Abstract

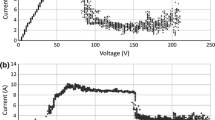

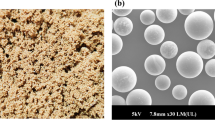

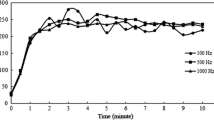

The effects of surface pretreatment of 304 stainless steel (SS) substrates on copper film formation, adhesion, and purity obtained by galvanostatic electrodeposition at a current density of – 30 mA cm−2 are presented. The polished substrate produced more copper nuclei, resulting in an increase of the adhesion as compared to chemically oxidized SS substrate. The adhesion of the copper deposits was characterized by a Nano-scratch tester (NST). The nucleation behavior is associated with the flatband potential of the SS surface, which was derived from capacitance measurements. The grain size of copper deposits was characterized by field emission scanning electron microscopy (FESEM). Copper grains were smaller on the polished SS with a size of less than 1 µm after 5 min of electrodeposition. High-purity copper deposits with < 1 ppm S (detection limit) were obtained on the oxidized SS substrate compared to 2.5 ppm for the polished SS substrate. Atomic force microscopy (AFM) measurements showed that the copper deposits were 25% less rough on the polished SS as compared to the oxidized SS. The results indicate that the obtained purity of the copper deposit relates to the grain size of the deposit, rather than the initial surface roughness. In the context of industrial electrowinning, high adherence to the polished substrate could increase the operation time of the copper cathode stripping. Hence for electrowinning from copper sulfate electrolytes, oxidizing the SS surface prior to deposition could lead to higher purity along with enhanced stripping.

Graphic abstract

Similar content being viewed by others

Data aavailability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

The custom made software used in the study is available from the corresponding author on reasonable request.

References

Schlesinger ME, King MJ, Sole KC, Davenport WG (2011) Extractive metallurgy of copper. Elsevier, Amsterdam

Cui W, Moats M (2014) Effect and interactions of commercial additives and chloride ion in copper electrowinning. Missouri Univerity of Science and Technology, Rolla

Aromaa J, Kekki A, Stefanova A, Forsén O (2012) Copper nucleation and growth patterns on stainless steel cathode blanks in copper electrorefining. J Solid State Electrochem 16:3529–3537. https://doi.org/10.1007/s10008-012-1898-x

Cooper WC (1985) Advances and future prospects in copper electrowinning. J Appl Electrochem 15:789–805. https://doi.org/10.1007/BF00614357

Alfantazi AM, Valic D (2003) A study of copper electrowinning parameters using a statistically designed methodology. J Appl Electrochem 33:217–225. https://doi.org/10.1023/A:1024014727082

Mackinnon DJ, Lakshmanan VI, Brannen JM (1978) The effect of glue, LIX65N and chloride ion on the morphology of electrowon copper. J Appl Electrochem 8:223–234. https://doi.org/10.1007/BF00616425

Sun M, O’Keefe TJ (1992) The effect of additives on the nucleation and growth of copper onto stainless steel cathodes. MTB 23:591–599. https://doi.org/10.1007/BF02649719

Luyima A, Cui W, Heckman C, Moats MS (2016) Examination of copper electrowinning smoothing agents. Part IV: nucleation and growth of copper on stainless steel. Miner Metall Process 33:39–46. https://doi.org/10.19150/mmp.6465

Owais A (2009) Effect of electrolyte characteristics on electrowinning of copper powder. J Appl Electrochem 39:1587–1595. https://doi.org/10.1007/s10800-009-9845-y

Andersen TN, Pitt CH, Livingston LS (1983) Nodulation of electrodeposited copper due to suspended particulate. J Appl Electrochem 13:429–438. https://doi.org/10.1007/BF00617517

Guo L, Searson PC (2010) On the influence of the nucleation overpotential on island growth in electrodeposition. Electrochim Acta 55:4086–4091. https://doi.org/10.1016/j.electacta.2010.02.038

Zhao T, Zagidulin D, Szymanski G, Lipkowski J (2006) Application of atomic force microscopy and scaling analysis of images to predict the effect of current density, temperature and leveling agent on the morphology of electrolytically produced copper. Electrochim Acta 51:2255–2260. https://doi.org/10.1016/j.electacta.2005.06.042

Getrouw MA, Dutra AJB (2001) The influence of some parameters on the surface roughness of thin copper foils using statistical analysis. J Appl Electrochem 31:1359–1366. https://doi.org/10.1023/A:1013823021551

