Abstract

Industrial aquaculture has proliferated due to increased world demand for fish and seafood. Aerobic bacterial biofilters typically perform the nitrogen abatement of wastewater. Recirculation aquaculture systems (RAS) require nitrifying microorganisms developed in the biofilter. Despite the advantages of these biofilters, there are disadvantages, such as the time needed to mature, decrease in oxygen concentration, accumulation of organic matter and difficulty of backflushing, among others. On the other hand, microalgae effectively eliminate nutrients-pollutants, consuming inorganic carbon, nitrogen, and phosphorus and balancing soluble oxygen, conditions not attributable to nitrifying biofilters. The current study used a photo-biofilter to determine the depuration capacity of an immobilized co-culture of microalga Tetradesmus dimorphus and nitrifying bacteria isolated from a Salmon RAS. Bacteria frorm genera Flavobacterium, Microbacterium, Raoultella, Sphingobacterium, and Pseudomonas were identified. Biofilters were tested in sequential batch (lab-scale; 2.85 L) and continuous mode (pilot-plant scale; 120 L) attached to a RAS system for rearing rainbow trout. The algal–bacterial community structure was studied using 16S rRNA gene sequencing. Results showed that at typical loading rates, the algal–bacterial community could simultaneously remove ammonium, total ammonium nitrogen (TAN), nitrate and phosphate. Moreover, the system evaluated removed TAN daily, at an average of 1.18 kg per m3 of beads.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Recirculation aquaculture systems (RAS) can potentially reduce the environmental impacts of aquaculture compared to traditionally used open-flow systems. The latter requires an average of 30 m3 of fresh water per year for each kilogram of farmed trout, while RAS fluctuate between 0.3 and 3 m3 kg fish−1 year−1 allowing for 95.9–99.6% of water savings (Pedersen et al. 2012; Bregnballe 2015). The water treatment step must eliminate nitrogenous compounds (ammonium, nitrite and, optionally, nitrate), whose accumulation causes toxicity, decreased body size, increased mortality, abnormal behaviours, and skeletal deformities in fish (Martins et al. 2009; Davidson et al. 2014; Ciji and Akhtar 2020). Additional equipment should also supply the system's oxygen consumed by fish and nitrogen abatement. Ammonium and nitrite are the most damaging compounds, comparatively. For this reason, biological nitrification treatment in "Nitrifying Biofilters" has been the most employed method in RAS. In addition to nitrifying biofilters, other processes such as reverse osmosis and electrochemical technology have been reported to control nutrient concentrations (Qin et al. 2005; Gupta et al. 2015). However, its high energy requirement is an unavoidable drawback so far.

Additionally, nitrifying biofilters have other significant drawbacks that include a decrease in the concentration of dissolved O2, the contribution of CO2, alkalinity consumption, difficulty in filter back-rinsing, accumulation of organic matter and presence of undesired microorganisms. Nitrifying bacteria are obligate autotrophs that use carbon dioxide as the primary carbon source and require oxygen to grow (Hagopian and Riley 1998). In RAS biofilters, this group accounts for roughly 15% of the total bacterial community (Roalkvam et al. 2020). The fast-growing heterotrophic bacteria dominate the rest of the biofilm (Schreier et al. 2010). An inoculum with the desired nitrifying species is needed to activate a nitrifying biofilter. The biofilter containing plastic carriers could be fed with inoculum by a closed loop, or the biofilter could use carriers from a mature filter (Gutierrez-Wing and Malone 2006; Delong and Losordo 2012). Biofilm development on the carriers is time-consuming since nitrifying bacteria grow slowly (Gutierrez-Wing and Malone 2006; Zhang et al. 2019).

Microalgae already constitute a real possibility for the removal of nutrients from urban (de-Bashan and Bashan 2010; Calicioglu and Demirer 2019), industrial (Bordel et al. 2009; Wu et al. 2017) and agricultural wastewater (Markou and Georgakakis 2011; Jayakumar et al. 2017). Algal photobioreactors (PBR) have been proposed for aquaculture facilities as additional units. However, the two main concerns are economic and practical feasibility (light supply, high retention times) (Ramli et al. 2020). The culture of microalgae in wastewater is fascinating since they can take up both N and P in their biomass, which could eventually be used in agriculture. Microalgae grown in RAS systems could also produce biomass for aquaculture feeding (Rawat et al. 2011), thereby contributing to the circular economy approaches. In addition to the efficiency in removing nutrients, these systems can significantly reduce costs related to oxygenation and CO2 degassing (de Godos et al. 2009). The main limitations of using microalgae would be their culture systems, which require light-permeable surfaces and larger land areas (compared to nitrifying biofilters). In addition, another disadvantage of using algae in suspension is their unavoidable presence in the fishponds that would increase the turbidity, hindering fish feeding. Microalgal culture systems based on cell immobilization have attempted to overcome some previously discussed issues (He and Xue 2010; Pires et al. 2013). Cell encapsulation in a polymeric matrix and biofilm formation on a solid surface (Mallick 2002; Eroglu et al. 2015) are the standard methods for microalgal immobilization. Common polymeric matrixes are alginate and carrageenan. As with nitrifying bacteria, it is almost impossible to maintain a monoculture of microalgae in these processes. Far from being a problem for nutrient removal, several studies reported the advantages of using microalgal-bacterial consortia (Muñoz and Guieysse 2006; Subashchandrabose et al. 2011; Gonçalves et al. 2017; Sun et al. 2022). These consortia can occur naturally in the environment or be generated artificially by combining microorganisms that do not necessarily coexist for a specific purpose. Generally, photosynthetic microorganisms and heterotrophic bacteria constitute the microalgae and bacteria consortiums for wastewater treatment (Gonçalves et al. 2017). Before full-scale biofilters are designed and built in RAS, tests must be performed on pilot-scale units to determine the efficiency and design accuracy. Such pilot-scale tests also allow for the evaluation of system operation, performance, and economics.

