Abstract

The sustainability of agri-food supply chains (AFSCs) is severely threatened by regional and global events (e.g., conflicts, natural and human-made disasters, climate crises). In response, the AFSC industry is seeking digital solutions using Industry 4.0 (I4.0) technologies to enhance resilience and efficiency. However, why I4.0 adoption remains stubbornly low in the agri-food industry remains poorly understood. To address this gap, this study draws on middle-range theory (MRT) and uses thematic analysis, the fuzzy analytic hierarchy process, total interpretive structural modelling, and fuzzy cross-impact matrix multiplication applied to classification to produce insights from nine case studies in China that have invested in I4.0 technologies to improve their AFSC sustainability. New drivers of I4.0 unique to the agri-food industry are identified, showing how I4.0 can contribute to the environmental, economic, and social dimensions of AFSC sustainability. The results have implications for AFSC researchers and practitioners with an interest in supply chain sustainability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Agri-food supply chains (AFSCs) are inherently complex systems involving various stakeholders (e.g., suppliers, farmers, processors, wholesalers, distributors, and retailers) who engage in agriculture-related activities to move products across the chain from ‘farm to fork’ (De Carvalho et al., 2022; Zhao et al., 2024). In contrast to the supply chains of other foods (e.g., tinned food), agri-food products are characterized by perishability, seasonality, and short life cycles, and require specialized transportation and storage conditions are required to maintain product quality (Zissis et al., 2017).

AFSCs are critical achieving the United Nations Sustainable Development Goal 2, to end hunger, achieve food security and improved nutrition and promote sustainable agriculture. Despite their importance, AFSCs’ sustainability is threatened by regional and global challenges. For example,to deal with the predicted population growth, urbanization, and consumption, agri-food production will need to increase by 70% by 2050 (Spanaki et al., 2021). At the same time, the environmental effects of agri-food system may increase by 50% to 90% by 2050, reaching levels beyond planetary boundaries that define a safe operating space for humanity (Springmann et al., 2018). Agri-food systems have environmental impacts: for example, excessive use of agrichemicals to increase productivity may contaminate water supplies and the agricultural sector contributes 21% of global greenhouse gas emissions (SDWF, 2023).

In this study, we draw on nine case studies in China that have invested in I4.0 technologies to improve their AFSC sustainability. China offers a unique context for this study. Almost 99 billion US dollars-worth of agricultural products were exported from China in 2023, yet it has become the largest importer of agricultural products in the world (Statista, 2024). This over reliance on imports has arisen because the Chinese agricultural industry can no longer meet increased demand owing to a scarcity of arable land, making it less competitive in an open trade environment (Stastista, 2024).

I4.0 technologies have the capability to enhance AFSCs’ sustainability by improving stakeholder collaboration, enhancing information sharing, augmenting decision making and creating value (Gebhardt et al., 2022; Huber et al., 2022). Recent studies (e.g., Chatterjee et al., 2023; Chou & Shao, 2023; Margherita & Braccini, 2023) have explored various aspects of I4.0 and supply chain sustainability such as factors mediating between I4.0 and supply chain practices, sustainable supply chains and the circular economy, and evaluation of sustainability performance. Despite the important contributions of these studies, a holistic understanding of the drivers of I4.0 applications and their impact on the three pillars of sustainable performance (environmental, social and economic) is lacking (Srhir et al., 2023). Furthermore, few studies have used a range of techniques to analyze the drivers of I4.0 technology deployment to achieve AFSC sustainability (Agrawal et al., 2022; Taddei et al., 2022; Yadav et al., 2022).

Another deficiency in knowledge relating to I4.0 and its effects on AFSCs is that extant studies focus largely on manufacturing industries, where understanding of its adoption and implementation is well developed (Yadav et al., 2022). As the agri-food industry is distinct from manufacturing industry, its challenges to adopting I4.0 and understanding its contributions to AFSC sustainability are less well understood (Birkel & Muller, 2021; Tseng et al., 2018). Therefore, identifying and prioritizing drivers are warranted to better understand the potential of I4.0 technologies in AFSCs. Several literature reviews (e.g., Agrawal et al., 2022; Srhir et al., 2023; Taddei et al., 2022; Yadav et al., 2022) highlight the need to employ different analytical techniques to gain a deeper understanding of the enablers and drivers of I4.0 technology deployment to achieve sustainable supply chains. Our literature review reveals that only six of the 56 primary papers we identified focus on analyzing drivers, enablers, success factors, decision frameworks, or facilitators to achieve sustainable supply chain, green supply chain, circular economy, or sustainable development. This study addresses this gap by conducting an empirical study of I4.0 technology deployment to achieve AFSC sustainability using multiple analytical techniques.

Against this background, in this study we aim to answer three interrelated research questions (RQs).

-

RQ 1. What drivers facilitate the adoption of I4.0 in AFSCs?

-

RQ 2. How are these drivers prioritized?

-

RQ 3. On Which of these drivers should AFSC practitioners focus?

To answer these questions, we conducted three phases of research: first, semi-structured interviews were conducted with AFSC practitioners in China to identify drivers facilitating the adoption of I4.0 (RQ1). Next, the fuzzy analytic hierarchy process (AHP) was used to rank the drivers and evaluate their weightings in relation to the three pillars of AFSC sustainability (RQ2). Finally, interpretive structural modelling (TISM) and fuzzy cross-impact matrix multiplication applied to classification (MICMAC) analysis was conducted to identify key drivers by building a hierarchical framework and categorizing the drivers based on their driving and dependence power (RQ3).

This study advances understanding of the deployment of I4.0 technology to achieve AFSC sustainability and suggests adoption routes for AFSC practitioners. Furthermore, by identifying two key drivers of I4.0 adoption not mentioned in previous AFSC studies, and aggregating several agri-food industry-specific drivers rarely mentioned in previous studies, we provide a more holistic understanding of this important phenomenon that impacts all societies.

The remainder of this paper is structured as follows. First, background literature to middle-range theory (MRT), and a systematic literature review on the applications of I4.0 in the context of AFSCs is provided. Next, the data collection and data analysis methods are explained. Then, the analysis and findings are presented. Followed by a discussion, implications, and opportunities for future research. The paper ends with a conclusion.

2 Literature Review

2.1 Middle-Range Theory (MRT)

Various theories have been used to explore the relationship between I4.0 and sustainability issues. For example, Abdul-Hamid et al. (2021) investigate drivers of I4.0 in a circular economy by deploying ecological modernization theory, which posits that advanced technologies can improve value added on both economic and environmental dimensions. Karmaker et al. (2023) explore the impact of I4.0 on sustainable supply chain performance through the resource-based view (RBV), which assumes that firms gain competitive advantage by controlling scarce and valuable resources. Other theories frequently used to understand supply chain sustainability in an I4.0 context, include institutional theory, dynamic capabilities (DC), innovation diffusion theory, social network theory, and information processing theory. These are useful for exploring a wide range of phenomena by defining relationships and concepts, but are criticized by scholars for focusing on phenomena operationalized at a high level of abstraction with little functional context or specificity (Stank et al., 2017). This results in weak understanding of why and when the investigated phenomena occur.

MRT differs from other theories by restricting explanation of causal connections to a subset of phenomena operating within a given context (Pellathy et al., 2018). It focuses on understanding how and why constructs are related, and under what conditions, thereby helping to consolidate knowledge in a particular domain. For example, Burns et al. (2023) develop an MRT to understand motives for and controls on insider computer abuse, and Hassan and Lowry (2015) call for MRT to be used in more information systems research. Formal MRT has three essential elements: (1) conducting research within a specific domain of knowledge; (2) building or establishing relationships based on existing findings within that domain; and (3) concentrating on causal mechanisms and the contexts in which they produce outcomes (Pawson & Tilley, 1997). MRT was suited to our study for several reasons. First, MRT aims to extend knowledge within a mature discipline, and the topic of our study has already been explored by various scholars (Bhatia & Kumar, 2022; Lu et al., 2022; Mastrocinque et al., 2022). Second, we aim to understand I4.0 deployment to achieve AFSC sustainability by exploring various drivers. In this case, drivers can be considered as the enabling environment and deployment of I4.0 technology can be considered as a mechanism to jointly achieve AFSC sustainability, thus fulfilling the MRT framework of mechanisms + context = outcomes (Pawson & Tilley, 1997). Third, accumulated knowledge of I4.0 and supply chain sustainability can be leveraged to establish relationships between variables. To build a theoretical framework empowered by MRT, we first examined this accumulated knowledge in order to formulate appropriate research questions (Craighead et al., 2024). For example, in this study, our research questions focused on identification and prioritization drivers that facilitate the adoption of I4.0 in AFSCs. Having derived our research questions, we then contextualized our MRT to determine how to engage with the theory. The three basic approaches are induction, deduction and abduction. An inductive approach was appropriate because it examines meanings, processes, or contexts that are difficult to quantify. For example, we aimed to understand why and how drivers are related, and under what conditions that these drivers can be used to facilitate the adoption of I4.0 technologies. Since it would have been difficult to gain a deep understanding through a quantitative approach, we began by analyzing rich qualitative data to reveal drivers facilitating the adoption of I4.0 technologies. We then employed two research techniques to further explore our key findings to draw out their theoretical and practical implications. Finally, we linked the mechanisms, contexts, and outcomes to formulate a conceptual MRT framework as shown in Fig. 1.

