Abstract

Corrosion of steel bars is one cause of deterioration in reinforced concrete structures. The state of corrosion of rebar in concrete structures can be measured using the AC impedance method. The typical three-electrode AC impedance method requires electrical continuity between the rebar and the measurement device, which may be inconvenient because the structure requires to be partly damaged by processes such as drilling. The present study proposes a method to obtain the same impedance spectra as the three-electrode method by modifying the electrode configuration of the four-electrode method. The procedures for such a measurement are as follows: first, place the counter electrode and the measurement reference electrode at the measurement point; place another counter electrode at a sufficient distance from the measurement point; place another reference electrode at a sufficient distance from both the measurement point and the applied counter electrode; and connect WE_I to the applied counter electrode, WE_V to the reference electrode, CE to the applied counter electrode, and RE to the applied counter electrode, and measure the impedance. In this paper, the physical experiments and the numerical experiments demonstrate the validity of the above method. Under the conditions of this physical experiment (concrete W/C = 54.2%, cover 50 mm), the distance between the measurement point and the application counter electrode was required to be about 1.3 m. The distance between the measurement point and the reference matching electrode was also required to be about 1.3 m.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

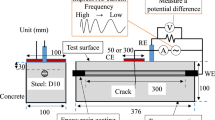

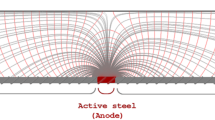

Corrosion of steel bars is one cause of deterioration in reinforced concrete structures [1]. Because of the highly alkaline pore water in concrete with a pH of 12–13, the steel bars in concrete form a passive film on their surfaces, making them corrosion resistant [2]. However, neutralization of the concrete or introduction of external chloride ions leads to corrosion of the steel bars and the resulting volumetric expansion of the steel causes cracks in the concrete [3]. Such cracks are broadly referred to as corrosion cracks. Since it becomes increasingly difficult to repair or reinforce the rebar as the corrosion progresses, it is important to ascertain the corrosion of the rebar before corrosion cracks occur. The state of corrosion of rebar in concrete structures can be measured using the AC impedance method [4,5,6,7,8]. The three-electrode and four-electrode AC impedance methods are commonly used to obtain the AC impedance of a steel bar in concrete. Figure 1 shows the electrode configuration for the three-electrode method and four-electrode method.

In Fig. 1, WE_V, WE_I, CE, and RE are the working terminal for voltage measurement, the working terminal for current measurement, the counter terminal, and the reference terminal, respectively. In the three-electrode method, a counter electrode and a reference electrode are placed on the concrete surface. WE_V, WE_I, CE, and RE are connected as shown in the Fig. 1a, respectively, AC is then applied between the counter electrodes and the rebar, the potential difference between the reference electrodes is measured. After the measurement, the impedance is calculated from the applied current value and the potential difference change [9,10,11]. The typical three-electrode AC impedance method requires electrical continuity between the rebar and the measurement device, which may be inconvenient because the structure requires to be partly damaged by processes such as drilling. The three-electrode method requires that all rebar present between the connection and measurement positions be in continuity. However, not all rebar in the concrete is electrically conductive, and the risk of non-conductivity increases the further the measurement position is from the connection position. In the four-electrode method, two counter electrodes are placed on the concrete surface, and two reference electrodes are placed between the two counter electrodes. WE_V, WE_I, CE, and RE are connected as shown in the Fig. 1b, respectively, AC is then applied between the counter electrodes and the potential difference between the reference electrodes is measured. After the measurement, the impedance is calculated from the applied current value and the potential difference change. Thus, the four-electrode method does not require a connection between the rebar and the measurement device. The advantage of the four-electrode method is that it does not involve the destruction of the concrete for electrical continuity. The four-electrode method requires that the electrode setup range be within the electrical continuity range. Therefore, the risk of falling outside the continuity range is reduced. This is another advantage of the four-electrode method. Therefore, several previous studies have investigated the ways of obtaining impedance spectra without electrical continuity in the rebar using a four-electrode method (Fig. 1) [11,12,13]. In the three-electrode method, all of the applied current flows into the rebar. In contrast, in the four-electrode method, the applied current flows in two paths, as shown in Fig. 1. Therefore, the current flowing into the rebar cannot be quantified, and the measurement results are often interpreted relatively. The present study proposes a method to obtain the same impedance spectra as the three-electrode method by modifying the electrode configuration of the four-electrode method. The principle of this measurement is described in the Discussion section.