The main goal of this research was to develop a pilot-scale biofiltration system that could be used to perform tests involving the depuration of N and P from Salmon RAS water. The specific objectives of this project were to: 1) Design and build three lab-scale biofilters and a pilot-scale biofilter with the capability to monitor various parameters such as temperature, irradiance, and flow rate, and 2) Test and compare the performance of the biofilter units for removing nitrate and phosphate. The novelty of this study also lies in the fact that the algal–bacterial lab-scale biofilter tested for N and P depuration was successfully scaled to a pilot unit attached to a RAS system for rearing rainbow trout.

Materials and methods

Natural aquaculture wastewater

A demonstration aquaculture recirculation system provided the wastewater (Department of Oceanography, Universidad de Concepción, Dichato, Bio-Bio, Chile). The facility reared Oncorhynchus mykiss (rainbow trout) under an intensive culture approach. For the optimization assays (described below), 0.3 m3 of water leaving the fishponds was treated and stored at 3ºC in a sealed container. Treatment consisted of 50 μm filtration and disinfection in a recirculated UV system for 12 h. The concentration of ammonium, nitrate and phosphate was checked daily; averaged values were 1.6 ± 0.5, 50 ± 0.4 and 7 ± 0.8 mg L−1, respectively.

Algal–bacterial beads preparation

The inoculum was composed of the microalga Tetradesmus dimorphus and nitrifying biomass obtained from the nitrification biofilter of the demonstrative aquaculture recirculation (Dichato, Bio-Bio, Chile). The microalgal strain was isolated from the fishponds using the standard serial-dilution technique (Button et al. 1993). The bacterial inoculum provided was cultured in agitated flasks (120 rpm) in a chamber at 10 °C using wastewater. Suspension of 0.5 g L−1 (dry weight) of T. dimorphus and the bacterial biomass was mixed in 1:1 proportion and then cultured in batch mode using the aquaculture wastewater supplemented with NH4Cl up to 20 mg L−1. These cultures were carried out in 2 L agitated flasks with 0.75 L of working volume under agitation in an orbital shaker and an irradiance of 100 µmol photons m−2 s−1. After two consecutive batches, where the initial ammonium concentration (20 mg L−1) was abated (approximately 15 days), biomass was concentrated by centrifugation from 1.6 to 15 g L−1. This suspension was the feedstock for the formulation of microalgal-bacterial alginate beads. Food grade sodium alginate (W201502; Sigma-Aldrich) was weighed and dispersed slowly in cold distilled water to achieve a concentration of 2% w/v and then heated with continued stirring until a clear solution was obtained (approximately 30 min). It was then transferred to a container and allowed to stand for 24 h to eliminate air bubbles formed during homogenization. The algal–bacterial suspension and the alginate solution were mixed in 1:10 proportion. Then, the alginate solution was dropped into a 2 w/v% calcium chloride (CaCl2) solution to form alginate beads. The diameter of the discharge tip gives the size of the sphere. This study prepared spheres with a nominal diameter of 3 mm. Beads were allowed to harden for 5 h before use in the photobioreactors.

Algal–bacterial genetic characterization

A genetic analysis assessed the algal–bacterial biomass grown. Microbial community analyses were based on 16S rRNA. Algal–bacterial biomass was suspended in PBS (phosphate buffered saline at pH = 7.5) and then diluted in series with a dilution factor of 10. Onehundred μL of the algal–bacterial biomass solution was transferred to Trypto-Casein Soy Agar (TSA) or Luria–Bertani Agar (LBA; Lennox) plates for incubation at 18 °C for ten days. Isolated colonies were cultured under similar conditions three times consecutively. Then the biomass was transferred to a Tryptic Soy Broth (TSB) medium, cultured for four days, and harvested (centrifuged at 15,900 RCF for 15 min, followed by supernatant removal). DNA extraction followed the protocol of the EZNA bacterial DNA extraction kit (Omega Bio-Tek, USA). Total genomic DNA was quantified using an Epoch® micro-volume spectrophotometer system (BioTek Instruments, USA). DNA quality was verified in a UV transilluminator using agarose gel (1.0% w/v) stained with GelRed Nucleic Acid Gel StainTM (Biotium, USA). DNA samples were stored at -20 °C. Specific markers for denitrification (nriK and nirS), nitrite oxidation (nxrB), ammonium oxidation (amoA and cmx) and nitrogen-fixing (nifh) were assayed (Touchdown-PCR; Don et al. 1991). The molecular classification of the isolated bacterial strains was based on the 16S rRNA gene sequences using the commercial kit SapphireAmp Fast PCR Master Mix (Takara Bio, Japan). The assay used 250 ng of DNA and 200 nM of each primer. PCR products were analyzed in a UV transilluminator using agarose gel (1.5% w/v) stained with GelRed Nucleic Acid Gel Stain (Biotium, USA). Likewise, PCR products were purified and sequenced by MACROGEN Inc. (Seoul, Korea) using an ABI3730 ADN XL Analyser (Applied Biosystems). The platform Geneious R11 (Biomatters Ltd, NZ) processed the sequences. The bioinformatics pipeline included clustering, error-trimming, and taxonomic classification. The 16S rRNA gene sequences are available at GenBank (Benson et al. 2008), ENA (Leinonen et al. 2011) and DDBJ (Kaminuma et al. 2010).