2.2 Applications of I4.0 Technologies in AFSC Management

I4.0, representing the fourth industrial revolution, was originally proposed in 2011 to upgrade and reshape the manufacturing sector by integrating advanced information technologies (Lu et al., 2022). The aims are to maximize production efficiency to satisfy customized individual needs for products and services, enhance flexibility and connectivity, and minimize production costs by establishing smart, automated, integrated, and intelligent manufacturing processes (Zhang et al., 2021a, 2021b). Several I4.0 technologies have been widely discussed and applied, including facial recognition enabled by AI to enhance value in the travel and tourism industry (Gupta et al., 2023), IoT-based information systems for logistics 4.0 (Tang et al., 2023), and smart city management using big data analytics (BDA) powered by AI-machine learning (Alahakoon et al., 2023). Yin et al. (2018) concludes that I4.0 comprises seven technologies, whereas Tang and Veelenturf (2019) identify six. Zheng et al. (2021) propose ten I4.0 technologies: IoT, cyber-physical systems, BDA, cloud technology, AI, blockchain, simulation and modeling, augmented/virtual reality, automation and industrial robots, and additive manufacturing. The lists of I4.0 technologies in the literature lack consistency, perhaps for two reasons. First, scholars understand I4.0 design principles differently, resulting in diverse I4.0 technologies. For example, Qin et al. (2016) and Alguliyev et al. (2018) suggest six key characteristics of I4.0 technologies: decentralization, modularity, interoperability, virtualization, real-time support, and service orientation. However, Aoun et al. (2021) consider only three characteristics: vertical networking of smart production systems, horizontal integration of global value chain networks, and through-life engineering across the entire value chain. Second, industries have unique characteristics, and therefore emphasize different technologies in accelerating I4.0 adoption. For example, the logistics industry may focus on blockchain technology, the healthcare industry may concentrate on BDA, and the maritime industry may strengthen automation through robotics. Based on a critical review of papers published in reputable journals and consideration of I4.0 characteristics, our synthesis of existing works consists of eleven I4.0 technologies (see Table 1), adding drones to Zheng et al. (2021) list.

AFSCs are facing challenges such as food price volatility, quality and safety issues, food wastage and loss, and food fraud (Zhao et al., 2022). I4.0 technologies have been applied to alleviate or tackle these challenges. For example, self-driving robots have been utilized for automatic spraying of pesticides and crop harvesting (Javaid et al., 2022), machine learning algorithms have been used for crop and soil monitoring, and BDA has been applied to track and anticipate environmental impacts on agricultural outputs (Ranjha et al., 2022). IoT is widely used to monitor and control food processing equipment and can be utilized with AI to take corrective actions to avert machine breakdowns (Dadhaneeya et al., 2023). Pele et al. (2023) propose an IoT- and blockchain-based framework that can be applied to AFSC logistics. This promises several benefits, including reducing the number of middlemen and building trust at the intra-company level, creating transparency and reducing errors at the inter-company level, and reducing cost and delivery times at the customer level. Duong et al.’s (2020) summary of applications of robotics and autonomous systems in AFSCs suggests that applications commonly integrate these technologies into AFSCs to achieve food quality, safety, and waste reduction, and enhance supply chain efficiency and analysis. Based on a review of over 80 journal articles, Sharma et al. (2020) identify that machine learning has been adopted in four phases of AFSC management: pre-production (e.g., irrigation management and analysis of soil properties), production (e.g., disease detection and weather prediction), processing (e.g., demand and quality management), and distribution (e.g., transportation and retail management). I4.0 is a relatively new concept encompassing many technologies. Each has unique features that allow its application in different phases of AFSCs including farming, processing, distribution, and retailing. For example, IoT, sensors, smartphones, and machine learning can be applied to the production phase for irrigation management (Kamienski et al., 2019), and 3D printing is characterized by layer-by-layer material deposition directly from a pre-designed file, can be applied at the food processing stage for customized food design and personalized food nutrition (Liu et al., 2017); IoT, blockchain, and sensors can be used in the distribution phase for traceability (Zhao et al., 2019); and BDA, smartphones, and cloud computing can be used in the retailing phase to predict consumer preferences (Erevelles et al., 2016). Evidence of how I4.0 applications are used in AFSCs are listed in Table 1, whereby three ticks (√√√) indicate strong evidence, one tick (√) indicates weak evidence, and no tick indicates no evidence.

2.3 I4.0 Technologies and Supply Chain Sustainability

Previous studies have examined the impact of I4.0 on supply chain digitalization and performance analysis, its utilization to improve supply chain productivity, and barriers to its deployment to achieve supply chain sustainability (Agrawal et al., 2022; Bag et al., 2021; Gebhardt et al., 2022). In research on the relationship between I4.0 and sustainability, particular attention is given to I4.0’s contributions to the three pillars of sustainability. Some papers take a general perspective, while others concentrate on specific factors. For example, Ghobakhloo et al. (2020) indicate 16 opportunities provided by I4.0 for sustainability, including some frequently mentioned by other scholars, such as greenhouse gas emissions reduction, energy and resource sustainability, human resource development, and social welfare enhancement. According to Naseem and Yang (2021), I4.0 empowers product planning and scheduling, storage, and distribution, purchasing and sourcing, and production processes, thereby enhancing the environmental, social, and economic sustainability of supply chains. The topic of supply chain digitalization and performance analysis focuses on I4.0 technology implementation and its implications for supply chain performance. For example, Sengupta et al.’s (2022) case study illustrates how blockchain technology improves supply chain resilience and generates income opportunities for those in poor fishing communities. Mesquita et al. (2022) highlight the integration of lean and I4.0 to achieve environmental sustainability, another important topic closely linked with both I4.0 and supply chain productivity. Amongst many conceptual and empirical studies relevant to this topic are Fragapane et al.’s (2022) examination of the role of autonomous robotics in increasing the productivity and flexibility of production networks and Enrique et al.’s (2023) study of arrangements of I4.0 technologies to achieve different purposes (e.g., manufacturing flexibility, process quality, and productivity). Papers on challenges or barriers to I4.0 deployment to achieve supply chain sustainability focus on identifying, prioritizing, linking, and clustering them using various analytical and modeling techniques. Finally, subtopics relevant to I4.0 and the circular economy include theoretical models for implementing of I4.0 in the context of the circular economy and case studies exploring intersections between the circular economy and I4.0 (Awan et al., 2021; Chauhan et al., 2021).

This research area is fragmented because supply chain sustainability is a broad term comprising many elements (environmental, social, and economic), and can be achieved through various capabilities, such as collaboration, coordination, and supply chain integration (Piccarozzi et al., 2022). Although extant literature explores a range of topics relating to I4.0 technologies and supply chain sustainability, further investigation of the drivers of I4.0 deployment will advance understanding of their integration into sustainable supply chains (Srhir et al., 2023; Taddei et al., 2022).

3 Systematic Review of the Literature on Drivers of I4.0 Technology Deployment to Achieve Supply Chain Sustainability

Consistent with previous reviews of the literature on achieving supply chain sustainability using I4.0 technologies (Birkel & Muller, 2021; Piccarozzi et al., 2022; Srhir et al., 2023), a search string of 18 keywords was used to identify the drivers of I4.0 technology deployment (see Fig. 2).

Characteristics of the 56 primary papers identified are presented in Table 2.

Our systematic literature review revealed many drivers reported in previous studies, as well as new drivers (highlighted in bold) emerging from this phase of our study (see Table 3).

