Abstract

Testing solar reflective building materials is mainly performed in laboratories using Solar Spectrum Reflectometer (SSR) or spectrophotometry. To obtain aged materials values, after exposing materials in test farms for natural ageing or applying ASTM-D7897, treated samples shall be tested again using SSR. On-site measurements of new and aged surfaces is allowed using pyranometers or albedometers, which present issues caused both by high-pitched roof and by solar and sky requirements in several locations such as at southern and middle Europe latitudes, where clay tiles are a typical coverage of roof surfaces. The use of battery-powered SSR offsite could be a solution to obtain reliable measurements in every climate, lighting, and slope condition. However, the shape of roof surfaces remains an issue since most of the tiles are characterized by elaborated morphologies that cannot fit the measurement head of the SSR. In this study, two sets of cylindrical adapters for SSR, made via Fused Deposition Modeling and coated with solar reflective white diffuse paint or specular reflective coating were produced and tested to overcome this problem. The adapters were attached to the top of the measurement head and measurements were performed according to ASTM-C1549. These adapters were tested with samples characterized by ASTM-C1549, analyzing the output from all 6 detectors of SSR, and by spectrophotometry according to ASTM-E903, using both AM1GH and ASTM E891-87 irradiance spectra. Aluminum-coated adapters proved ideal due to non-impact on measurements. Solar reflectance showed strong linear correlation for 30–50 mm adapter lengths, indicating minimal signal damping. They will allow testing most of the samples that cannot be tested with standard methods, especially aged ones, without altering their surface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Optimizing the building envelope is crucial to have high-energy performances and indoor comfort [1]. Winter energy performance is related to the level of insulation of the building while summer energy efficiency needs also reduction of the solar gains through transparent and opaque elements. In particular solar absorption of opaque element is one of the causes of the Urban Heat Island Effect [2,3,4]. Among the parameters that can be useful to evaluate solar heat gains through opaque building elements, solar reflectance and thermal emittance can be counted. The so-called cool materials are characterized by both high solar reflectance and thermal emittance (if non-metallic) [5]. On this paper the focus will be put on solar reflectance since the majority of used roofing products is made of non-metallic materials [6], naturally characterized by high-thermal emittance. Solar reflectance can be defined as the fraction of incident solar radiation directly reflected from an irradiated surface in the range between 300 and 2500 \(\mu m\) [7]. Different measurements methods, also applied by both the Cool Roof Rating Council [8] and the European Cool Roof Council [9], are available to measure solar reflectance and all of them are rated by ASTM standards: UV–Vis-NIR Spectrophotometer with 150 mm integrating sphere [10], Solar Spectrum Reflectometer, SSR [11], Pyranometer or Albedometer [12]. Pyranometer or Albedometer adheres to the ASTM E1918 standard for use and, even if the method allows measurements on wide areas and on site using the real irradiance conditions of the analyzed site, there are several limitations: to perform measurements the operator needs unobstructed sunlight (clear skies), high sun (solar zenith angle \(\le\) 45\(^\circ\)) and large and horizontal surfaces. These conditions are not always available, for instance, in densely populated and industrialized areas where pollution-induced haze is often present (e.g., the Po Valley in Italy), and for residential roofs where the majority of buildings have steep-sloped roofs. ASTM E903 measurements involve a UV–Vis-Nir spectrophotometer with a 150 mm integrating sphere working in the range of 250–2500 \(\mu m\). The value of solar reflectance is obtained by integrating the measured spectral reflectance, weighted by the standard spectral irradiance of the sun according to several standardized spectra (e.g. AM1GH [13], E891BN [14], G173 [15]). This measurement technique allows obtaining detailed spectral information of the analyzed materials, moreover once raw data are collected, there are wide data editing options and measurements parameters fully customizable. On the other hand, some weak point can be represented by the limitation of a small measured area (1 cm\(^2\)) that often