Optimization of operating parameters in lab-scale

An experimental design was carried out in a lab-scale photobioreactor (see details below) to optimize operating parameters. A Response Surface Design (Central Composite) was the model chosen to evaluate the effect of three factors (incident irradiance and air and liquid flow) with a total of 17 experiments (resumed in Table 1). The experiment response variables were the concentration of ammonium, nitrate, and phosphate, expressed in mg L−1 over time. The study considered a duplication of each sample.

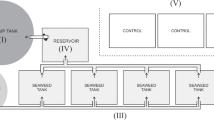

Lab-scale algal–bacterial biofilter

Lab-scale experiments required building three three-phase fluidized photobioreactors (Fig. 1). Each 3 L photobioreactor was custom manufactured using cylindrical methacrylate tubes (polymethyl methacrylate, PMMA), with external dimensions of 74 cm height and 9 cm diameter. The working liquid volume was 2.85 L. The setup included an air compressor, individual buffer tanks, pumps and additional instrumentation for adjusting air and fluid inlet flow. Temperature control systems in buffer tanks kept the temperature at 10ºC. Light-emitting diode (LED) string placed inside the transparent cylindrical vessel using a sealed tube with 2 cm of diameter supplied light to the photobioreactors.

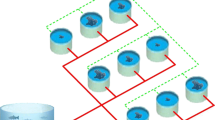

Pilot-scale algal–bacterial biofilter

Pilot-scale biofilters were built, installed, and operated in a RAS line of an aquaculture facility at Dichato (Bio-Bio, Chile) for rearing rainbow trout using commercial polyvinyl chloride (PVC) pipes and accessories (Fig. 2). The facility operates as a typical RAS system with auxiliary equipment for water recirculation (e.g., sand filter, air blowers, submerged nitrifying biofilter, etc.). The pilot-scale algal–bacterial biofilter used pumped wastewater from a fishpond with fish weighing 100 and 200 g during operation. The average fish density was 25 kg m−3, and the fed rate was 1 to 1.5% of their daily body weight. The protocol included daily environmental parameters checking. Table 2 summarises lab- and pilot-scale biofilter dimensions and alginate beads-related parameters. Vessels 0.95 m high and 0.4 m wide had a working volume of 120 L. Air flowed at 6 L min−1 (0.3 L min−1 through 20 sparger holes). Inlet flow (water recirculation) was 3 L min−1, and 40 min of hydraulic retention time. Irradiance was kept at 200 µmol photons m−2 s−1 using four fluorescent lamps (T8 Tuxline F25W/30"/840) located outside the vessel (Fig. 2). The study protocol included the analysis of ammonium, nitrate and phosphate by duplicating each sample.

Chemical analysis

Standard analytical procedures determined the nutrient concentrations. The nitrate and phosphate quantification protocols were 4500-P and 4500-N from APHA (APHA 2012) using a Biotek EpochTM microplate spectrophotometer. Ammonium was quantified using Nessler Reagent (K2HgI4) according to a modified version of the ASTM D1426-08 method (ASTM 2008). Additionally, nutrient removal measurements for batch assays followed the equation (Eq. 1):

Cinlet and Coutlet are inlet and outlet concentrations (mg L−1) of a particular nutrient. t represents treatment time (hours) (the experimental design time setup was 5 h).

For continuous systems, the depuration rate (mg L−1 day−1) equation is:

Surface and volumetric depuration rates were calculated from Eqs. 3 and 4, respectively:

where Cinlet and Coutlet are inlet and outlet concentrations of a particular nutrient, respectively; Q is inlet liquid flow; Abeads is the total surface area of alginate beads; V is the working liquid volume in the biofilter; Vbeads is the total volume of alginate beads; Abeads and Vbeads assumed that the bead shape was spherical (3 mm in diameter). SDR and VDR were calculated in mg m−2 day−1 and mg L−1 day−1, respectively.

Statistical analysis

Statistical analyses used the multivariate statistical software package Statgraphics Centurion XIV (USA). The experimental results were the average values of the two independent samples (N = 2) and their standard deviation. Normality and homogeneity analysis used the Kolmogorov–Smirnov and Levene tests. A three-factor ANOVA analysis was performed for the operating condition optimization.

Results

The consortium algal–bacterial (biomass) came from a non-axenic isolated microalgal culture and bacterial biomass extracted from a mature biofilter grown on a plastic carrier (Kaldness, K1). This biomass forms a dense biofilm on the plastic support as the biofilter works for more than 12 months. The Materials and Methods section indicated that algal and bacterial inoculum was mixed and co-cultured. Then, two batches arranged sequentially operate for 15 days (each) using outlet pond water supplemented with an ammonium concentration of 20 mg L−1. The biomass was harvested by centrifugation from an initial concentration of 1.6 g L−1 (in the broth) to 15 g L−1.

