Abstract

A novel electrode, carbon paste electrode modified with a nanocomposite of zirconium dioxide nanoparticles and ionic liquid (ZrO2NP/IL/CPE), has been fabricated and used to determine both the paracetamol (PAR) and metoclopramide (MCP) mixture in bulk powder, pharmaceutical formulations, and biological fluids. Furthermore, it is the first reported method to determine the paracetamol in presence of its toxic impurities (i.e., p-aminophenol and p-chloroacetanilide) simultaneously. Square wave (SWV) and cyclic voltammetric (CV) techniques were used to investigate the effect of scan rate, concentration, and pH in order to optimize sensor’s response. The calibration curves were obtained in both low and wide concentration ranges from (0.1–200 nM) to (3.0–100.0 µM) for both drugs with limit of detection (LOD) as low as 28 and 29 pM and limit of quantification (LOQ) 93 and 97 pM for PAR and MCP, respectively. The proposed sensor was used to assess PAR, MCP, and paracetamol toxic impurities in human plasma, urine samples, and pharmaceutical formulations with satisfactory results showing a broad dynamic linear range from 100 pM to 100 µM with high sensitivity and good reproducibility.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The most prevalent complaint of patients examined by the physician is headache [1]. The intracranial and extracranial arteries dilate causing vascular headaches which are categorized as migraine or non-migraine [2]. A reported study regarding the paracetamol/metoclopramide co-formulation showed that this combination was more efficient than using paracetamol only [3]. Metoclopramide (MCP) is a dopamine receptor antagonist, and it is mainly used for its antiemetic effect. Moreover, MCP is used for management of symptomatic gastro-esophageal reflux, vomiting, and nausea induced by chemotherapeutic drugs [4]. Pharmacological effects of metoclopramide is mediated through the cholinergic response of gastrointestinal tract by preventing smooth muscle relaxation resulted from released dopamine [5]. Furthermore, transdermal antiemetic patches with low dose are very effective in relieving chemotherapy patients’ nausea. Therefore, it is crucial to develop a reliable, sensitive, and easy analytical sensors for MCP in vitro/in vivo determination [6].

Paracetamol (PAR) or acetaminophen (AC) is a widely used over-the-counter pain killer and fever reliever [7]. Standard usage of paracetamol is safe on the human body; however, drug over-use may have serious side effects, such as disorders in liver functions, rashes on the skin, and pancreas inflammation [8]. Overdose of PAR is the leading cause of acute liver failure in the UK and the USA. However, currently there is not any rapid and selective point-of-care diagnostic kit available for PAR assessment in the emergency triage [9]. Thus, development of a simple, precise, and selective sensor for determining both PAR and its impurities is very important [10] as PAR impurities are toxic. The PAR impurities that have been studied in this research are the genotoxic and nephrotoxic p-aminophenol (PAP), i.e., acetaminophen impurity E and the hepatotoxic and nephrotoxic p-chloroacetanilide (i.e., acetaminophen related compound J) [11]. PAP is reported to be five times more toxic to the kidney than acetaminophen. PAP is considered as acetaminophen nephrotoxic metabolite as it mediates acetaminophen renal toxicity. Drug safety is affected by the toxicological properties of both the active pharmaceutical ingredient and its impurities. Impurities affect the quality and safety of pharmaceutical products. The impurity profiling of active pharmaceutical ingredients has recently acquired a greater attention [12].

The literature review shows that numerous techniques have been used for the detection of paracetamol, including (HPLC) [13], spectrophotometry [14], chemiluminescence [15], capillary electrophoresis (CE) [16], and titrimetry [17]. These methods are of high cost, tedious, and require pre-treatment step of samples [18].

There is an increasing interest in electrochemical sensors in general [19,20,21] and that involve using chemically modified electrodes in particular [22] due to its quick response, high selectivity, and sensitivity in determining trace-level analytes [10]. Carbon paste electrodes since introduced by Ralph N. Adams [23] have been increasingly used because their charging background current is low, low cost, and easiness of preparation compared to solid graphite, gold, silver, and platinum electrodes [24]. Their miniaturization possibility as well as the simple surface renewal process makes them desirable substrates for electrochemical sensors. Moreover, they can be easily modified with different nanoparticle compounds [25]. Modifying carbon paste electrodes using nano-materials have been employed in different analytical methods [26]. Nanoparticles and nano-materials exhibit distinctive chemical, physical, and electrochemical characteristics resulted from their tiny sizes, and these characteristics are different from the bulk of the same compounds [27].

