Abstract

Engaging students in hands-on engineering design-based instruction as called for in national science, and technology and engineering (T&E) education standards in the United States (U.S.) poses inherent hazards and risks that science, technology, engineering, and mathematics (STEM) educators must be adequately prepared to address. Helping students develop safer habits while creating solutions to design challenges can translate to practices they will implement at home, in post-secondary education programs, and in the workplace. This study analyzed responses from 117 P-12 educators delivering hands-on engineering design-based STEM instruction in the U.S. Certain protective factors (e.g., safety training) were found to be significantly associated with reducing the odds of an accident; however, when controlling for course enrollment sizes, the odds of an accident significantly increased. Logistic regression models demonstrated that STEM courses with enrollments of 24 or fewer students had an 87.5% reduction in the odds of an accident occurring. Courses with enrollments surpassing 24 students were 8 times more likely to have had an accident, and courses with more than 30 students were 21 times more likely to have had an accident occurrence within the past five years. The findings from this study provide insight about the importance of occupancy load and overcrowding in hands-on engineering design-based STEM courses. STEM educators can utilize the results from this study to make informed decisions about addressing significant risk and protective factors associated with accident occurrences. Most importantly, this study has implications for improving safety policies and changing legal precedent related to overcrowding and course enrollment sizes in P-12 STEM courses, which the analyses in this study suggest should help reduce accident occurrences.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

According to the National Institute for Occupational Safety and Health (NIOSH), in 2021 young workers (those under the age of 25) made up 12.4% of the workforce in the United States (U.S.). Work-related injuries among workers who were 15–24 years old was 1.5 times greater than the rate for workers 25 years of age and older (NIOSH, 2023). However, safety instruction/training and modeling safer practices in science, technology, engineering, and mathematics (STEM) education programs can help improve the safety knowledge and habits of young workers (Threeton & Evanoski, 2014). In this article the author uses the term STEM in reference to science, technology and engineering (T&E), and career and technical education (CTE) programs and courses which implement hands-on engineering design-based practices. As Love and Roy (2022a) pointed out, science (NGSS Lead States, 2013) and T&E (ITEEA, 2020) academic standards in the U.S. call for teaching engineering practices. Moreover, many CTE programs apply STEM concepts and engineering design skills to solve authentic problems, and numerous state departments of education in the U.S. (e.g., Virginia) categorize T&E education under the CTE umbrella (Love, in press-b; Love & Roy, 2022a; Love et al., 2023a).

Schulte et al. (2005) discovered that safety training and experiences received in high school can influence students’ safety practices at future workplaces. Similarly, Threeton and Evanoski (2014) found that students transfer the safety habits they develop in secondary STEM programs to tasks performed at home and in the workplace. Safety has also been a focus of post-secondary engineering education programs. Russel and Vinsel (2019) proposed that the safety, health, and welfare of the public are paramount for developing innovators in post-secondary engineering education programs. Sandri et al. (2023) argued there is often a disconnect between views about public safety and sustainability among post-secondary engineering education programs, and safety should be integrated as a sustainability issue for engineering professionals. The literature indicates there are important long-term implications for emphasizing safety in P-12 and post-secondary STEM education programs, especially those engaging students in hands-on engineering design challenges.

Safety has been an enduring concept and concern among P-12 STEM education programs for decades as evidenced by its longstanding inclusion in academic standards and curricula (Love, 2019, 2023; Love et al., 2020). Although the emergence of new technologies and processes has spawned improved safety features and protocols, there are still potential hazards and risks associated with current tools/equipment and facilities that provide opportunities for students to develop solutions to hands-on engineering design challenges. Safety concerns were raised by both science educators (NSTA, 2020b) and engineering educators (Love & Roy, 2018) following the release of the Next Generation Science Standards (NGSS Lead States, 2013), which called for science educators in the U.S. to teach engineering practices despite limited to no safety training in this area (NSTA, 2020b). Recognizing this concern, the Standards for Technological and Engineering Literacy (ITEEA, 2020) placed a greater emphasis on safety throughout the standards, practices, and context areas aimed at enhancing students’ technological and engineering literacy (Love et al., 2020). The growing shortage of highly qualified educators in STEM content areas, coupled with the increasing percentage of educators entering the profession through alternative licensure with little to no safety training related to managing a P-12 STEM learning environment, has exacerbated concerns about maintaining valuable hands-on engineering design-based learning experiences (Love & Love, 2023; Love & Maiseroulle, 2021; Love et al., 2022; Reed & Ferguson, 2021). This has also led to growing enrollment sizes in STEM courses, increasing the level of risk for teachers and students in these courses (Love & Roy, 2022a).

Authentic hands-on engineering-design based learning experiences are critical for student sensemaking of STEM phenomena. Therefore, it is paramount to emphasize safety during students’ engineering design and fabrication decisions as this has important implications for improving young worker safety, safety in the workplace, and enhancing the safety awareness of students entering post-secondary STEM education programs (Love, in press-b; Love et al., 2023b; Love & Roy, 2022a; Love et al., 2022; Threeton & Evanoski, 2014). Numerous studies have examined an array of safety issues pertaining to different P-12 STEM content areas; however, there is limited data to inform safety policies and practices in courses implementing hands-on engineering design challenges. Building upon previous research from STEM education, the goal of this study was to examine the relationship between prevalent safety factors from the literature (e.g., occupancy load) and accident occurrences in P-12 STEM courses facilitating hands-on engineering design-based learning experiences.

Literature review

The literature is replete with support for hands-on engineering design-based learning experiences in P-12 STEM education courses (Love, 2023; Niiranen, 2021). Connections between hands-on engineering design-based learning experiences and foundational educational concepts proposed by Dewey (1916), Piaget (1953), Vygotsky (1962), Maslow (1970), Skinner (1974), Kolb (1984), and Bandura (1997) have been described in the literature (Love, in press-a; Love et al., 2022, 2023a, b; Threeton & Kim, 2021; Threeton et al., 2021). Eng et al. (2010) described engineering as a practical based discipline, where much learning occurs during laboratory experiences that allow students to manipulate authentic situations or materials, better preparing students for what they will see in the field. However, there are inherent safety hazards and risks associated with hands-on learning that mirrors the authentic experiences of engineers, engineering technologists, industry employees, scientists, and others.

The literature has also documented a severe lack in safety relative to various aspects of P-12 STEM education (Love & Roy, 2022a). Specifically, Love et al. (2022) highlighted the lack of improvement in P-12 STEM education safety issues reported by studies published from 2002 to 2022. For example, in 2002 only 81% of STEM teachers in the U.S. reported having appropriate eye protection for every student in their classes, but in 2022 that percentage only increased slightly to 83%. Further data was provided by a 2022 national STEM education safety study published by the International Technology and Engineering Educators Association (ITEEA) in collaboration with the American Society for Engineering Education (ASEE) and the National Science Education Leadership Association (NSELA) (Love & Roy, 2022a) which reported descriptive statistics from 718 educators teaching engineering design-based STEM courses across 42 states in the U.S. This study revealed a number of alarming safety concerns such as: only 56% of teachers received safety training from their school system within the past five years, only 69% required students and parents/guardians to sign a safety acknowledgement form before participating in any laboratory activities, and 80% of teachers reported they had at least one minor accident occurrence in their class that year. Follow up studies provided a closer look at this data through statistical analyses. Love et al. (2023a) analyzed the full sample and discovered 17 protective factors (e.g., safety zones taped/painted on the floor near potentially hazardous equipment) and eight risk factors (e.g., percentage of class time spent doing hands-on lab activities) that were significantly correlated with accident occurrences in STEM education courses.