4 Research Methodology

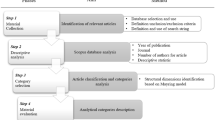

We adopted a qualitative approach to analyze the drivers of I4.0 technology deployment to achieve AFSC sustainability, which promised several advantages. First, a qualitative approach potentially provides a deeper understanding of the phenomenon would be gained from a quantitative study. Second, qualitative data can capture the diversity of environments or situations. In our study, we analyzed various drivers, captured through qualitative interviews. Third, qualitative data can help to generate new ideas, concepts, and theories (Jogulu & Pansiri, 2011). We addressed criticism that qualitative data may be subject to credibility and reliability issues by employing multiple data analysis techniques, including thematic analysis, fuzzy AHP, TISM, and fuzzy MICMAC analysis (see Fig. 3).

4.1 Data Collection Method

Semi-structured interviews, simply defined as purposeful conservations (Burgess, 1984), are a widely used qualitative research method allowing researchers and participants to explore a pre-determined set of research questions (Saunders et al., 2009). We adopted this method for several reasons. First, our conservations with interviewees were guided by a pre-defined list of open-ended questions, providing a set of themes on which to focus, while also allowing us to probe interesting and relevant issues (Barriball & While, 1994). This critical advantage over structured and unstructured interviews enabled elicitation of more valuable and complete information on the topic. Second, participants were provided with sufficient opportunities to speak freely during the interviews, even on sensitive topics, thereby helping to generate highly meaningful information and reveal novel aspects (McIntosh & Morse, 2015). For example, government subsidies may be one driver of farmers’ use of advanced agricultural facilities, and this approach allowed us to discuss the amounts of subsidies they received from the government. Finally, a high response rate was achieved by ensuring that participants were able to answer all the questions.

4.2 Data Analysis Techniques

Four complementary data analysis techniques (thematic analysis, fuzzy AHP, TISM, and fuzzy MICMAC analysis) were employed in this study. Each is presented in order of use in this study.

-

Thematic analysis: This technique was used to generate drivers based on the data collected from the semi-structured interviews. Thematic analysis is an easily grasped, widely accepted, and foundational method for conducting qualitative analysis, used mainly to identify, describe, organize, and report themes found within a dataset (Braun & Clarke, 2006). It was adopted for several reasons. First, the results of thematic analysis are easily understood by members of the public with low educational levels, which suited our research context and would enable broad impacts on the agri-food industry. Furthermore, thematic analysis enables key features of a large dataset to be summarized (Nowell et al., 2017), and was thus suited to this study, which produced 130 pages of transcripts from 26 semi-structured interviews. Thematic analysis is also useful for generating insights into aspects and highlighting similarities and differences across diverse participants (King, 2004).

-

Fuzzy AHP: The results of our thematic analysis were used as inputs into fuzzy AHP. Our aims were to prioritize the drivers and understand the contributions of I4.0 technologies to different dimensions of AFSC sustainability. AHP is a widely applied multiple-criteria decision-making (MCDM) method for prioritizing alternatives hierarchically (Awasthi et al., 2018). We integrated fuzzy sets with AHP because this helps to tackle the imprecision of AHP while retaining its advantages (Liu et al., 2020). Other prioritization methods are available but could not be applied in this study owing to various limitations. For example, the interpretive ranking process (IRP) is an effective MCDM method used to rank a set of variables, but the process becomes difficult with more than 10 variables and the interpretive process is highly subjective (Mangla et al., 2018). Data envelopment analysis (DEA), a powerful mathematical model for ranking alternatives in multi-criteria decision analysis, is better suited to performance measurement activities (Mardani et al., 2017).

-

TISM: This technique was used to identify key drivers by constructing interrelationships between them, thereby helping to understand potential routes through which AFSC practitioners might effectively deploy I4.0 technologies to achieve AFSC sustainability. TISM is an effective qualitative modeling method widely deployed to build hierarchical frameworks to illustrate interactions between variables (Sushil, 2012). It offered several advantages for this study. For example, TISM enables interpretation of links between two variables, which is lacking in ISM (Jena et al., 2017). The decision-making trial and evaluation laboratory (DEMATEL) can be used to identify cause-effect relationships between variables by building structural models, but it has limited applicability (Si et al., 2018), whereas TISM can be used in a range of areas. Finally, ANP is effective in revealing interdependencies between variables in a network-based system but, unlike TISM, it relies heavily on experts’ judgments and experience (Zhao et al., 2020).

-

Fuzzy MICMAC: This technique was used to classify drivers and validate the TISM model based on each driver’s driving and dependence power. We adopted this method for several reasons. We initially used (non-fuzzy) MICMAC analysis to categorize variables based on binary relationships. However, one drawback of MICMAC is that it does not evaluate the strength of relationships between two variables, thereby causing imprecision (Mota et al., 2021). Thus, fuzzy MICMAC analysis was applied to strengthen our sensitivity analysis. Furthermore, TISM and fuzzy MICMAC analysis have previously been combined to analyze issues relating to supply chain sustainability (Luthra & Mangla, 2018).

5 Empirical Data Collection

Our data collection was conducted in province of China between November 2021 and March 2022. Shandong was suited to this study as its vegetable production has been ranked first among China’s 34 provinces since 2015. More than 80 million tons of vegetables were produced in 2021 (Ministry of Agriculture and Rural Affairs, 2021). Purposive sampling (Creswell, 2014) was used to identify individuals with extensive experience relating to the AFSC industry. As a result, 26 qualified individuals agreed to participate in semi-structured interviews (see Table 4).

All interviews were recorded with permission, using voice memos on iPhone 13, and many probing questions were asked to enable participants to clarify their answers. Each interview lasted between 75 and 120 min to give participants sufficient time to elaborate on their answers. 48 h of digital recordings were collected.

6 Data Analysis and Findings

6.1 Identification of Drivers through Thematic Analysis

The thematic analysis consisted of five steps (see Fig. 4). The first step was verbatim transcription of all digital recordings, which produced four to six pages of transcript per recording. A total of 130 pages of transcripts was generated from the 26 interviews. Second, each transcript was read several times to increase familiarity with the data before generating initial codes. Third, during the coding process, data relevant to drivers of I4.0 technology deployment to achieve AFSC sustainability were coded inductively. NVivo 13 was used to assist in the coding process by highlighting, tagging, and naming data extracts. Next, codes extracted from the coding process were organized into groups by considering their interrelationships, and these overarching themes were labelled. These themes were then organized into higher-level aggregate dimensions by considering links between themes, which were named using established constructs from existing literature on supply chain sustainability (Martins & Pato, 2019). Next, we refined the codes and themes by checking for links between codes, themes, and different levels of themes. During this process, an iterative approach was adopted, moving back and forth between relevant theory and data. Finally, we used King and Horrocks’s (2010) framework to organize the empirical evidence into first-order codes, second-order themes, and aggregate dimensions. Table 5 presents a sample of the empirical evidence on drivers of AFSC sustainability in the I4.0 context.

The results of the thematic analysis pinpointed 13 drivers of I4.0 technology deployment to achieve AFSC sustainability. For example, from a social perspective, AFSC practitioners deploy I4.0 technologies to assist in reducing work intensity, labor headcount, and human exposure to pesticides, strengthening farmers’ agri-tech skills training, and improving working conditions. From an environmental perspective, deploying I4.0 technologies in AFSCs has positive effects in reducing carbon emissions and groundwater pollution, and reducing waste by controlling resource competition. From an economic perspective, the drivers identified are enhancing the efficiency of water and fertilizer use, acquiring government subsidies for agricultural facilities, improving product safety and farms’ productivity, reducing labor costs, and accelerating circular agriculture.

6.2 Prioritization of Drivers using Fuzzy AHP

Fuzzy AHP was used to prioritize the identified drivers to gain a better understanding of the management of I4.0 technologies to achieve AFSC sustainability. This consisted of five steps.

-

Step I: Defining and structuring the objective. One of our research objectives was to rank the drivers to understand the contribution of each to AFSC sustainability in relation to applying I4.0 technologies. This objective was decomposed into a hierarchical structure, with the objective in the top level, followed by categories of drivers in the middle level (social, environmental, economic) and the drivers of each category in the bottom level.

