Abstract

Arthrospira platensis is a cyanobacterium known for its widespread use as nutraceutical and food additive. Besides a high protein content, this microorganism is also endowed with several bioactivities related to health benefits in humans that make it a candidate for functional foods. These properties are strain and culture condition dependent. We compared, in terms of biomass productivity and protein, C-phycocyanin, and polysaccharide content, two A. platensis strains, A. platensis F&M-C256 and A. platensis F&M-C260, characterized by morphological differences. The organisms were grown in annular photobioreactors with light-emitting diodes (LED) as light source in fed-batch and semi-continuous regimes. No significant differences in biomass productivity were found between the two strains. Both strains showed a protein content >55% in all culture conditions. C-phycocyanin content was higher in A. platensis F&M-C260 in semi-continuous regime. Cellular polysaccharide (PS) content, which included intracellular polysaccharide and those bound to the cell wall, was higher in A. platensis F&M-C256 during semi-continuous cultivation. In both strains, a higher release of polysaccharide was observed at the end of the fed-batch regime. A. platensis F&M-C256 showed the advantage to form clumps which facilitate harvesting, behavior not observed in A. platensis F&M-C260 and probably related to the different predominant monosaccharide found in the PS of the two strains (i.e., rhamnose in A. platensis F&M-C256 and glucose in A. platensis F&M-C260). The results show that the two strains are suitable for commercial production of high-value products, such as protein and C-phycocyanin, while for polysaccharide production, A. platensis F&M-C256 is preferable.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Arthrospira platensis, commonly known as spirulina, represents one of the most important commercial cyanobacteria. Arthrospira biomass is produced all over the world and mainly sold in the health food market as dried products, with a total production worldwide estimated at 15,000 tonnes annually (Belay 2013; Meticulous Market Research 2017; Hu 2019). Besides being rich in proteins and antioxidants (e.g., phycocyanin and carotenoids), Arthrospira also represents an important source of minerals and vitamins (Khumuda et al. 2010; Becker 2013; Belay 2013). Many health benefits derived from the consumption of this cyanobacterium have been observed in animals (Pérez-Juárez et al. 2016; Bigagli et al. 2017) and humans (de la Jara et al. 2018; Abu-Taweel et al. 2019). Arthrospira has a long history as food, as far back as the ninth century (Abdulqader et al. 2000), and it is consumed worldwide (Lafarga et al. 2020). Arthrospira is considered GRAS (Generally Recognized as Safe) in the USA (FDA 2003; Borowitzka 2013); in Europe only A. platensis is included in the catalogue of foods consumed prior to May 1997 and thus can be commercialized as food and food ingredient (EU 2015).

Arthrospira is mostly cultivated in open ponds exploiting sunlight; it grows at high pH (>9) and bicarbonate concentration, which makes the culture medium rather selective (Belay 2013), although some strains of A. maxima have been also cultivated in seawater (Tredici et al. 1986). Lighting technologies are improving rapidly, providing options for supplemental or sole artificial lighting in microalgal cultivation systems (Tredici et al. 2009; Nwoba et al. 2019). Artificial illumination in microalgal research and production was for long time attained with fluorescent tubes, which mimic natural radiation spectrum and thus include those wavelengths, such as green (\(\lambda \approx\) 520–560 nm) with low photosynthetic activity for certain microalgae (Schulze et al. 2014); alternatively, LED can be used (Schulze et al. 2014; McGee et al. 2020). LED are long lasting (about 50,000 h), mercury-free, and can provide nearly monochromatic light at various wavelengths by virtue of solid-state electronics (Schulze et al. 2014). The exploitation of artificial light results in high investment and electricity costs, which increase the final biomass production costs and are sustainable only if high-value products are the target (Blanken et al. 2013). However, artificial light has numerous advantages compared to solar radiation, among which are (i) independence from climatic conditions and site location, (ii) possibility to select light spectrum, (iii) optimization of the photosynthetic photon flux density (PPFD) and light regimes, and (iv) higher stability of culture conditions. Several studies performed under artificial light with Arthrospira showed that quantity and quality of light play a key role in biomass productivity and composition (Wang et al. 2007; da Fontoura et al. 2020).

The genus Arthrospira shows a broad variety in morphological and physiological characteristics. In natural habitats, trichome diameter can range from 2.5 to 15 μm, and helix pitch can reach 80 μm with a diameter from 15 to 60 μm (Sili et al. 2012). According to environmental conditions, straight trichomes are also observed (Tomaselli 1997). The optimum growing conditions include alkaline media (pH 8.5–11) and temperature between 35 and 40 °C (Lupatini et al. 2017). Differences can also be found in the content of the main constituents of interest for industrial application. Protein content can vary from 55 to 70% of the dry biomass (Becker 2013; Belay 2013) and C-phycocyanin content from 9 to 18% (Belay 2013; Park et al. 2018). Arthrospira represents the main source of C-phycocyanin in the market. This pigment is used as a colorant for food and cosmetics and also as fluorescent dye for pharmaceutical applications (Lehto et al. 2017; Seyedi et al. 2020). While the antioxidant and radical scavenging activities of purified C-phycocyanin are well documented (Park et al. 2018), other positive health effects of this pigment, which include anticancer and anti-inflammatory properties, are still under investigation (Rodríguez-Sánchez et al. 2012; Liu et al. 2016). The current market value for phycobiliproteins is estimated to vary from US$ 120 per gram of food/cosmetic grade pigments to US$ 1,500 per milligram of highly purified molecular markers labeled with antibodies and fluorescent molecules (Park and Dinh 2019).