2 Experimental

2.1 Specimen preparation

Figure 2 shows the dimensions and reinforcement of the specimen.

The dimensions of the concrete specimens were 1600 mm × 1600 mm × 100 mm with 15 rebars each in the vertical and horizontal directions. The rebar was φ19 mm × 1600 mm and was placed such that the first cover was 50 mm and the second cover was 69 mm. The placement and distance of the electrodes are important for this method. The size of the specimen was determined to be the largest possible so that the electrodes could be placed freely on the specimen. Two types of concrete specimens were prepared: in one, the entire surface of the rebar was corroded (the “corroded specimen”) while in another, it was not corroded (the “non-corroded specimen”). The rebar in the corroded specimen was corroded by spraying it with 3% salt water in air before embedding it in concrete. Rebars were electrically short-circuited by welding, and measurement leads were connected at the end points. The concrete was prepared using ordinary Portland cement and crushed aggregate. Table 1 shows the concrete mixture proportions. In Table 1, W/C is the water to cement weight ratio, W is the unit contents of water, C is the cement, S is the fine aggregate, G is the coarse aggregates, and Ad is the Admixture.

2.2 Electrochemical impedance measurements

Electrochemical impedance measurements were carried out using a potentiogalvanostat and a frequency response analyzer in a four-electrode setup (Fig. 1). The coordinates on the specimen are indicated using the notation (x mm, y mm, z mm) as per the coordinate axes shown in Fig. 2. The measurement position was (150 mm, 150 mm, 100 mm). One counter electrode and one reference electrode were placed for each measurement position, and they are referred to as the measurement counter electrode and the measurement reference electrode, respectively. Table 2 shows the measurement configurations. Moreover, WE_V, WE_I, CE, and RE are the working terminal for voltage measurement, the working terminal for current measurement, the counter terminal, and the reference terminal, respectively. Configurations labeled “Rebar” represent connections between the rebar and the conducting lead wire described in the specimen preparation.

The arrangement for Configuration 0-0, which is the typical three-electrode configuration, is shown in Fig. 3. For simplicity, only two dimensions are represented in Figs. 3, 4, 5. The actual arrangement is three-dimensional, as shown by the coordinates in the table. To show the correspondence between Fig. 2 and Figs. 3, 4, 5, a top view of the specimen is also added to Fig. 3. To save space, Fig. 4, 5 do not include a top view.

The arrangements of Configurations 0-1 to 0-8 are shown in Fig. 4, those of Configurations 1-0 to 8-0 in Fig. 5, and that of Configuration 8-8 in Fig. 6. In Configurations 0-1 to 0-8 and 8-8, there is an additional counter electrode relative to the arrangement of Configuration 0-0, which is referred to as the application counter electrode. In addition, in Configurations 1-0 to 8-0 and 8-8, there is an additional reference electrode relative to the arrangement of Configuration 0-0, which is referred to as the reference reference electrode. In Configurations 0-1 to 0-8 and 8-8, the application counter electrode was connected to WE_I, and in Configurations 1-0 to 8-0 and 8-8, the reference reference electrode was connected to WE_V. This is because the authors anticipated that by separating the application counter electrode or reference reference electrode sufficiently from the measurement point, impedance spectra similar to the three-electrode method could be obtained for each electrode arrangement. Further details are given in the Discussion. Therefore, the above was conducted to experimentally confirm that the impedance spectra of the three-electrode method can be obtained (1) without connecting WE_I to the rebar in concrete for Configurations 0-1 to 0-8, (2) without connecting WE_V to the rebar in concrete for Configurations 1-0 to 8-0, and (3) without connecting WE_I or WE_V to the rebar in concrete for Configuration 8-8.

