Abstract

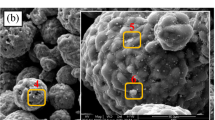

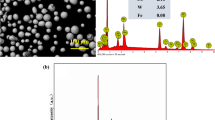

A CeO2-doped plasma electrolytic oxidation (PEO) composite coating was prepared on the surface of Cu–Zn alloys by adding CeO2 nanoparticles into the mixed electrolytes of Na2SiO3·9H2O and sodium hydroxide. Surface microstructure and element composition of PEO coatings were studied by a scanning electron microscope (SEM) with energy-dispersive X-ray spectroscopy (EDS) and X-ray diffraction (XRD). Microstructure analysis showed that CeO2 nanoparticles were uniformly deposited on the sample surface, and most of the particles were embedded into PEO coatings. Ce element found in the EDS and XRD analysis confirmed the successful incorporation of CeO2 nanoparticles. Furthermore, with the addition of CeO2 nanoparticles, the coating porosity decreased gradually, while the thickness and surface roughness of PEO coatings decreased and then increased. Corrosion resistance of PEO coatings was investigated by using a potentiodynamic polarization test. The results show that the addition of CeO2 nanoparticles has significantly improved the corrosion resistance of PEO coatings. Especially, the corrosion current density of the PEO coating with 4 g/L CeO2 concentration is 3 orders of magnitude more than that of the bare alloy substrate.

Graphical abstract

Similar content being viewed by others

Data availability

All data and materials are available.

Code availability

All software application is available.

References

Ren ZH, Zhang DZ, Fu G, Jiang JJ, Zhao M (2021) High-fidelity modelling of selective laser melting copper alloy: laser reflection behavior and thermal-fluid dynamics. Mater Des 207:109857. https://doi.org/10.1016/j.matdes.2021.109857

Liu Y, Xu TH, Liu Y, Gao YL, Di C (2020) Wear and heat shock resistance of Ni-WC coating on mould copper plate fabricated by laser. J Mark Res 9:8283–8288. https://doi.org/10.1016/j.jmrt.2020.05.083

Michał C, Szymon S, Jacek B, Artur M, Marcin S (2021) New copper alloys used to make products intended for contact with drinking water. Materials 14:6301–6301. https://doi.org/10.3390/MA14216301

Dong QY, Wang MP, Shen LN, Jia YL, Li Z (2015) Diffraction analysis of α-Fe precipitates in a polycrystalline Cu–Fe alloy. Mater Charact 105:129–135. https://doi.org/10.1016/j.matchar.2015.05.012

Zhao XD, Yan CM, Shao J, Yang J, Liu J, Sun DY, Wang S (2019) Influence of pseudomonas aeruginosa and sulfate-reducing bacteria composite on the corrosion behavior of brass. Int J Electrochem Sci 14:6468–6477. https://doi.org/10.20964/2019.07.19

Zhao Q, Wang F, Dang PL (2019) 6-dibutylamino-1,3,5-triazine-2,4-dithiolmonosodium as an inhibitor of brass corrosion in 0.5 M sodium chloride solution. Int J Electrochem Sci 14:10121–10129. https://doi.org/10.20964/2019.11.09

Radovanović MB, Tasić ŽZ, Mihajlović MBP, Simonović AT, Antonijević MM (2019) Electrochemical and DFT studies of brass corrosion inhibition in 3% NaCl in the presence of environmentally friendly compounds. Sci Rep 9:16081. https://doi.org/10.1038/s41598-019-52635-2

Liu F, Liu CS, Chen SY, Tao XQ, Zhang Y (2010) Laser cladding Ni–Co duplex coating on copper substrate. Opt Lasers Eng 48:792–799. https://doi.org/10.1016/j.optlaseng.2010.02.009

Jiang SZ, Guo ZN, Deng Y, Dong HS, Li XY, Liu JW (2018) Effect of pulse frequency on the one-step preparation of superhydrophobic surface by pulse electrodeposition. Appl Surf Sci 458:603–611. https://doi.org/10.1016/j.apsusc.2018.07.120

Ranjan A, Islam A, Pathak M, Khan MK, Keshri AK (2019) Plasma sprayed copper coatings for improved surface and mechanical properties. Vacuum 168:108834–108834. https://doi.org/10.1016/j.vacuum.2019.108834

Kasalica B, Petković-Benazzouz M, Sarvan M, Belča I, Maksimović B, Misailović B, Popović Z (2020) Mechanisms of plasma electrolytic oxidation of aluminum at the multi-hour timescales. Surf Coat Technol 390:125681. https://doi.org/10.1016/j.surfcoat.2020.125681

Joseph J, Gallo SC, Catubig R, Wang K, Somers A, Howlett P, Fabijanic D (2020) Formation of a corrosion-resistant coating on zinc by a duplex plasma electrolytic oxidation and conversion surface treatment. Surf Coat Technol 395:125918. https://doi.org/10.1016/j.surfcoat.2020.125918