needs destructive sampling, relatively long-lasting measurements (if compared to the Solar Spectrum Reflectometer described in the following), delicate maintenance protocol of the spectrophotometer, moreover the spectrophotometer cannot be used on field. ASTM C1549 paved the way for the use of a portable Solar Spectrum Reflectometer (SSR), where the sample is illuminated by diffuse light originated by a source placed into the measurement’s head (BaSO\(_4\)) and the reflected light is collected by four detectors at an angle of 20 degrees from normal. The sample will cover a 2.5 cm diameter port and the solar reflectance is automatically calculated by SSR by using irradiance spectra pre-loaded on the device. Four filtered detectors (UV, Blue, Red, IR) and two virtual detectors (sampling the Red and IR detectors at a lower color temperature, \(\approx\)2300 K vs \(\approx\)3125 K) are used. The two additional curves for the Red and IR detectors show the degree to which the Red and IR detectors are shifted to longer wavelengths at the lower color temperature as reported in Devices & ServicesFootnote 1 technical notes [16]. By characterizing samples with ASTM C1549, faster measurements can be performed, moreover since the device is easily transportable, on field measurements are possible and, even though the measurement area is significantly smaller than for the ASTM E1918 technique (2.5 cm diameter sampling area) the chance of applying methods such as CRRC-1 and Template tile method allows measuring wider surfaces [17] by averaging the results of several single-point measurements. Finally, this method is a nondestructive sampling technique allowing the analysis of surfaces without contamination due to sampling and cutting allowing, for instance, measurements on aged surfaces onsite without damaging the building’s roof. On the other side, this technique does not provide much spectral information on the sample (just the data provided by the six sensors), moreover particular attention should be put on the analysis of spectrally selective materials even if most of the issues have been resolved in the latest version of the SSR-v6 used in this work [18]. SSR seems thus to be the most suitable compromise to have good information about materials avoiding surface damaging for sampling procedures and maintaining a good reference to standardized irradiance spectra. However, due to the shape of the measurement’s head it is not always possible to measure samples with flat surface but complex geometries such as most of the concrete and clay roof tiles. These tiles are in fact characterized by very prominent concavities which, on the one hand generate strong inhomogeneities in the aging process and on the other do not allow the measuring port of SSR to approach and adhere to the surface. This does not allow the application of the measurement standard for large radius cylindrical surfaces (i.e. Technical Note 11-1 [19]), leaving the operator with the only possibility of estimating the reflectance through corrective methods for profiled surfaces (i.e. Tecnihcal Note 9-2 [20]). To address this challenge, we took inspiration from the approach adopted by Devices & Services for the AE1RD1 emissometer [21]. This instrument is provided with accessories designed to extend the measuring head, thereby reducing its diameter and enabling the measurement of surfaces within narrow cavities. This study contributes to an ongoing research initiative that initially involved the development and testing of a first generation of adapters featuring a truncated-cone shape. The current work introduces a second generation consisting of cylindrical extension of the measuring port, tested with three different lengths (30 mm, 40 mm, and 50 mm) in order to evaluate the damping of the signal reflected from the surface and understand whether there is a limit in the geometry of the adapter. These adapters have been tested in two configurations: (1) by internally painting them with white diffuse solar reflective paint, reproducing the internal surface of the SSR measuring head; (2) by covering the internal surface with an aluminum foil, aiming to replicate a polished metallic surface, in the event of manufacturing these adapters from a single piece of aluminum, avoiding painting. [21,22,23]. These adapters will allow testing a significant amount of samples that could not be tested with standard method due to their peculiar geometry, since, thanks to these, surfaces can be measured without cutting or breaking clay roof tiles. This feature is relevant mainly in Europe where more than 75% of roof coverage is made of clay roof tiles [24].