Polysaccharides produced by Arthrospira have shown biological activities of potential interest for the medical field, for example, Ca-spirulan, a complex sulfated polysaccharide, has been shown to inhibit the replication of different enveloped viruses (Hayashi et al. 1996; Lee et al. 1998). Strain and cultivation regime can considerably affect polysaccharide content in A. platensis, which generally ranges from 6 to 12% of biomass dry weight (Wang et al. 2018). Arthrospira also releases polysaccharides in the culture medium, which can be easily recovered and, due to their physicochemical properties, are suitable for a variety of industrial applications (Phélippé et al. 2019).

For the commercial production of A. platensis biomass or derived products (e.g., protein, C-phycocyanin, polysaccharides), the choice of a suitable strain is fundamental as many biological properties, besides productivity, are strain-dependent (Satora et al. 2015). The aim of this study was to compare two A. platensis strains, A. platensis F&M-C256 and A. platensis F&M-C260, in terms of growth performance and production of high-value products (C-phycocyanin and polysaccharide), besides protein. To this end, the strains were cultivated in annular reactors under white LED illumination, firstly in fed-batch and then in semi-continuous regimes.

Materials and methods

Organisms and culture conditions

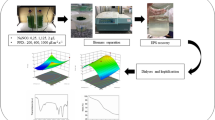

Two strains of Arthrospira platensis were used in this study: A. platensis F&M-C256 and A. platensis F&M-C260, both obtained from the Microalgae and Cyanobacteria Culture Collection of Fotosintetica & Microbiologica S.r.l. (Florence, Italy). Filaments of A. platensis F&M-C256 were straight, with a thickness of 7–8 μm. Filaments of A. platensis F&M-C260 were wavy with a thickness of 6–7 μm. Both strains were grown in Zarrouk medium (Zarrouk 1966). The air for mixing was bubbled at a flow rate of 0.3 L of gas mixture (air:CO2, 98:2, v/v) per liter of culture per minute, culture temperature was maintained at 35 °C, and pH in the range 9.2–9.4. CO2 was used to regulate pH and provide carbon. The two strains were grown in fed-batch for 4 days, and then the cultures were diluted with fresh medium to reach an initial concentration of about 0.7 g L−1 (24 g m−2 of illuminated surface area) and maintained in semi-continuous regime, during which 50% of the culture volume was harvested daily and replaced with fresh medium. The experiments were carried out under continuous illumination at an average photosynthetic photon flux density (PPFD) of 700 μmol photons m–2 s–1 which was measured on the reactors illuminated surface with a Photosynthetically Active Radiation (PAR) DO 9721 sensor connected to an LP 9021 quantum-photo-radiometer (DELTA OHM, Italy). The reactors were wrapped to screen them from ambient light.

Culture system

Growth experiments were performed in 6-L annular photobioreactors made of two Plexiglas cylinders of different diameter (9 and 15 cm) placed one inside the other so as to form a 2.7-cm-thick and 63-cm-high annular culture chamber. Culture mixing was attained by bubbling an air:CO2 mixture through a perforated tube, positioned at the bottom of the culture chamber. Illumination was provided by 90 W white (400–750 nm) LED (C-LED Penta Industrial, Italy) positioned inside the inner cylinder. The reactor had an illuminated culture surface of 0.178 m2.

Analytical procedures

Microscopic observations of the cultures were carried out daily using a direct-light microscope (Nikon Eclipse 50i, Nikon Corporation, Japan). Culture growth was estimated by measurement of biomass dry weight concentration. For dry weight determination, culture samples (5 mL) were filtered through pre-weighed 1.2-μm glass-fiber filters (MFV3, Filter-Lab, Spain), washed with deionized water, and dried at 105 °C to constant weight. Biomass concentration was expressed as grams of dry biomass per unit of culture volume (L) and per unit of culture illuminated surface (m2). Biomass for biochemical analyses was harvested using a nylon filter cloth with a porosity of 15 μm (PA 15/11, Gaudenzi S.r.l., Italy). The samples were washed with a saline solution (NaCl, 1 g L−1), lyophilized, and stored at −20 °C. The lyophilized biomasses were analyzed for C-phycocyanin, protein, and polysaccharide.

C-phycocyanin was extracted according to Herrera et al. (1989). About 1 g of lyophilized biomass was suspended in 20 mL of 1% CaCl2 in water (w/v) and kept under agitation on a magnetic stirrer for 4 h. Then, samples were centrifuged (Neya 8, Neya, Italy) at 3500 rpm for 20 min. Phycocyanin in the supernatant of the extracts was measured spectrophotometrically (Cary 50, Varian Inc., USA) and the concentration calculated using Bennett and Bogorad (1973) equations.

Protein content was determined according to Lowry et al. (1951). About 15 mg of lyophilized biomass suspended in 50 mL of demineralized water were sonicated (Sonics Vibra Cell TM VCX 130, Sonics & Materials Inc., USA) for 10 min at the maximum power (20 kHz, 130W). 0.5 mL of the sonicated sample was mixed with the same volume of NaOH 1N and, after thermic treatment (water bath at 100 °C for 5 min), cooled in cold water. The samples were then added with 2.5 mL of a solution prepared by adding 2 mL of a 0.5% (w/v) solution of pentahydrate CuSO4 in 1% (w/v) K-Na tartrate in water to 50 mL of a 5% (w/v) Na2CO3 in water solution. After 10 min, 0.5 mL of 1N Folin-Ciocalteau reactive was added. The absorbance of the sample was measured at 750 nm after incubation for 30 min in the dark. Protein concentration was calculated based on a calibration curve obtained with bovine serum albumin (Sigma Aldrich, Germany) following the same procedure used for samples.