Measurements were performed in the frequency range of 50 mHz to 100 Hz at five frequencies per decade, an AC amplitude of 30 mV, and an applied DC voltage of 0 V. Figure 7a shows the configuration of Measurement Reference Electrode and Measurement Counter Electrode. A saturated silver-silver chloride electrode was used as the reference electrode. The counter electrode consisted of aluminum and saturated KCl gel covered with nylon gauze to ensure a smooth bonding surface with the concrete. The dimensions of the bonding surface on the concrete were 100 mm × 100 mm. Figure 7b, c shows Application Counter Electrode, and Reference Reference Electrode, respectively. The parts used for these are the same as for Measurement Reference Electrode and Measurement Counter Electrode.

3 Results

Figure 8 shows the impedance spectra of the specimens measured with the electrode arrangements for Configurations 0-0 and 8-8. The spectra for Configurations 0-0 and 8-8 were broadly in agreement. Part of the capacitive semicircle was observed in both non-corroded and corroded specimens. The capacitive semicircle was smaller for the corroded specimen than for the non-corroded specimen.

Figure 9 shows the impedance spectra of the specimens measured with the electrode arrangements for Configurations 0-0 and 0-1 to 0-8. Figure 9a and b show the measurement results for the non-corroded and corroded specimens, respectively. Comparison of Configurations 0-1 to 0-8 allows interpretation of the change in impedance when the distance between the application counter electrode and the measurement point is changed. Part of the capacitive semicircle was observed for all configurations. Focusing on the results of the non-corroded specimen, in Non-corr_0-1 to 0-5, the size of the capacitive semicircle tended to increase as the distance between the application counter electrode and the measurement point increased, but no change was found for Non-corr_0-6 to 0-8. Capacitive semicircles of approximately the same size were obtained for Non-corr_0-6 to 0-8 and Non-corr_0-0. Focusing next on the results of the corroded specimen, in Corr_0-1 and 0-2, the size of the capacitive semicircle tended to increase as the distance between the reference reference electrode and the measurement point increased, but no change was found for Corr_0-3 to 0-8. Capacitive semicircles of approximately the same size were obtained for Corr_0-3 to 0-8 and Corr_0-0.

Figure 10 shows the impedance spectra of the specimens measured with the electrode arrangements for configurations 0-0 and 1-0 to 8-0. Figure 10a and b show the measurement results for the non-corroded and corroded specimens, respectively. Comparison of Configurations 1-0 to 8-0 allows interpretation of the change in impedance when the distance between the reference reference electrode and the measurement point is changed. Part of the capacitive semicircle was observed for all configurations in the low-frequency region. Focusing on the results of the non-corroded specimen, in Non-corr_1-0 to 5-0, the size of the capacitive semicircle tended to increase as the distance between the reference reference electrode and the measurement point increased, but no change was found for Non-corr_6-0 to 8-0. Capacitive semicircles of approximately the same size were obtained for Non-corr_6-0 to 8-0 and Non-corr_0-0; however, the positions of the capacitive semicircles differed by approximately 50 Ω on the X-axis. Since the measurement times of Non-corr_6-0 to 8-0 and Non-corr_0-0 differ by a few hours, it was surmised that this difference in the position of the capacitive semicircles was due to a change in concrete resistance over time. Focusing next on the results of the corroded specimen, in Corr_1-0 and 2-0, the size of the capacitive semicircle tended to increase as the distance between the reference reference electrode and the measurement point increased, but no change was found for Corr_3-0 to 8-0. Capacitive semicircles of approximately the same size were obtained for Corr_3-0 to 8-0 and Corr_0-0; however, the positions of the capacitive semicircles differed by approximately 50 Ω on the X-axis. Since the measurement times of Corr_3-0 to 8-0 and Corr_0-0 differ by a few hours, it was surmised that this difference in the position of the capacitive semicircles was due to a change in concrete resistance over time.