Follow up studies analyzed responses from teachers in the northeastern (Love et al., 2023a, b), mid-Atlantic (Love, in press-b), and southern (Love, press-a) regions of the U.S. and found significant protective and risk factors that were similar to those presented by Love et al. (2023a, b). More specifically, Love et al. (2023a, b) found that safety training helped to reduce the effect of prevalent risk factors, but when class enrollments above 24 students were considered in the model, the odds of an accident increased significantly. Analyses focused on educators who taught pre-engineering courses (Love, in press-a; Love & Roy, 2023b) found that hot glue guns were involved in significantly more accidents in P-12 pre-engineering courses than other engineering design-based STEM courses. Moreover, research by Love (in press-b) that focused on safety in P-12 engineering courses taught within the middle Atlantic states, found manufacturing and construction courses to have a significantly greater occurrence of accidents in comparison to other P-12 engineering education courses.

Recognizing potential safety differences according to course focus, Love and Roy (2023a) examined safety issues specific to secondary construction and built environment courses. Their study revealed a number of unique safety factors associated with increased accident occurrences in construction and built environment courses (e.g., school district training on OSHA standards). The studies described in this section demonstrated that safety factors can be unique to certain regions of the U.S. based on the types of curricula and engineering design-based STEM courses being taught. They provided valuable foundational data that was missing from the P-12 STEM education literature and helped inform this study. The most prevalent safety factors across these studies are described in greater detail within the subsequent sections.

Course enrollment size (occupancy load)

Adequate workspace and an appropriate student to teacher ratio are critical for facilitating safer hands-on engineering design-based learning experiences. They allow instructors to provide proper supervision and behavioral reinforcements to maintain a safer hands-on learning culture. The literature indicates adequate space in areas that facilitate potentially hazardous STEM-related laboratory activities has been a concern for decades. Science teachers in West et al.’s (2002) study reported that overcrowding was the greatest hazard they faced in their classes. Studies focused on CTE (Threeton & Evanoski, 2014) and engineering design-based STEM education courses (Love & Roy, 2022a) found overcrowding to be the second greatest cause of accidents reported by teachers, with the greatest cause being students not following directions.

Concerns about overcrowding can be found in early safety guides that were published to help school boards implement safer engineering practices in local industrial and vocational education programs, “The board should make provision for ample room about machinery” (Wilson, 1916, p. 11). These industrial education learning areas served as the pre-cursor to T&E education instructional spaces, Fab Labs, and makerspaces (Hynes & Hynes, 2018; Love, 2019, 2023). Storm (1976) recommended course enrollments ranging from 16 to 24 students depending on the type of instructional area and activities being conducted, “Laboratories should be large enough for the activities indicated by the program objectives…Adequate space at each laboratory workstation is an important ingredient for safe working conditions” (p. 44). Stroud et al. (2021) reiterated guidelines from NSTA, NSELA, the Council of State Science Supervisors (CSSS), and the American Chemical Society (ACS) which recommended no more than 24 students per teacher in STEM instructional spaces if there is enough room to comply with the National Fire Protection Association (NFPA) 101 Life Safety Code Occupant Load Factor requirements of 50 net square feet per occupant (NFPA, 2024, p. 101 − 85). Safety specialists provided the same recommendation for T&E instructional areas (DeLuca et al., 2014) and makerspaces, fabrication labs (Fab Labs), and integrative STEM education facilities (Love & Roy, 2017). Some safety specialists (NSTA, 2020a; Stroud et al., 2021) have advocated for 60 net square feet per occupant based on Stephenson et al.’s (2003) analysis, which found accidents decreased from 66 to 11% as square footage rose from 45 to 60 square feet per occupant in science instructional spaces.

Occupancy load research findings

However, despite decades of safety concerns pertaining to overcrowding and lack of workspace in instructional areas facilitating hands-on STEM instruction, there has been limited research published on the effect that overcrowding has on accident occurrences in these P-12 settings. One early study examining this issue focused on accidents in high school chemistry classes. Macomber (1961) found that 22% percent of teachers had a moderate accident occur in the course they taught when enrollment was 20 or fewer students. The percentage of accidents increased to 38% and 40% when enrollments were 21–30 students and above 30 students respectively. Macomber also discovered that serious accident occurrences increased from 2 to 17% when course enrollments increased from 21 to 30 students to above 30 students respectively. Young (1972) found that one third of the science teachers in his study had overcrowded classes. He discovered that when workspace decreased below 41 square feet per student in the instructional area, there was a significant increase in accident occurrences. This led Young to conclude that, based on the average square footage of science education facilities reported by respondents, a reasonable and safer class size was 22 students per science course. West et al. (2003) reiterated Young’s recommendation of 22 students per course when they found that 69% of accidents occurred in science instructional spaces with more than 22 students.

Stephenson et al.’s (2003) research resulted in one of the more notable studies on safety in P-12 science instructional areas. Their study serves as the basis for the NSTA’s current recommendations regarding safer class enrollment sizes (NSTA, 2020a). Stephenson et al. (2003) found accident occurrences significantly increased when: (a) course enrollment sizes exceeded 24 students, and (b) the instructional space had less than 60 net square feet per student. A follow up study by West and Kennedy (2014) revealed similar results. West (2016) later indicated that these findings had applications to T&E and CTE courses in absence of comparable studies from these content areas, and because T&E and CTE laboratories have the same square footage requirements per occupant as school science laboratories according to the NFPA 101 Life Safety Code. As described in detail by P-12 STEM education safety scholars (Love & Roy, 2022a; Love et al., 2024), the Occupant Load Factor of the NFPA 101 Life Safety Code applies to all “labs, shops, and other vocational spaces” (NFPA, 2024, p. 101 − 85), which encompasses science, T&E, CTE, Fab Lab, and makerspace areas in schools where laboratory activities are conducted.

More recently Love et al.’s (2023a) national study revealed that when class enrollment exceeded 24 students, the odds of an accident increased by 48%. Other recent studies examining STEM courses implementing hands-on engineering design challenges also found course enrollments above 24 students to have a significant positive correlation with accident occurrences (Love, in press-b; Love & Roy, 2023a, b; Love et al., 2023b). Love and Roy (2023a) discovered that construction and built environment courses had significant increases in major accident occurrences when enrollments exceeded 20 students per instructor. This may be due to increased risks associated with the type of equipment, materials, processes and walking traffic patterns that are present in these specific courses, thereby warranting additional square footage, workspace, and a lower student to teacher ratio (Love & Roy, 2023a; Storm, 1976).

Similar findings have indicated certain types of science and interdisciplinary STEM instructional spaces potentially pose greater risks than others, suggesting it is better legal and professional safety practice to lower the enrollment limit in those courses (Roy & Love, 2017; Stroud et al., 2021; Stephenson et al., 2003). In light of the aforementioned research findings and NFPA 101 Life Safety Code standards, professional educator associations (e.g., NSTA), some state education departments in the U.S., and P-12 STEM safety specialists (Love & Roy, 2022a; NSTA, 2020a; Roy & Love, 2017; Stephenson et al., 2003; Stroud et al., 2021; West, 2016) have recommended that enrollments in courses involving laboratory activities should never exceed a student to [adequately safety trained] teacher ratio of 24:1. Even if a facility has the net square footage to host more than 24 students in accordance with the Occupant Load Factor of the NFPA 101 Life Safety Code standards, research findings and better professional practices suggest that the student to teacher ratio never exceed 24:1.