Cellular polysaccharide (PS) content, which includes both intracellular and capsular (i.e., tightly bound to the cell wall) polysaccharides, was analyzed according to Chaiklahan et al. (2013). PS was extracted from 0.5 g biomass samples kept in water (1:45 w/v) at 90 °C for 120 min. After centrifugation, the supernatant containing the PS was separated. Then, a 1% cetyltrimethylammonium bromide (CTAB) solution in water was used to precipitate polysaccharides. The precipitate was collected by centrifugation (4500 rpm for 20 min) and washed stepwise with a saturated sodium acetate solution in 95% ethanol and then with absolute ethanol. The precipitated polysaccharide was then resuspended in 50 mL of deionized water and quantified by the phenol-sulfuric acid method (Dubois et al. 1956). One milliliter of 5% (w/v) phenol in water was added to 1 mL of the suspended polysaccharide. Then, 5 mL of H2SO4 were added, and after 10 min, the samples were placed in a cold-water bath to stop the reaction. The absorbance was measured at 488 nm. Carbohydrate concentration was calculated using a calibration curve obtained with anhydrous glucose (Sigma Aldrich, Germany). Released polysaccharides (RPS) were extracted from the culture media, which were previously centrifuged at 4500 rpm for 20 min to remove the cells, by overnight precipitation with ethanol (1:9 v/v) at +4 °C. The precipitate was suspended in 5 mL of deionized water, and the RPS concentration was determined by the phenol-sulfuric acid method.

The monosaccharide composition of PS at the end of the fed-batch cultivation period was determined according to Zampieri et al. (2020). PS extracts were obtained as described above and lyophilized. Ten milligrams of extracted PS were hydrolyzed with 2N trifluoroacetic acid (TFA) at 120 °C for 120 min and then cooled in an ice bath. Afterwards, hydrolysates were centrifuged (Ultra-4 Amicon, Millipore, USA) at 8200 ×g for 20 min, and the excess of TFA was removed through evaporation by a rotary evaporator (Rotavapor R-100, Büchi, Switzerland). The dried extracts were re-solubilized in 2 mL of deionized water. Samples were then analyzed using a Dionex ICS-2500 ion exchange chromatograph (Dionex, USA) equipped with an ED50 pulsed amperometric detector operating with a gold working electrode and a DionexCarboPac PA1 column of 250-mm length and 4.6-mm internal diameter (Thermo Scientific, USA). Eluents used were HPLC-grade water (A), 0.185M sodium hydroxide (B), and 0.488M sodium acetate (C). In the first stage of the analysis (from injection time to 20 min), the eluent was constituted by 90% A and 10% B; in the second stage (from 20 to 30 min), the eluent was constituted by 50% B and 50% C; in the final stage (from 30 to 60 min), the eluent was that of the first stage. The flow rate was kept at 1 mL min−1. Peaks for each sugar were identified and quantified on the basis of known standards (Sigma Chemicals Co., USA, for all monosaccharides except L(+)-rhamnose, Carlo Erba Reagents, Italy and D-glucosamine, Alfa Aesar, India). The analyses were conducted in duplicate.

Photosynthetic efficiency

Light energy input (Ein; kJ m−2 day−1) was calculated by converting the average PPFD (mol photons m−2 day−1) to light energy assuming the average energy content of the PAR spectrum to be 217 kJ mol−1 (Tredici 2010). The energy output (Eout; kJ m−2 day−1) was calculated by multiplying Bp (g m−2 day−1), representing the biomass averagely produced per square meter per day, by the biomass caloric content (Bcc; kJ g−1). The caloric content, measured at the end of the fed-batch phase and as average value for the semi-continuous phase, was obtained by multiplying the protein, carbohydrate, and lipid content of the biomasses produced in each culture condition by 23.8, 17.6, and 38.9 kJ g−1, respectively (Abiusi et al. 2014). The photosynthetic efficiency (PE) was calculated by dividing Eout by Ein.

Clump formation in A. platensis F&M-C256

As A. platensis F&M-C256 was seen to clump when left without bubbling, clump formation was measured in separate trials, by placing 200 mL of culture in a 14.8-cm diameter glass Petri dish. Pictures were taken at different times, and the area occupied by the clumped biomass was measured using an image analysis software (ImageJ, NIH, USA).

Statistical analysis

Differences in productivity, photosynthetic efficiency, and content of the biomass components (protein, C-phycocyanin, and polysaccharides) were analyzed between different culture regimes (for the same strain) and between different strains (for the same culture regime) using two tailed t-test with software Prism (GraphPad Inc., USA). The significance level was P<0.05. For biomass components, three technical replicates for duplicate samples were analyzed.

Results

Growth in annular reactors under LED light

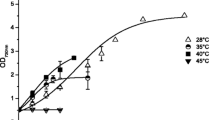

The growth curves of A. platensis F&M-C256 and A. platensis F&M-C260 cultivated in 6-L annular reactors firstly in fed-batch and then in semi-continuous (50% daily dilution rate) are shown in Fig. 1. The growth of the two Arthrospira strains was not significantly different neither in fed-batch nor in semi-continuous. In fed-batch the two strains reached a final concentration of 3.4 ± 0.2 g L−1 (Fig. 1) and showed a biomass productivity of 0.71 and 0.77 g L−1 day−1 (24 and 26 g m−2 day−1) for A. platensis F&M-C256 and A. platensis F&M-C260, respectively (Table 1). In semi-continuous, the biomass productivities were 0.94 and 0.95 g L−1 day−1 (32 g m−2 day−1) for A. platensis F&M-C256 and A. platensis F&M-C260, respectively. Comparing batch and semi-continuous cultivation within the same strain, both A. platensis strains showed significantly higher productivity in semi-continuous compared to fed-batch regime. A. platensis F&M-C256 and A. platensis F&M-C260 did not show any morphological modification during cultivation.

Photosynthetic efficiency

Biomass caloric content, as determined by biochemical composition, was 22.5 and 21.9 kJ g−1 for A. platensis F&M-C256 and 24.4 and 21.7 kJ g−1 for A. platensis F&M-C260 at the end of the fed-batch and as average of the semi-continuous phase, respectively (Table 1). PE was significantly lower in fed-batch for both strains (4.1 and 4.8% for F&M-C256 and F&M-C260, respectively) compared to semi-continuous (5.3% for both strains) (Table 1). The two strains showed similar PE within the same culture regime.