It is worthy to clarify that the reported electrochemical method for determination of acetaminophen and metoclopramide was done using graphite pencil electrode [28]. The calibration curves were obtained over the range of 0.1 × 10–7 to 1.1 × 10–7 M and reached a detection limit of 3.25 nM for PAR and 1.16 nM for MCP only. While as in our study, we did not only study the simultaneous electrochemical determination of acetaminophen and metoclopramide but, moreover, included the toxic metabolites of paracetamol which to the best of our knowledge, has not been reported in the literature. This study has been applied successfully on different biological fluids and pharmaceutical formulations using the nanocomposite of zirconium dioxide nanoparticles and ionic liquid (ZrO2NP/IL)-modified carbon paste electrode. These modifiers greatly enhanced the electrode kinetics. It has been reported that the addition of ILs to a carbon paste electrode modifies the microstructure of the paste, decreases the charge transfer resistance, and increases charge transfer kinetics between the CPE surface and the analyte. Ionic liquid addition plays a crucial role to enhance the electroactivity of the electrode, which was partly due to excellent characteristics of IL/CPE, such as good electrical conductivity [29], high chemical stability, and high surface area. Moreover, metal oxides, in particular, transition metal oxides, have appealing physical and chemical characteristics, such as morphological structure, oxygen stoichiometry, electrochemical conductivity, and interfacial microenvironment of the reaction. Among the transition metal oxides, zirconium oxide nanoparticles (ZrO2 NPs) showed interesting electrochemical properties, including nontoxicity, thermal stability, wide band gap, and good electrical and surface properties. The proposed sensor has been employed for analytes quantitative determination and reached an LOD of 28 and 29 pM for PAR and MCP, respectively. The calibration curves were obtained in both low and wide concentration ranges from (0.1–200 nM) to (3.0–100.0 µM) for both drugs showing a broad range of linearity and low sensitivity.

In this study we modified CPE using zirconium oxide (ZrO2) nanoparticles together with an ionic liquid (IL). This work major objective is to develop a rapid, simple voltammetric sensor using the ionic liquid (n-hexyl-3-methylimidazolium hexafluorophosphate) and ZrO2 nanoparticles modified CPE to simultaneously determine PAR and MCP in their pharmaceutical formulation and in different biological fluids (plasma and urine). To our knowledge, there is not any report in the literature that has been developed for concurrent determination of PAR and MCP together with the PAR toxic impurities. The modified CPE has been characterized by cyclic voltammetry and SWV has been employed for analytes quantitative determination.

2 Experimental

2.1 Apparatus

The electrochemical workstation Bio-logic SP 150 was used for all voltammetric and impedimetric measurements. As a counter electrode, a platinum wire (BAS, USA) was used. The potential differences were measured with respect to a reference electrode of Ag/AgCl (3.0 mol L−1 KCl) (BAS, USA). For electrochemical tests, a glass cell (5 mL) was employed. For pH measurements, a JENWAY 3510 pH meter with a glass combination electrode (Staffordshire, England) was utilized. TEM measurements for examining the modified CPE (Japan Electro Company) were done by a JEM-1400 electron microscope.

2.2 Materials and reagents

Memphis Co. For Pharm. and Chemical Ind., (Cairo – Egypt) generously supplied pure PAR and MCP samples, and the standard purity were determined to be 99.91% (±1.6) and 99.94% (±1.7), respectively, according to the US Pharmacopeia [30]. Methanol (HPLC grade) and graphite powder were obtained from Sigma-Aldrich (Steinheim, Germany). Analytical reagent grade solvents and reagents were used as received without additional purification. Bi-distilled water was also used. Supporting electrolytes were Britton–Robinson (BR) buffer solutions (pH 2.0–10.0). To attain the required pH, buffer solutions were adjusted with an appropriate amount of 0.2-mol L−1 NaOH from Win Lab (Leicestershire, UK). Merck provided paraffin oil, which was the liquid employed to prepare the carbon paste electrode. The samples of human urine and plasma were provided by Holding Company for Biological Products and Vaccines (VACSERA, Egypt), where the plasma samples were stored frozen at −20 °C and the urine samples were stored at 4 °C. The ionic liquid, 1-hexyl-3-methylimidazolium hexafluorophosphate (purity 99%), was supplied from Alfa Aesar (Massachusetts, USA). Zirconium oxide nanoparticles were obtained from US-Nano, USA. p-aminophenol and p-chloroacetanilide were obtained from (NODCAR, Egypt). Migracid® tablets (10/500 mg) and Migracid® syrup (2/100 mg) were manufactured by Chemical Industries Development (CID), Egypt (batch NOs. 03170409 and 08180143, respectively). Miguara® tablets (5/500 mg) were manufactured by Memphis for Pharmaceuticals and Chemical, Egypt (batch NO. 317385).

2.3 Preparation of standard solutions and working solutions

2.3.1 PAR and MCP stock and working standard solutions

Stock solutions (1.0 mmol L−1) of PAR and MCP were prepared by transferring 24.9 mg of PAR and 29.0 mg of MCP into a 100-mL volumetric flask each and then the volume was completed with bi-distilled water. PAR and MCP working solutions (0.1 mmol L−1 to 1.0 µmol L−1) were prepared by suitable dilutions from its stock solution using bi-distilled water as a solvent.

2.3.2 Toxic impurities PAP and p-chloroacetanilide

PAP and p-chloroacetanilide (10–2 mmol L−1) were prepared by transferring 10.9 mg of PAP and 16.9 mg of p-chloroacetanilide each into a 10-mL volumetric flask and then completing the volume with bi-distilled water. PAP and p-chloroacetanilide working solutions (1.0 µmol L−1) were prepared by suitable dilutions from its stock solution using bi-distilled water as a solvent.