The culture condition simultaneously considered bacterial and microalgal growth (See Materials and Methods section). Characterizing any RAS biofilter in bacterial communities is essential for understanding biofilter performance. The biofilter's stability and efficiency depend on the dynamic balance of the bacterial groups that should be adapted to the specific conditions of every RAS (Schreier et al. 2010). In the present study a source of irradiance and the presence of microalgae may also impact bacterial diversity. Consequently, the study included measuring the bacterial composition after the microalgal-bacterial co-culture. Results showed at least twelve viable heterotrophic aerobic bacterial strains, recoverable in culture using TSA, and five likely heterotrophic aerobic bacterial strains, recoverable in the culture at 18 °C using LBA. Only ten bacterial strains from the isolated ones showed the presence of genetic markers (at least one) associated with the denitrification process (nriK and nirS), nitrite oxidation (nxrB), ammonium oxidation (amoA and cmx), or nitrogen fixation (nifH). Table 3 lists the classification and characterization of isolated bacterial strains.

The study on optimizing the operating conditions of algal–bacterial biofilters relied on previous tests. Accordingly, earlier runs in batch mode defined the accurate sampling time for the optimization experiments. As shown in Fig. 3A, differences in depletion rates for each nutrient compromised the sampling time based on ammonium concentration. In other words, the removal of almost all ammonium took 5 h. The removal rate for nitrate was steady after the first hour, whereas the phosphate removal rate slope slightly decreased after 5 h. The experimental time (24 h) was insufficient to remove nitrate and phosphate altogether. Additionally, the medium condition combination of airflow and irradiance performed well for removing ammonium, according to Fig. 3B.

Ammonium depuration rate (mg L−1 h−1) was the response variable for the experimental design. Table 1 shows the experimental design for optimizing the lab-scale biofilter operating conditions. A bubble column reactor of 2.85 L with airflow rate from 0.1 to 0.5 L min−1 implied a volume of air/volume of liquid/time ratio (typically volume/volume/minute) of 0.035, 0.105 and 0.176 vvm for low, medium and high flow rates, respectively. These are typical values for a bubble column reactor with suspended microalgae (Sánchez Mirón et al. 2000). On the other hand, bubble column reactors with continuous water flow are not typical in microalgal processes, and fluid dynamics depend only on bubbling. In our system, we imposed liquid flow rates of 1, 3 and 5 L min−1 (low, medium and high, respectively), achieving hydraulic retention times of 2.85, 0.95 and 0.57 min, respectively. These values were comparatively lower than those of tubular photobioreactors. Tubular PBRs, for instance, keep liquid rates from 0.25 to 0.5 m s−1 in the solar collector (Acién Fernández et al. 1999; Molina et al. 2001) resulting, for 9 cm diameter tubes, in a water flow of around 190 L min−1. In tubular photobioreactors, a turbulent flow regime (high flow rates) is required in the tubes for the cells to be equally exposed to light. The only source of turbulence is the liquid flow (its velocity). In our experiments, water and air flow upward mixed, requiring much less flow to homogenates beads. Based on literature, the limiting, optimal and saturating irradiance of the microalgal strain were 7, 206 and 406 µmol photons m−2 s−1, respectively (Macintyre et al. 2002).

Table 4 summarizes the results from the ANOVA analysis. This analysis explored the influence of A, B and C factors on the response variable (ammonium depuration rate). Only airflow and irradiance influence the response variable (P-value < 0.05). Based on F-ratio values, we can conclude that the airflow had a more substantial impact on the response variable than irradiance (9.28 vs 6.62). Figure 3B shows the dependence of the ammonium depuration rates against the airflow and the irradiance. The medium irradiance and airflow conditions achieved the maximum values.

The lab-scale biofilter system was scaled up to 120 L. The pilot-scale biofilter operated in a steady-state mode for 20 days at 3 L min−1 of wastewater. The hydraulic retention time was 40 min, higher than the hydraulic retention in lab-scale system (Table 2). The pilot-scale biofilter considered a similar density value of beads to the lab-scale biofilter. The aspect ratio was modified, resulting in a less slender biofilter (Fig. 2). Pipes and fitting were PVC standard water supply items. For bubbling, an inlet airflow of 6 L min−1 flowed through 20 holes homogenously distributed, resulting in a flow of 0.3 L min−1 per inlet hole. The setting of the inlet airflow and irradiance considered those operating conditions where the lab-scale reactor achieved the maximum ammonium depuration rate (Fig. 3B). Figure 4 shows the evolution of inlet and outlet concentrations of ammonium (Fig. 4A), nitrate (Fig. 4B) and phosphate (Fig. 4C). For example, an initial ammonium concentration of 4 mg L−1 shown in Fig. 4A was reduced to 0.3 mg L−1, estimating an average ammonium depuration rate of 0.1 mg L−1 min−1 (148.5 mg L−1 day−1). Table 5 summarizes the average depuration rates at operation parameters.

The algal–bacterial systems have a distinct advantage on removing nitrate and phosphate because microalgae fix it into their biomass. Our system consumed 78% and 64% of the nitrate and phosphate, achieving removal rates of 284.7 and 165.5 mg L−1 day−1, respectively.