Wu T, Balawert C, Serdechnova M, Karlova P, Dovzhenko G, Wieland DCF, Stojadinovic S, Vasilic R, Mojsilovic K, Zheludkevich ML (2022) Formation of plasma electrolytic oxidation coatings on pure niobium in different electrolytes. Appl Surf Sci 573:151629. https://doi.org/10.1016/j.apsusc.2021.151629

Hsieh SF, Ou SF, Chou CK (2017) The influence of the substrate on the adhesive strength of the micro-arc oxidation coating developed on TiNi shape memory alloy. Appl Surf Sci 392:581–589. https://doi.org/10.1016/j.apsusc.2016.09.001

Yang WB, Li QB, Liu WM, Liang J, Peng ZJ, Liu BX (2017) Characterization and properties of plasma electrolytic oxidation coating on low carbon steel fabricated from aluminate electrolyte. Vacuum 144:207–216. https://doi.org/10.1016/j.vacuum.2017.08.003

Cheng YL, Zhu ZD, Zhang QH, Zhuang XJ, Cheng YL (2020) Plasma electrolytic oxidation of brass. Surf Coat Technol 385:125366–125366. https://doi.org/10.1016/j.surfcoat.2020.125366

Asgari M, Aliofkhazraei M, Barati DG, Sabour RA (2020) How nanoparticles and submicron particles adsorb inside coating during plasma electrolytic oxidation of magnesium. Surf Coat Technol 383:125252. https://doi.org/10.1016/j.surfcoat.2019.125252

Liu X, Zhang TC, He HQ, Ouyang LK, Yuan SJ (2020) A stearic Acid/CeO2 bilayer coating on AZ31B magnesium alloy with superhydrophobic and self-cleaning properties for corrosion inhibition. J Alloys Compds 834:155210. https://doi.org/10.1016/j.jallcom.2020.155210

Gong Y, Geng JW, Huang J, Chen Z, Wang ML, Chen D, Wang HW (2021) Self-healing performance and corrosion resistance of novel CeO2-sealed MAO film on aluminum alloy. Surf Coat Technol 417:127208. https://doi.org/10.1016/j.surfcoat.2021.127208

Toorani M, Aliofkhazraei M, Rouhaghdam AS (2018) Microstructural, protective, inhibitory and semiconducting properties of PEO coatings containing CeO2 nanoparticles formed on AZ31 Mg alloy. Surf Coat Technol 352:561–580. https://doi.org/10.1016/j.surfcoat.2018.08.053

Ji RN, Peng GC, Zhang SG, Li Z, Li J, Fang T, Zhang Z, Wang Y, He YD, Wu JS (2018) The fabrication of a CeO2 coating via cathode plasma electrolytic deposition for the corrosion resistance of AZ31 magnesium alloy. Ceram Int 44:19885–19891. https://doi.org/10.1016/j.ceramint.2018.07.250

Oh YJ, Mun JI, Kim JH (2009) Effect of alloying elements on microstructure and protective properties of Al2O3 coatings formed on aluminum alloy substrates by plasma electrolysis. Surf Coat Technol 204:141–148. https://doi.org/10.1016/j.surfcoat.2009.07.002

Wang DD, Liu XT, Wu YK, Han HP, Yang Z, Su Y, Zhang XZ, Wu GR, Shen DJ (2019) Evolution process of the plasma electrolytic oxidation (PEO) coating formed on aluminum in an alkaline sodium hexametaphosphate ((NaPO3)6) electrolyte. J Alloy Compd 798:129–143. https://doi.org/10.1016/j.jallcom.2019.05.253

Acknowledgements

The authors would like to acknowledge the financial support from the Natural Science Foundation of Shandong Province (ZR2021ME159 and ZR2021ME211) and the Open Research Fund Program of Shandong Provincial Key Laboratory of Precision Manufacturing and Non-traditional Machining.

Funding

This work was supported by the Natural Science Foundation of Shandong Province (ZR2021ME159 and ZR2021ME159) and the Open Research Fund Program of Shandong Provincial Key Laboratory of Precision Manufacturing and Non-traditional Machining.

Author information

Authors and Affiliations

Contributions

JM contributed to investigation, conducting a research and investigation process, and project administration. SW contributed to specifically performing the experiments and writing the original draft. QG contributed to visualization. XD contributed to data/evidence collection. LL contributed to data curation. HY contributed to writing—review & editing. HL contributed to writing—review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publication

We confirm that this work is original and has not been published elsewhere, nor is currently under consideration for publication elsewhere. All the authors listed have agreed to publish the manuscript that is enclosed.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Meng, J., Wang, S., Guan, Q. et al. Fabrication and performance of composite coating doped with CeO2 nanoparticles by plasma electrolytic oxidation on Cu–Zn alloy surface. J Appl Electrochem 53, 2347–2357 (2023). https://doi.org/10.1007/s10800-023-01926-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-023-01926-8