2.3.3 Preparation of working electrodes

Carbon paste electrode (CPE) with a diameter of 3 mm was prepared by mixing approximately 0.3 mL of paraffin oil with 0.5 g of graphite powder in a glass mortar. The carbon paste was packed into the hole of the electrode body. It is smoothed with touching the surface on a filter paper until it had a shiny appearance. Modified carbon paste electrodes were prepared by mixing different concentrations of the zirconium dioxide, ionic liquid, and graphite powder and then mixing with suitable amount of paraffin oil in a glass mortar until a homogeneously wetted paste was obtained; zirconium dioxide nanoparticle-modified carbon paste electrode (ZrO2NP/CPE)) was prepared by mixing of 1, 2, and 3% (w/w) of ZrO2NP and graphite powder; ionic liquid-modified carbon paste electrode (IL/CPE)) was prepared by mixing of 0.5, 1, and 1.5% (w/w) of ionic liquid and graphite powder; and zirconium dioxide nanoparticles and ionic liquid-modified carbon paste electrode ZrO2NP/IL/CPE was prepared by mixing 2% (w/w) ZrO2NP, 1% (w/w) of ionic liquid, and 97% (w/w) graphite powder.

2.4 Procedures

The modified ZrO2NP/IL/CPE was activated by cycling in the potential range of 0–1.6 V with a scan rate of 100 mV.s−1 in BR buffer of pH 7.0 several times until a reproducible response was achieved. After that, the ZrO2NP /IL/CPE was transferred into another cell containing BRB of pH 7.0 and the adequate amount of PAR and MCP were added.

2.4.1 Simultaneous determination of PAR and MCP in bulk powder

Square wave voltammetry (SWV) technique was used to determine PAR and MCP in bulk powder. Different volumes equivalent to 100.0 pM to 3.0 µM for PAR and MCP were accurately transferred from PAR and MCP standard solutions into of 5-mL volumetric flask and the volume was completed with BR buffer pH 7.0. The solutions were then transferred to the measurement cell and then SWV at the working ZrO2NP/IL/CPE was recorded at a scan rate of 100 mV s−1, amplitude of 25.0 mV, a step potential of 5 mV, and a frequency of 100 Hz. Calibration curves were constructed and the regression equations were calculated.

2.4.2 Determination of PAR and MCP in different pharmaceutical preparations: Migracid® Tablets (10/500 mg), Miguara® Tablets (5/500 mg), and Migracid® Syrup (2/100 mg)

Twenty tablets of each (Migracid and Miguara) were weighed and then finely powdered. In a 100.0-mL volumetric flask, 50.0-mL methanol was used to extract an accurately weighed quantity of the powder equivalent to the weight of one tablet. The flask was sonicated for 25 min, then filled with methanol to a volume of 100.0 mL, mixed thoroughly, and then filtered to eliminate the insoluble excipients. Water was used to dilute the filtrate further, with 100.0 mL of bi-distilled water added to only 1.0 mL of the filtrate.

5 mL of Migracid syrup were accurately measured and completed to 100.0 mL using methanol in a 100.0-mL volumetric flask. The flask was mixed well. Further dilution was done with water by adding 100.0 mL of bi-distilled water to only 10.0 mL of the solution.

Different volumes equivalent to (1 × 10–5 M and 2 × 10–7 M), (1 × 10–5 M and 1 × 10–7 M), and (2 × 10–5 M and 4 × 10–7 M) of PAR and MCP for Migracid tablet, Miguara tablet, and Migracid syrup, respectively, were accurately transferred from PAR and MCP standard solutions into of 5-mL volumetric flask and the volume was completed with BRB pH 7.0. The solutions were then transferred to the measurement cell, and the SWV at the working ZrO2NP/IL/CPE ratio was measured. The concentrations of PAR and MCP were then calculated using the regression equation from Sect. 2.4.1. To test the validity of the proposed method, an additional (8, 60, 90 µM), (20, 40, 80 µM), and (8, 10, 90 µM) of pure PAR and MCP for Migracid tablet, Miguara tablet, and Migracid syrup, respectively, were added to the previously prepared solution of the dosage form. After that, the mean percentage recoveries of the added PAR and MCP were computed.

2.4.3 Analysis of PAR and MCP in human urine

Urine samples of 3.0 mL were spiked with aliquots of both drugs equivalent to (3 × 10–10–6 × 10–8 M). The peak current at working ZrO2NP/IL/CPE was measured with SWV at a scan rate of 100 mVs−1. The regression equations were then calculated after constructing a calibration curve by plotting the peak current (ip) against each drug concentration (M).

2.4.4 Analysis of PAR and MCP in human plasma

In a 10.0-mL centrifuge tube, 3.0 mL of plasma was mixed with 1.0 mL of each drug (1.0 mM) and then 5.0 mL of acetonitrile was added to precipitate plasma protein. Following centrifugation, 2.0 mL of the supernatant was diluted with BR buffer (pH 7.0) to obtain different concentrations equivalent to (4 × 10–10 M—6 × 10–8 M) of PAR and MCP. Calibration curve was constructed by plotting the peak current (ip) against each drug concentration (M).