State occupancy load policies, statutes, and data

Recognizing the alarming safety concerns with overcrowding and high occupancy loads, some states in the U.S. have adopted course enrollment limits for lab-based courses. For example, the Commonwealth of Virginia has an Administrative Code that regulates the maximum enrollment in specific CTE and T&E focused STEM courses (Maximum Class et al., 2012). This code limits enrollment to a maximum of 20 students in courses ranging from engineering studies to materials and processes technology. However, most states do not have legislation limiting course enrollment sizes in STEM courses. Stroud et al. (2021) found that among 15 states that have legislation regulating enrollment size in STEM courses, only 8 states limited enrollment to 24 students or less. Despite these concerns and supporting data, along with legal standards directly related to net square footage required per occupant as mandated by the NFPA 101 Life Safety Code (NFPA, 2024), school systems have continued to place more students in STEM lab-based courses than suggested. Some scholars have proposed this is linked to teacher shortages and funding issues in school systems, because lower class sizes require students to be placed in other courses or require the hiring of additional highly qualified teachers with adequate laboratory space to house those courses (Love & Love, 2023; Love & Maiseroulle, 2021; Love & Roy, 2023; Love et al., 2023a, b; Stroud et al., 2021; West et al., 2003). For example, an alarming percentage of educators teaching engineering design-based STEM courses in the state of Utah reported average class sizes exceeding 24 students (39%) and 30 students (23%), with 62% indicating their largest class size that year exceeded 30 students (ITEEA, 2023). From a national U.S. perspective, Love and Roy (2022a) discovered that 57% of educators teaching engineering design-based STEM courses reported having class enrollments greater than 24 students; however, only 26% reported having an instructional facility large enough to accommodate more than 24 students according to the NFPA 101 Life Safety Code net square footage requirements.

The literature clearly indicates that occupancy load continues to be an alarming concern, which has been exacerbated by the growing shortage of certified teachers in STEM education fields (Love & Love, 2023; Love & Maiseroulle, 2021; Love & Roy, 2023a; Love et al., 2023a; National Academies of Sciences, Engineering, and Medicine, 2018; NRC, 2006; Reed & Ferguson, 2021). Although prior studies have found 24 students to be the tipping point at which accidents significantly increase, studies have also revealed that many school systems continue to operate with alarmingly dangerous enrollments in STEM courses. This knowingly increases the potential safety hazards and risks for the school system, teacher, and others involved with that instructional space as Stroud et al. (2021) highlighted, “Liability for the teacher and school district is a real possibility in overcrowded laboratory conditions” (p. 263).

Other prevalent safety factors

Risk factors

The literature has documented a number of risk factors which were found to have a significant association with increased accident occurrences. Love (in press-b) revealed there were noticeable differences among accident occurrences in different types of engineering design-based STEM courses. Manufacturing and construction courses were found to have a significantly higher proportion of accident occurrences in comparison to other engineering related courses. Additionally, an array of engineering related courses categorized as potentially having greater hazards (e.g., materials processing) were found to be significantly associated with accidents in comparison to engineering related courses categorized as potentially having fewer hazards (e.g., computer aided drafting [CAD] and architectural design) (Love, in press-b; Love et al., 2023a, b). Studies have also found that accident occurrences increased in STEM classes as the amount of class time spent doing hands-on laboratory activities increased (Love, in press-b; Love & Roy, 2023a, b; Love et al., 2023a, b).

The type of facility where STEM instruction occurs has also been found to be associated with significant increases in accident occurrences. Research has revealed the most common type of facility housing STEM courses is a hybrid classroom/laboratory facility (Love & Roy, 2022a; NRC, 2006; West et al., 2003). While these facilities provide benefits in regard to the flexibility of the learning space, they also present a number of safety issues that make it difficult to isolate and limit exposure to hazards within these hybrid spaces (Love, 2022; Love et al., 2023a; Roy & Love, 2017; NRC, 2006). Studies have discovered that STEM education classrooms with a laboratory area in the room or connected directly to the room experience a significantly higher occurrence of accidents. Additionally, studies have found that accidents increased as the number of course preparations (preps) increased for STEM teachers (Love et al., 2023a, b; West et al., 2003). Course preps require additional time to set up laboratory activities and prepare chemicals or materials; hence, course preps have been described as “similar to teaching an additional course” (West et al., 2003, p. 180).

Protective factors

In addition to risk factors, the literature has identified numerous protective factors which have been significantly correlated with decreased accident rates. STEM education scholars have proposed that state certification to teach T&E education makes a difference in a teachers’ preparation to facilitate potentially hazardous engineering design-based activities compared to educators entering the professional through an alternative licensure route (Love & Love, 2023; Love & Maiseroulle, 2021; Reed & Ferguson, 2021). Love and Roy (2023a) found alternative licensure to be a risk factor associated with significantly greater accident occurrences in STEM-based construction and built environment courses. Furthermore, Love et al. (2023b) found that educators who earned a graduate certificate in T&E education, STEM education, or an engineering field had significantly less accident occurrences in the engineering design-based STEM courses they taught compared to educators who did not possess a graduate certificate in one of these areas.

Safety training

Safety training has been one of the most studied protective factors and has built upon foundational occupational safety and health (OSH) industry training research as described by Love et al. (2022). Gerlovich and Parsa (2002) discovered that 46% of science teachers never received safety training, and only 40% received training within the five years prior to their study. Similarly, Stephenson et al. (2003) found that 35% of science teachers did not receive any form of safety training within one year of their study. More recently, Love and Roy (2022a) revealed that 33% of educators teaching engineering design-based STEM courses did not receive safety training during their undergraduate coursework, 68% did not receive safety training from their school district when initially hired, and 44% did not receive any safety training updates or retraining within the five years prior to their study. The aforementioned statistics are concerning as federal and state OSH standards require training at all three phases (Love & Roy, 2022a), and comprehensive safety training experiences have been found to reduce the odds of an accident by 49% in engineering-design based STEM courses (Love et al., 2023a).

Safety training has also been found to significantly increase STEM educators’ safety self-efficacy (SE) (Bandura, 1997) related to the use of engineering tools and materials during engineering design challenges (Love, 2017a, b, 2022). Love et al. (2022) highlighted parallels between OSH training methods used in industry and strategies that can be applied to enhance safety training efforts in STEM education contexts. Furthermore, good housekeeping practices as called for by OSHA’s general industry housekeeping “Walking-Working Surfaces Standard Number: 1910.22” can provide legal documentation of a teachers’ commitment to safety, and these practices have been found to significantly decrease the odds of an accident occurrence (Love & Roy, 2022a, 2023b). Previous studies have also found safety zones taped or painted on the floor around workspaces and hazardous activity areas to be significantly correlated with reduced accident occurrences. These zones are important for protecting the operator and other lab occupants from serious injury (Love & Roy, 2022a; Love et al., 2023a).

Rationale and research questions

It is evident from the literature that hands-on engineering design-based learning experiences offer opportunities for students to apply abstract STEM concepts in practical and concrete ways to solve authentic problems. From the literature it is also clear there remains a lot of progress to be made regarding the safety associated with hands-on P-12 engineering design-based STEM teaching and learning experiences (Love & Roy, 2022a; Love et al., 2022). Addressing prevalent safety issues identified as significantly correlated with accident occurrences could be expected to help reduce the chance of an accident. By reducing the odds of an accident occurrence, this should help maintain the inclusion of valuable hands-on engineering-design based learning experiences in STEM curricula.

While previous studies provided foundational data on risk and protective factors to inform future research efforts such as this study, they did not examine the influence of course enrollment in depth. Past studies discovered that accidents significantly increased when course enrollments rose above 24 students per instructor; however, they did not examine the extent to which the odds of an accident occurrence increased as course enrollment levels incrementally increased. Therefore, this study was conducted to investigate changes in accident occurrences when accounting for prevalent safety factors identified in the literature and incremental increases in course enrollments. The following research questions guided this study:

RQ1:

To what extent are prevalent safety factors from the literature associated with accident occurrences in hands-on engineering-design based STEM courses?

RQ2:

What influence do prevalent risk and protective factors have on the odds of an accident occurring in hands-on engineering-design based STEM courses?