Discussion

A wide variety of commercial biofilters are available elsewhere for aquaculture facilities running at different operation conditions, enabling comparisons within them (Malone and Pfeiffer 2006). Bacterial biofilters have two approaches, suspended growth and fixed film. Although the first is a lesser standard, microbial floc systems were proposed to produce tilapia and marine shrimp (McIntosh 2001; Browdy et al. 2009). A bacterial biofilm is formed either in a moving or fixed carrier. The floating bead filters used in this study typically depurate at 140 to 350 mg L−1 day−1 (Malone and Beecher 2000). Microbead or fluidized sand biofilters have good volumetric depuration rates (200–1000 mg L−1 day−1 (Timmons et al. 2006); however, they are energy-intensive reactors and high-cost operation systems (Timmons et al. 2006). The floating bead bioreactor uses plastic carriers (e.g., Kaldness K1) to avoid clogging. The plastic media have a common surface area of 250–500 m2 m−3. The bacterial biomass film covering the plastic carrier usually achieves depuration rates from 200 to 400 mg L−1 day−1 (Rusten et al. 2006). These depuration rates are higher than in this study; however, researchers studied and optimized bacterial systems for decades, which is still not the case with our biological system. In response, we could increase the depuration rates by expanding the number of beads per unit of volume though we should find an optimum value for irradiance for pilot-scale biofilter.

Due to its high volatility, a part of NH3 can be removed abiotically. The rate of ammonia volatilization is known to be pH-dependent. For pH < 8 the proportion of NH3 is less than 10% (Eshchar et al. 2006). Since, rainbow trout ponds were maintained at a pH around 7, most of the ammonia would be in its ionized form (NH4+). The range of pH for bacteria in moving bed bioreactors is similar to microalgal cultures (Shitu et al. 2022). Therefore, there are no advantages of one system over the other in this aspect. For both systems most of the ammoniacal nitrogen is removed biotically. For instance, in sparged microalgal cultures with pH in the range of 7–8, volatilization was shown to be under 5% (Yu et al. 2022).

The literature describes only a few examples of immobilized algae systems for RAS. Ramli et al. (2017) compared the performance of bubbling column photobioreactors with suspended Stigeoclonium nanum or S. nanum immobilized in alginate beads. The main advantage of this species is that its filamentous appearance allows it to adapt well to immobilized systems. Their results showed higher TAN removal in immobilized alginate beads than in free suspension cultures. Notwithstanding, the ammonium depuration rate was less than 1 mg L−1 day−1 in their best scenario (Ramli et al. 2017). Although limited studies refer to the use of microalgae in RAS facilities, they propose integrating microalgal cultures (suspended or immobilized) as an additional treatment unit (Ramli et al. 2020). The additional unit could be incorporated alone or with a nitrification biofilter. In the first case, the ammonium tolerance of the selected microalgal species is critical. Accordingly, these systems' high retention times and light supply are the two main issues, introducing a meaningful impact on production costs. For example, production costs could grow 20 to 30% if only microalgae assimilate all the ammonia-N generated in a tilapia RAS facility (Ramli et al. 2020). Although these systems are not yet fully optimized, microalgae introduce other vital advantages.

The microbial communities from RAS biofilters with different fish species vary significantly in their composition from one another (Sugita et al. 2005). However, the type of water (freshwater or marine) or specific RAS operating conditions (e.g., installation of UV lamps and ozonizers) leads to unique microbial flora development (Schreier et al. 2010). A nitrification biofilter was originally the source of the bacterial biomass; consequently, it was expected to find Nitrosomonas, Nitrosococcus and Nitrospira. Nonetheless, Flavobacterium and Sphingobacterium were identified along with the heterotrophic bacteria (e.g. Pseudomonas stutzeri), also commonly found in RAS systems. Contrary to expected, the analysis did not show the heterotrophic denitrifiers since anaerobic conditions were incompatible with photosynthetic oxygen produced within the algal–bacterial beads.

Ramli et al. (2017) reported significant differences in the composition of bacterial communities between a conventional RAS system and a RAS supplemented with an algal pond as an additional treatment unit. The authors concluded that the bacteria contributing to those differences were mainly heterotrophic. This additional unit contributed to stabilized nitrite concentrations after any system perturbation.

Our pilot-scale biofilter reached 78% and 64% of the nitrate and phosphate consumption, meaning depuration rates of 284.7 and 165.5 mg L−1 day−1, respectively. These values are high compared to systems that use immobilized microalgae for treating wastewater (tertiary/polishing treatment) (Taziki et al. 2015). However, different strains, operational conditions and immobilization techniques led to considerable differences in the depuration rates. Mallick and Rai (1994) compared N-nitrate and N-nitrite depuration rates of two photosynthetic cells: Anabaena doliolum and Chlorella vulgaris. The comparison between suspended cells and cells immobilized in chitosan, agar, alginate, and carrageenan showed the best results for chitosan biomedia. In this case, A. doliolum and C. vulgaris reached nitrate depuration rates of 3.66 and 2.86 μg mg−1 h−1 (based on dry biomass), respectively. Our study reached nitrate depuration rates of 86.2 μg mg−1 h−1 (based on dry biomass). The inhibition effect of high ammonium concentration or other inhibitor constituents of the wastewater could explain these differences. Algal–bacterial beads used in this study performed well in nitrate removal, even if we compared them to suspended microalgal cultures. For example, the best results found for C. vulgaris and Neochloris oleoabundans are 103.3 and 150.74 mg L−1 day−1, respectively (Li et al. 2008; Hulatt et al. 2012).

