Abstract

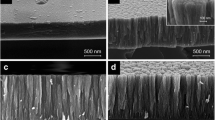

This paper reports the effects of polyethylene glycol (PEG) as a morphological template for spray-pyrolyzed TiO2 films. The virtues of PEG-modified TiO2 films as photoanodes in a photoelectrochemical (PEC) water splitting system are determined by the formation of nano-sized roughness, which is proposed to be originated from the role of PEG in controlling polycondensation of TiO2 precursor and segregating seed growth. Results in this paper, combined with those we reported earlier, show that the concentration of PEG in precursor solutions is more important than its molecular weight in enhancing the morphology of the resultant films and their eventual PEC properties. Based on PEC assessments, critical concentrations of PEG were found in the range of 25–50 mM, where nano-sized features are optimally developed and uniformly distributed across the surface. The best rough-surface TiO2 in this study managed to achieve PEC efficiency of as high as 1.23% and charge-transfer resistance of as low as 2.4 kΩ at − 0.7 V vs HgO|Hg, remarkably superior to the smooth-surface unmodified film with 0.40% efficiency and nearly 19 kΩ charge-transfer resistance at the same applied potential.

Graphical abstract

Controlled PEG templating leads to distinct characteristics of nanoscale roughness of spray-pyrolized TiO2 films, which drive their eventual photoelectrochemical output.

Similar content being viewed by others

References

Mercado CC et al (2019) Comparison of photoelectrochemical current in amorphous and crystalline anodized tio2 nanotube electrodes. Int J Photoenergy 2019:9848740. https://doi.org/10.1155/2019/9848740

Shao G, Zang Y, Hinds BJ (2019) TiO2 Nanowires Based System for Urea Photodecomposition and Dialysate Regeneration. ACS Appl Nano Mater 2(10):6116–6123. https://doi.org/10.1021/acsanm.9b00709

Pandanga JJ et al (2019) Synthesis and application of TiO2 nanorods as photo-anode in dye-sensitized solar cells. J Phys: Conf Ser 1191:012023. https://doi.org/10.1088/1742-6596/1191/1/012023

Xie J et al (2019) TiO2 nanotrees for the photocatalytic and photoelectrocatalytic phenol degradation. New J Chem 43(28):11050–11056. https://doi.org/10.1039/C9NJ02219H

Zhang D et al (2019) Growth of black TiO2 nanowire/carbon fiber composites with dendritic structure for efficient visible-light-driven photocatalytic degradation of methylene blue. J Mater Sci 54(10):7576–7588. https://doi.org/10.1007/s10853-019-03424-9

Osterloh FE (2013) Inorganic nanostructures for photoelectrochemical and photocatalytic water splitting. Chem Soc Rev 42(6):2294–2320. https://doi.org/10.1039/C2CS35266D

Pu P et al (2013) Relation between morphology and conductivity in TiO2 nanotube arrays: an electrochemical impedance spectrometric investigation. J Solid State Electrochem 17(3):817–828. https://doi.org/10.1007/s10008-012-1931-0

Peter L (2013) Kinetics and mechanisms of light-driven reactions at semiconductor electrodes: principles and techniques in: photoelectrochemical water splitting: materials processes and architectures. R Soc Chem. https://doi.org/10.1039/9781849737739-00019

Jo EH et al (2014) Pore size-controlled synthesis of PEG-derived porous TiO2 particles and photovoltaic performance of dye-sensitized solar cells. Mater Lett 131:244–247. https://doi.org/10.1016/j.matlet.2014.05.191

Yu J et al (2002) Atomic force microscopic studies of porous TiO2 thin films prepared by the sol-gel method. J Sol-Gel Sci Technol 24(3):229–240. https://doi.org/10.1023/A:1015384624389

Ibadurrohman M, Hellgardt K (2015) Morphological modification of TiO2 thin films as highly efficient photoanodes for photoelectrochemical water splitting. ACS Appl Mater Interfaces 7(17):9088–9097. https://doi.org/10.1021/acsami.5b00853

Yu J et al (2001) Preparation and characterization of super-hydrophilic porous TiO2 coating films. Mater Chem Phys 68(1–3):253–259. https://doi.org/10.1016/S0254-0584(00)00364-3

Djaoued Y et al (2008) Photocatalytic degradation of domoic acid using nanocrystalline TiO2 thin films. J Photochem Photobiol A 193(2–3):271–283. https://doi.org/10.1016/j.jphotochem.2007.07.006

Chang H et al (2013) Synthesis of PEG-modified TiO2–InVO4 nanoparticles via combustion method and photocatalytic degradation of methylene blue. Mater Lett 92:202–205. https://doi.org/10.1016/j.matlet.2012.11.006

Negishi N, Takeuchi K, Ibusuki T (1998) Surface structure of the TiO2 thin film photocatalyst. Appl Surf Sci 33(24):5789–5794. https://doi.org/10.1016/S0169-4332(97)00349-8