Nuñez M (2005) Metal electrodeposition. Nova Publishers, New York

Urda M, Oniciu L, Delplancke J-L, Winand R (1997) Influence of phosphorous acid on the nucleation and growth of copper. J Appl Electrochem 27:616–620. https://doi.org/10.1023/A:1018467200031

Tarallo A, Heerman L (1999) Influence of thiourea on the nucleation of copper on polycrystalline platinum. J Appl Electrochem 29:585–591. https://doi.org/10.1023/A:1003410720266

Kim S-B, Kim K-T, Park C-J, Kwon H-S (2002) Electrochemical nucleation and growth of copper on chromium-plated electrodes. J Appl Electrochem 32:1247–1255. https://doi.org/10.1023/A:1021610813395

Gu M, Zhong Q (2011) Copper electrocrystallization from acidic sulfate electrolyte containing MPS additive. J Appl Electrochem 41:765. https://doi.org/10.1007/s10800-011-0293-0

Dutra AJB, O’Keefe TJ (1999) Copper nucleation on titanium for thin film applications. J Appl Electrochem 29:1217–1227. https://doi.org/10.1023/A:1003537318303

Adcock PA, Quillinan A, Clark B et al (2004) Measurement of polarization parameters impacting on electrodeposit morphology. II: conventional zinc electrowinning solutions. J Appl Electrochem 34:771–780. https://doi.org/10.1023/B:JACH.0000035604.53451.25

Adcock PA, Adeloju SB, Newman OMG (2002) Measurement of polarization parameters impacting on electrodeposit morphology I: theory and development of technique. J Appl Electrochem 32:1101–1107. https://doi.org/10.1023/A:1021251603240

Muresan L, Nicoara A, Varvara S, Maurin G (1999) Influence of Zn2 + ions on copper electrowinning from sulfate electrolytes. J Appl Electrochem 29:723–731. https://doi.org/10.1023/A:1003474616691

Moats MS, Derrick A (2012) Investigation of nucleation and plating overpotentials during copper electrowinning using the Galvanostatic Staircase Method. Electrometallurgy 2012. Wiley, Hoboken, pp 125–137

Delplancke J-L, Sun M, O’Keefe TJ, Winand R (1990) Production of thin copper foils on microporous titanium oxide substrates. Hydrometallurgy 24:179–187. https://doi.org/10.1016/0304-386X(90)90085-G

Delplancke J-L, Sun M, O’Keefe TJ, Winand R (1989) Nucleation of electrodeposited copper on anodized titanium. Hydrometallurgy 23:47–66. https://doi.org/10.1016/0304-386X(89)90017-0

Delplancke J-L, Ongaro M, Winand R (1992) Growth of electrodeposited copper on anodized titanium. J Appl Electrochem 22:843–851. https://doi.org/10.1007/BF01023728

Zhou Z, O’Keefe TJ (1998) Electrodeposition of copper on thermally oxidized 316 L stainless steel substrates. J Appl Electrochem 28:461–469. https://doi.org/10.1023/A:1003209009910

Heakal FE-T, Shehata OS (2020) Insight into the electrochemical and semiconducting properties of native oxide films on Ti metal and its Ti–6Al–4V alloy in borate buffer solutions. Prot Met Phys Chem Surf. https://doi.org/10.1134/S2070205120020082

Yue Y, Liu C, Shi P, Jiang M (2018) Passivity of stainless steel in sulphuric acid under chemical oxidation. Corros Eng Sci Technol 53:173–182. https://doi.org/10.1080/1478422X.2017.1388648

Tsuchiya H, Fujimoto S, Chihara O, Shibata T (2002) Semiconductive behavior of passive films formed on pure Cr and Fe–Cr alloys in sulfuric acid solution. Electrochim Acta 47:4357–4366. https://doi.org/10.1016/S0013-4686(02)00508-X

Ohtsuka T, Abe M, Ishii T (2015) The effect of impurity concentration and Cr content on the passive oxide films in ferritic stainless steels. J Electrochem Soc 162:C528. https://doi.org/10.1149/2.0621510jes

Ohtsuka T, Hyono A, Sasaki Y (2012) Potential modulation reflectance of passivated type 304 stainless steel in sulfuric acid solution. Electrochim Acta 60:384–391. https://doi.org/10.1016/j.electacta.2011.11.064

Coelho LB, Kossman S, Mejias A et al (2020) Mechanical and corrosion characterization of industrially treated 316L stainless steel surfaces. Surf Coat Technol 382:125175. https://doi.org/10.1016/j.surfcoat.2019.125175