Clump formation

During cultivation of the two strains in the same reactors to provide the inocula for the experiments, an interesting feature was noted in A. platensis F&M-C256. Once the aeration was stopped, the culture formed a single clump that compacted with time, thus favoring separation of the filaments from the culture medium. The dynamic of clump formation in A. platensis F&M-C256 is shown in Figs. 2 and 3. After 1 h, a compact clump, which occupied a surface area about 6% the initial one, was observed. Additional time did not further reduce the occupied area. Clump formation did not occur in A. platensis F&M-C260, which still spread out over the entire plate after 17 h of rest (Figs. 2 and 3). The same behavior was observed during the experiments. In the absence of air-bubbling, clump formation occurred in less than an hour. In this case as well, A. platensis F&M-C260 did not show this behavior.

Protein and C-phycocyanin

Protein and C-phycocyanin content at the end of the fed-batch and in semi-continuous (as an average content of the 4 days of cultivation), is shown in Table 2. No significant differences were found in protein content between the two strains in the two culture regimes. Both strains showed a significantly higher protein content in fed-batch. The protein productivity was about 0.5 g L−1 day−1 (corresponding to about 17 g m−2 day−1) for both the strains and culture regimes.

In fed-batch the two strains showed comparable C-phycocyanin content (12.0% and 11.2% for A. platensis F&M-C256 and A. platensis F&M-C260, respectively), which was significantly higher for both strains compared to semi-continuous cultivation. In semi-continuous regime, A. platensis F&M-C260 showed a significantly higher C-phycocyanin content (9.1%) compared to A. platensis F&M-C256 (7.5%). C-phycocyanin productivity was not significantly different between the two strains and the two cultivation regimes (about 0.08 g L−1 day−1 corresponding to about 2.7 g m−2 day−1).

Polysaccharide

Cellular polysaccharide (PS) content and released polysaccharides (RPS) at the end of the fed-batch and in semi-continuous (as the average content of the 4 days of cultivation) are reported in Table 3. In fed-batch, no significant difference was found in PS content between the two A. platensis strains. In semi-continuous, A. platensis F&M-C256 showed a significantly higher PS content (5.8%) compared to A. platensis F&M-C260 (4.3%). Moreover, PS productivity of A. platensis F&M-C256 cultivated in semi-continuous (53.7 mg L−1 day−1 corresponding to 1.8 g m−2 day−1) was significantly higher compared to that obtained in fed-batch (41.7 mg L−1 day−1 corresponding to 1.4 g m−2 day−1). In A. platensis F&M-C260, PS productivities were not significantly different between the two culture regimes (about 35 mg L−1 day−1 corresponding to 1.2 g m−2 day−1).

RPS concentration in the culture medium (Table 3) was significantly higher in fed-batch compared to semi-continuous for both strains. Within each cultivation regime, no significant difference in released polysaccharides was found between A. platensis F&M-C256 and A. platensis F&M-C260. RPS productivity (3–4 mg L−1 day−1) was not significantly different between the two culture regimes and the two strains.

Monosaccharide composition of PS

PS of the two Arthrospira platensis strains cultivated in fed-batch were analyzed for their monosaccharide content (Fig. 4). PS of A. platensis F&M-C260 was composed of seven predominant monosaccharides (>5 mol%) on a total of twelve detected, while the PS of A. platensis F&M-C256 was composed of five predominant monosaccharides on a total of eleven detected, being mannose absent. Rhamnose and glucose were the most abundant monosaccharides in both strains PS, but their relative content was different. In the PS of A. platensis F&M-C256, rhamnose was predominant (55 mol%) followed by glucose (18 mol%), while in the PS of A. platensis F&M-C260, glucose (30 mol%) prevailed on rhamnose (21 mol%). The PS of the two strains presented the same amount of galactose (about 11 mol%). Fucose, arabinose, glucosamine, mannose (present only in F&M-C260), and xylose content was lower than 10 mol% for both strains. The other monosaccharides were present only in traces.

Monosaccharide composition expressed as molar ratio (mol%) on PS total sugars produced by A. platensis F&M-C256 and A. platensis F&M-C260 cultivated in fed-batch. Data are the average of duplicate samples ± SD. Abbreviations: ara, arabinose; fru, fructose; fuc, fucose; gal, galactose; galA, galacturonic acid; glc, glucose; glcA, glucuronic acid; glcN, glucosamine; man, mannose; rha, rhamnose; rib, ribose; xyl, xylose.

Discussion

Both A. platensis strains presented higher biomass productivity in semi-continuous compared to fed-batch regime likely due to the fact that photosynthesis decreases with the increase of biomass concentration because of the shadowing effect (Borowitzka 2016; Borowitzka and Vonshak 2017). Besides, in semi-continuous cultivation, the renewal of nutrients is guaranteed by partial replacement of the exhausted medium. Together with the maintenance of a higher growth rate, semi-continuous cultivation also has operational advantages, such as maintaining a more constant cell concentration (Ho et al. 2014). Moreover, nutrient concentration required for growth and toxic metabolites can be always maintained at non-limiting and non-inhibitory levels (Bezerra et al. 2011). Only few papers deal with photobioreactors of the type used in this work (cylinders with internally lodged lamps) or with similar culture depth (3 cm) or illuminated surface/volume ratio (30 m−1). Markou (2014) and Yim et al. (2016) cultivated A. platensis in reactors similar to that used in the present work but under different culture conditions (temperature, initial cell concentration, light intensity, and CO2 supply, often absent). The productivities attained were between 0.015 and 0.08 g L−1 day−1 (Markou 2014; Yim et al. 2016), much lower than those found in our study (0.73–0.96 g L−1 day−1).