2.4.5 Analysis of Toxic Impurities PAP and p-chloroacetanilide

A concentration of 50 nM of PAP and p-chloroacetanilide mixed with 90 nM of PAR and MCP is measured using SWV in BR buffer pH 7.0. The oxidation peaks were measured and plotted. PAP and P-chloroacetanilide limit in dosage formulation should not exceed 50 ppm (0.458 µM) and 10 ppm (0.0589 µM), respectively, in British Pharmacopoeia (BP) and in US Pharmacopoeia (USP).

3 Results and discussion

3.1 Morphological characterization of ZrO2NP/IL/CPE

The ZrO2 nanoparticles and ionic liquid used in fabricating the ZrO2NP/IL/CPE electrochemical sensor were morphologically characterized and presented in Fig. 1 using transmission electron microscopy (TEM). The images revealed the nano-size tetragonal grains of zirconium dioxide (Fig. 1A), while the ionic liquid (Fig. 1B) shows the irregular crystal-like shape. Both ZrO2NP/IL (Fig. 1C) show different morphologies in comparison with CPE, showing the incorporation of the zirconium oxide and the ionic liquid which together significantly enhance the modified electrode active surface area.

3.2 Electrochemical behavior of ZrO2NP/IL/CPE using cyclic voltammetry

Zirconium oxide (ZrO2) nanoparticles have attracted significant attention and are considered as a temperature-dependent semiconductor. Moreover, ZrO2 nanoparticles are known for their high conductivity. Other characteristics include being biocompatible, chemically inert, and having large surface area. Thus, it is recently used as an electrochemical sensor to facilitate the electron transfer kinetics [27]. On the other side, ILs are conductive liquids that completely consist of anions and cations. Their high viscosity enables their use as carbon paste electrodes (CPE) binder. Whereas, being non-volatile helps the spreading of ILs casts from volatile solvent all over the electrode surface. ILs have high ionic conductivity up to 0.1 S cm−1; therefore, incorporating these materials in bulk electrode increases the conductivity. ILs are non-flammable and have low vapor pressure, unlike most organic solvents. As a result, IL-modified electrodes are easy to use and handle before being immersed in an aqueous electrolyte [31].

To investigate the benefits of using the proposed nanocomposite ZrO2NP/IL/CPE as a sensor base, the electrochemical response was investigated using bare CPE, ZrO2NP/CPE, and IL/CPE as control electrodes. Using 5.0-mmol L−1 K3Fe(CN)6 as redox probe in 0.1 mol L−1 KCl, the electrodes’ electroactive area is measured using the cyclic voltammetric technique; the current is collected at various scan rates and fitted using the Randles–Sevcik [32] (data not shown). The plot shows a linear relation between ip against ν1/2 and the slope was utilized to compute the electroactive areas of different electrodes which were found to be 0.048, 0.079, 0.088, and 0.139 cm2 for plain CPE, ZrO2NP/CPE, IL/CPE, and ZrO2NP/IL/CPE, respectively. This demonstrates that the ZrO2NP/IL/CPE has increased the electrode surface area.

Figure 2 shows the cyclic voltammetry responses toward PAR and MCP using prepared electrodes. Two voltammetric peaks indicating the electrochemical oxidation of PAR and MCP are recorded. When compared to the bare CPE, the ZrO2NP/IL/CPE-modified electrode has doubled the current. The electrode has a value of 16.0 and 38.0 µA for PAR and MCP, respectively. This is most likely because of the synergistic impact of ZrO2 nanoparticles and ionic liquid confirming that the proposed nanocomposite has superior electron transfer kinetics than the other electrodes and that it enhances the rate of electron transfer. The peak potential (Ep) at ZrO2 NP/IL/CPE was observed to be shifted toward negative potential compared to bare CPE, indicating that the modified electrodes facilitate electron transfer and improves the electrode kinetics.

3.3 Optimization of nanocomposite content

Figure 3A represents cyclic voltammograms of 0.1-mmol L−1 PAR and MCP in BRB of pH 7.0 and scan rate of 100 mV S−1 at bare CPE, ZrO2NP/CPE, and IL/CPE ZrO2NP/IL/CPE. The CV shows anodic peaks for both PAR and MCP with separation peak potential. The impact of the amount of both ZrO2 nanoparticles and ionic liquid, impregnated within the sensor, upon the height of ip was examined. As shown in Fig. 3A, the anodic peak current for both medications were investigated by screening the ratio of ZrO2 nanoparticles in the range of 1.0–3.0% w/w and ionic liquid in the range of 0.50–1.50% w/w. The results show that, when the ZrO2NP/IL/CPE sensor is modified with 2% w/w of ZrO2 nanoparticles and 1% w/w of ionic liquid, the anodic peak current is optimum. The addition of larger amounts from either ZrO2 nanoparticles or ionic liquid increases the background current and therefore, decreases the limit of detection as shown in Fig. 3A.