Cámara OR, de Pauli CP, Vaschetto ME et al (1995) Semiconducting properties of TiO2 films thermally formed at 400 °C. J Appl Electrochem 25:247–251. https://doi.org/10.1007/BF00262963

Mahboob SS, Swanson K, Gonzalez JA, Shepherd JL (2016) On the use of atomic force microscopy and scaling analysis to quantify the roughness of zinc electrodeposits produced from an industrial acid sulfate electrolyte containing glue. J Appl Electrochem 46:539–549. https://doi.org/10.1007/s10800-016-0943-3

Robinson TG, Sole KC, Sandoval S et al (2013) Copper electrowinning—2013 world tankhouse operating data. Santiago, Chile, p 13

Yoshioka T, Matsushima H, Ueda M (2018) In situ observation of Cu electrodeposition and dissolution on Au(100) by high-speed atomic force microscopy. Electrochem Commun 92:29–32. https://doi.org/10.1016/j.elecom.2018.05.019

Grujicic D, Pesic B (2002) Electrodeposition of copper: the nucleation mechanisms. Electrochim Acta 47:2901–2912. https://doi.org/10.1016/S0013-4686(02)00161-5

Rangel CM, Silva TM, Belo M da C (2005) Semiconductor electrochemistry approach to passivity and stress corrosion cracking susceptibility of stainless steels. Electrochim Acta 50:5076–5082. https://doi.org/10.1016/j.electacta.2005.03.064

Otsu N (1979) A threshold selection method from gray-level histograms. IEEE Trans Syst Man Cybernetics 9:62–66. https://doi.org/10.1109/TSMC.1979.4310076

Olsson C-OA, Landolt D (2003) Passive films on stainless steels—chemistry, structure and growth. Electrochim Acta 48:1093–1104. https://doi.org/10.1016/S0013-4686(02)00841-1

Ramanathan R, Voorhees PW (2019) Morphological stability of steady-state passive oxide films. Electrochim Acta 303:299–315. https://doi.org/10.1016/j.electacta.2019.01.146

Burstein GT, Liu C, Souto RM, Vines SP (2004) Origins of pitting corrosion. Corros Eng Sci Technol 39:25–30. https://doi.org/10.1179/147842204225016859

Hamm D, Ogle K, Olsson C-OA et al (2002) Passivation of Fe–Cr alloys studied with ICP-AES and EQCM. Corros Sci 44:1443–1456. https://doi.org/10.1016/S0010-938X(01)00147-0

Keller P, Strehblow H-H (2004) XPS investigations of electrochemically formed passive layers on Fe/Cr-alloys in 0.5 M H2SO4. Corros Sci 46:1939–1952. https://doi.org/10.1016/j.corsci.2004.01.007

Asami K, Hashimoto K, Shimodaira S (1978) An XPS study of the passivity of a series of iron–chromium alloys in sulphuric acid. Corros Sci 18:151–160. https://doi.org/10.1016/S0010-938X(78)80085-7

Kirchheim R, Heine B, Hofmann S, Hofsäss H (1990) Compositional changes of passive films due to different transport rates and preferential dissolution. Corros Sci 31:573–578. https://doi.org/10.1016/0010-938X(90)90164-Z

Calinski C, Strehblow H-H (1989) ISS depth profiles of the passive layer on Fe/Cr alloys. J Electrochem Soc 136:1328. https://doi.org/10.1149/1.2096915

Bard A, Faulker L (2001) Electrochemical methods: fundamentals and applications, 2nd edn. Wiley, Hoboken

Plieth W (2010) The process chain of electrodeposition. Russ J Electrochem 46:1119–1124. https://doi.org/10.1134/s1023193510100071

Milchev A (1985) Contribution to the theory of nucleation on preferred sites—I. Electrochim Acta 30:125–131. https://doi.org/10.1016/0013-4686(85)80070-0

Bindra P, Gerischer H, Kolb DM (1977) Electrolytic deposition of thin metal films on semiconductor substrates. J Electrochem Soc 124:1012–1018. https://doi.org/10.1149/1.2133471

Raposo M, Ferreira Q (2007) A guide for atomic force microscopy analysis of soft-condensed matter. In: Modern research and educational topics in microscopy. Formatex, Badajoz

Maksumov A, Vidu R, Palazoglu A, Stroeve P (2004) Enhanced feature analysis using wavelets for scanning probe microscopy images of surfaces. J Colloid Interface Sci 272:365–377. https://doi.org/10.1016/j.jcis.2003.09.047