-

Step II: Constructing a fuzzy judgment matrix \(\widetilde{E}\). Fuzzy judgment matrix \(\widetilde{E}\) is a pairwise comparison matrix obtained by pairwise comparison of categories of drivers and the drivers in each. Appendix 1 shows the linguistic scales used to conduct pairwise comparisons. In this study, we produced five fuzzy judgment matrices because we sought to understand the relative importance of drivers in each category, the categories of drivers, and the global ranking of drivers.

Where

-

Step III: Calculating the fuzzy weights of each criterion. We followed Buckley’s (1985) method to calculate the fuzzy weights of each criterion. In the following, \({\widetilde{E}}_{ij}\) is the fuzzy comparison value of criterion i to criterion j, \({\widetilde{r}}_{i}\) is the geometric mean of the fuzzy comparison value of criterion i to each criterion, and \({\widetilde{w}}_{i}\) is the fuzzy weight of the ith criterion.

-

Step IV: Hierarchical layer sequencing. The final fuzzy weight of each alternative was calculated through hierarchical sequencing:

Where \({\widetilde{r}}_{ij}\) is the fuzzy weight value of the jth criterion to the ith driver. \({\widetilde{u}}_{i}\) can be indicated by a triangular fuzzy number, \({\widetilde{U}}_{i}= \left(l, m, u\right).\)

-

Step V: Ranking drivers. The final fuzzy weight values of drivers are represented in terms of fuzzy numbers. Thus, we followed Lee and Li’s (1988) method to defuzzify and rank the fuzzy numbers.

The fuzzy AHP analysis reveals the contributions of I4.0 technology deployment to achieving AFSC sustainability. The rankings of categories of drivers, the drivers in each category, and the global rankings of the specific drivers are shown in Table 6. The economic category is ranked first among the three categories of drivers, with a relative weighting of 0.5784. This means that AFSC practitioners are most concerned about the economic benefits of deploying I4.0 technologies, for several reasons. First, the cost of intelligent agricultural technical equipment is too high because applications of I4.0 technologies have just begun and production of this kind of equipment has not yet reached scale. For example, a water and fertilizer integration system will be expensive when integrated with customized automatic controls, PH value detection, and wireless mobile controls. Second, most AFSC practitioners work in small and medium-sized enterprises (SMEs) and are reluctant to apply these technologies unless they guarantee significant income increases. As one interviewee stated: “intelligent agricultural equipment can only be applied by a farmer who has more than 200 or 300 acres of farmland, because the increased profits can cover the cost of this equipment”. Enhancing the efficiency of water and fertilizer is ranked first among the five drivers in this category,, followed by improving product safety and farms’ productivity, reducing labor costs, accelerating circular agriculture, and acquiring government subsidies for agricultural facilities. For example, from the perspective of saving water, applying a water and fertilizer integration system and a drip irrigation system may reduce water use by more than 70%.

The environmental category of drivers is second in the priority list, with a relative weighting of 0.2942. The Chinese government’s science and technology-supported action plan is to reach peak carbon emissions by 2030 and achieve carbon neutrality by 2060 (Ministry of Science and Technology, 2022). Therefore, technologies such as advanced sensors, intelligent greenhouses, IoT, and remote controls should be used to monitor and reduce carbon emissions. For example, light, humidity, carbon dioxide, acidity, and irrigation monitoring sensors are applied in intelligent greenhouses to manage crops precisely. One interviewee stated: “In the intelligent greenhouses, the heat flow can be controlled and used effectively. For example, if the ground temperature reaches above 12 degrees, we can grow warm-loving crops, and if the temperatures are between 6 and 8 degrees, we can grow cold-resistant crops”. The three drivers in this category in rank order are reducing carbon emissions, reducing groundwater pollution, and reducing waste by controlling resource competition.

Finally, the social category of drivers is ranked in last among the three categories. We assume that these category of drivers have received least attention owing to China’s hierarchical cultural value orientation. In this cultural environment, people view competition as good, and are required to obey the expectations of those in higher-status roles (Schwartz, 2006). For example, the 996 working hour system implemented by some companies in China requires employees to work from 9am to 9 pm, six days per week. Under the 13th Five-Year Plan, the Chinese government proposed several tasks relating to agriculture, including increasing the informatization of agricultural equipment, improving agricultural support and protection systems, and enhancing the safety of agricultural products. Thus, I4.0 technologies, such as intelligent greenhouses, advanced sensors, and IoT, are applied to reduce work intensity and improve working conditions. However, blockchain technology and automatic tractors are not widely deployed for several reasons. First, Chinese farmers are aging, with the majority aged between 45 and 55, and are relatively unwilling to learn new knowledge: “Farmers are relatively high in age level and relatively low in knowledge structure. Therefore, both model application and equipment maintenance are relatively lacking”. Second, no standardized model can be used to apply these technologies because soil and weather conditions vary in different areas. Third, applying these technologies will significantly increase the costs of terminal logistics, particularly for blockchain technology applications. Amongst the five drivers in this category: reducing work intensity is ranked first with a relative weighting of 0.4331, reducing human exposure to pesticides is ranked last with a relative weighting of 0.0576, and reducing labor headcount, improving work conditions, and strengthening farmers’ agri-tech skills training are ranked from second to fourth. As one interviewee stated: “Local governments have provided training for new farmers, part of which includes information technology courses (e.g., technical equipment, IoT, blockchain, organizational models, and application models)”.

6.3 Generation of Key Drivers through TISM

Simply understanding the contributions of I4.0 technology deployment to AFSC sustainability is insufficient, as more than 80% of businesses in AFSCs are SMEs, so most AFSC practitioners lack the resources necessary to implement these technologies. The focus must therefore be on key resources, drivers, and enablers to initiate I4.0. We used TISM to identify the key drivers by constructing a hierarchical model, implementing a nine-step process.

-

Step I: Identification and definition of drivers. This step involved identifying and defining the drivers to be modeled. The 13 drivers identified through the thematic analysis were used as inputs into the TISM process.

-

Step II: Determination of contextual relationships. Our research objective was to identify key drivers to provide practical guidance to AFSC practitioners seeking to initiate I4.0. To fulfill this objective, a contextual relationship between two drivers was defined as “Driver A will enhance or enable Driver B.”

-

Step III: Interpretation of relationships. Two professors in operations management who had been collaborating with the agri-food industry for more than 20 years were involved in interpreting relationships between pairs of drivers. Their opinions were initially captured to determine whether “Driver A will enhance or enable Driver B”. If their answer was “yes”, a follow-up question was asked: “In what way will Driver A enhance or enable Driver B.” Capturing the experts’ opinions, enabled us to obtain in-depth knowledge of relationships between drivers.

-

Step IV: Interpretive logic of pair-wise comparison. We conducted pair-wise comparisons of the 13 drivers identified to obtain an interpretive logic-knowledge base. Each driver was individually compared with all the other drivers. The two professors’ opinions were captured to rate relationships between two drivers by coding them as “Y” for yes and “N” for no. Further interpretation was required if the relationship between two drivers was “yes”. The knowledge base for this study consisted of n × (n-1) = 13 × (13–1) = 156 rows, where n represents the number of drivers.

-

Step V: Reachability matrix and transitivity test. The initial reachability matrix was obtained by transforming “Y” codes in the knowledge base into “1” and “N” codes into “0”. We then transformed the initial reachability matrix into a final reachability matrix by conducting a transitivity test: if driver A relates to driver B, and driver B relates to driver C, then driver A necessarily relates to driver C. The initial and final reachability matrices are shown in Appendix 2.

-

Step VI: Level determination by partitioning the reachability matrix. This step was performed to determine the level of each driver in the TISM model by obtaining each driver’s reachability and antecedent sets in the final reachability matrix. The reachability set for a particular driver consists of the driver itself and other drivers that it will enhance or enable, whereas a driver’s antecedent set consists of the driver itself and other drivers that will enhance or enable it. The intersection set of each driver consists of common elements between the reachability and antecedent sets. If the elements in the reachability and intersection sets are the same, the driver is placed in the top level of the TISM model. The level partitioning process was performed until the level of each driver had been determined (see Appendix 3).

-

Step VII: Digraph development. We developed a digraph by allocating the drivers to their respective levels and drawing direct links according to the relationships shown in the final reachability matrix. Only important transitive links were retained following discussion with the two professors.

-

Step VIII: Interpretive matrix. A binary interpretive matrix was developed by translating all interactions in the digraph into 1 in the respective cell. The appropriate interpretation was selected from the interpretive logic-knowledge base to interpret relationships between pairs of drivers.