Proteins are the most abundant constituents of Arthrospira biomass, making it a valuable feedstock for the food, feed, and nutraceutical markets (Belay 2013). The two A. platensis strains investigated in this work showed a similar protein content, which was always higher than 55%, a value comparable to the content (50%) reported for A. platensis SAG 21.99 cultivated in photobioreactors under white LED light by Markou (2014). A similar protein content (about 53%) was observed in Arthrospira sp. LEB 18 grown in 1.8-L bubble columns with external lighting provided by a combination of white LED and fluorescent tubes (da Fontoura et al. 2018; 2020).

Among high-value proteins, there is C-phycocyanin, owing to its antioxidant and anti-inflammatory properties (Liu et al. 2016). In our work, both strains showed a high C-phycocyanin content, which provides a basis for the development of new natural products. C-phycocyanin content was lower in semi-continuous in both strains following cyanobacterial photoadaptation for which, at higher light intensities, phycobiliproteins decrease (Grossman et al. 1993; Xie et al. 2015). Markou (2014) observed a 10% C-phycocyanin content under white LED light with A. platensis SAG 21.99 cultivated in semi-continuous regime. The higher value compared to our results in semi-continuous (7.5 and 9.1%) can be due to the lower PPFD adopted, besides by the different strain. Xie et al. (2015) with A. platensis WH879 grown in fed-batch at 300 μmol photons m−2 s−1 in a 1-L glass vessel found a C-phycocyanin content of about 12%, similar to that found by Chen et al. (2013) in a 1-L flat reactor at 700 μmol photons m−2 s−1 (the same PPFD used in this work). The values of phycocyanin reported in these papers are similar to those found in the present work in fed-batch. The decrease in phycocyanin content with increasing light intensity is not always linear, and beyond a certain intensity, depending on culture conditions and reactor characteristics, the phycocyanin content remains stable (Takano et al. 1995; Yim et al. 2016).

A characteristic found in A. platensis F&M-C256 that may become advantageous in large-scale production is the ability to clump in compact aggregates in short time (<1 h), so that it would be possible to avoid handling large volumes of culture at harvest, whether this phenomenon will be confirmed in large-scale cultures. A. platensis F&M-C260 did not show this ability. Clumping ability was reported for an A. platensis strain when cultivated at 35 °C (Karemore et al. 2020), the same temperature adopted in this work, and for other Oscillatoriales from hot springs (Castenholz 1967). In order to improve harvesting, a wild-type strain of A. platensis (NIES 39) was subjected to mutagenesis to increase clump formation (Kim et al. 2013). The formation of clumps is beneficial to survive under critical environmental conditions or to adhere to a solid surface (Fattom and Shilo 1984; Ohmori et al. 1992). Enomoto et al. (2020) reported for Arthrospira that the formation of clumps, that assume the shape of the containing vessel (Ohmori et al. 1998), is stimulated by cyclic adenosine monophosphate (cAMP), which is correlated to an increase of respiration and trichome motility; cAMP signaling is also probably regulated by light (Ohmori and Okamoto 2004). In addition, straight trichomes seem to improve directionality and speed of gliding motility (Chaiyasitdhi et al. 2018). Ohmori et al. (1992) suggested that cAMP might stimulate extracellular polysaccharide production, which is directly involved in cell aggregation. In the present study, we observed that the two A. platensis strains produce a similar amount of polysaccharide. The different clumping behavior might, thus, be related to a different monosaccharide composition of the polysaccharides (Henriques Vieira et al. 2008). Some cyanobacteria exopolysaccharides are characterized by a significant level of hydrophobicity due to the presence of ester-linked acetyl groups, peptidic moieties, and deoxysugars such as rhamnose and fucose (Pereira et al. 2009). In our study, PS monosaccharide composition of the two A. platensis strains was consistent with that reported in previous studies for other Arthrospira strains (Phélippé et al. 2019). Glucose is usually one of the most abundant monosaccharides in cyanobacteria exopolysaccharide (Pereira et al. 2009), and it resulted to be the predominant sugar in the PS of A. platensis F&M-C260. The clumping capacity observed in A. platensis F&M-C256 may be due to the higher content of rhamnose in its PS compared to that of A. platensis F&M-C260. Polysaccharides rich in rhamnose have been shown to increase the adhesion properties thus favoring cell aggregation in diatoms (Henriques Vieira et al. 2008) and cyanobacteria (Yoshikawa et al. 2021).

For both strains, the final RPS concentration was about three times higher in fed-batch compared to semi-continuous, and thus, it is convenient to conduct A. platensis cultivation in fed-batch when RPS are the target products. To further increase RPS production, it is advisable to reach the stationary phase, since RPS concentration in the culture medium can be enhanced during this phase (Cogne et al. 2003). In the stationary phase, due to reduced metabolic activity, light can bear an excess of energy that can generate oxidative stress to the cells. To avoid this damage, cells activate a drain of excess ATP in the form of, for example, exopolysaccharide production (Cogne et al. 2003).

According to their chemical and physiochemical features, exopolysaccharide can find many applications as gelling or thickening agents in the food and cosmetic and pharmaceutical industries as well as for the recovery of valuable metals from industrial waters (Pereira et al. 2009; Pierre et al. 2019). Besides, rare sugars (e.g., fucose, rhamnose, or uronic acids) can confer important biological properties (e.g., anti-aging, anti-inflammatory, hydrating, aroma precursors) to polysaccharides that thus could find application for high-value products (cosmetics, pharmaceuticals, functional foods) (Roca et al. 2015). The two A. platensis strains investigated represent an interesting source of rare sugar containing polysaccharides thus increasing their market value. Moreover, the physical chemical properties of the polysaccharides and thus their potential applications as thickeners, emulsion stabilizers, and flocculants are enhanced by the presence of deoxysugars (e.g., rhamnose) (Pereira et al. 2009).

