D Gaussian heat sources,” Metals 7 (8), 307 (2017).

X. He and T. Debroy, “Probing temperature during laser spot welding from vapor composition and modeling,” J. Appl. Phys. 94 (10), 6949–6958 (2003).

A. N. Cherpanov and V. P. Shapeev, “Modeling of laser welding of flat parts using modifying nanopowders,” Termophys. Aeromech. 20 (2), 237–250 (2013).

V. I. Bogdanovich, M. G. Giorbelidzhe, A. V. Sotov, et al., “Mathematical modeling of powder melting processes in the selective laser melting technology,” Izv. Samara Nauchn. Tsentr RAS 19 (4), 105–114 (2017).

L. S. Petrova, “Mathematical modeling of processes of heating of piece-homogeneous bodies with allowance for the heat flux relaxation,” Naukovedenie 9 (1), (2017). http://naukovedenie.ru/PDF/38TVN117.pdf.

M. N. Libenson, E. B. Yakovlev, and G. D. Shandybina, Interaction of Laser Radiation with a Material (Power Optics). Part I: Absorption of Laser Radiation in a Material: Abstract of Lectures, Ed. by V. P. Veiko (SPbGU ITMO, St. Petersburg, 2008).

M. N. Libenson, E. B. Yakovlev, and G. D. Shandybina, Interaction of Laser Radiation with a Material (Power Optics). Part II: Laser Heating and Fracture of Materials: Textbook, Ed. by V. P. Veiko (NIU ITMO, St. Petersburg, 2014).

T. Sibillano, A. Ancona, V. Berardi, and P. Lugara, “A real time spectroscopic sensor for monitoring laser welding processes,” Sensors 9 (5), 3376–3385 (2009).

V. A. Firago, “Principles of contactless monitoring parameters of laser processing of structural materials,” in Proceedings of X International Scientific-Engineering Conference on Quantum Electronics (Minsk, 2015), pp. 202–205.

I. Zhirnov, D. V. Kotoban, and A. V. Gusarov, “Evaporation-induced gas-phase flows at selective laser melting,” Appl. Phys. A 124 (2), 9 (2018).

I. Zhirnov, C. Protasov, D. Kotoban, A. V. Gusarov, and T. Tarasova, “New approach of true temperature restoration in optical diagnostics using IR-camera,” J. Therm. Spray Technol. 26 (4), 648–660 (2017).

D. Dagel, G. Grossetete, and O. Danny, Measurement of Laser Weld Temperature for 3D Model Input (Sandia National Laboratories, New Mexico, 2016).

D. You, X. Gao, and S. Katayama, “Review of laser welding monitoring,” Sci. Technol. Weld. Join. 19 (3), 181–201 (2014).

J. Stavridis, J. Papacharalampopoulos, and P. Stavropoulos, “Quality assessment in laser welding: a critical review,” Intern. J. Advanc. Manufact. Technol. 94 (5–8), 1825–1847 (2017).

V. Firago, and W. Wojcik, “High-temperature three-colour thermal imager,” Przeglad Electrotechn. 91 (2), 208–214 (2015).

V. Firago, W. Wojcik, and I. Volkova, “The principles of reducing temperature measurement uncertainty of modern thermal imaging systems,” Przeglad Electrotechn. 92 (8), 117–120 (2016).

A. N. Magunov, Spectral Pyrometry (Fizmatlit, Moscow, 2012).

V. A. Firago, I. A. Sakovich, and A. N. Sobchuk, “Spectrophotometer for determination of the emission spectrum forming in the region of action of power laser radiation,” in Proceedings of XI International Scientific-Engineering Conference on Quantum Electronics (Minsk, 2017), pp. 177–179.

V. A. Firago, A. G. Sen’kov, E. N. Savkova, and T. V. Golub, “Pyrometric monitoring of temperature of heated metals at mechanical-engineering enterprises,” Control. Diagnost., No. 5, 17–25 (2011).

Emitting Properties of Solids, Ed. by A.E. Sheindlin (Energiya, Moscow, 1974).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Yu. Ryzhkov

Rights and permissions

About this article

Cite this article

Firago, V.A., Wojcik, W. & Dzhunisbekov, M.S. Monitoring of the Metal Surface Temperature during Laser Processing. Russ. Metall. 2019, 1224–1230 (2019). https://doi.org/10.1134/S0036029519110053

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029519110053