RQ3:

How do the odds of an accident occurrence change as course enrollment levels incrementally increase in hands-on engineering-design based STEM courses while accounting for prevalent risk and protective factors?

Methods

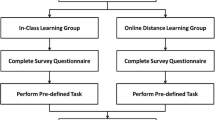

Instrumentation

This study utilized the The Technology and Engineering Education - Facilities and Safety Survey (TEE-FASS) (Love & Roy, 2022b). A panel of STEM education safety specialists created the TEE-FASS by adapting the survey items from Stephenson et al.’s (2003) science education safety study. The modifications involved slight updates to the survey items to include current safety practices, applicable U.S. legal safety standards (e.g., OSHA, NFPA), and add additional questions specifically related to newer technologies and practices involved with safer engineering design-based teaching and learning (laser engravers/cutters, 3D printers, etc.). The TEE-FASS collected information related to participants’ demographics, experience, teaching conditions, facility characteristics, safety training, safety practices, and accidents. Due to the large volume of questions and the type of information teachers had to recall (e.g., number of accident occurrences within the past five years), the instrument collected mostly nominal and ordinal data to make it more user-friendly. For this study, the term accident encompassed minor and major accident occurrences, which ranged from needing minor first-aid attention (band-aid, visit to the school nurse, etc.) to major medical attention (doctor or hospital visit, stitches, etc.) (Love et al., 2023a).

As described by Love et al. (2023a, p. 4), due to the ordinal and nominal nature of the TEE-FASS items, it was determined that certain reliability and validity measures were not applicable. The TEE-FASS was pilot tested with a small sample of STEM teachers, school system STEM curriculum supervisors/administrators, school system STEM safety officers, and a state supervisor of STEM education. Based on their feedback, minor modifications were again made to provide greater clarity for some of the questions and improve the online functionality of the survey instrument for educators. The TEE-FASS was then sent to state P-12 science and T&E education associations in New Jersey, New York, and Pennsylvania to advertise the study online for any educator of engineering-design based STEM courses to voluntarily participate. After the survey closed, the researcher organized the responses in SPSS and analyzed the results quantitatively using the data analyses methods described in the next section. The TEE-FASS can be accessed in its entirety from Love and Roy (2022b).

Data analyses

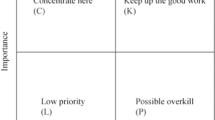

Polychoric correlations

For the first research question the author conducted correlational analyses to estimate the independent associations between safety factors that were prevalent in the review of literature (Love, in press-b; Love & Roy, 2023a, b; Love et al., 2023a, b) and the occurrence of accidents over a five-year period. Previous studies (Love, in press-a, in press-b; Love & Roy, 2023a, b; Love et al., 2023a, b) conducted similar polychoric correlational analyses in an exploratory manner; however, the current study was able to be more intentional about the safety factors that were analyzed based on findings from those previous studies. Associations were estimated as a polychoric correlation coefficient, which is an alternative to the Pearson r for normally distributed data. Polychoric correlational analyses are recommended when variables represent a continuous measure, but the data is organized in an ordinal manner (i.e., accident occurrence categories) (Rigdon & Ferguson, 1991). Quantile-quantile (Q-Q) plots and chi-square goodness of fit tests were conducted to examine if the data was normally distributed for the polychoric correlation tests. Q-Q plots for each safety factor indicated that all or most of the data fell within the 95% confidence ellipse; therefore, the assumption of bivariate normality was reasonable (Oppong & Agbedra, 2016). Additionally, chi-square goodness of fit tests were conducted between each safety factor and the occurrence of accidents over a five-year period. The p values from the goodness of fit tests suggested the assumption of bivariate normality was reasonable for each safety factor (Maydeu-Olivares et al., 2009). No prior hypotheses were made regarding the direction of the polychoric correlations, instead the correlation coefficients that emerged from the analyses revealed the direction of the correlation for each safety factor. These were reported as risk factors (positive correlation) or protective factors (negative correlation). The polychoric correlation coefficient and p value for the likelihood ratio test were reported in Table 1 for each safety factor.

Binary logistic regressions

To investigate RQ2 the researcher conducted a series of three binary logistic regression models to estimate the predicted change in odds of one or more accidents occurring when accounting for specific safety factors. The first model looked at the odds of an accident occurring when only considering prevalent risk factors, the second model examined the odds of an accident occurring when considering prevalent risk and protective factors, and the third model examined the odds of an accident occurring when considering prevalent risk and protective factors as well as average enrollment sizes of the STEM courses that participants taught. The purpose of these models was to examine if the magnitude or precision of the covariates in the model changed with the inclusion of the new predictors described above.

Four additional binary logistic regression models were then utilized to examine RQ3. All of these models included the same prevalent risk and protective factors as covariates, but the average course enrollment size served as a new predictor in each independent model. The purpose of these models was to investigate changes in the odds of an accident occurring as average course enrollment sizes increased (while accounting for prevalent risk and protective factors). These models were also used to examine if the magnitude or precision of the covariates in the model changed with the incremental increases in average course enrollment size. Holm’s sequential Bonferroni procedure (Abdi, 2010; Holm, 1979) was used to control for familywise error rate (FWER) for the multiple models in RQ3 and mitigate the risk of accepting results that might be a false positive, or Type I error. The model coefficients produced by each of the binary logistic regression models presented in Table 2 remained significant when using the corrected p values from Holm’s sequential Bonferroni procedure.

The unstandardized beta coefficient (B) and p value were reported for each covariate in the binary logistic regression models conducted for RQ2 and RQ3. Tolerance values greater than 0.2 and variance in inflation factor (VIF) scores below 2.5 for the covariates in each model met the assumption of no multicollinearity (Midi et al., 2010). Since unstandardized beta coefficients were reported in this study and there were differences in the units of measure or scale among the categorical covariates, caution was used not to compare the covariates or rank them within each model. The unstandardized beta coefficients and odds ratios reported for the binary logistic regression models were utilized to examine changes in the odds of an accident occurrence according to the inclusion of covariates or changes in the magnitude of the covariates.

Participants

The TEE-FASS yielded voluntary responses from 117 educators who were teaching engineering-design based STEM courses. The sample identified as mostly white (94%) and male (74%) with a bachelor’s degree in either technology education/T&E education (43%) or an engineering field (5%). Nineteen percent had earned a master’s degree in technology education/T&E education, 6% in STEM education, and 1% in an engineering field. In regard to teaching licensure/certification, most were certified by their state to teach T&E education (87%), while a small percentage (6%) were certified in a science content area, elementary education (4%), a CTE area (1%), or other content area (e.g., instructional technology) (2%). Only one participant (1%) reported they were teaching with alternative or provisional licensure. Participants possessed a broad spectrum of P-12 teaching experience, with 28% in their first eight years of teaching, 68% had taught for 9–25 years, and 21% had taught for more than 25 years. Most participants were teaching students in grades 6–8 (30%) or 9–12 (53%) when they completed the TEE-FASS. Participants also reported teaching a broad spectrum of engineering-design based STEM courses. T&E design (38%), materials processing and manufacturing (23%), electronics and robotics (10%), pre-engineering (9%), and computer aided design (CAD) (9%) related courses were the most commonly reported for main teaching focus.