Conclusion

To improve the economic performance of Arthrospira production, all its valuable components, including those found in the culture medium, must be used. Despite the morphological differences, the two A. platensis strains tested showed similar biomass productivity and content of C-phycocyanin, protein, and polysaccharide, both exhibiting favorable characteristics for cultivation under artificial light. In both the strains, semi-continuous cultivation allowed higher biomass productivity, whereas in fed-batch regime, the content of C-phycocyanin and protein in the biomass, and released polysaccharides in the medium, increased. A. platensis F&M-C256 has the advantage to spontaneously form clumps, which facilitates harvesting and allows easier separation of the biomass and recovery of released polysaccharides from the culture medium.

Data availability

Main data generated or analyzed during this study are included in this article.

Change history

24 July 2022

Missing Open Access funding information has been added in the Funding Note.

References

Abdulqader G, Barsanti L, Tredici MR (2000) Harvest of Arthrospira platensis from Lake Kossorom (Chad) and its household usage among the Kanembu. J Appl Phycol 12:493–498

Abiusi F, Sampietro G, Marturano G, Biondi N, Rodolfi L, D’Ottavio M, Tredici MR (2014) Growth, photosynthetic efficiency, and biochemical composition of Tetraselmis suecica F&M-M33 grown with LEDs of different colors. Biotechnol Bioeng 111:956–964

Abu-Taweel GM, Antonisamy P, Arokiyaraj S, Kim HJ, Kim SJ, Park KH, Kim YO (2019) Spirulina consumption effectively reduces anti-inflammatory and pain related infectious diseases. J Infect Public Heal 12:777–782

Becker EW (2013) Microalgae for human and animal nutrition. In: Richmond A, Hu Q (eds) Handbook of microalgal culture: applied phycology and biotechnology, 2nd edn. Wiley-Blackwell, Oxford, pp 461–503

Belay A (2013) Biology and industrial production of Arthrospira (Spirulina). In: Richmond A, Hu Q (eds) Handbook of microalgal culture: applied phycology and biotechnology, 2nd edn. Wiley-Blackwell, Oxford, pp 339–358

Bennett A, Bogorad L (1973) Complementary chromatic adaptation in a filamentous blue-green alga. J Cell Biol 58:419–435

Bezerra RP, Ortiz Montoya EYO, Sato S, Perego P, de Carvalho JCM, Converti A (2011) Effects of light intensity and dilution rate on the semicontinuous cultivation of Arthrospira (Spirulina) platensis. A kinetic Monod-type approach. Bioresour Technol 102:3215–3219

Bigagli E, Cinci L, Niccolai A, Tredici MR, Biondi N, Rodolfi L, Lodovici M, D’Ambrosio M, Mori G, Luceri C (2017) Safety evaluations and lipid-lowering activity of an Arthrospira platensis enriched diet: a 1-month study in rats. Food Res Int 102:380–386

Blanken W, Cuaresma M, Wijffels RH, Janssen M (2013) Cultivation of microalgae on artificial light comes at a cost. Algal Res 2:333–340

Borowitzka MA (2013) High-value products from microalgae -their development and commercialization. J Appl Phycol 25:743–756

Borowitzka MA (2016) Algal physiology and large-scale outdoor cultures of microalgae. In: Borowitzka M, Beardall J, Raven J (eds) The physiology of microalgae. Springer, Cham, pp 601–652

Borowitzka MA, Vonshak A (2017) Scaling up microalgal cultures to commercial scale. Eur J Phycol 52:407–418

Castenholz RW (1967) Aggregation in a thermophilic Oscillatoria. Nature 215:1285–1286

Chaiklahan R, Chirasuwan N, Triratana P, Loha V, Tia S, Bunnag B (2013) Polysaccharide extraction from Spirulina sp. and its antioxidant capacity. Int J Biol Macromol 58:73–78

Chaiyasitdhi A, Miphonpanyatawichok W, Riehle MO, Phatthanakun R, Surareungchai W, Kundhikanjana W, Kuntanawat P (2018) The biomechanical role of overall-shape transformation in a primitive multicellular organism: a case study of dimorphism in the filamentous cyanobacterium Arthrospira platensis. PLoS One 13:e0196383

Chen CY, Kao PC, Tsai CJ, Lee DJ, Chang JS (2013) Engineering strategies for simultaneous enhancement of C-phycocyanin production and CO2 fixation with Spirulina platensis. Bioresour Technol 145:307–312

Cogne G, Gros JB, Dussap CG (2003) Identification of a metabolic network structure representative of Arthrospira (Spirulina) platensis metabolism. Biotechnol Bioeng 84:667–676

da Fontoura Prates D, Radmann EM, Duarte JH, de Morais MG, Costa JAV (2018) Spirulina cultivated under different light emitting diodes: enhanced cell growth and phycocyanin production. Bioresour Technol 256:38–43

da Fontoura Prates D, Duarte JH, Vendruscolo RG, Wagner R, Ballus CA, da Silva Oliveira W, Costa JAV (2020) Role of light emitting diode (LED) wavelengths on increase of protein productivity and free amino acid profile of Spirulina sp cultures. Bioresour Technol 306:123184

de la Jara A, Ruano-Rodrigue C, Polifrone M, Assunçao P, Brito-Casillas Y, Wägner AM, Serra-Majem L (2018) Impact of dietary Arthrospira (Spirulina) biomass consumption on human health: main health targets and systematic review. J Appl Phycol 30:2403–2423

Dubois M, Gilles KA, Hamilton JK, Rebers PT, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Enomoto G, Wilde A, Ikeuchi M (2020) Light-regulated nucleotide second messenger signaling in cyanobacteria. In: Chou SH, Guiliani N, Lee VT, Römling U (eds) Microbial cyclic di-nucleotide signaling. Springer, Cham, pp 311–327

EU (2015) Regulation EU 2015/2283 of the European Parliament and of the Council of 25 November 2015 on novel foods. Official Journal of the European Communities, https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32015R2283&qid=1551104546958&from=PT; searched on 2 December 2020