-

Step IX: TISM model of drivers. A TISM model of the drivers was developed (see Fig. 5) by allocating the drivers to different layers of the framework, linking them with solid and dotted lines, and interpreting each link.

The TISM analysis of drivers resulted in a seven-level hierarchical model. Strengthening farmers’ agri-tech skills training (S4) and government subsidies for agricultural facilities (C2) are located at level VII of the TISM hierarchy, reducing work intensity (S1), reducing human exposure to pesticides (S3), and reducing groundwater pollution (E2) are at level I, and the other drivers are spread from levels II to VI. Drivers located at lower levels of the model can enable more other drivers of the system, whereas those occupying higher levels of the model require more other drivers to achieve them. The analysis reveals two key drivers of the system: strengthening farmers’ agri-tech skills training (S4) and government subsidies for agricultural facilities (C2). One interviewee stated: “The local government spends more than ¥6 million per year to support agricultural technology, smart greenhouses, and other professional training. Furthermore, government subsidies are provided to exemplary agricultural enterprises because they act as links between farmers and agricultural research institutes and have a strong willingness to apply I4.0 technologies”. Applications of I4.0 technologies in agriculture, such as IoT, water and fertilizer integration systems, advanced sensors, and smart greenhouses, have positive effects in reducing water and agrichemical use, and enhancing mechanized and automatized agriculture, thereby reducing waste (E3), improving working conditions (S5), and accelerating circular agriculture (C5). Specifically, a water and fertilizer integration system may significantly increase the efficiency of water and fertilizer use (C1). As one interviewee stated: “The application of a water and fertilizer integration system can achieve more than 70% of water saving, which is critical for North China because they generally lack water”. Other benefits achievable by deploying I4.0 technologies include reducing labor costs (C4), reducing labor headcount (S2), reducing carbon emissions (E1), improving product safety and farms’ productivity (C3), reducing work intensity (S1), reducing human exposure to pesticides (S3), and reducing groundwater pollution (E2).

6.4 Categorization of Drivers using Fuzzy MICMAC Analysis

We used fuzzy MICMAC analysis to critically analyze the scope of each driver by considering its driving and dependence power (Bhosale & Kant, 2016). Two primary considerations led us to adopt this method. First, AFSC practitioners must understand the scope of each driver when they are implementing I4.0 technologies to achieve AFSC sustainability. Adopting some drivers may achieve synergies, or they may conflict with other drivers, thereby reducing effective achievement of AFSC sustainability. Second, fuzzy MICMAC analysis was implemented as a complement to TISM because the latter tends not to consider the strength of relationships between pairs of drivers. For example, relationships between two drivers were coded as “0” or “1” during the TISM implementation, with “0” representing no relationship, and “1” representing a relationship between the two drivers. However, other aspects of relationships need to be considered, as some relationships may be strong, some very strong, and some weak (Zhao et al., 2020). Our fuzzy MICMAC analysis was conducted in three steps.

-

Step I: Development of a binary direct relationship matrix. We obtained the binary direct relationship matrix (see Appendix 4(a)) by converting the diagonal entries of Appendix 3(a) into 0.

-

Step II: Establishment of a fuzzy direct relationship matrix. We employed fuzzy set theory to increase the sensitivity of analysis. Potential interactions between pairs of drivers can be qualitatively defined by linguistic variables on 0–1 scale, with 0 – indicating no influence, 0.1 – very low influence, 0.3 – low influence, 0.5 – medium influence, 0.7 – high influence, 0.9 – very high influence, and 1 – complete influence. The two professors involved in step III of the TISM analysis were asked to re-rate the relationships between drivers using these values. Based on their opinions, we superimposed these new values onto the binary direct relationship matrix to obtain the fuzzy direct relationship matrix (see Appendix 4(b)).

-

Step III: Generation of a fuzzy MICMAC stabilized matrix. We followed Kandasamy et al.’s (2007) method to conduct fuzzy matrix multiplication, which is a process for generalizing Boolean matrix multiplication. According to fuzzy set theory, when two fuzzy matrices are multiplied, the outcome is still a fuzzy matrix. The matrix was multiplied repeatedly until the driving and dependence power of each driver was constant. We used the following rule to conduct the multiplication process:

Following this rule and using MATLAB to calculate the matrices, we obtained the fuzzy MICMAC stabilized matrix shown in Appendix 4(c). We then produced a scatter chart to portray each driver based on the sum of its driving and dependence power (see Fig. 6).

Based on the fuzzy MICMAC analysis results, we clustered the 13 drivers into four categories: independent, linkage, autonomous, and dependent.

-

Independent drivers cluster: Drivers in this cluster are characterized by strong driving but weak dependence power. The five independent drivers are strengthening farmers’ agri-tech skills training (S4), government subsidies for agricultural facilities (C2), reducing waste by controlling resource competition (E3), improving working conditions (S5), and accelerating circular agriculture (C5). These drivers can enable or enhance other drivers and are the root cause of all drivers, thereby improving the performance of I4.0 technology deployment to achieve AFSC sustainability. Strengthening farmers’ agri-tech skills training (S4) and government subsidies for agricultural facilities (C2) should be critically considered, as they have the highest driving power and are located at the lowest level of the TISM hierarchy. However, it is difficult to reskill and upskill farmers, because aging farmers may be reluctant to receive new knowledge. One interviewee stated: “Most young people have gone out to work, leaving some 50 to 60, or even 70-year-olds who are still farming, and it is difficult for these people to accept new knowledge”.

-

Dependent drivers cluster: Drivers in this cluster are characterized by strong dependence but weak driving power. Unlike independent drivers that mainly enable or enhance other drivers, dependent drivers have the fewest opportunities to enable others. They are strongly dependent on other drivers for their achievement, and therefore appear at a relatively high level of the TISM hierarchy. The seven dependent drivers are reducing work intensity (S1), reducing human exposure to pesticides (S3), reducing groundwater pollution (E2), reducing carbon emissions (E1), improving product safety and farms’ productivity (C3), reducing labor costs (C4), and reducing labor headcount (S2).

-

Linkage drivers cluster: Drivers in this cluster have relatively strong driving and dependence power and are characteristically as unstable. They act as links between independent and dependent drivers; therefore, any changes in the lower level of independent drivers may affect these drivers and further influence the higher level of dependent drivers. Only one linkage driver is identified in this study: enhancing the efficiency of water and fertilizer use (C1).

-

Autonomous drivers cluster: Drivers in this cluster are characterized by relatively weak driving and dependence power. They are considered to have few or even no connections with other drivers, and thus have little influence on the system. There are no drivers in this cluster, which means that all the drivers identified are effective for deploying I4.0 technologies to achieve AFSC sustainability.

7 Discussion

This study generates insights into the deployment of I4.0 technologies to achieve AFSC sustainability, thus addressing our three questions. First, we identify 13 drivers that facilitate I4.0 deployment to achieve AFSC sustainability, including some rarely mentioned in previous literature. Second, we prioritize the drivers by ranking the categories of drivers, drivers within each category, and their global ranking. Third, we generate models of drivers’ interrelationships and categorizations, and thereby provide insights into which should be given critical attention.

Our study makes several contributions to existing knowledge. First, it contributes by identifying new drivers of I4.0 technology deployment to achieve sustainable AFSCs. For example, we find that reducing work intensity, reducing human exposure to pesticides, reducing groundwater pollution, and enhancing the efficiency of water and fertilizer use are seldom mentioned in previous studies (see Table 2). However, other drivers are supported by the extant literature. Yadav et al. (2020) highlight that sustainable human resource management, continuous monitoring of emissions reductions, and green design and disposal systems are drivers of I4.0 technology deployment to achieve sustainability in manufacturing organizations. Our study confirms that the agri-food industry is adopting I4.0 technologies to reduce labor costs, headcount, and carbon emissions, and to reduce waste by controlling resource competition. Bhatia and Kumar (2022) find that improving the efficiency of the manufacturing process, product quality, consumption of resources, and information sharing are success factors for deploying I4.0 technologies in India’s automobile industry. Our study supports their results by highlighting that enhancing the efficiency of water and fertilizer use and increasing product safety and farms’ productivity are drivers of I4.0 deployment in China’s agri-food industry. Rad et al. (2022) reveal that training and new competencies, top management support, and knowledge development are enablers of I4.0 technology deployment. Our study partially supports their results by confirming that AFSC stakeholders implement I4.0 technologies to strengthen their agri-tech skills. Srhir et al. (2023) highlight that I4.0 technologies can enhance various aspects of supply chain sustainability, including improved productivity and value creation opportunities on the economic dimension, better water management, efficient use of energy, and reduced carbon emissions on the environment dimension, and good working conditions on the social dimension. However, their study is a literature review, and therefore lacks industry-specific drivers. Our study confirms agri-food industry-specific drivers, including improving working conditions, enhancing the efficiency of water and fertilizer use, reducing groundwater pollution, and accelerating circular agriculture.