The oxidation current peaks were recorded to be 6.0 and 11.0 µA for PAR and MCP, respectively, at bare CPE, whereas the current values were 13.0 and 22.0 µA for PAR and MCP, respectively, when ZrO2NP/CPE was used. When IL/CPE was used, the peak current increased to 13.0 and 32.0 µA for PAR and MCP, respectively, and the data are summarized in Fig. 3B. The electrochemical behavior was further investigated using CV and EIS as surface characterization techniques in a solution of ferrocyanide/ferricyanide redox probe, as shown in Fig. 3C, D, respectively. The results showed enhanced response upon modification with either ZrO2 NP or ILs and synergistic effect when both are combined.

3.4 Selection of the optimum experimental conditions

3.4.1 Effect of pH

The used buffer’s pH has a great effect on the electrochemical sensitivity and voltammetric peak separation. Optimization of the electro-catalytic oxidation of PAR and MCP was performed using BR buffer at various pHs ranging from 2.0 to 8.0 using unmodified (bare CPE) as well as the modified (ZrO2NP/IL/CPE). The oxidation peak of PAR and MCP appearing from pH 3.0–8.0 is shown in Fig. 4A. As the pH raises, the oxidation peak currents of PAR and MCP rise significantly and at pH 7.0, their maximum values are reached, and then from pH 7.0 to 8.0, the peak currents decline. Thus, all further studies were carried out at pH 7.0.

A Investigation of the ZrO2 nanoparticles and ionic liquid amount used in the fabrication of the ZrO2NP/IL/CPE on the electrochemical behavior. B Comparison showing the effect of using the modified electrode (ZrO2NP/IL/CPE) on the peak current of both PAR and MCP improving the current to 10.3 and 26.94 µA, respectively

According to the following Nernst equations, PAR and MCP have pH-dependent peak potentials (Ep) and is shown in (Fig. 4B):

The results are closely similar to the theoretical Nernst value of 0.0592 V for an electrochemical process with equal numbers of electrons and protons. Furthermore, the response of peak current (ip) is pH dependent and the maximum anodic current/analytical signal for both PAR and MCP was obtained at pH 7.0.

3.4.2 Effect of scan rate

The voltammetric scan rate effect was studied, and the results are shown in Fig. 5A. The electrochemical signals of PAR and MCP were investigated at scan rates (ν) range 20–150 mV s−1. The results indicate that both peak potential and peak height are linearly dependent on the scan rate. To further investigate this relation, the peak current is plotted versus square root of scan rate in Fig. 5B, From the regression equation, (ip) is linear with (ν)1/2 up to 100mVs−1 [33].

where ip is the peak current (μA), n is the number of electrons, ν is the scan rate (V s−1), C is the target analyte concentration, A is the electrode area, and D0 is the diffusion coefficient (cm2 s−1). We calculated the apparent diffusion coefficient, Dapp, of MCP and PAR from cyclic voltammetry results which increases from 9.6 × 10−7 cm2 s−1 in case of bare CPE to 6.2 × 10−5 cm2 s−1 upon modification with ZrO2/IL nanocomposite. This shows the fast mass transfer of the analyte molecules toward ZrO2NP /IL/CPE surface from bulk solutions and enhanced electron transfer kinetics at the electrode surface. Furthermore, the calculated Dapp values shows that ZrO2 nanoparticles and ionic liquid enhance the electron transfer kinetics at the electrode/solution interface indicating that it is a diffusion-controlled electrode reaction [34].

A Scan rate effect on the electrochemical signal of 0.1 mmol L−1 of PAR and MCP at different scan rates (ν) 20–150 mV s−1 in BRB pH 7.0. B Relation between peak current and the square root of scan rate. C Relation between log scan rate and log peak current. D Relation between log scan rate and peak potential

We obtained a linear relationship between logarithm of current and logarithm of scan rate, Fig. 5C, and the regression equations for each drug are calculated to be

The slope values for PAR and MCP is slightly larger than 0.5, implying that the electroactive species are transported via both diffusion-limited process combined with some adsorption contribution [35].

The relation between the peak potential and scan rate shows that increasing the scan rate shifts Ep to more positive potentials as represented in Fig. 5D, and the results can be expressed by the following equations:

Lavern’s theory for irreversible processes [36] was applied in order to calculate the number of electron transferred and to determine other kinetic parameters for PAR and MCP oxidation on the ZrO2NP/IL/CPE.

where R is the gas constant, T is the temperature, F is the Faraday constant, α is the electron transfer coefficient, and n is the number of the electrons and αn can be calculated from the slope of peak potential against log scan rate. For the system under study, the slopes were 0.0557 and 0.0539 and αn were calculated to be 1.061 and 1.095 for PAR and MCP at ZrO2NP/IL/CPE, respectively. Since for a totally irreversible electron transfer α assumed to be 0.5 [37], therefore “n” value was calculated to be 2.12 and 2.19 for PAR and MCP, respectively, which is consistent with 2 electron transfer processes involved in the oxidation of PAR and MCP at the modified sensor.