4 Discussion

4.1 Equivalent circuit of this experimental system

In this section, we will examine the reasons why the electrode arrangements in Fig. 4, 5 and 6 obtained impedance spectra similar to those of Configuration 0-0 (three-electrode method) and validate the result. The derivations of the equations of this section are summarized in the Appendix. Figure 11 shows one of simplest circuit equivalents to Configuration 0-0 (the electrode arrangement in Fig. 3.

In this equivalent circuit, the rebar/concrete interface is represented as a parallel RC circuit and the concrete resistance is represented using series resistance, based on previous work [14,15,16]. Here, Rc is the polarization resistance, C is the double-layer capacitance and Rs is the concrete cover resistance. Considering that the potentiogalvanostat measures the current flowing between CE and WE_I and the potential difference between RE and WE_V, the three-electrode method can be considered as acquiring the potential difference Vsteel between the measurement reference electrode and the rebar when the current Isteel is applied between the measurement counter electrode and the rebar. The calculated impedance is Z1 is acquired by dividing the obtained Vsteel by Isteel.

Figure 12 shows the circuit equivalent to Configurations 0-1 to 0-8 (the electrode arrangement in Fig. 4. The concrete resistance between the application counter electrode and the measurement counter electrode is R2, and the impedance between the application counter electrode and the rebar is Z2.

Considering that the current flowing between CE and WE_I and the potential difference between RE and WE_V are measured, this electrode arrangement can be considered as acquiring the potential difference Vsteel arising between the measurement reference electrode and the rebar when the current Iobsfig12 is applied between the application counter electrode and the measurement counter electrode. By dividing the obtained Vsteel by Iobsfig12, the calculated impedance Zobsfig12 can be obtained as follows. The derivation is summarized in Appendix 1.

Here, 1/R2 approaches 0 assuming the measurement counter electrode and application counter electrode are sufficiently far apart. Therefore, Eq. (2) becomes the following limit.

Equation (3) shows that if the measurement counter electrode and application counter electrode are sufficiently far apart, an impedance spectrum similar to that of Configuration 0–0 (the three-electrode method) can be obtained with the electrode arrangement shown in Fig. 4. Since Vsteel can be divided by Z1 to obtain Isteel, Eq. (2) can be expanded as follows.

Assuming that the measurement counter electrode and application counter electrode are sufficiently far apart, 1/R2 approaches 0. Therefore, Eq. (4) becomes the following limit.

Equation (5) shows that Iobsfig12 and Isteel agree if the measurement counter electrode and application counter electrode are sufficiently far apart.

Figure 13 shows the circuit equivalent to Configurations 1-0 to 8-0 (the electrode arrangement in Fig. 5). The concrete resistance between the reference reference electrode and the measurement reference electrode is R3, and the impedance between the reference reference electrode and the rebar is Z3.

Considering that the current flowing between CE and WE_I and the potential difference between RE and WE_V are measured, this electrode arrangement can be considered as acquiring the potential difference Vobsfig13 arising between the measurement reference electrode and the reference reference electrode when the current Iobsfig13 is applied between the measurement counter electrode and rebar. By dividing the obtained Vobsfig13 by Iobsfig13, the calculated impedance Zobsfig13 can be obtained as follows. The derivation is summarized in Appendix 2.

Assuming that the distance between the measurement reference electrode and the reference reference electrode is sufficiently far apart, 1/R3 approaches 0. Therefore, Eq. (6) becomes the following limit.