Unlike nitrate, microalgae actively store phosphate (Powell et al. 2009). They face low concentrations of phosphate in their natural environment. Therefore, microalgae must store a large amount of phosphate whenever it becomes available (Solovchenko et al. 2019). However, high concentrations of phosphate could inhibit growth. For instance, more than 150 mg L−1 and 24 mg L−1 inhibited growth of the green microalga Chlorella (Li et al. 2018)) and the dinoflagellate Peridinium reticulatum (Gallardo-Rodríguez et al. 2009), respectively. Phosphate uptake rates strongly depend on the strain and operational conditions. To illustrate, suspended C. vulgaris achieved a phosphate depuration rate of 62 mg L−1 day−1 (Singh et al. 2018), but phosphate depuration rates by C. vulgaris decreased to 2 mg L−1 day−1 for wastewater (Lavrinovics et al. 2021). Other species showed values even lower, as Lavrinovics et al. (2021) reported.

Conclusions

We demonstrated the improvement in the depuration rates using a biofilter with immobilized algal–bacterial beads. The ammonium depuration rates of the pilot-scale continuous photo-biofilter were comparable to industrial bacterial biofilters, but our photo-biofilters could reduce operational costs and recycle exhausted algal–bacterial biomass. The primary concern is the beads' mechanical and physical stability and durability. Further investigation should predict the life span of beads to determine the harvesting time of biofilters biomedia. The algal–bacterial biomass from our biofilters is a valuable by-product of the aquaculture facilities, unlike typical plastic biomedia. Microalgae capture different forms of nitrogen and phosphorus, unlike bacteria of traditional nitrification–denitrification systems. Accordingly, the obvious application for our algal–bacterial biomass is the production of biofertilizers and biostimulants. Ongoing studies also include transforming biomass into new applications like biomaterials.

Data availability

Data will be available from the corresponding author on request.

Change history

16 July 2023

Incorrect Open Access funding information has been corrected in the Funding Note.

References

AciénFernández FG, García Camacho F, Chisti Y (1999) Photobioreactors: Light regime, mass transfer, and scaleup. Prog Ind Microbiol 35:231–247

APHA (2012) Standard methods for the examination of water & wastewater, 22nd edn. American Public Health Association, Washington DC

ASTM (2008) Standard test methods for ammonia nitrogen in water ASTM D1426–08. ASTM International, West Conshohocken

Benson DA, Karsch-Mizrachi I, Lipman DJ, Ostell J, Wheeler DL (2008) GenBank. Nucleic Acids Res 36:25–30

Bordel S, Guieysse B, Muñoz R (2009) Mechanistic model for the reclamation of industrial wastewaters using algal−bacterial photobioreactors. Environ Sci Technol 43:3200–3207

Button DK, Schut F, Quang P, Martin R, Robertson BR (1993) Viability and isolation of typical marine oligotrophic bacteria by dilution culture: theory, procedures and initial results. Appl Environ Microbiol 59:881–891

Bregnballe J (2015) A guide to recirculation aquaculture. Food and Agriculture Organization of the United Nations (FAO) and EUROFISH International Organisation. https://www.fao.org/3/i4626e/i4626e.pdf

Browdy CL, Venero JA, Stokes AD, Leffler J (2009) Superintensive bio-floc production technologies for marine shrimp Litopenaeus vannamei: Technical challenges and opportunities. In: Burnell G, Allan G (Eds), New Technologies in Aquaculture, Woodhead Publishing, Cambridge, pp 1010–1028

Calicioglu O, Demirer GN (2019) Carbon-to-nitrogen and substrate-to-inoculum ratio adjustments can improve co-digestion performance of microalgal biomass obtained from domestic wastewater treatment. Environ Technol 40:614–624

Ciji A, Akhtar MS (2020) Nitrite implications and its management strategies in aquaculture: a review. Rev Aquac 12:878–908

Davidson J, Good C, Welsh C, Summerfelt ST (2014) Comparing the effects of high vs. low nitrate on the health, performance, and welfare of juvenile rainbow trout Oncorhynchus mykiss within water recirculation aquaculture systems. Aquac Eng 59:30–40

de-Bashan LE, Bashan Y (2010) Immobilized microalgae for removing pollutants: a review of practical aspects. Bioresour Technol 101:1611–27

de Godos I, González C, Becares E, García-Encina PA, Muñoz R (2009) Simultaneous nutrients and carbon removal during pretreated swine slurry degradation in a tubular biofilm photobioreactor. Appl Microbiol Biotechnol 82:187–194

Delong DP, Losordo TM (2012) How to start a biofilter, SRAC Publication Nº 4502. http://aquaculture.ca.uky.edu/sites/aquaculture.ca.uky.edu/files/srac_4502_how_to_start_a_biofilter.pdf

Eroglu E, Smith SM, Raston CL (2015) Application of various immobilization techniques for algal bioprocesses. In: Moheimani N, McHenry M, de Boer K, Bahri P (Eds) Biomass and biofuels from microalgae. Springer, Cham, pp 19–24