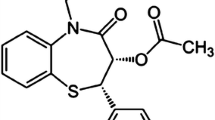

3.4.3 Suggested mechanism of PAR and MCP electrochemical oxidation

Based on the results of the experiments, the number of electrons transported (n) for both medicines were determined to be two electrons. As a result, the likely electro-oxidation pathways for both medicines are provided in Scheme 1.

3.5 Method validation

The figures of merit were established in compliance with the International Conference on Harmonization (ICH) Guidelines [38].

3.5.1 Linearity

We investigated the electro-analytical response to PAR in the presence of MCP to determine the specificity of the proposed ZrO2NP/IL/CPE sensor. This was accomplished by varying the concentrations of the PAR and MCP at the same time while recording the SWVs with the ZrO2NP/IL/CPE and comparing the results to bare CPE. The voltammetric response of ZrO2NP/IL/CPE sensor toward PAR in the presence of MCP is shown in Fig. 6A. Peak current values and the calibration curves were plotted using the average of three replicate measurements as illustrated in Fig. 6B, C. Linear regression equations of the low concentration range for both the drugs arising from calibration plots are represented as follows:

A Square wave voltammogram for different concentrations of PAR and MCP shows well-defined anodic peaks at potentials of +0.421 and +0.792 V (vs. Ag/AgCl), corresponding to the oxidation of PAR and MCP, respectively. B Calibration curve for the low range of concentrations of PAR and MCP. C Calibration curve for the wider range of concentrations of PAR and MCP

The findings show well-defined anodic peaks corresponding to the oxidation of PAR at potential (+0.421 V) and MCP at potential (+0.792 V) (vs. Ag/AgCl). The calibration parameters are shown in Table 1.

The formula LOD = 3 s/m is used to measure the limit of detection (LOD), while the formula LOQ = 10 s/m is used to measure the limit of quantification (LOQ), where s is the standard deviation of background current and m is the slope of calibration curve [39]. The LODs for PAR and MCP were determined to be 28 and 29 pM, respectively, while the LOQs were determined to be 93.3 and 96.6 pM, respectively. The calibration characteristics acquired for MCP and PAR are listed in Table 1 since it is vital to calculate validation parameters for any analytical procedure. These results indicate that the proposed method is both accurate and precise.

3.5.2 Specificity (separation peak potential (ΔE p))

Table 2 shows the peak potentials of PAR, MCP, and the toxic metabolites PAP and p-chloroacetanilide. Therefore, we find that the separation peak potential (ΔEp) between PAP and PAR = 0.323 V, PAR and MCP = 0.371 V, and MCP and p-chloroacetanilide = 0.438 V indicating excellent and complete separation of peaks. The suggested method’s specificity was demonstrated by its ability to assess PAR and MCP in pharmaceutical product without interference from frequently used excipients.

Paracetamol is hydrolyzed to p-aminophenol and acetic acid. p-chloroacetanilide could be one of the most related substances to paracetamol [40]. These interfering molecules were chosen from a list of components that are often encountered in pharmaceutical formulations or biological fluids. The concentration of PAR and MCP in a mixed solution containing PAP and p-chloroacetanilide was determined and represented in Fig. 7 showing no interference and good recovery.

3.5.3 Effect of interfering materials

Interfering materials such as starch, glucose, cellulose, sucrose, and K+, Mg2+, and Na+ ions can affect the electro-catalytic determination of PAR and MCP. The response signal of PAR and MCP has been recorded after the incorporation of these compounds into sample solution showing that the applied sensors have high selectivity, and no interference affects the electro-analytical assessment of PAR and MCP, as illustrated in Table 3.

3.5.4 Determination of PAR and MCP in drug product

The suggested SWV approach was effectively employed to detect PAR and MCP in pharmaceutical formulations after confirming its validity, as shown in Table 4.

3.5.5 Application in urine and plasma

In addition, we used the SWV method to measure PAR and MCP in spiked human plasma and urine samples, with the findings presented in Table 5. Both medications PAR and MCP recovered well in BR buffer at pH 7.0, according to the results shown in Table 5.

3.5.6 Statistical comparison of obtained results with the reported method

The accuracy of proposed method was further examined utilizing the student t test and F value to compare the results produced by the suggested approach to a published method [41], which showed no statistically notable difference between the two approaches in terms of accuracy and precision, as shown in Table 6. Moreover, the figures of merit of the sensor were compared to other reported methods as shown in supporting information Table S1.

3.5.7 Reproducibility

Ten electrodes were produced in parallel (as stated in the experimental section) to test the reproducibility of the proposed sensor. For a 0.1 mmol L−1 of two drugs, the relative standard deviation (RSD) for the Ip between electrodes is 2.11% showing that the modified electrodes are reproducible. The relative standard deviation (RSD) of the peak current was 2.30% after the ZrO2NP/IL/CPE was stored dry in air for two weeks, indicating excellent stability of the modified electrodes. Based on the results, the proposed sensor is suitable for regular analysis of PAR and MCP in their combined medicinal dose form. The suggested method provided promising results for further investigations to determine both compounds in plasma and urine.