Equation (7) shows that if the distance between the measurement reference electrode and the reference reference electrode is sufficiently large, an impedance spectrum similar to that of Configuration 0-0 (the three-electrode method) can be obtained with the electrode arrangement shown in Fig. 5. Moreover, the left-hand side of Eq. (6) can be expanded as follows by transferring Iobsfig13 to the right-hand side.

Assuming that the distance between the measurement reference electrode and the reference reference electrode is sufficiently far apart, 1/R3 approaches 0. Therefore, Eq. (8) becomes the following limit.

Equation (9) shows that Vobsfig13 and Vsteel agree if the distance between the measurement reference electrode and the reference reference electrode is sufficiently large.

Figure 14 shows the circuit equivalent to Configuration 8-8 (the electrode arrangement in Fig. 6).

Considering that the potentiogalvanostat measures current flowing between CE and WE_I and the potential difference between RE and WE_V, this electrode arrangement can be considered as acquiring the potential difference Vobsfig14 arising between the measurement reference electrode and the reference reference electrode when the current Iobsfig14 is applied between the measurement counter electrode and the application counter electrode. By dividing the obtained Vobsfig14 by Iobsfig14, the calculated impedance Zobsfig14 is obtained as follows. The derivation is summarized in Appendix 3.

Here, 1/R2 and 1/R3 approach 0 if the distances between the application counter electrode and the measurement counter electrode and between the reference reference electrode and the measurement reference electrode are assumed to be sufficiently far apart. Equation (10) becomes the following limit.

Equation (11) shows that if both the distance between the measurement counter electrode and the application counter electrode and the distance between the measurement reference electrode and the reference reference electrode are sufficiently large, an impedance spectrum similar to that of Configuration 0-0 (the three-electrode method) can be obtained with the electrode arrangement shown in Fig. 6.

4.2 Discussion on physics experiment results

In the following discussion, Rs, Rc, and C in Fig. 11 are set to 300 Ω, 500 Ω, and 0.1 F, respectively, and Z1 is obtained by substituting the relation between impedance and frequency of Eq. (12) [16]. The values of Rs, Rc, and C were set in reference to the Non-corr_0-0 configuration as a typical example of concrete resistance and resistance at the concrete/reinforcing bar interface. The derivation of impedance and frequency is given in the Appendix 4.

Here, f is the frequency [Hz].

Figure 15 shows the calculation results of Eq. (2) for various values of R2 in the circuit shown in Fig. 12. Moreover, changes in the distance between the measurement counter electrode and the application counter electrode in Configurations 0-1 to 0-8 are represented by varying the value of R2. The frequency was set to range from 0.05 Hz to 100 Hz. The horizontal axis is the real component of the impedance, and the vertical axis is the imaginary component of the impedance. Z1 is also shown on the same graph for comparison. Moreover, Z2 was set to have the same value as Z1.

Calculated Zobs for the electrode arrangement in Fig. 12

As R2 increases, the size of the capacitive semicircle increases, and it was found that if R2 is large enough, Zobs_fig4 and Z1 will match. The increase in magnitude of R2 represents an increase in the distance between the measurement counter electrode and the application counter electrode; this result is similar to the experimental results shown in Fig. 9. The fact that the results of the numerical experiments and the physical experiments show similar trends suggests that Eqs. (2) and (3) are valid.

Figure 16 shows the calculation results of Eq. (6) for various values of R3 in the circuit shown in Fig. 13. Moreover, changes in the distance between the measurement reference electrode and the reference reference electrode in Configurations 1-0 to 8-0 are represented by changing the value of R3. The frequency was set to 0.05–100 Hz. The horizontal axis is the real component of the impedance, and the vertical axis is the imaginary component of the impedance. Z1 is also shown on the same graph for comparison. Moreover, Z3 was set to have the same value as Z1.