Findings

Research question 1

The first research question asked to what extent safety factors, which were identified as prevalent in the literature, were associated with the accidents which occurred in the hands-on engineering-design based STEM courses that participants taught within the prior five years? The polychoric correlational analyses discovered two risk factors (negative correlation) and one protective factor (positive correlation) to be significantly associated (p < 0.05) with reported accident occurrences. These analyses indicate that if a risk factor existed (e.g., a binary variable of 0 represented their facility did not include/was not directly connected to a laboratory, or a value of 1 represented they did have a laboratory facility), or as a risk factor increased (e.g., ordinal Likert-scale responses about average percentage of daily class time that students were engaged in hands-on engineering design-based activities), the number of reported accidents also increased. Conversely, as protective factors were present or increased, the number of reported accidents decreased. Having a lab in a facility or connected directly to a facility where participants taught and average course enrollment were both found to be statistically significant risk factors at the p < 0.05 level. Teaching courses that were classified as having potentially increased hazards and average percentage of daily class time that students were engaged in hands-on engineering design-based activities demonstrated marginal significance (p < 0.10) (Olsson-Collentine et al., 2019) as risk factors. Receiving some form of STEM related safety training during one’s undergraduate coursework was determined to be a statistically significant protective factor (Table 1).

Research question 2

After examining the independent associations between accident occurrences and safety factors which were identified as prevalent in the literature, the researcher wanted to examine how these risk and protective factors collectively predicted the occurrence of an accident. Accident occurrences reported by participants were converted to a binary variable represented as (1) an accident occurred or (0) no accident occurred within the prior five years. A series of three binary logistic regression models were then conducted (Models I-III). The p values for the Hosmer-Lemeshow goodness-of-fit tests were greater than 0.05 (Table 3), indicating that each model was a good fit in regard to predicting an accident occurrence. Model I, which included only prevalent risk factors as predictors, was significantly associated with accident occurrences at the p < 0.05 level (χ2(4) = 12.572, p = 0.014). When prevalent protective factors were added as predictors in Model II, the model was again significantly associated with accident occurrences, but the p value increased (χ2(10) = 20.162, p = 0.028). In Model III when average course enrollment size was included as a predictor, the model was also significantly associated with accident occurrences and the p value decreased (χ2(11) = 24.716, p = 0.010). When examining specific safety factors, the average course enrollment size predictor in Model III was significantly associated with accident occurrences and revealed that as course enrollment increased, the odds of an accident occurring was twice as likely (B = 0.775, p = 0.036, OR = 2.172).

The unstandardized beta coefficients (B) and odds ratios (OR) in this study were derived from the binary logistic regression models conducted in SPSS. The unstandardized beta coefficient indicates there was either an increase (positive B) in the dependent variable (accident occurrence) as the covariate (safety factor) increased, or a decrease (negative B) in the dependent variable as the covariate increased. Given that the data were categorical, the OR is presented to help make sense of the results. If the OR is less than one, every unit increase in the covariate (e.g., course enrollment size category) corresponds with a decrease in the odds of the dependent variable occurring (e.g., accident occurrence); however, if the OR is greater than one, every unit increase in the covariate corresponds with an increase in the odds of the dependent variable occurring. For example, an OR of 2.172 indicates that as course enrollment size increased by one categorical unit, the odds of an accident increased 2.172 times. Furthermore, the OR can be viewed as the percent change in odds that an accident could be expected to occur. This percentage can be calculated by subtracting one from the OR, and then multiplying by 100. The previous example including an OR of 2.172 results in a 117% percent increase in accident occurrences [2.172-1 = 117.2%], or in terms of safety training received during participants’ undergraduate education there is a 83.2% percent decrease in accident occurrences ([0.168–1 = -0.832] x 100 = -83.2%). Furthermore, the unstandardized betas in the examples described above indicate if there was an increase in the dependent variable (positive B) or decrease in the dependent variable (negative B).

Safety training received during participants’ undergraduate education was a significant predictor in Model II (B = -1.785, p = 0.047, OR = 0.168) and Model III (B = -2.283, p = 0.030, OR = 0.102), demonstrating an increased reduction in the odds of an accident occurrence from 83 to 90% when accounting for course enrollment size. Furthermore, having a laboratory facility in or directly connected to participants’ STEM instructional area was significantly associated with accidents in all three models (Table 2). When only accounting for the prevalent risk factors, educators with a laboratory facility were eight times more likely to have had an accident occur (B = 2.127, p = 0.007, OR = 8.392). The prevalent protective factors helped to reduce the significance (p = 0.011) of having a laboratory facility and the association with accidents; however, when accounting for enrollment size, those who reported teaching in a laboratory facility were 25 times more likely to have had an accident occur (B = 3.233, p = 0.006, OR = 25.350).

Moreover, the addition of prevalent protective factors and average course enrollment size as predictors helped yield progressively greater Nagelkerke R square values from Model I (23%) to Model III (43%). This indicates that the proportion of variation in accident occurrences explained by the models improved as these predictors were added. Furthermore, in all three models the area under the Receiver Operating Characteristic (ROC) curve was calculated. The area under the ROC curve represents the model’s ability to discriminate between participants who had an accident occurrence versus those who did not (Hosmer et al., 2013). Model I (0.814), Model II (0.872), and Model III (0.895) yielded strong discrimination measures (Hosmer et al., 2013). There is a noticeable increase in the area under the ROC curve values when comparing Models I and III (Table 2), suggesting that the inclusion of the prevalent protective factors and average course enrollment size helped to improve the model’s ability to predict the probability of an accident occurrence.

The models in Table 2 piqued the researcher’s interest, which prompted a closer look at the association between average class enrollment sizes and the odds of an accident occurring. To investigate this in greater detail, additional binary logistic regression models were conducted according to course enrollment size categories that were reported through the TEE-FASS.

Research question 3

Four additional binary logistic regression models were conducted to examine RQ3. It should be noted that unlike the Models conducted in RQ2, the Models for RQ3 were independent models which did not build upon each other and were numbered in a manner to reflect this (Table 3). A different course enrollment size predictor was included in each model, making Models IV-A thru IV-D distinctly different. The intent of Models IV-A thru IV-D were to examine the occurrence of accidents as course enrollment sizes changed incrementally. These models also examined changes in the magnitude or precision of the covariates in the model when accounting for the course enrollment size. Accident occurrences remained classified as a binary variable (0 = no accident, 1 = accident occurrence within the prior five years). The p values for the Hosmer-Lemeshow goodness-of-fit tests exceeded 0.05 (Table 3), demonstrating that each model was a good fit in regard to predicting an accident occurrence.

Models IV-A thru IV-C analyzed course enrollments equal to or less than the specified thresholds. This was intentionally done to determine if smaller enrollments were significantly associated with decreased odds of an accident occurrence. Models IV-A and IV-B did not find course enrollments of ≤ 15 (p = 0.513) and ≤ 20 students (p = 0.169) to be significantly associated with accident occurrences. Model IV-C discovered courses with average enrollments of ≤ 24 students were significantly associated with accident occurrences. Specifically, there was an 87.5% reduction in the odds of an accident occurring when average course enrollment was ≤ 24 (B = -2.082, p = 0.037, OR = 0.125). For the next course enrollment predictor, Model IV-D analyzed the association between accident occurrences and average course enrollments > 30 students. Examining > 30 students instead of ≤ 30 students was intentionally done to avoid hazardous enrollment levels between 25 and 30 (as established from Model IV-C) from being included in the course enrollment predictor in Model IV-D. This model revealed that participants who had course enrollment sizes exceeding 30 students were 21 times more likely to have had an accident occur (B = 3.070, p = 0.014, OR = 21.535) (Table 3).

In addition to average course enrollment size, having a laboratory in or directly connected to participant’s facility where STEM instruction occurred was significantly associated with accident occurrences. Participants who reported having this risk factor were 19 times more likely to have had an accident occur in their STEM courses when enrollments were ≤ 24 (B = 2.947, p = 0.009, OR = 19.056) and > 30 (B = 2.969, p = 0.009, OR = 19.468). Receiving safety training during participants’ undergraduate education was a safety protective factor found to be significantly associated with accident occurrences at the ≤ 24 and > 30 enrollment levels. Participants who had course enrollments ≤ 24 and received safety training in their undergraduate education had an 86% reduction in the odds of an accident occurring (B = -1.992, p = 0.043, OR = 0.136). Among teachers who had enrollments exceeding 30 students, those who received safety training during their undergraduate education had a 91% reduction in the odds of an accident occurring (B = -2.415, p = 0.023, OR = 0.089).