Calderon-Moreno JM et al (2014) Effect of polyethylene glycol on porous transparent TiO2 films prepared by sol–gel method. Ceram Int 40(1):2209–2220. https://doi.org/10.1016/j.ceramint.2013.07.139

Guo B et al (2005) Sol gel derived photocatalytic porous TiO2 thin films. Surf Coat Technol 198(1–3):24–29. https://doi.org/10.1016/j.surfcoat.2004.10.055

An T et al (2008) Structural and photocatalytic degradation characteristics of hydrothermally treated mesoporous TiO2. Appl Catal A 350(2):237–243. https://doi.org/10.1016/j.apcata.2008.08.022

Jiao J et al (2008) Effect of PEG with different MW as template direction reagent on preparation of porous TiO2/SiO2 with assistance of supercritical CO2. Colloid Polym Sci 286(13):1485–1491. https://doi.org/10.1016/j.jcis.2007.08.056

Liu X et al (2005) Influences of solvent on properties of TiO2 porous films prepared by a sol-gel method from the system containing PEG. J Sol-Gel Sci Technol 36(1):103–111. https://doi.org/10.1007/s10971-005-2746-6

Ibadurrohman M, Hellgardt K (2014) Photoelectrochemical performance of graphene-modified TiO2 photoanodes in the presence of glycerol as a hole scavenger. Int J Hydrogen Energy 39(32):18204–18215. https://doi.org/10.1016/j.ijhydene.2014.08.142

Ibadurrohman M, Hellgardt K (2020) Importance of surface roughness of TiO2 photoanodes in promoting photoelectrochemical activities with and without sacrificial agent. Thin Solid Films 705:138009. https://doi.org/10.1016/j.tsf.2020.138009

Kajihara K, Yao T (2000) Macroporous morphology of the titania films prepared by a sol-gel dip-coating method from the system containing poly(ethylene glycol): effects of molecular weight and dipping temperature. J Sol-Gel Sci Technol 19(1–3):219–222. https://doi.org/10.1023/A:1008736305330

Scheutjens JMHM, Fleer GJ (1979) Statistical theory of the adsorption of interacting chain molecules. 1. Partition function, segment density distribution, and adsorption isotherms. J Phys Chem 83(12):1619–1635

Kajihara K et al (1998) Preparation of macroporous titania films by a sol-gel dip-coating method from the system containing poly(ethylene glycol). J Am Ceram Soc 81(10):2670–2676. https://doi.org/10.1111/j.1151-2916.1998.tb02675.x

Li Y et al (2004) Synthesis and characterization of nano titania powder with high photoactivity for gas-phase photo-oxidation of benzene from TiOCl2 aqueous solution at low temperatures. Langmuir 20(25):10838–10844. https://doi.org/10.1021/la0489716

Zhou C-H et al (2012) Effect of poly (ethylene glycol) on coarsening dynamics of titanium dioxide nanocrystallites in hydrothermal reaction and the application in dye sensitized solar cells. J Colloid Interface Sci 374(1):9–17. https://doi.org/10.1016/j.jcis.2011.12.006

Poznyak SK, Kokorin AI, Kulak AI (1998) Effect of electron and hole acceptors on the photoelectrochemical behaviour of nanocrystalline microporous TiO2 electrodes. J Electroanal Chem 442(1):99–105. https://doi.org/10.1016/S0022-0728(97)00458-0

Liu M, de Leon Snapp N, Park H (2011) Water photolysis with a cross-linked titanium dioxide nanowire anode. Chem Sci 2(1):80–87. https://doi.org/10.1039/C0SC00321B

Zhang Z, Wang P (2012) Optimization of photoelectrochemical water splitting performance on hierarchical TiO2 nanotube arrays. Energy Environ Sci 5(4):6506–6512. https://doi.org/10.1039/C2EE03461A

Salvador P (1984) Hole diffusion length in n-TiO2 single crystals and sintered electrodes: photoelectrochemical determination and comparative analysis. J Appl Phys 55(8):2977–2985. https://doi.org/10.1063/1.333358

Meda L et al (2010) Photo-electrochemical properties of nanostructured WO3 prepared with different organic dispersing agents. Sol Energy Mater Sol Cells 94(5):788–796. https://doi.org/10.1016/j.solmat.2009.12.025

Bu S et al (2004) Fabrication of TiO2 porous thin films using peg te1mplates and chemistry of the process. Mater Chem Phys 88(2–3):273–279. https://doi.org/10.1016/j.matchemphys.2004.03.033

Acknowledgements

This research is supported by the Directorate General of Higher Education (DIKTI), Indonesian Ministry of Research, Technology, and Higher Education, via a doctoral scholarship for M.I. (568/E4.4/K/2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ibadurrohman, M., Hellgardt, K. Effects of PEG templating of spray-pyrolyzed TiO2 films on their nanoscale roughness and eventual photoelectrochemical properties. J Appl Electrochem 52, 929–940 (2022). https://doi.org/10.1007/s10800-022-01682-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-022-01682-1