Second, our driver prioritization results also provide new understandings. For example, in Jamwal et al.’s (2021) study of a sustainability framework for I4.0, their prioritization results give the economic dimension the highest weighting, and the environmental dimension the lowest. Our study partially supports their results by highlighting that Chinese AFSC stakeholders are more concerned about the economic dimension of AFSC sustainability when deploying I4.0 technologies, followed by the environmental and social dimensions. Sharma et al.’s (2021) study of the impact of I4.0 adoption on sustainability shows that productivity, reduced emissions, and non-invasive interactions are ranked first on the economic, environmental, and social dimensions of sustainability, respectively. However, our results differ in prioritizing enhancing the efficiency of water and fertilizer use, reducing groundwater pollution, and reducing work intensity on these three dimensions of sustainability. This contrast illustrates that various sustainability frameworks for I4.0 have been proposed because different countries have differing I4.0 strategies (e.g., China’s Made in China 2025 and India’s Digital India) and diverse cultural value orientations, and specific industries have unique characteristics.

Third, we identify that strengthening farmers’ agri-tech skills training and government subsidies for agricultural facilities are two key drivers of I4.0 technology deployment to achieve AFSC sustainability. This finding differs from most existing studies. For example, Krishnan et al. (2021) propose that top management interest in implementing I4.0 is critical, Harikannan et al. (2021) suggest that societal pressure and public awareness are of prominent importance, and Kumar et al. (2022) state that environmental regulations for sustainability, adequate labor laws for less-skilled workforces in the digital environment, and continuous support and commitment from top management are key. Our study differs from these in considering specific characteristics of the Chinese agri-food industry. First, more than 60% of farmers in China are over the age of 45, and older individuals tend to be less receptive to new knowledge and skills. Second, national, provincial, and local governments have agri-tech extension and service centres that act as knowledge brokers between knowledge providers and agri-food industry practitioners. However, these exist in name only in many places. Third, with China’s hierarchical value orientation, agri-food industry practitioners are expected to use intelligent agricultural equipment, so more subsidies are provided to those willing to do so. Accordingly, we conclude that simply receiving governmental support or subsidies is insufficient, and that reskilling or upskilling of agri-food industry practitioners is also necessary.

7.1 Theoretical Contributions

Although studies have integrated various theories to explore I4.0 adoption to achieve supply chain sustainability. Widely adopted theories include RBV, the practice-based view (PBV), and DC. For example, Bag et al. (2021) adopt DC and PBV to understand why adopting I4.0 may facilitate sustainable supply chain management. Their results indicate that the mediating role of 10R (e.g., refuse, reuse, rethink, and repurpose) principles has positive impacts on sustainable supply chain performance. Belhadi et al. (2022) combine DC and PBV to understand how I4.0-enabled practices can help to achieve sustainable supply chains. They conclude that the adoption of I4.0 enables digital business transformation, organizational ambidexterity (OA), and circular business models, thus contributing to supply chain’s sustainable performance. Erboz et al. (2022) adopt the theoretical lens of RBV to understand the relationship between I4.0 adoption and sustainable supply chain performance. They conclude that I4.0 adoption activates supply chain integration, and that the latter contributes to supply chain sustainability latter contributes to supply chain sustainability. Appendix 5 presents empirical studies focusing on I4.0 enabled sustainable supply chains.

Despite previous studies have adopted various theories to explore the topic, most concentrate on post-I4.0 adoption conditions to examine the mediating roles of mechanisms or capabilities that can be used to leverage supply chain sustainability. For example, Umar et al. (2022) explore the impact of I4.0-enabled sustainable green supply chain practices on supply chain sustainability and Khan et al. (2023) investigate how I4.0 adoption impacts on the, environmental and economic performance of supply chain sustainability. Less understood is when I4.0 technologies can be successfully adopted and thus help to tackle sustainability challenges and achieve supply chain sustainability. Our study differs from most of the previous studies and takes an initial step in shedding light on pre-I4.0 adoption conditions, highlighting the social, economic and environmental forces that may enable I4.0 adoption. Therefore, this study contributes to MRT by explaining how mechanisms (adoption of I4.0 technologies) + contexts (social, economic, and environmental forces) = achievement of AFSC sustainability (see Fig. 7). Other studies (e.g., Bag et al., 2021; Erboz et al., 2022; Khan et al., 2023; Margherita & Braccini, 2023; Strandhagen et al., 2022) suggest that adoption of I4.0 can be used as a mechanism and posit some general contexts (e.g., manufacturing, shipping building, textile and agri-food) in which it can be used, but fail to highlight specific contexts for achieving supply chain sustainability. However, we still find several studies do adopt the framework of mechanisms + context = outcomes. For example, in the context of lean and sustainable manufacturing, the ambidextrous innovation capabilities generated by the context may facilitate I4.0 adoption and contribute to the development of sustainable supply chains (Dixit et al., 2022). Coercive, normative, and mimetic pressures may facilitate exploration or exploitation orientations and thereby encourage I4.0 technology adoption (Gupta et al., 2020). Our results also indicate that strengthening farmer’s agri-tech skills training and government subsidies for agricultural facilities are two key contextual forces enabling I4.0 technologies.

7.2 Implications for AFSC Practice

This study has two key implications for practice. First, the drivers and the prioritization framework can be used by AFSC practitioners to better understand the benefits of I4.0 technology deployment. For example, it has positive effects on lowering groundwater pollution and carbon emissions, reducing work intensity and human exposure to pesticides, enhancing water and fertilizer use and reducing labor costs. This is critical for AFSC practitioners to understand because China has promised to achieve peak carbon emissions before 2030 and to fight climate change. Thus, these results should be widely disseminated across policymakers, AFSC practitioners, research institutes, and wider society to maximize their impacts. Second, governments should focus on agri-tech skills training and providing subsidies to accelerate applications of I4.0 technologies. Chinese AFSC practitioners might gain knowledge and skills from agricultural equipment manufacturers and agricultural research institutes, but most practitioners do not trust these bodies, believing that they lack experience. Thus, knowledge brokers, and especially non-profit knowledge brokers, should be established to work to improve sharing of knowledge and skills. For example, the Chinese government should make national, provincial, and local agri-tech extension and service centres work more effectively to share knowledge and skills with AFSC practitioners. Regarding subsidies, these are currently only given to agricultural equipment manufacturers. Governments should also consider giving subsidies to knowledge brokers, based on performance indicators such as the number of educated AFSC practitioners.

7.3 Limitations and Future Research Directions

As with all research, our study has limitations that must be acknowledged. First, we collected data specific to the agri-food industry in China, limiting the generalizability of the results. Future studies might use large-scale surveys to collect data from other countries or regions that are also actively pursuing I4.0 technologies, thereby enabling cross-cultural comparisons and a broader understanding of the drivers. Second, this study does not distinguish between different agri-food industry contexts (e.g., meat processing, canned food processing), limiting deeper understanding of a specific context. Future studies should encompass a wider range of agri-food industry contexts, such as collecting data from a range of agri-food industry practitioners focusing on crops, livestock, and fisheries to gain a more comprehensive understanding of how I4.0 technologies impact on various sectors of the agri-food industry.

Third, in this study we used two MCDM techniques (fuzzy AHP and fuzzy-TISM-MICMAC) to analyze our drivers, but the results are not definitive. Other MCDM techniques might be applied to enrich and deepen understanding, such as the best–worst method to determine the most and least desirable drivers or DEMATEL to analyze cause-effect relationships between the drivers or VIekriterijumsko KOmpromisno Rangiranje (VIKOR) to rank and select from a set of drivers. Combining two or more MCDM techniques is useful for balancing the shortcomings of any single method, validating the findings, and providing a more robust understanding of the relative importance of drivers (Velasquez & Hester., 2013). Fourth, we conducted a cross-sectional survey to collect data from November 2021 to March 2022, providing limited understanding of the rapidly evolving nature of I4.0. Future research might adopt a longitudinal approach to capture the evolving nature of I4.0 technology adoption in AFSCs.