From examining the four independent models there was a noticeable decrease across Model IV-A to IV-D in the model coefficient, indicating a greater association with accident occurrences. There was also a progressive increase in the Nagelkerke R square values and the area under the ROC curve. The Nagelkerke R square values increased from (39%) in Model IV-B to 42.6% and 44.7% in Models IV-C and IV-D respectively. This shows that the proportion of variation in accident occurrences explained by the models improved as the different course enrollment size predictors were included. Additionally, all Models in Table 3 yielded strong discrimination measures according to the area under the ROC curve (Hosmer et al., 2013). Models IV-C (0.888) and IV-D (0.907) demonstrated an increase in the area under the ROC curve values compared to the other Models in Table 3, suggesting that the model’s ability to predict the probability of an accident occurrence improved as course enrollment sizes increased.

Discussion

Research question 1

The results from the polychoric correlation analyses in RQ1 revealed safety factors that were significantly associated with accident occurrences specific to the sample in this study. Identifying these factors can help raise awareness regarding significant safety risks that need to be monitored and addressed to theoretically reduce the odds of an accident occurring. Moreover, the implementation and inclusion of the protective factors found to be significantly associated with accidents should be reviewed by school systems and educators to help reduce the odds of an accident occurring. The literature has documented the increased safety hazards and risks associated with STEM education laboratories, hybrid classroom/laboratory facilities, and makerspaces (Love & Roy, 2022a; National Academies of Sciences, Engineering, and Medicine, 2018; NRC, 2006; West et al., 2003). Similarly, this study found that having a laboratory within a STEM education instructional area or directly connected to the instructional area significantly increased the chances of an accident occurrence. Laboratory and hybrid laboratory/classroom facilities often warrant special engineering controls based on the activities being performed and require increased focus on direct supervision to ensure students are implementing safer practices at all times (Love & Roy, 2022a; National Academies of Sciences, Engineering, and Medicine, 2018; NRC, 2006; Roy & Love, 2017; West et al., 2003). Hybrid laboratory/classroom facilities grew in popularity to help reduce costs and maximize allotted STEM instructional space in schools (NRC, 2006; West et al., 2003), and they continued to increase in popularity with the rise of makerspaces and other collaborative STEM instructional spaces (Hynes & Hynes, 2018; Love, 2022; National Academies of Sciences, Engineering, and Medicine, 2018; Roy & Love, 2017). Due to the amalgam of STEM activities and safety hazards one may encounter in a hybrid laboratory/classroom facility or makerspace, safety training is extremely important for preparing educators to teach in these areas. These collaborative spaces help foster interdisciplinary learning opportunities that align with current science (NGSS Lead States, 2014) and T&E standards (ITEEA, 2020) in the U.S., and teach authentic interdisciplinary problem-solving skills that students will be expected to implement in post-secondary education programs and the workplace (Love, in press-b; Love et al., 2023b). However, educators must be adequately prepared to oversee and maintain safer instruction in these areas.

The literature indicates that safety training can significantly increase in-service teachers’ safety awareness and safety self-efficacy related to makerspaces and integrated STEM learning areas (Love, 2017a, b, 2022; Love et al., 2022; Nykänen et al., 2019). The literature has also documented that pre-service safety training experiences can significantly reduce the odds of an accident for STEM educators (Love et al., 2023b). In alignment with the literature, this study found that receiving safety training during one’s undergraduate studies was significantly associated with reduced accident occurrences; however, in-service safety training updates were not found to be a significant protective factor. While safety training updates and some of the other protective factors were not significant, they did demonstrate negative correlations and negative unstandardized beta values, which indicates they had protective qualities. It is also important to note that while these safety factors individually were not significant protective factors in this study, they did play an important role when examined as a collective group of protective factors that reduced the negative effects of the prevalent risk factors in RQ2.

The results from RQ1 also revealed that courses categorized as having potentially increased hazards and the percentage of class time spent doing hands on activities each had a marginally significant (Olsson-Collentine et al., 2019) association with accident occurrences. While these factors have been found to be statistically significant in previous studies (Love, in press-b; Love & Roy, 2023a, b; Love et al., 2023a, b) the researcher cautions that entirely removing these risk factors may not be feasible while teaching the content and practices called for in national and state standards in the U.S. (ITEEA, 2020; NGSS Lead States, 2014). Authentic hands-on learning experiences are the cornerstone of STEM education and should remain an important part of STEM curricula. However, legal risks and safety hazards can be reduced by implementing significant protective factors and determining when to reduce specific risks through the use of effective pedagogical and classroom management strategies (Love in press-a). These practices can provide a safer yet comparable hands-on engineering design-based STEM learning experience for students. The findings from this study should not be misinterpreted to reduce hands-on learning time from STEM courses or limit laboratory-based STEM course offerings, rather the findings should be viewed holistically. For example, if a school system is offering a course with potentially increased safety hazards (e.g., materials processing) compared to other courses (e.g., CAD and architectural design), they must ensure the instructor has adequate safety training to teach that course as required by OSHA Hazard Communication Standard 29 CFR 1910.1200 or an applicable OSH state plan. They must also ensure the facility has adequate engineering controls and other protective factors (e.g., safety zones) in place as called for under OSHA 29 CFR 1910 and 29 CFR 1926 or applicable OSH state plans. Furthermore, the findings related to course enrollment size and sufficient horizontal workspace per student (≥ six square feet per student [Stephenson et al., 2002]) in this study suggest that school systems should not overcrowd STEM instructional spaces. While sufficient horizontal workspace per student was not found to be significantly associated with accident occurrences, it emerged as a protective factor which contributed to reducing the effects of the prevalent risk factors in the models. These results corroborate findings related to occupancy load and overcrowding from previous P-12 STEM education safety studies (Love, in press-b; Love & Roy, 2023a, b; Love et al., 2023a, b; Macomber, 1961; Stephenson et al., 2003; West & Kennedy, 2014; Young, 1972). Additionally, these results also reiterate the importance of following legal occupancy load standards (NFPA, 2024) to avoid knowingly increasing the risk or odds of an accident based on decades of research on occupancy loads in STEM-related instructional spaces.

Research question 2

The binary logistic regressions addressing RQ2 revealed that the addition of prevalent protective factors in Model II not only improved the ability of the model to predict accident occurrences, but in comparison to Model I (p = 0.014), the protective factors had an effect on the model coefficient (p = 0.028) associated with the occurrence of accidents. The addition of average class enrollment size in Model III, one of the most prevalent safety factors discussed throughout the P-12 STEM education safety literature, further improved the model’s predictive capabilities. Even when controlling for the prevalent protective factors, average course enrollment size posed potential risks that significantly increased the odds of an accident occurrence. This indicates that while the prevalent protective factors collectively helped to reduce accident occurrences (Model II), the risks and resulting safety hazards associated with class enrollment size overshadowed the benefits of the protective factors, increasing the odds of an accident occurrence. The addition of average class enrollment size as a predictor in Model III also increased the significance of some other risk and protective factors, such as safety training during one’s undergraduate studies. This suggests that undergraduate safety training, when considered collectively with other prevalent protective factors, becomes increasingly important to help reduce the odds of an accident as course enrollments increase. This finding supports claims made in the literature which suggested that safety training is one of many important components of undergraduate STEM educator preparation programs, and can improve educators’ ability to manage STEM learning environments more effectively (including specialized training on safer hazards management and supervision strategies related to different STEM content areas and types of facilities) (Love, 2022; Love & Roy, 2023a; Love et al., 2022, 2023a, b).