2 Materials and Methods

2.1 Adapter Design Description

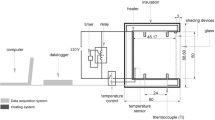

White PolyLactic Acid (PLA) filament modelled via Fused Deposition Modeling (FDM) was used to create the adapters. Two sets of hollow cylindrical adapters (25 mm inner diameter–3 mm thickness) were designed, each one made by three different heights: 30 mm, 40 mm, and 50 mm. One set is internally coated by aluminum tape while the second set is internally coated by white diffuse solar reflective paint (Fig. 1). Since the adapters should be placed on the SSR measurement head, they are equipped with a wider base to facilitate application. The coupling between measurement head and adapters is sealed with duct tape. Fig. 2 shows an installation diagram of the adapter (in yellow) for carrying out measurements on irregular surfaces such as tiles.

2.2 Testing procedure

The behavior of the adapters is characterized by carrying out repeated measurements on 15 different samples of different color and finishing has been analyzed to validate all the adapters. The testing procedure goes, first, through the characterization of the samples and then to the measurement of solar reflectance both with and without the adapters.

Since this study is mainly focused to find a solution for roof tiles, typically made by ceramic materials, just two samples were made by polymeric materials, while the remaining ones were ceramic based tiles coated with different glazes (Fig. 3). Firstly, the samples are characterized according to their solar reflectance and color through a Spectrophotometer with 150 mm integrating sphere and Solar Spectrum Reflectometer. Jasco V-670 UV-VIS-NIR Spectrophotometer equipped with a 150 mm integrating sphere was used to measure samples spectral behavior, evaluate L*a*b* parameters and solar reflectance according to ASTM E903 Standard test method [10]. L*a*b* values were calculated, starting from spectral reflectance in the visible range, by using equation reported in UNI EN ISO 11664-1 [25]. L*a*b* provides information about the sample that may not necessarily be deduced from reflectance alone, allowing for a better framing of results and improved reproducibility. The solar reflectance, \(\rho _{sol}\), of both internal coating of adapters and samples used for validation, was calculated by integrating over the range from 300 nm to 2500 nm @ 5 nm interval the measured values of spectral reflectance \(\rho _{\lambda }\) (defined as the ratio of reflected part and total amount of incident radiation at the considered wavelength \(\lambda\)), weighted by the standard spectral irradiance of the sun at the earth surface, \(I_{sol,\lambda }\) [Wm\(^{-2}\) nm\(^{-1}\)] as reported in Eq. 1:

Two standard spectral irradiance functions were considered to measure solar reflectance: clear sky, AM1, global horizontal irradiance (AM1GH) solar spectral irradiance and Hazy sky air mass 1.5 beam normal irradiance (E891BN) [13, 26]. Solar Spectrum Reflectometer (SSR) v.6.0 by Devices and Services was used to measure solar reflectance both without the adapters, to check measurement reliability against measurements performed via Spectrophotometer, and with the six adapters produced. The measurements were obtained, in accomplishment with ASTM C1549 [11], by applying AM1GH and E891BN irradiance spectra, moreover the irradiance spectrum called AM1.5 was used to allow compare measurements performed with a version 6 SSR with measurements performed with a version 5 device. In addition, the reflectance measured by the four physical detectors operating at temperature \(\approx\)3125 K in the range of UV, Blue, Red, and NIR and the two virtual detectors operating at temperature \(\approx\)2300 K in the range of Red and NIR were collected. Samples were lighted by diffuse illumination from a halogen source and reflected radiation is collected by detectors through a 25 mm diameter aperture reaching a near normal collimating tube. Regarding ASTM E903 measurements, 3 different measurements were performed for each sample, while regarding ASTM C1549 measurements, 10 different measurements were performed for each sample.

3 Results

3.1 Sample Characterization

L*a*b* values of every sample were calculated from spectral reflectance and are reported in Fig. 4 together with each sample visual response. From the figure it can be noticed how the visual response of the samples varies among the typical colors of roof coatings from the lighter color that is typical of low slope roof to the darker color/brown/green that can easily be found on steep slope roofs. Since our interest is not limited to the visual response of the samples, for each of them can be found, in Fig. 5, the spectral reflectance spectrum. As studied in [27], important information about the nature of the coatings can be retrieved from the spectra. For instance, apart from sample 001 with its flat irradiance spectrum, the only sample characterized by a decrease in spectral reflectance in the higher wavelength is sample 007, that is the only polymeric tile, while all the other samples, characterized by ceramic coating, present a nice and high section from 2000 \(\mu\)m to 2500 \(\mu\)m.

Samples characterized by an absorption band in the 1250\(\div\)1750 \(\mu\)m are characterized by the presence of Cobalt oxide, while samples characterized by an absorption band in the 1100\(\div\)1300 \(\mu\)m are characterized by the presence of Iron Oxide.

Since the first characterizations was performed with a UV–Vis-Nir Spectrophotometer, while adapters validation was performed with ASTM C1549, in Fig. 6 the comparison between measurements performed on the calibration samples without any adapter are reported. As it can be noticed from the regression line, ASTM C1549 measurement are in a good agreement with ASTM E903 measurement both regarding the use of AM1GH irradiance spectrum and E891BN irradiance spectrum, showing a linear correlation with high R\(^2\) values, moreover it is interesting to notice how the correlation between the two measurements method create a line that almost perfectly bisect the plot. Thank to this, we can reasonably assume, by comparing measurements with and without adapters performed in accomplishment to ASTM C1549, that also the measures with the adapters can be considered reliable. The only outlier if considering the correlation trend is related to a white pearlescent sample, which supports the need of checking the behavior of samples characterized by this kind of optical effect.

Comparison between measurement performed on the samples shown in Fig. 5 without adapter, according to ASTM E903 and ASTM C1549 according AM1GH and E891BN irradiance spectra

3.2 Characterization of the Internal Coating of the Adapters

The characterization of the adapters first involves measuring L*a*b* and \(\rho _{sol}\) of the two internal coatings used (i.e. white diffuse reflective paint and aluminum foil). The measures were carried out by following the ASTM E903 considering both AM1GH and E891BN irradiance spectra. To perform these measurements a same layer of both coatings was applied on a flat support and then evaluated through the Jasco V-670 UV-VIS-NIR spectrophotometer. The set internally coated by a white diffuse solar reflective paint is characterized by L* = 96.60, a* = 0.81, b* = 2.00, \(\rho _{sol}\) (AM1GH) = 0.87 and \(\rho _{sol}\) (E891BN) = 0.90, while the second set, internally coated by aluminum coating, is characterized by L* = 91.60, a* = 0.67, b* = \(-\)0.67, \(\rho _{sol}\) (AM1GH) = 0.77 and \(\rho _{sol}\) (E891BN) = 0.78. In Fig. 7 the spectral reflectance measured via ASTM E903 of both coatings are reported together with the two irradiance spectra.