4 Conclusion

The proposed electrochemical sensor is a simple, selective, and reliable approach for determining PAR and MCP simultaneously using nanocomposite of both ZrO2NP- and IL-modified CPE. The modification of the CPE with nanocomposite increased the electrode surface area and enhanced electron transfer kinetics that resulted in improved sensitivity toward both drugs. The novel approach for electrochemical detection of both PAR and MCP is stable, highly selective, has a wide linear dynamic range, and a low detection limit, with high reproducibility. The suggested sensor was successfully used to determine PAR and MCP in a variety of pharmaceutical formulations (tablets and syrup), as well as spiked human plasma and urine samples, with good results. When compared to other approaches for determining PAR and MCP that have been reported, the suggested method is simple, selective, and quick, as well as possibly portable, and might be utilized for quality control, clinical analysis, as point-of-care in hospital emergency for early detection of PAR overdose and routine drug testing in pharmaceutical formulations.

Data Availability

All detailed data and equations are included in the results and discussion section and also any other samples and information of the compounds are available from the corresponding author on reasonable request.

References

Frese T, Druckrey H, Sandholzer H (2014) Headache in general practice: frequency, management, and results of encounter. Int Sch Res Not 2014:169428–169428

Gazerani P, Cairns BE (2018) Dysautonomia in the pathogenesis of migraine. Expert Rev Neurother 18:153–165

Matts SG, Boston PF (1983) Paracetamol plus metoclopramide ('Paramax’) as an adjunct analgesic in the treatment of arthritis. Curr Med Res Opin 8:547–552

Pinder RM, Brogden RN, Sawyer PR et al (1976) Metoclopramide: a review of its pharmacological properties and clinical use. Drugs 12:81–131

Van Nueten JM, Janssen PA (1978) Is dopamine an endogenous inhibitor of gastric emptying? In Duthie HL (ed) Gastrointestinal Motility in Health and Disease: Proceedings of the 6th International Symposium on Gastrointestinal Motility, held at the Royal College of Surgeons of Edinburgh, 12–16th September, 1977. Dordrecht: Springer, pp. 173–181

Kahali N, Khanam J (2018) A novel HPLC method validation based on analytical techniques of metoclopramide benzamide derivative (metoclopramide base) and its determination from solid dispersion by solvent evaporation method. J Appl Pharma Sci 8:18–26

Toussaint K, Yang XC, Zielinski MA, Reigle KL, Sacavage SD, Nagar S, Raffa RB (2010) What do we (not) know about how paracetamol (acetaminophen) works? J Clin Pharmacy Ther 35:617–638

Vermeulen NPE, Bessems JGM, Van De Straat R (1992) Molecular aspects of paracetamol-induced hepatotoxicity and its mechanism-based prevention. Drug Metab Rev 24:367–407

Zhang Y, Huang Z, Wang L et al (2018) Point-of-care determination of acetaminophen levels with multi-hydrogen bond manipulated single-molecule recognition (eMuHSiR). Anal Chem 90:4733–4740

Mehretie S, Admassie S, Tessema M, Solomon T (2011) Voltammetric determination of paracetamol with poly(3,4-ethylenedioxythiophene) modified glassy carbon electrode. Anal Bioanal Electrochem 3:28–50

Abdelwahab NS, AbdelrahmanMM, Boshra JM, Taha AA (2019) Different stability-indicating chromatographic methods for specific determination of paracetamol, dantrolene sodium, their toxic impurities and degradation products. Biomed Chromatogr 33:e4598 https://doi.org/10.1002/bmc.4598

Braimah HY, Tijjani AB, Amos SC (2019) Impurity profiling of paracetamol dosage forms used in Maiduguri metropolis. World J Pharma Res 8(9):1659–1685

Marı́n A, Garcı́a E, Garcı́a A, Barbas C (2002) Validation of a HPLC quantification of acetaminophen, phenylephrine and chlorpheniramine in pharmaceutical formulations: capsules and sachets. J Pharma Biomed Anal 29:701–714

Morelli B (1989) Spectrophotometric determination of paracetamol in pure form and in tablets. J Pharm Biomed Anal 7:577–584

Ruengsitagoon W, Liawruangrath S, Townshend A (2006) Flow injection chemiluminescence determination of paracetamol. Talanta 69:976–983

Zhao S, Bai W, Yuan H, Xiao D (2006) Detection of paracetamol by capillary electrophoresis with chemiluminescence detection. Anal Chim Acta 559:195–199

Burgot G, Auffret F, Burgot J-L (1997) Determination of acetaminophen by thermometric titrimetry. Anal Chim Acta 343:125–128

Engin C, Yilmaz S, Saglikoglu G et al (2015) Electroanalytical investigation of paracetamol on glassy carbon electrode by voltammetry. Int J Electrochem Sci 10:1916–1925

Acer S, Demir E, İnam R (2020) Square wave voltammetric determination of pencycuron fungicide and application to commercial formulation. J Food Meas Charact 14:2099–2107

Demir E, İnam O, Silah H, Karimi-Maleh H (2020) Studies of mechanism, kinetic model and determination of bupivacaine and its application pharmaceutical forms. Microchem J 159:105531