8 Conclusion

This study was motivated to identify and understand drivers of I4.0 deployment unique to AFSC sustainability. Using several quantitative analytical techniques, these drivers were weighted based on the environmental, economic, and social dimensions of AFSC sustainability. A conceptual framework was developed to provide AFSC practitioners with a holistic understanding of I4.0 technology deployment across the three dimensions of AFSC sustainability. The results also have implications for AFSC researchers as we make a call to action for future research to focus on AFSC sustainability across regions. Specifically in the context of developing countries as there is a stubbornly low number of studies that are being published from a Southern perspective, as such studies can inform national and international interventions to achieve sustainability.

Data Availability

Data will be made available on request.

References:

Abdul-Hamid, A.-Q., Ali, M. H., Osman, L. H., & Tseng, M.-L. (2021). The drivers of industry 4.0 in a circular economy: The palm oil industry in Malaysia. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2021.129216

Agrawal, R., Wankhede, V. A., Kumar, A., Luthra, S., & Huisingh, D. (2022). Progress and trends in integrating industry 4.0 within circular economy: A comprehensive literature review and future research propositions. Business Strategy and the Environment, 31(1), 559–579.

Alahakoon, D., Nawaratne, R., Xu, Y., Silva, D. D., Sivarajah, U., & Gupta, B. (2023). Self-building artificial intelligence and machine learning to empower big data analytics in smart cities. Information Systems Frontiers, 25, 221–240.

Alguliyev, R., Imamverdiyev, Y., & Sukhostat, L. (2018). Cyber-physical systems and their security issues. Computers in Industry, 100, 212–223.

Antonucci, F., Figorilli, S., Costa, C., Pallottino, F., Raso, L., & Menesatti, P. (2019). A review on blockchain applications in the agri-food sector. Journal of the Science of Food and Agriculture, 99(14), 6129–6138.

Aoun, A., Ilinca, A., Ghandour, M., & Ibrahim, H. (2021). A review of Industry 4.0 characteristics and challenges, with potential improvements using blockchain technology. Computers & Industrial Engineering. https://doi.org/10.1016/j.cie.2021.107746

Awan, U., Sroufe, R., & Shahbaz, M. (2021). Industry 4.0 and the circular economy: A literature review and recommendations for future research. Business Strategy and the Environment, 30(4), 2038–2060.

Awasthi, A., Govindan, K., & Gold, S. (2018). Multi-tier sustainable global supplier selection using a fuzzy AHP-VIKOR based approach. International Journal of Production Economics, 195, 106–117.

Bag, S., Gupta, S., & Kumar, S. (2021). Industry 4.0 adoption and 10R advance manufacturing capabilities for sustainable development. International Journal of Production Economics. https://doi.org/10.1016/j.ijpe.2020.107844

Barriball, K. L., & While, A. (1994). Collecting data using semi-structured interview: A discussion paper. Journal of Advanced Nursing, 19, 328–335.

Belaud, J.-P., Prioux, N., Vialle, C., & Sablayrolles, C. (2019). Big data for agri-food 4.0: Application to sustainability management for by-products supply chain. Computers in Industry, 111, 41–50.

Belhadi, A., Kamble, S., Gunasekaran, A., & Mani, V. (2022). Analyzing the mediating role of organizational ambidexterity and digital business transformation on industry 4.0 capabilities and sustainable supply chain performance. Supply Chain Management: An International Journal, 27(6), 696–711.

Bhatia, M. S., & Kumar, S. (2022). Critical success factors of industry 4.0 in automotive manufacturing industry. IEEE Transactions on Engineering Management, 69(5), 2439–2435.

Bhosale, V. A., & Kant, R. (2016). An integrated ISM fuzzy MICMAC approach for modelling the supply chain knowledge flow enablers. International Journal of Production Research, 54(24), 7374–7399.

Birkel, H., & Muller, J. M. (2021). Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability – A systematic literature review. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2020.125612

Braun, V., & Clarke, V. (2006). Using thematic analysis in psychology. Qualitative Research in Psychology, 3, 77–101.

Buckley, J. J. (1985). Fuzzy hierarchical analysis. Fuzzy Sets and Systems, 17(3), 233–247.

Burgess, R. G. (1984). In the field: An introduction to field research. Unwin Hyman.

Burns, A. J., Roberts, T. L., Posey, C., Lowry, P. B., & Fuller, B. (2023). Going beyond deterrence: A middle-range theory of motives and controls for insider computer abuse. Information Systems Research, 34(1), 342–362.

Chai, J. J. K., O’Sullivan, C., Gowen, A. A., Rooney, B., & Xu, J.-L. (2022). Augmented/mixed reality technologies for food: A review. Trends in Food Science & Technology, 124, 182–194.

Chatterjee, S., Chaudhuri, R., Kamble, S., Gupta, S., & Sivarajah, U. (2023). Adopting of artificial intelligence and cutting-edge technologies for production system sustainability: A moderator-mediation analysis. Information Systems Frontiers, 25, 1779–1794.

Chauhan, C., Sharma, A., & Singh, A. (2021). A SAP-LAP linkages framework for integrating Industry 4.0 and circular economy. Benchmarking: An International Journal, 28(5), 1638–1664.

Chou, Y.-C., & Shao, B. B. M. (2023). An empirical study of information technology capabilities to enable value chain activities and interfaces. Information Systems Frontiers, 25, 1533–1547.

Craighead, C. W., Cheng, L., & Ketchen, D. J., Jr. (2024). Using middle-range theorizing to advance supply chain management research: A how-to primer and demonstration. Journal of Business Logistics, 45, e12381.

Creswell, J. W. (2014). Research design: Qualitative, quantitative, and mixed methods approaches (4th ed.). Sage Publications.

Dadhaneeya, H., Nema, P. K., & Arora, V. K. (2023). Internet of things in food processing and its potential in Industry 4.0 era: A review. Trends in Food Science & Technology. https://doi.org/10.1016/j.tifs.2023.07.006

Dankar, I., Haddarah, A., Omar, F. E. L., Sepulcre, F., & Pujola, M. (2018). 3D printing technology: The new era for food customization and elaboration. Trends in Food Science & Technology, 75, 231–242.

De Carvalho, M. I., Relvas, S., & Barbosa-Povoa, A. P. (2022). A roadmap for sustainability performance assessment in the context of agri-food supply chain. Sustainable Production and Consumption, 34, 565–585.

De Sousa Jabbour, A. B. L., Jabbour, C. J. C., Choi, T.-M., & Latan, H. (2022). Better together: evidence on the joint adoption of circular economy and industry 4.0 technologies. International Journal of Production Economics. https://doi.org/10.1016/j.ijpe.2022.108581

Dixit, A., Jakhar, S. K., & Kumar, P. (2022). Does lean and sustainable manufacturing lead to Industry 4.0 adoption: The mediating role of ambidextrous innovation capabilities. Technological Forecasting & Social Change. https://doi.org/10.1016/j.techfore.2021.121328

Dora, M., Kumar, A., Mangla, S. K., Pant, A., & Kamal, M. M. (2022). Critical success factors influencing artificial intelligence adoption in food supply chains. International Journal of Production Research, 60(14), 4621–4640.

Duong, L. N. K., Al-Fadhli, M., Jagtap, S., Bader, F., Martindale, W., Swainson, M., & Paoli, A. (2020). A review of robotics and autonomous systems in the food industry: From the supply chain perspective. Trends in Food Science & Technology, 106, 355–364.

Enrique, D. V., Marodin, G. A., Santos, F. B. C., & Frank, A. G. (2023). Implementing industry 4.0 for flexibility, quality, and productivity improvement: technology arrangements for different purposes. International Journal of Production Research, 61(20), 7001–7026.

Erboz, G., Huseyinoglu, I. O. Y., & Szegedi, Z. (2022). The partial mediating role of supply chain integration between Industry 4.0 and supply chain performance. Supply Chain Management: An International Journal, 27(4), 538–559.

Erevelles, S., Fukawa, N., & Swayne, L. (2016). Big data consumer analytics and the transformation of marketing. Journal of Business Research, 69(2), 897–904.