Models I-III also reiterate the importance of ensuring that educators who are tasked with teaching in a laboratory or hybrid laboratory/classroom facility have the adequate safety training and knowledge to facilitate safer teaching and learning opportunities. Furthermore, increases in the negative B coefficients along with decreases in the p values of all six protective factors from Model II to Model III signify the increased importance that protective factors play when also accounting for prevalent risk factors that are associated with accident occurrences. Table 2 depicts the complexity of pinpointing specific safety factors that can individually improve safety. School systems and educators should approach safety from a systems lens as described by DeLuca et al. (2014). As demonstrated by Models II and III, protective factors can collectively improve safety, but focusing on only one or a few significant factors and disregarding the others may not yield the same safety results. Additionally, school systems and educators must be cognizant that the risks and protective factors accounted for in this study are not inclusive of all legal safety standards and better professional safety practices that must be followed under local, state, and federal regulations. The addition and/or reduction of protective and risk factors specific to each STEM course and curriculum can potentially change the safety outcomes. The literature indicates that a wide variety of risk and protective factors have been found to be significantly correlated with accidents that occur within different STEM education contexts (Love, in press-b; Love & Roy, 2023a, b; Love et al., 2023a, b). This further exemplifies the importance of viewing and approaching safety from a dynamic systems lens unique to the curriculum, teacher, students, facility, and other potentially influential variables.

Research question 3

The four independent binary logistic regression models in Table 3 corroborated findings from the literature and built upon previous studies examining the relationship between course enrollment size and accident occurrences within various STEM-related courses. Models IV-A and IV-B revealed course enrollments of ≤ 15 and ≤ 20 students were not significantly associated with accident occurrences. However, similar to the literature, course enrollments of ≤ 24 students were significantly associated with reduced accident occurrences and demonstrated an 87.5% reduction in the odds of an accident occurring. Conversely, if analyzing this from the perspective of ≥ 25 students when accounting for the same risk and protective factors as included in Model IV-C, the results reveal that when course enrollment size exceeds 24 students the odds of an accident occurring increase eight times (B = 2.082, p = 0.037, OR = 8.017). As mentioned previously, course enrollment sizes were intentionally analyzed as less than or equal to 15, 20, and 24 students to determine at what threshold enrollment size increased to a significantly hazardous level, which was discovered to be ≥ 25 students. The researcher presents the results from analyzing the enrollment as ≥ 25 students merely to provide comparisons to previous studies who analyzed enrollment from a similar perspective.

Stephenson et al.’s (2003) study, which has been widely cited throughout the literature and acknowledged by professional STEM education associations as the research supported recommendation for safer STEM course enrollments, conducted a more simplified chi-square test involving 76 science educators from Texas. Their study found there was a significant relationship between accident occurrences and courses that had enrollments exceeding 24 students. They reported that 13% of educators with > 20 students reported having an accident occurrence in their class compared to 62% of educators who had enrollments exceeding 24 students. Love et al. (2023a) later found as enrollment exceeded 24 students per instructor the odds of an accident occurrence increased by 48%. While these findings have been valuable to help advocate for safer STEM course enrollment sizes, neither of the aforementioned studies examined changes in the association between enrollment size and accident occurrences as enrollment levels increased incrementally. This study found that when course enrollments exceeded 24 students per instructor the odds of an accident occurring were eight times more likely, and when course enrollments exceeded 30 students the odds of an accident were 21 times more likely! This is a very concerning finding considering that Love and Roy (2022a) discovered 57% of educators teaching engineering design-based STEM courses in the U.S. reported having one or more courses with enrollments exceeding 24 students, and 23% had 30 or more students in their class(es).

The recent literature reporting on course enrollment sizes in STEM related courses and the findings from this study suggest that occupancy loads in STEM instructional areas present an alarming issue given the increased odds of an accident occurring in overcrowded STEM classes. Models IV-C and IV-D indicate that educators who are teaching STEM courses in a laboratory or hybrid laboratory/classroom facility may face greater safety risks and have higher odds of an accident occurring. These models also suggest that providing STEM educators with safety training as part of their undergraduate educational experience can help to reduce the odds of an accident by 86–91% when accounting for other risk and protective factors, including course enrollment. However, caution must be exercised when interpreting the findings from this study. School systems should not view additional safety training as a means to justify course enrollments of 25 or more students. The models from this study demonstrate that when various protective factors are in place, they can help to reduce the negative impact that safety risk factors have; however, increasing enrollment sizes beyond 24 students per instructor significantly increases the odds of an accident despite the implementation of protective factors.

Safety researchers have also cautioned that while school systems have legal, professional, and ethical responsibilities to follow the NFPA 101 Life Safety Code net square footage requirements (50 net square feet per occupant) in STEM instructional spaces, this must be enforced with STEM course enrollment research findings in mind (Love & Roy, 2022a; NSTA, 2020a; Roy & Love, 2017; Stephenson et al., 2003; Stroud et al., 2021; West, 2016). Specifically, if a STEM education facility is large enough to accommodate an enrollment of 30 or more students according to the NFPA 101 Life Safety Code net square footage requirements, this does not mean it is safer to do so. As this current study and previous studies suggest (Stephenson et al., 2003), STEM course enrollments should not exceed 24 students per each adequately safety trained educator facilitating instruction in that space. The literature and research findings indicate that school systems and administrators who allow enrollments to exceed 24 students in a hands-on STEM education course with only one adequately safety trained instructor are significantly increasing the odds of an accident, consequently jeopardizing the safety of all occupants in that instructional space.

Limitations

Despite the important findings to improve safety in P-12 hands-on engineering design-based STEM education courses, there are a few limitations that must be acknowledged with this study. The findings cannot be generalized beyond the sample to all engineering-design based STEM courses and teachers in the mid-Atlantic states, the U.S., or other countries. There was a high percentage of white and male participants in this study; however, this is consistent with demographic results reported in national (Williams & Ernst, 2022; Love & Roy, 2022a) and similar regional (Love, 2015) studies involving STEM educators delivering engineering design-based instruction. The results from this study were voluntarily self-reported, and it is unknown if educators who responded had an increased interest in participating due to safety issues they experienced and felt strongly about reporting. It is also unknown if the occurrence of accidents was underreported by participants. Researchers have described how some self-reported accident studies from industry have found participants sometimes underreport accidents, which has applications to education employers and employees, and is a limitation with any safety study collecting self-reported data (Love & Roy, 2023b; Threeton & Evanoski, 2014).

Moreover, the TEE-FASS collected information about accident occurrences as ordinal data instead of continuous data. This warranted the use of polychoric correlational analyses to examine associations with accident occurrences similar to the method used in other safety studies (Love, in press-a, in press-b; Love & Roy, 2023a, b; Love et al., 2023a). The results from these analyses should be interpreted with caution as they do not indicate causation, but simply show the magnitude of the relationship that exists between each safety factor and accident occurrences. Lastly, educators and school systems should not view the safety factors in this study as the only factors that should be implemented to improve safety. This study merely showed the influence that those specific factors, which were found to be prevalent across the literature, had on safety and accidents when considering them collectively. Additionally, educators and school systems should not view the protective factors from this study as a means to improve safety while ignoring significant risk factors (e.g., overcrowding in STEM courses). Risk and protective factors should be addressed collectively to improve safety, and additional factors may change the safety outcomes in different contexts. Educators and school systems must ensure that in addition to the safety recommendations provided in this study, they are following all legal safety standards and better professional safety practices applicable to their local/state jurisdiction and specific STEM content area.