Demir E, İnam R (2014) Electrochemical behaviour and determination of rimsulfuron herbicide by square wave voltammetry. Int J Environ Anal Chem 94:1330–1341

Elhassan MM, Mahmoud AM, Hegazy MA, Mowaka S (2021) In-line monitoring of sitagliptin dissolution profile from tablets utilizing an eco-friendly potentiometric sensor. Chem Papers 75:4165–4176

Adams RN (1958) Carbon paste electrodes. Anal Chem 30:1576

Apetrei C, Apetrei IM, De Saja JA, Rodriguez-Mendez ML (2011) Carbon paste electrodes made from different carbonaceous materials: application in the study of antioxidants. Sensors (Basel, Switzerland) 11:1328–1344

Barek J (2021) How to improve the performance of electrochemical sensors via minimization of electrode passivation. Chemosensors 9:1–15

Nazlawy HN, Zaazaa HE, Merey HA, Attay SA (2023) Green voltammetric nano scaled determination of toldimfos and its residues in cattle meat and milk in presence of its toxic metabolite and Co-administered vitamin C. Sustain Chem Pharm 31:100906 https://doi.org/10.1016/j.scp.2022.100906

Chikere CO, Faisal NH, Kong-Thoo-Lin P, Fernandez C (2020) Interaction between amorphous zirconia nanoparticles and graphite: electrochemical applications for gallic acid sensing using carbon paste electrodes in wine. Nanomaterials 10:537

Patil S, Pattar VP, Nandibewoor ST (2016) Simultaneous electrochemical determination of acetaminophen and metoclopramide at electrochemically pre-treated disposable graphite pencil electrode. J Electrochem Sci Eng 6:265–276

El-Nassan HB, El-Mosallamy SS, Mahmoud AM (2023) Unexpected formation of hexahydroxanthenediones by electrochemical synthesis in deep eutectic solvents. Sustain Chem Pharm 35:101207

Formulary USPatN (2019) U.S.Pharmacopeia. Rockville: United States Pharmacopeial Convention

Opallo M, Lesniewski A (2011) A review on electrodes modified with ionic liquids. J Electroanal Chem 656:2–16

Atty SA, Sedik GA, Morsy FA et al (2019) A novel sensor aluminum silicate modified carbon paste electrode for determination of anti-depressant dothiepin HCl in pharmaceutical formulation and biological fluids. Microchem J 148:725–734

Bard AJ (1980) Electrochemical methods: fundamentals and applications. Wiley, New York

Steentjes T, Jonkheijm P, Huskens J (2017) Electron transfer processes in ferrocene-modified poly(ethylene glycol) monolayers on electrodes. Langmuir 33:11878–11883

Shamsipur M, Farhadi K (2000) Adsorptive stripping voltammetric determination of ketoconazole in pharmaceutical preparations and urine using carbon paste electrodes. Analyst 125:1639–1643

Laviron E (1979) The use of linear potential sweep voltammetry and of a.c. voltammetry for the study of the surface electrochemical reaction of strongly adsorbed systems and of redox modified electrodes. J Electroanal Chem Interfacial Electrochem 100:263–270

Atty SA, Ghany MFA, Hussein LA et al (2020) TiO2 nanoparticles and ionic liquid platform for selective electrochemical determination of indacaterol in pharmaceutical formulations and human fluids: application to content uniformity. J Iran Chem Soc 17:383–395

Guideline IHT (2005) Validation of analytical procedures: text and methodology Q2 (R1). In International conference on harmonization. Geneva, Switzerland

Uhrovcik J (2014) Strategy for determination of LOD and LOQ values–some basic aspects. Talanta 119:178–180

Kader EF (2011) Detection of impurities in paracetamol and aspirin dosage forms used in the Gaza Strip Detection of impurities in paracetamol and aspirin dosage forms used in the Gaza Strip. PhD Thesis, Al-Azhar University-Gaza-Faculty of Pharmacy 1–94

Hegazy A, Löbenberg R, Hassan N, Abdel-Kawy M (2018) Application and validation of two smart spectrophotometric and a HP-TLC densitometric methods for determination of metoclopramide hydrochloride/paracetamol in raw material and in pharmaceuticals. Int J Pharm 3:470–81

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The present research did not get any specific grant from funding agencies in the commercial, public, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

All authors have read and approved the manuscript. Shimaa Abdel Atty and Haya Salah collected all the data, prepared all figures, and wrote the article. Amr Mahmoud participated in writing the article. Hanan Merey revised the whole article and updated it.

Corresponding authors

Ethics declarations

Conflict of interest

All authors have no conflicts of interest and no significant competing financial, professional, or personal interests that might have influenced the performance or presentation of the work described in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sawan, H.S., Merey, H.A., Mahmoud, A.M. et al. Electrochemical sensor based on ZrO2/ionic liquid for ultrasensitive simultaneous determination of metoclopramide and paracetamol in biological fluids. J Appl Electrochem 54, 703–718 (2024). https://doi.org/10.1007/s10800-023-01982-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-023-01982-0