Calculated Zobs for the electrode arrangement in Fig. 13

As R3 increases, the size of the capacitive semicircle increases, and it was found that if R3 is large enough, Zobs_fig5 and Z1 will match. The increase in magnitude of R3 represents the increase in the distance between the measurement reference electrode and the reference reference electrode; the result is similar to the experimental results shown in Fig. 10. The fact that the results of the numerical experiments and the physical experiments show similar trends suggests that Eqs. (6) and (7) are valid. Figure 17 shows the calculation results of Eq. (10) for various values of R2 and R3 in the circuit shown in Fig. 14. To avoid overcomplicating the results, R2 and R3 were set to the same value. Moreover, changes in the distance between the measurement counter electrode and the application counter electrode and in the distance between the measurement reference electrode and the reference reference electrode in Fig. 14 are represented by varying R2 and R3 values. The frequency was set to 0.05–100 Hz. The horizontal axis is the real component of the impedance, and the vertical axis is the imaginary component of the impedance. Z1 is also shown on the same graph for comparison. Moreover, Z2 and Z3 were set to have the same value as Z1.

Calculated Zobs for the electrode arrangement in Fig. 14

As R2 and R3 increase, the size of the capacitive semicircle increases, and it was found that if R2 and R3 are large enough, Zobs_fig6 and Z1 will match. The increase in the magnitude of R2 and R3 represents the increase in the distance between the measurement counter electrode and the reference counter electrode; this result is similar to the experimental results shown in Fig. 8. The fact that the results of the numerical experiments and the physical experiments show similar trends suggests that Eqs. (10) and (11) are valid.

From the above discussion, it may be inferred that the same impedance spectra as those of the three-electrode method can be obtained even with the non-conductive four-electrode method by setting up the measurement reference electrode, measurement counter electrode, application counter electrode, and reference reference electrode as shown in Fig. 6 while separating both the distance between the measurement point and both the application counter electrode and the reference reference electrode. The measurement procedures for such measurements are shown below.

-

1.

Place the measurement counter electrode and the measurement reference electrode at the measurement point.

-

2.

Place the application counter electrode at a sufficient distance from the measurement point.

-

3.

Place the reference reference electrode at a sufficient distance from both the measurement point and the application counter electrode.

-

4.

Connect WE_I to the application counter electrode, WE_V to the reference reference electrode, CE to the measurement counter electrode, and RE to the measurement reference electrode, and then measure the impedance.

5 Conclusions

The present study proposes a method to obtain the same impedance spectra as the three-electrode method by modifying the electrode configuration of the four-electrode method. The procedures for such a measurement are as follows: first, place the counter electrode and the measurement reference electrode at the measurement point; place another counter electrode at a sufficient distance from the measurement point; place another reference electrode at a sufficient distance from both the measurement point and the applied counter electrode; and connect WE_I to the applied counter electrode, WE_V to the reference electrode, CE to the applied counter electrode, and RE to the applied counter electrode, and then measure the impedance. In this paper, the physical experiments and the numerical experiments demonstrate the validity of the above method.

References

Hussain SE, Rasheeduzzafar (1994) ACI Mater J 91:264

Montemor MF, Simoes AMP, Salta MM (2000) Cem Concr Compos 22:175

Bentur A, Diamond S, Berke NS (1997) Sreel Corrosion in Concrete. Taylor & Francis, London

Andrade C, Soler L, Alonso C, Novoa XR, Keddam M (1995) Corros Sci 37:2013

Vedalakshmi R, Saraswathy V, Song HW, Palaniswamy N (2009) Corros Sci 51:1299

Hoshi Y, Koike T, Okamoto T, Tokieda H, Shitanda I, Itagaki M, Kato Y (2019) J Electrochem Soc 166:C3316

Hoshi Y, Hasegawa C, Okamoto T, Soukura M, Tokieda H, Shitanda I, Itagaki M, Kato Y (2019) Electrochemistry 87:78