Fattom A, Shilo M (1984) Hydrophobicity as an adhesion mechanism of benthic cyanobacteria. Appl Environ Microbiol 47:135–143

Food and Drug Administration (FDA) (2003) GRAS notice No. 127: Spirulina, the dried biomass of Arthrospira platensis.https://www.cfsanappsexternal.fda.gov/scripts/fdcc/index.cfm?set=GRASNotices&id=127&sort=GRN_No&order=DESC&startrow=1&type=basic&search=spirulina; searched on 2 December 2021

Grossman AR, Schaefer MR, Chiang GG, Collier JL (1993) The phycobilisome, a light-harvesting complex responsive to environmental conditions. Microbiol Rev 57:725–749

Hayashi K, Hayashi T, Kojima I (1996) A natural sulfated polysaccharide, calcium spirulan, isolated from Spirulina platensis: in vitro and ex vivo evaluation of anti-herpes simplex virus and anti-human immunodeficiency virus activities. AIDS Res Hum Retrov 12:1463–1471

Henriques Vieira AA, Coelho Ortolano PI, Giroldo D, Dellamano Oliveira MJ, Bittar TB, Lombardi AT, Sartori AL, Paulsen BS (2008) Role of hydrophobic extracellular polysaccharide of Aulacoseira granulata (Bacillariophyceae) on aggregate formation in a turbulent and hypereutrophic reservoir. Limnol Oceanogr 53:1887–1899

Herrera A, Boussiba S, Napoleone V, Hohlberg A (1989) Recovery of c-phycocyanin from the cyanobacterium Spirulina maxima. J Appl Phycol 1:325–331

Ho SH, Chen CNN, Lai YY, Lu WB, Chang JS (2014) Exploring the high lipid production potential of a thermotolerant microalga using statistical optimization and semi-continuous cultivation. Bioresour Technol 163:128–135

Hu Q (2019) Current status, emerging technologies, and future perspectives of the world microalgal industry. In: Book of Abstracts AlgaEurope Conference, Paris, France, 3-5 December 2019, p 139

Karemore A, Yuan Y, Porubsk W, Chance R (2020) Biomass and pigment production for Arthrospira platensis via semi-continuous cultivation in photobioreactors: temperature effects. Biotechnol Bioeng 117:3081–3093

Khumuda A, Kumar SS, Thakur MS, Ravishankar GA, Sarada R (2010) Purification, identification, and characterization of methylcobalamin from Spirulina platensis. J Agric Food Chem 58:9925–9930

Kim YH, Park HJ, Lee SH, Lee JH (2013) Isolation and characterization of autoflocculating mutants of cyanobacterium Arthrospira platensis. Kor J Chem Eng 30:413–416

Lafarga T, Fernández-Sevilla JM, González-López C, Acién-Fernández FG (2020) Spirulina for the food and functional food industries. Food Res Int 137:109356

Lee JB, Hayashi T, Hayashi K, Sankawa U, Maeda M, Nemot T, Nakanishi H (1998) Further purification and structural analysis of calcium spirulan from Spirulina platensis. J Nat Prod 61:1101–1104

Lehto S, Buchweitz M, Klimm A, Straßburger R, Bechtol C, Ulberth F (2017) Comparison of food colour regulations in the EU and the US: a review of current provisions. Food Addit Contam A 34:335–355

Liu Q, Huang Y, Zhang R, Cai T, Cai Y (2016) Medical application of Spirulina platensis derived C-phycocyanin. Evid-Based Compl Alt 2016:7803846

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Lupatini AL, Colla LM, Canan C, Colla E (2017) Potential application of microalga Spirulina platensis as a protein source. J Sci Food Agric 97:724–732

Markou G (2014) Effect of various colors of light-emitting diodes (LEDs) on the biomass composition of Arthrospira platensis cultivated in semi-continuous mode. Appl Biochem Biotechnol 172:2758–2768

McGee D, Archer L, Fleming GT, Gillespie E, Touzet N (2020) Influence of spectral intensity and quality of LED lighting on photoacclimation, carbon allocation and high-value pigments in microalgae. Photosynth Res 143:67–80

Meticulous Market Research (2017) Global Spirulina Market Outlook 2017-2022. https://www.researchandmarkets.com/research/gmnvb5/global_spirulina; searched on 20 January 2021

Nwoba EG, Parlevliet DA, Laird DW, Alameh K, Moheimani NR (2019) Light management technologies for increasing algal photobioreactor efficiency. Algal Res 39:101433

Ohmori K, Hirose M, Ohmori M (1992) Function of cAMP as a mat-forming factor in the cyanobacterium Spirulina platensis. Plant Cell Physiol 33:21–25

Ohmori K, Hirose M, Ohmori M (1998) cAMP-triggered Spirulina cell aggregateLupatinis maintain the shapes of their vessels. Microbes Environ 13:23–27

Ohmori M, Okamoto S (2004) Photoresponsive cAMP signal transduction in cyanobacteria. Photochem Photobiol Sci 3:503–511

Park WS, Kim HJ, Li M, Lim D, Kim J, Kwak SS, Ahn MJ (2018) Two classes of pigments, carotenoids and C-phycocyanin, in spirulina powder and their antioxidant activities. Molecules 23:2065

Park J, Dinh TB (2019) Contrasting effects of monochromatic LED lighting on growth, pigments and photosynthesis in the commercially important cyanobacterium Arthrospira maxima. Bioresour Technol 291:121846

Pereira S, Zille A, Micheletti E, Moradas-Ferreira P, De Philippis R, Tamagnini P (2009) Complexity of cyanobacterial exopolysaccharides: composition, structures, inducing factors and putative genes involved in their biosynthesis and assembly. FEMS Microbiol Rev 33:917–941