Murray A, Khakbaz H, Pranowo A et al (2016) Effects of process parameters on the adhesive strength of copper electrodeposits in a bench-scale electrowinning cell. Miner Process Ext Metall 125:10–16. https://doi.org/10.1080/03719553.2015.1109183

Kossowsky R (1989) Surface modeling engineering. CRC Press, Boca Raton

Schultze JW, Osaka T, Datta M, Staikov G (2002) Electrochemical microsystem technologies. CRC Press, Boca Raton

Ivshin YV, Shaikhutdinova FN, Sysoev VA (2018) Electrodeposition of copper on mild steel: peculiarities of the process. Surf Eng Appl Electrochem 54:452–458. https://doi.org/10.3103/S1068375518050046

London Metal Exchange: LME Copper Physical. https://www.lme.com/Metals/Non-ferrous/Copper/Physical. Accessed 16 Jun 2019

Korzhavyi PA, Abrikosov IA, Johansson B (1999) Theoretical investigation of sulfur solubility in pure copper and dilute copper-based alloys. Acta Mater 47:1417–1424. https://doi.org/10.1016/S1359-6454(99)00036-1

Abrahams MS, Rao ST, Buiocchi CJ, Trager L (1986) Decorated boundaries observed in copper electrodeposits. J Electrochem Soc 133:1786. https://doi.org/10.1149/1.2109019

Wasekar NP, O’Mullane AP, Sundararajan G (2019) A new model for predicting the grain size of electrodeposited nanocrystalline nickel coatings containing sulphur, phosphorus or boron based on typical systems. J Electroanal Chem 833:198–204. https://doi.org/10.1016/j.jelechem.2018.11.057

Haumesser P-H (2016) 3—The precipitation of metals: thin film electroplating and nanoparticle synthesis. In: Haumesser P-H (ed) Nucleation and growth of metals. Elsevier, Amsterdam, pp 59–70

Winand R (1991) Electrocrystallization: fundamental considerations and application to high current density continuous steel sheet plating. J Appl Electrochem 21:377–385. https://doi.org/10.1007/BF01024572

Winand R (1992) Electrocrystallization—theory and applications. Hydrometallurgy 29:567–598. https://doi.org/10.1016/0304-386X(92)90033-V

Acknowledgements

This research was financially supported by the Flemish Agency for Innovation and Entrepreneurship (Vlaio) via a Baekeland PhD fellowship to Florian Verbruggen (HBC.2017.0224) and by the Research & Development Umicore Group. EF is supported by the Fonds voor Wetenschappelijk Onderzoek - Vlaanderen (FWO) PROJECT G020616N. KR and AP are supported by a Ghent University Bijzonder Onderzoeksfonds GOA grant (BOF19/GOA/026). LB is supported by the Fonds voor Wetenschappelijk Onderzoek - Vlaanderen (FWO) PROJECT 3G0I1818W. The authors thank Umicore for the permission to publish the results. We gratefully acknowledge Louis Van der Meeren for performing the AFM measurements.

Funding

This research was financially supported by the Flemish Agency for Innovation and Entrepreneurship (Vlaio) via a Baekeland PhD fellowship to Florian Verbruggen (HBC.2017.0224) and by the Research & Development Umicore Group. EF is supported by the Fonds voor Wetenschappelijk Onderzoek - Vlaanderen (FWO) PROJECT G020616N. KR and AP are supported by a Ghent University Bijzonder Onderzoeksfonds GOA grant (BOF19/GOA/026). LB is supported by the Fonds voor Wetenschappelijk Onderzoek - Vlaanderen (FWO) PROJECT 3G0I1818W.

Author information

Authors and Affiliations

Contributions

FV: conceptualization, methodology, validation, formal analysis, investigation, writing—original draft, and visualization. EF: methodology, validation, writing, review & editing. LB: investigation, methodology, validation, writing, review & editing. AP: methodology, validation, writing, review & editing. MSM: supervision, resources, review & editing, and conceptualization. TH: supervision, project administration, resources, and conceptualization. KR: supervision, project administration, resources, visualization, and review.

Corresponding author

Ethics declarations

Conflict of interest

The authors report no conflicts of interest. The authors alone are responsible for the content and writing of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Verbruggen, F., Fiset, E., Bonin, L. et al. Stainless steel substrate pretreatment effects on copper nucleation and stripping during copper electrowinning. J Appl Electrochem 51, 219–233 (2021). https://doi.org/10.1007/s10800-020-01485-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-020-01485-2