Eshchar M, Lahav O, Mozes N, Peduel A, Ron B (2006) Intensive fish culture at high ammonium and low pH. Aquaculture 255:301–313

Gallardo-Rodríguez JJ, Sánchez-Mirón A, Cerón-García MC, Belarbi EH, García-Camacho F, Chisti Y, Molina-Grima E (2009) Macronutrients requirements of the dinoflagellate Protoceratium reticulatum. Harmful Algae 8:239–246

Gonçalves AL, Pires JCM, Simões M (2017) A review on the use of microalgal consortia for wastewater treatment. Algal Res 24:403–415

Gupta VK, Sadegh H, Yari M, ShahryariGhoshekandi R, Maazinejad B, Chahardori M (2015) Removal of ammonium ions from wastewater: A short review in development of efficient methods. Glob J Environ Sci Manag 1:149–158

Gutierrez-Wing MT, Malone RF (2006) Biological filters in aquaculture: Trends and research directions for freshwater and marine applications. Aquac Eng 34:163–171

Hagopian DS, Riley JG (1998) A closer look at the bacteriology of nitrification. Aquac Eng 18:223–244

He S, Xue G (2010) Algal-based immobilization process to treat the effluent from a secondary wastewater treatment plant (WWTP). J Hazard Mater 178:895–899

Hulatt CJ, Lakaniemi AN, Puhakka JA, Thomas DN (2012) Energy demands of nitrogen supply in mass cultivation of two commercially important microalgal species, Chlorella vulgaris and Dunaliella tertiolecta. BioEnergy Res 5:669–684

Jayakumar S, Yusoff MM, Rahim MHA, Maniam GP, Govindan N (2017) The prospect of microalgal biodiesel using agro-industrial and industrial wastes in Malaysia. Renew Sustain Energy Rev 72:33–47

Kaminuma E, Mashima J, Kodama Y, Gojobori T, Ogasawara O, Okubo K, Takagi T, Nakamura Y (2010) DDBJ launches a new archive database with analytical tools for next-generation sequence data. Nucleic Acids Res 38:33–38

Lavrinovics A, Murby F, Zıverte E, Mežule L, Juhna T (2021) Increasing phosphorus uptake efficiency by phosphorus-starved microalgae for municipal wastewater post-treatment. Microorganisms 9:1598

Leinonen R, Akhtar R, Birney E, Bower L, Cerdeno-Tárraga A, Cheng Y, Cleland I, Faruque N, Goodgame N, Gibson R, Hoad G, Jang M, Pakseresht N, Plaister S, Radhakrishnan R, Reddy K, Sobhany S, Ten Hoopen P, Vaughan R, Zalunin V, Cochrane G (2011) The European nucleotide archive. Nucleic Acids Res 39:28–31

Li Y, Horsman M, Wang B, Wu N, Lan CQ (2008) Effects of nitrogen sources on cell growth and lipid accumulation of green alga Neochloris oleoabundans. Appl Microbiol Biotechnol 81:629–636

Li Q, Fu L, Wang Y, Zhou D, Rittmann BE (2018) Excessive phosphorus caused inhibition and cell damage during heterotrophic growth of Chlorella regularis. Bioresour Technol 268:266–270

Macintyre HL, Kana TM, Anning T, Geider RJ (2002) Photoacclimation of photosynthesis irradiance response curves and photosynthetic pigments in microalgae and cyanobacteria. J Phycol 38:17–38

Mallick N (2002) Biotechnological potential of immobilized algae for wastewater N, P and metal removal: A review. Biometals 15:377–390

Mallick N, Rai LC (1994) Removal of inorganic ions from wastewaters by immobilized microalgae. World J Microbiol Biotechnol 10:493–443

Malone RF, Beecher LE (2000) Use of floating bead filters to recondition recirculating waters in warmwater aquaculture production systems. Aquac Eng 22:57–73

Malone RF, Pfeiffer TJ (2006) Rating fixed film nitrifying biofilters used in recirculating aquaculture systems. Aquac Eng 34:389–402

Markou G, Georgakakis D (2011) Cultivation of filamentous cyanobacteria (blue-green algae) in agro-industrial wastes and wastewaters: A review. Appl Energy 88:3389–3401

Martins CIM, Pistrin MG, Ende SSW, Eding EH, Verreth JAJ (2009) The accumulation of substances in Recirculating Aquaculture Systems (RAS) affects embryonic and larval development in common carp Cyprinus carpio. Aquaculture 291:65–73

McIntosh RP (2001) High rate bacterial systems for culturing shrimp. In: Proceedings from the Aquacultural Engineering Society's Second Issues Forum, Ithaca, NRAES-157, pp 117–129

Molina E, Fernández J, Acién FGG, Chisti Y (2001) Tubular photobioreactor design for algal cultures. J Biotechnol 92:113–131

Muñoz R, Guieysse B (2006) Algal–bacterial processes for the treatment of hazardous contaminants: A review. Water Res 40:2799–2815

Pedersen LF, Suhr KI, Dalsgaard J, Pedersen PB, Arvin E (2012) Effects of feed loading on nitrogen balances and fish performance in replicated recirculating aquaculture systems. Aquaculture 338–341:237–245

Pires JCM, Alvim-Ferraz MCM, Martins FG, Simões M (2013) Wastewater treatment to enhance the economic viability of microalgae culture. Environ Sci Pollut Res 20:5096–5105