Conclusions

This study provides a unique contribution to the P-12 STEM education literature by building upon prior class enrollment size studies and analyzing the relationship between course occupancy loads and accident occurrences in greater depth. One of the major findings from this study was that although prevalent protective factors helped to reduce the association between risk factors and accident occurrences in hands-on engineering design-based STEM courses, the safety hazards associated with increasing course enrollment sizes overshadowed the positive benefits of the prevalent protective factors. Other key findings revealed courses with enrollments of 24 or fewer students per instructor had an 87.5% reduction in the odds of an accident occurring. When course enrollments exceeded 24 and 30 students per instructor, respectively, they were eight and 21 times more likely to have had an accident occur. Not only do these results align with findings and recommendations from previous STEM education safety studies which advised against course enrollments exceeding 24 students per adequately safety trained instructor (Love & Roy, 2022a; NSTA, 2020a; Roy & Love, 2017; Stephenson et al., 2003; Stroud et al., 2021; West, 2016), but these findings corroborate the critical importance of safer occupancy loads in P-12 STEM education courses. Despite the various challenges that school systems face, including shortages of highly qualified teachers in STEM content areas and budget cuts (Love et al., 2024), school systems and administrators would be derelict in their duty to protect students and educators by allowing unsafe occupancy loads to continue in STEM classes.

Safely engaging students in valuable hands-on, engineering design-based learning opportunities must remain a cornerstone of STEM learning experiences. Allowing overcrowding and other research documented safety issues to exist without the proper precautions in place (safety training, engineering controls, etc.) significantly increases the odds of an accident and jeopardizes the continuation of valuable hands-on learning opportunities that allow students to solve authentic problems through the application of STEM content and practices. These experiences reflect the learning benefits advocated for by educational theorists while teaching students safer STEM problem solving skills that can be applied at home, in post-secondary education programs, and in the workplace. Legislators, state departments of education, boards of education, school systems, administrators, school counselors, and other stakeholders who have an influence on safety factors, course enrollment sizes, and policies in P-12 STEM courses need to consider the findings of this study in earnest. Ignoring the results and recommendations from this study could have costly legal consequences should an accident occur as a result of overcrowding or an unsafe occupancy load.

Recommendations

This research highlights that while there were some similarities between the safety factors found to be significantly correlated with accidents in this study and other safety studies, there may also be additional variables that contribute to improving safety based on a variety of factors (the types of STEM courses taught in specific regions, amount and type of safety training completed by educators, etc.). Further analyses are needed to examine which safety factors are significantly associated with accident occurrences in various regions of the U.S to improve STEM education instruction. The results from this study advocate for collaborative partnerships between post-secondary STEM programs, teacher preparation faculty, P-12 STEM educators, and OSH specialists to inform future research efforts and outreach initiatives aimed at improving safety. State departments of education, school systems, P-12 STEM educators, and STEM teacher preparation programs should consider the findings presented in this study to inform funding delegated for safety needs, professional development efforts, safety training needs for instructors and students, and resources required for safer engineering design-based instruction (e.g., engineering controls). This study has implications for informing research and laboratory-based instructional practices in various disciplines, especially in science education given the call for teaching engineering practices as part of the NGSS in the U.S. Most notably, the data from this study and previous studies clearly indicate that school systems should follow the NFPA 101 Life Safety Code net square footage requirements in conjunction with the research supported findings of no more than 24 students per adequately safety trained instructor in STEM courses where hands-on laboratory activities are being conducted.

Data Availability

All data generated or analyzed during this study are included in this published article.

Change history

17 June 2024

Change History text in Abstract the word likely has been updated.

References

Abdi, H. (2010). Holm’s sequential Bonferroni procedure. In N. Salkind (Ed.), Encyclopedia of Research Design (pp. 574–578). Sage.

Bandura, A. (1997). Self-efficacy: The exercise of control. W.H. Free- man and Company.

DeLuca, V. W., Haynie, W. J., Love, T. S., & Roy, K. R. (2014). Designing safer learning environments for integrative STEM education (4th ed.). International Technology and Engineering Educators Association.

Dewey, J. C. (1916). Democracy and education. Macmillan.

Eng, K. K., Md Zain, N., A., & Zainal, S. R. M. (2010). Review on OSH in engineering education. Paper presented at the 2nd International Congress on Engineering Education, 219–224. IEEE. https://doi.org/10.1109/ICEED.2010.5940795.

Gerlovich, J. A., & Parsa, R. (2002). Surveying science safety. The Science Teacher, 69(7), 52–55.

Holm, S. (1979). A simple sequentially rejective multiple test procedure. Scandinavian Journal of Statistics, 6(2), 65–70.

Hosmer, D. W., Lemeshow, S., & Sturdivant, R. X. (2013). Applied logistic regression (3rd ed.). Wiley.

Hynes, M. M., & Hynes, W. J. (2018). If you build it, will they come? Student preferences for makerspace environments in higher education. International Journal of Technology and Design Education, 28(3), 867–883. https://doi.org/10.1007/s10798-017-9412-5.

International Technology and Engineering Educators Association (ITEEA) (2020). Standards for technological and engineering literacy: The role of technology and engineering in STEM education. https://www.iteea.org/stel

International Technology and Engineering Educators Association (ITEEA) (2023). Safer engineering and CTE instruction: A national STEM education imperative. State reports. https://www.iteea.org/Safety.

Kolb, D. A. (1984). Experiential learning: Experience as the source of learning and development. Prentice-Hall Inc.

Love, T. S. (2015). Examining the demographics and preparation experiences of foundations of technology teachers. The Journal of Technology Studies, 41(1), 58–71. https://doi.org/10.21061/jots.v41i1.a.7.

Love, T. S. (2017a). Perceptions of teaching safer engineering practices: Comparing the influence of professional development delivered by technology and engineering, and science educators. Science Educator, 26(1), 21–31.

Love, T. S. (2017b). Tools and materials in primary education: Examining differences among male and female teachers’ safety self-efficacy. In L. Litowitz & S. Warner (Eds.), Technology and engineering education – Fostering the creativity of youth around the globe. Proceedings of the 34th Pupil’s Attitude Toward Technology Conference, Philadelphia, PA: Millersville University.

Love, T. S. (2019). Temporary concern or enduring practice? Examining the progress of safety in STEM education. Technology and Engineering Teacher, 78(6), 15–17.

Love, T. S. (2022). Examining the influence that professional development has on educators’ perceptions of integrated STEM safety in makerspaces. Journal of Science Education and Technology, 31(3), 289–302. https://doi.org/10.1007/s10956-022-09955-2.

Love, T. S. (2023). Embedding safety in integrative STEM teaching methods courses for pre-service elementary educators. Journal of Technology Education, 34(2), 22–42. https://doi.org/10.21061/jte.v34i2.a.2.

Love, T. S. (in press-b). Safety issues and accident occurrences reported by P-12 engineering educators in the middle Atlantic United States. Career and Technical Education Research.

Love, T. S. (in press-a). Safety in P-12 engineering courses within the southern United States. Journal of Pre-College Engineering Education Research.

Love, T. S., & Love, Z. J. (2023). The teacher recruitment crisis: Examining influential recruitment factors from a United States technology and engineering teacher preparation program. International Journal of Technology and Design Education, 33(1), 105–121. https://doi.org/10.1007/s10798-022-09727-4.

Love, T. S., & Maiseroulle, T. (2021). Are technology and engineering educator programs really declining? Reexamining the status and characteristics of programs in the United States. Journal of Technology Education, 33(1), 4–20. https://doi.org/10.21061/jte.v33i1.a.1.

Love, T. S., & Roy, K. R. (2018). Who should make your maker spaces? ASEE Prism, 28(2), 54.

Love, T. S., & Roy, K. R. (2022a). Safer engineering and CTE instruction: A national STEM education imperative. What the data tells us. International Technology and Engineering Educators Association. https://www.iteea.org/Safety.