Pérez-Juárez A, Chamorro G, Alva-Sánchez C, Paniagua-Castro N, Pacheco-Rosado J (2016) Neuroprotective effect of Arthrospira (Spirulina) platensis against kainic acid-neuronal death. Pharm Biol 54:1408–1412

Phélippé M, Gonçalves O, Thouand G, Cogne G, Laroche C (2019) Characterization of the polysaccharides chemical diversity of the cyanobacteria Arthrospira platensis. Algal Res 38:101426

Pierre G, Delattre C, Dubessay P, Jubea S, Vialleix C, Cadoret JP, Michaud P (2019) What is in store for EPS microalgae in the next decade? Molecules 24:4296

Roca C, Alves VD, Freitas F, Reis MAM (2015) Exopolysaccharides enriched in rare sugars: bacterial sources, production, and applications. Front Microbiol 6:288

Rodríguez-Sánchez R, Ortiz-Butrón R, Blas-Valdivia V, Hernández-García A, Cano-Europa E (2012) Phycobiliproteins or C-phycocyanin of Arthrospira (Spirulina) maxima protect against HgCl2-caused oxidative stress and renal damage. Food Chem 135:2359–2365

Satora P, Barwińska-Sendra A, Duda-Chodak A, Wajda Ł (2015) Strain-dependent production of selected bioactive compounds by cyanobacteria belonging to the Arthrospira genus. J Appl Microbiol 119:736–743

Schulze PS, Barreira LA, Pereira HG, Perales JA, Varela JC (2014) Light emitting diodes (LEDs) applied to microalgal production. Trends Biotechnol 32:422–430

Seyedi S, Parvin P, Jafargholi A, Jelvani S, Shahabi M, Shahbazi M, Moafi A (2020) Fluorescence properties of phycocyanin and phycocyanin-human serum albumin complex. Spectrochim Acta A 239:118468

Sili C, Torzillo G, Vonshak A (2012) Arthrospira (Spirulina). In: Whitton BA (ed) Ecology of cyanobacteria II: Their diversity in space and time. Springer, Dordrecht, pp 677–705

Takano H, Arai T, Hirano M, Matsunaga T (1995) Effects of intensity and quality of light on phycocyanin production by a marine cyanobacterium Synechococcus sp. NKBG 042902. Appl Microbiol Biotechnol 43:1014–1018

Tomaselli L (1997) Morphology, ultrastructure and taxonomy of Arthrospira (Spirulina) maxima and Arthrospira (Spirulina) platensis. In: Vonshak A (ed) Spirulina platensis (Arthrospira): physiology, cell-biology and biotechnology. Taylor & Francis, London, pp 1–15

Tredici MR, Papuzzo T, Tomaselli L (1986) Outdoor mass culture of Spirulina maxima in sea-water. Appl Microbiol Biotechnol 24:47–50

Tredici MR, Biondi N, Ponis E, Rodolfi L, Chini Zittelli G (2009) Advances in microalgal culture for aquaculture feed and other uses. In: Burnell G, Allan G (eds) New technologies in aquaculture: Improving production efficiency, quality and environmental management. Woodhead Publishing, Cambridge, pp 610–676

Tredici MR (2010) Photobiology of microalgae mass cultures: understanding the tools for the next green revolution. Biofuels 1:143–162

Wang CY, Fu CC, Liu YC (2007) Effects of using light-emitting diodes on the cultivation of Spirulina platensis. Biochem Eng J 37:21–25

Wang B, Liu Q, Huang Y, Yuan Y, Ma Q, Du M, Cai T, Cai Y (2018) Extraction of polysaccharide from Spirulina and evaluation of its activities. Evid Based Complement Altern Med 2018:3425615

Xie Y, Jin Y, Zeng X, Chen J, Lu Y, Jing K (2015) Fed-batch strategy for enhancing cell growth and C-phycocyanin production of Arthrospira (Spirulina) platensis under phototrophic cultivation. Bioresour Technol 180:281–287

Yim SK, Ki DW, Do HS, Kim H, Kwon TH (2016) Internally illuminated photobioreactor using a novel type of light-emitting diode (LED) bar for cultivation of Arthrospira platensis. Biotechnol Bioprocess Eng 21:767–776

Yoshikawa S, Kanesaki Y, Uemura A, Yamada K, Okajima M, Kaneko T, Ohki K (2021) Physiological and genomic analysis of newly-isolated polysaccharide synthesizing cyanobacterium Chroococcus sp. FPU101 and chemical analysis of the exopolysaccharide. J Gen Appl Microbiol 67:207–213

Zampieri RM, Adessi A, Caldara F, Codato A, Furlan M, Rampazzo C, De Philippis R, La Rocca N, Dalla Valle L (2020) Anti-inflammatory activity of exopolysaccharides from Phormidium sp ETS05, the most abundant cyanobacterium of the therapeutic Euganean thermal muds, using the zebrafish model. Biomolecules 10:582

Zarrouk C (1966) Contribution à l’étude d’une cyanophycée. Influence de divers facteurs physiques et chimiques sur la croissance et la photosynthèse de Spirulina maxima (Setch et Gardner) Geitler. PhD thesis, Université de Paris, France

Acknowledgements

The authors thank Centro di Competenza VALORE, Florence, Italy (Regione Toscana, Par-FAS 2007-2013 Projects), where part of the study was carried out.

Funding

Open access funding provided by Università degli Studi di Firenze within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The cyanobacterial strains belong to Fotosintetica & Microbiologica S.r.l., in which MRT and LR have a financial interest. VZ, NB, AN, FA, and AA declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zanolla, V., Biondi, N., Niccolai, A. et al. Protein, phycocyanin, and polysaccharide production by Arthrospira platensis grown with LED light in annular photobioreactors. J Appl Phycol 34, 1189–1199 (2022). https://doi.org/10.1007/s10811-022-02707-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10811-022-02707-0