Powell N, Shilton A, Chisti Y, Pratt S (2009) Towards a luxury uptake process via microalgae – Defining the polyphosphate dynamics.Water Res 43:4207–4213

Qin G, Liu CCK, Richman NH, Moncur JET (2005) Aquaculture wastewater treatment and reuse by wind-driven reverse osmosis membrane technology: a pilot study on Coconut Island. Hawaii Aquac Eng 32:365–378

Ramli NM, Verdegem MCJ, Yusoff FM, Zulkifely MK, Verreth JAJ (2017) Removal of ammonium and nitrate in recirculating aquaculture systems by the epiphyte Stigeoclonium nanum immobilized in alginate beads. Aquac Environ Interact 9:213–222

Ramli NM, Verreth JAJ, Yusoff FM, Nurulhuda K, Nagao N, Verdegem MCJ (2020) Integration of algae to improve nitrogenous waste management in recirculating aquaculture systems: a review. Front Bioeng Biotechnol 8:1004

Rawat I, Ranjith Kumar R, Mutanda T, Bux F (2011) Dual role of microalgae: Phycoremediation of domestic wastewater and biomass production for sustainable biofuels production. Appl Energy 88:3411–3424

Roalkvam I, Drønen K, Dahle H, Wergeland HI (2020) Comparison of active biofilm carriers and commercially available inoculum for activation of biofilters in marine recirculating aquaculture systems (RAS). Aquaculture 514:734480

Rusten B, Eikebrokk B, Ulgenes Y, Lygren E (2006) Design and operations of the Kaldnes moving bed biofilm reactors. Aquac Eng 34:322–331

Sánchez Mirón A, García Camacho F, Contreras Gómez A, Molina Grima E, Chisti Y (2000) Bubble-column and airlift photobioreactors for algal culture. AIChE J 46:1872–1887

Schreier HJ, Mirzoyan N, Saito K (2010) Microbial diversity of biological filters in recirculating aquaculture systems. Curr Opin Biotechnol 21:318–325

Shitu A, Liu G, Muhammad AI, Zhang Y, Tadda MA, Qi W, Liu D, Ye Z, Zhu S (2022) Recent advances in application of moving bed bioreactors for wastewater treatment from recirculating aquaculture systems: A review. Aquac Fish 3:244–258

Singh D, Nedbal L, Ebenhöh O (2018) Modelling phosphorus uptake in microalgae. Biochem Soc Trans 46:483–490

Solovchenko AE, Ismagulova TT, Lukyanov AA, Vasilieva SG, Konyukhov IV, Pogosyan SI, Lobakova ES, Gorelova OA (2019) Luxury phosphorus uptake in microalgae. J Appl Phycol 31:2755–2770

Subashchandrabose SR, Ramakrishnan B, Megharaj M, Venkateswarlu K, Naidu R (2011) Consortia of cyanobacteria/microalgae and bacteria: biotechnological potential. Biotech Adv 29:896–907

Sun X, Li X, Tang S, Lin K, Zhao T, Chen X (2022) A review on algal-bacterial symbiosis system for aquaculture tail water treatment. Sci Total Environ 847:157620

Taziki M, Ahmadzadeh H, Murry MA, Lyon SR (2015) Nitrate and nitrite removal from wastewater using algae. Curr Biotechnol 4:426–440

Timmons MB, Holder JL, Ebeling JM (2006) Application of microbead biological filters. Aquac Eng 34:332–343

Wu JY, Lay CH, Chen CC, Wu SY (2017) Lipid accumulating microalgae cultivation in textile wastewater: Environmental parameters optimization. J Taiwan Inst Chem Eng 79:1–6

Yu H, Kim J, Rhee C, Shin J, Shin SG, Lee C (2022) Effects of different pH control strategies on microalgae cultivation and nutrient removal from anaerobic digestion effluent. Microorganisms 10:357

Zhang M, Yu M, Wang Y, He C, Pang J, Wu J (2019) Operational optimization of a three-stage nitrification moving bed biofilm reactor (NMBBR) by obtaining enriched nitrifying bacteria: Nitrifying performance, microbial community, and kinetic parameters. Sci Total Environ 697:134101

Acknowledgements

We especially acknowledge FDM biofilters for their technical support. This research was supported by Copec-UC, 2018.J.1060. The demonstrative aquaculture recirculation system at the Department of Oceanography, Universidad de Concepción, located in Dichato, Bio-Bio, Chile, kindly provided the wastewater.

Funding

Funding for open access publishing: Universidad de Almería/CBUA. This research was supported by Copec-UC, 2018.J.1060.

Author information

Authors and Affiliations

Contributions

S. Rodríguez-Leal: Conceptualization, Investigation, Data curation, Reviewing and Editing; J. Silva-Acosta: Methodology, Writing- Reviewing and Editing; T. Marzialetti: Supervision, Writing- Reviewing and Editing; J. J. Gallardo-Rodríguez: Conceptualization, Supervision, Writing- Original draft preparation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rodríguez-Leal, S., Silva-Acosta, J., Marzialetti, T. et al. Lab- and pilot-scale photo-biofilter performance with algal–bacterial beads in a recirculation aquaculture system for rearing rainbow trout. J Appl Phycol 35, 1673–1683 (2023). https://doi.org/10.1007/s10811-023-02981-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-023-02981-6