Fragapane, G., Ivanov, D., Peron, M., Sgarbossa, F., & Strandhagen, J. O. (2022). Increasing flexibility and productivity in Industry 4.0 production networks with autonomous mobile robots and smart intralogistics. Annals of Operations Research, 308, 125–143.

Gebhardt, M., Kopyto, M., Birkel, H., & Hartmann, E. (2022). Industry 4.0 technologies as enablers of collaboration in circular supply chains: A systematic literature review. International Journal of Production Research, 60(23), 6967–6995.

Ghobakhloo, M. (2020). Industry 4.0, digitalization, and opportunities for sustainability. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2019.119869

Gupta, S., Modgil, S., Gunasekaran, A., & Bag, S. (2020). Dynamic capabilities and institutional theories for Industry 4.0 and digital supply chain. Supply Chain Forum: An International Journal, 21(3), 139–157.

Gupta, S., Modgil, S., Lee, C.-K., & Sivarajah, U. (2023). The future is yesterday: Use of AI-driven facial recognition to enhance value in the travel and tourism industry. Information Systems Frontiers, 25, 1179–1195.

Harikannan, N., Vinodh, S., & Gurumurthy, A. (2021). Sustainable industry 4.0 – An exploratory study for uncovering the drivers for integration. Journal of Modelling in Management, 16(1), 357–376.

Hassan, N., Lowry, P. B. (2015). Seeking middle-range theories in information systems research. International Conference on Information Systems (ICIS 2015), Fort Worth, December 13–18.

Huang, C.-H., Chen, P.-J., Chen, B.-W., & Zheng, J.-X. (2021). A robot-based intelligent management design for agricultural cyber-physical systems. Computers and Electronics in Agriculture. https://doi.org/10.1016/j.compag.2020.105967

Huber, R., Oberlander, A. M., Faisst, U., & Roglinger, M. (2022). Disentangling capabilities for industry 4.0 – An information systems capability perspective. Information Systems Frontiers. https://doi.org/10.1007/s10796-022-10260-x

Jamwal, A., Agrawal, R., Sharma, M., Kumar, V., & Kumar, S. (2021). Developing a sustainability framework for industry 4.0. Procedia CIRP, 98, 430–435.

Javaid, M., Haleem, A., Singh, R. P., & Suman, R. (2022). Enhancing smart farming through the applications of agriculture 4.0 technologies. International Journal of Intelligent Networks, 3, 150–164.

Jena, J., Sidharth, S., Thakur, L. S., Pathak, D. K., & Pandey, V. C. (2017). Total interpretive structural modeling (TISM): Approach and application. Journal of Advances in Management Research, 14(2), 162–181.

Jogulu, U. D., & Pansiri, J. (2011). Mixed methods: A research design for management doctoral dissertations. Management Research Review, 34(6), 687–701.

Kamienski, C., Soininen, J.-P., Taumberger, M., Dantas, R., Toscano, A., Cinotti, T. S., Maia, R. F., & Neto, A. T. (2019). Smart water management platform: IoT-based precision irrigation for agriculture. Sensors, 19, 276.

Karmaker, C. L., Aziz, R. A., Ahmed, T., Misbauddin, S. M., & Moktadir, M. A. (2023). Impact of Industry 4.0 technologies on sustainable supply chain performance: The mediating role of green supply chain management practices and circular economy. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2023.138249

Kandasamy, W. B. V., Smarandache, F., & IIanthenral, K. (2007). Elementary fuzzy matrix theory and fuzzy models for social scientists. Automaton.

Khan, S. A. R., Tabish, M., & Zhang, Y. (2023). Embracement of industry 4.0 and sustainable supply chain practices under the shadow of practice-based view theory: ensuring environmental sustainability in corporate sector. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2023.136609

King, N. (2004). Using templates in the thematic analysis of text. In C. Cassell & G. Symon (Eds.), Essential guide to qualitative methods in organizational research (pp. 257–270). Sage.

King, N., & Horrocks, C. (2010). Interviews in qualitative research. Sage.

Krishnan, S., Gupta, S., Kaliyan, M., Kumar, V., & Garza-Reyes, J. A. (2021). Assessing the key enablers for industry 4.0 adoption using MICMAC analysis: A case study. International Journal of Productivity and Performance Management, 70(5), 1049–1071.

Kumar, V., Vrat, P., & Shankar, R. (2022). Factors influencing the implementation of industry 4.0 for sustainability in manufacturing. Global Journal of Flexible Systems Management, 23(4), 453–478.

Lee, E. S., & Li, R. L. (1988). Comparison of fuzzy numbers based on the probability measure of fuzzy events. Computational Mathematics and Application, 15(10), 887–896.

Liu, Y., Eckert, C. M., & Earl, C. (2020). A review of fuzzy AHP methods for decision-making with subjective judgements. Expert Systems with Applications, 161,. https://doi.org/10.1016/j.eswa.2020.113738

Liu, Z., Zhang, M., Bhandari, B., & Wang, Y. (2017). 3D printing: Printing precision and application in food sector. Trends in Food Science & Technology, 69, 83–94.

Lu, H., Zhao, G., & Liu, S. (2022). Integrating circular economy and industry 4.0 for sustainable supply chain management: A dynamic capability view. Production Planning & Control. https://doi.org/10.1080/09537287.2022.2063198

Luthra, S., & Mangla, S. K. (2018). When strategies matter: Adoption of sustainable supply chain management practices in an emerging economy’s context. Resources, Conservation and Recycling, 138, 194–206.

Mahdad, M., Hasanov, M., Isakhanyan, G., & Dolfsma, W. (2022). A smart web of firms, farms and internet of things (IOT): Enabling collaboration-based business models in the agri-food industry. British Food Journal, 124(6), 1857–1874.

Mangla, S. K., Luthra, S., Rich, N., Kumar, D., Rana, N. P., & Dwivedi, Y. K. (2018). Enablers to implement sustainable initiatives in agri-food supply chains. International Journal of Production Economics, 203, 379–393.

Mardani, A., Zavadskas, E. K., Streimikene, D., Jusoh, A., & Khoshnoudi, M. (2017). A comprehensive review of data envelopment analysis (DEA) approach in energy efficiency. Renewable and Sustainable Energy Reviews, 70, 1298–1322.

Margherita, E. G., & Braccini, A. M. (2023). Industry 4.0 technologies in flexible manufacturing for sustainable organizational value: Reflections from a multiple case study of Italian manufacturers. Information Systems Frontiers, 25, 995–1016.

Martins, C. L., & Pato, M. V. (2019). Supply chain sustainability: A tertiary literature review. Journal of Cleaner Production, 225, 995–1016.

Mastrocinque, E., Ramirez, F. J., Honrubia-Escribano, A., & Pham, D. T. (2022). Industry 4.0 enabling sustainable supply chain development in the renewable energy sector: A multi-criteria intelligent approach. Technological Forecasting & Social Change. https://doi.org/10.1016/j.techfore.2022.121813

McIntosh, M. J., & Morse, J. M. (2015). Situating and constructing diversity in semi-structured interviews. Global Qualitative Nursing Research, 2, 1–12.

Mesquita, L. L., Lizarelli, F. L., Duarte, S., & Oprime, P. C. (2022). Explorig relationships for integrating lean, environmental sustainability and industry 4.0. International Journal of Lean Six Sigma, 13(4), 863–896.

Ministry of Agriculture and Rural Affairs of the People’s Republic of China. (2021). Shandong’s total agriculture output value breaks one trillion yuan. Shandong Agricultural Information Network, February 5. http://www.moa.gov.cn/xw/qg/202102/t20210205_6361286.htm. Accessed 18 Aug 2024.

Ministry of Science and Technology. (2022). Science and technology supported carbon peak and carbon neutrality implementation plan 2022 – 2030. Beijing: Ministry of Science and Technology. http://www.gov.cn/zhengce/zhengceku/2022-08/18/5705865/files/94318119 b8464e2583a3d4284df9c855.pdf. Accessed 7 July 2024.

Mota, R. O., Filho, M. G., Osiro, L., Ganga, G. M. D., & Mendes, G. H. S. (2021). Unveiling the relationship between drivers and capabilities for reduced time-to-market in start-ups: A multi-method approach. International Journal of Production Economics. https://doi.org/10.1016/j.ijpe.2020.108018

Naseem, M. H., & Yang, J. (2021). Role of Industry 4.0 in supply chains sustainability: a systematic literature review. Sustainability, 13, 9544.