Feliu S, Gonzalez JA, Miranda JM, Feliu V (2005) Corros Sci 47:217

Andrade C, Keddam M, Nóvoa XR, Pérez MC, Rangel CM, Takenouti H (2001) Electrochim Acta 46:3905

Choi YS, Kim JG, Lee KM (2006) Corros Sci 48:1733

Koleva DA, van Breugel K, de Wit JHW, van Westing E, Boshkov N, Fraaij ALA (2007) J Electrochem Soc 154:E45

Andrade C, Martinez I, Castellote M (2008) J Appl Electrochem 38:1467

Keddam M, Novoa XR, Vivier V (2009) Corros Sci 51:1795

Sagues AA (1993) Corrosion/93 The NACE annual conference and corrosion show, Paper No.353

Thompson NG, Lauson KM, Beavers JA (1987) Corrosion/87 The NACE annual conference and corrosion show, Paper NO.139

Kelly RG, Scully JR, Shoesmith DW, Buchheit RG (2003) Electrochemical techniques in corrosion science and engineering. Taylor & Francis, Boca Raton

Acknowledgements

The authors would like to thank H. Takata for technical assistance with the experiments. This work was supported by JSPS KAKENHI Grant Number JP21K20456.

Funding

Japan Society for the Promotion of Science, 21K20456.

Author information

Authors and Affiliations

Contributions

Hashimoto, Tanaka, kaneko, Kato, Hirama wrote the main manuscript text and Hashimoto and Tanaka prepared all figures. All authors reviewed the manuscript

Corresponding author

Ethics declarations

Conflict of interest

The authors declare the following financial interests/personal relationships which may be considered as potential competing interests-Japan Society for Promotion Science (Grant No. 21K20456).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Equation (2) is derived as below. With the electrode arrangement shown in Fig. 12, the combined resistance Ztotalfig12 of the entire circuit from WE_I to CE is as follows.

Therefore, the potential difference Vappfig12 applied between WE_I and CE is as follows.

Equation (14) is rearranged as follows.

Isteel is expressed using Vappfig12 as follows.

Thus, Vsteel is obtained as

By dividing Equation (17) by Equation (15), Zobsfig12 is obtained as follows.

Appendix 2

Equation (6) is derived as below. With the electrode arrangement shown in Fig. 13, the combined resistance Ztotalfig13 of the entire circuit from WE_I to CE is as follows.

Therefore, the potential difference Vappfig13 applied between WE_I and CE is as follows.

Equation (20) is rearranged as

Iobsfig13-Isteel is expressed using Vappfig13 as

Thus, Vobsfig13 is obtained as follows.

By dividing Equation (23) by Equation (21), Zobsfig13 is obtained as follows.

Appendix 3

Equation (10) is derived as below. With the electrode arrangement shown in Fig. 14, the combined resistance Ztotalfig14 of the entire circuit from WE_I to CE is as follows.

Therefore, the potential difference Vappfig14 applied between WE_I and CE is as follows.

Equation (26) is rearranged as

Vobsfig14 is expressed using Vappfig14 as follows.

By dividing Equation (28) by Equation (27), Zobsfig14 is obtained as follows.

Appendix 4

Equation (12) is derived as below. Eqs. (30, 31, 32) shows the transfer functions Z for resistors Rs, Rc, and capacitors C.

Here, \({Z}_{{R}_{s}}\) is the transfer function for Rs [Ω], \({Z}_{{R}_{c}}\) is the transfer function for Rc [Ω], and ZC is the transfer function for capacitors [Ω].

The following expression describes the impedance for Fig. 11 system Z1:

Z2 and Z3 are the same derivation as above.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hashimoto, N., Tanaka, M., Kaneko, Y. et al. Development of a method for obtaining Nyquist plots identical to those of the three-electrode AC impedance method in concrete-embedded rebar without requiring electrical continuity. J Appl Electrochem 53, 1895–1909 (2023). https://doi.org/10.1007/s10800-023-01891-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-023-01891-2