3.3 Measurements with Adapters

Each sample was analyzed checking the reflectance for each adapter and for each sensor of SSR (AM1GH, B891 and each single sensor in the UV, Blue, Red and IR range). The measurements performed with the white coated adapter are only related to the 30 mm high adapter since, for 40 mm and 50 mm high adapters, the output wasn’t recorded by the SSR detector. On the other hand, measurements for the adapters coated with aluminum layer were possible for all the three adapters. The diffuse reflection of white coating probably excessively attenuates the radiation coming from the measured surface, while a directional reflection coating (i.e. aluminum foil) allows a more efficient transport of the aforementioned radiation to the sensor. In Fig. 8 the correlations between solar reflectance measurements performed with and without adapter are reported for each irradiance spectrum considered. With the same color code the regression line calculated for each adapter is reported together with the line equation and the coefficient of determination.

It is interesting to notice how, for all the irradiance spectra considered, there are two cluster of points, one represented by the aluminum coated samples and the other represented by the white paint coated adapters. In addition, it can be noticed how the regression line of the first cluster (aluminum coated adapters) represents a linear correlation between measures performed without and with the adapter drawing a line that almost perfectly bisects the plot. On the other hand, the regression line for the samples coated with the white paint represents a polynomial grade 2 (quadratic) regression. Even though the two families of adapters present such different behavior, the R\(^2\) values for all the correlation performed suggest a good agreement between measurements performed with and without the adapter. Breaking down the contribution of each sensor, as reported in Fig. 9, the same trend shown from solar reflectance measurements can be found for all the six-wavelength band considered. However, an interesting aspect can be noticed regarding the UV detector: all the measured values range just from 0 to 0.5 even though the solar reflectance of the sample is significantly higher. This can be due to the nature of each coating, as it can be seen from the spectra reported in Fig. 5, where the majority of the samples present absorption band in the UV fraction. This is likely related to the presence of TiO\(_2\) in the coating formulation. This behavior does not affect much the final measure of solar reflectance due to the low amount of energy assigned to the UV radiation on both AM1GH and E891BN irradiance spectra (respectively 7% and 3%).

4 Conclusions

Solar reflectance is one of the key parameters, together with thermal emissivity, to assess performance of solar reflective materials. Among the most used methods to measure solar reflectance, the use of a Solar spectrum reflectometer (according to ASTM C1549) ensure performing measurements that can be referred to standardized solar irradiance spectra. ASTM C1549 has limitations in analyzing profiled samples like concrete or clay tiles that don’t fit the measurement head. To address this, two sets of cylindrical adapters were created, modifying the ASTM C1549 method. These adapters, with heights of 30 mm, 40 mm, and 50 mm, and a 25 mm internal diameter, were validated with 15 samples covering the whole solar spectrum.

The first set of adapters coated with aluminum were identified as ideal since their specular reflection does not affect measurements. In fact, the performed solar reflectance measurements were characterized by linear correlations with respect to standard measurements (without adapters), with high R\(^2\) values for all lengths from 30 to 50 mm, indicating that the signal reflected by the sample is not excessively damped by the aluminum foil. The same cannot be said for the adapters internally coated with highly reflective and diffuse white paint, for which it was only possible to measure reflectance for the 30 mm prototype, with the others (40 and 50 mm) leading to a received signal intensity below the sensitivity threshold of the SSR. Since in Europe clay roof tiles represents more than 70% of total roof coverage, the use of aluminum coated adapters will allow testing a wider percentage of samples that couldn’t be tested with standard methods without altering the sample by cutting it to be measured. As perspectives, the measurements performed with adapters both with E891BN and E1.5 SSR spectrum will allow the comparison of aged solar reflectance performed with Version 6 SSR to measurements on new samples, carried out by using SSR version 5 in the past. Finally, a new version of the adapters with a simplified geometry and made by polished aluminum could improve the matching between measurements with and without adapters. The use of a cap attached to the adapter will improve the mounting operation over the measurement’s head avoiding light leakage between the adapter and the head. Following these improvements and further experimental measurement campaigns on surfaces with a small radius of curvature (mainly tiles), it will be possible to validate and propose an extension of Technical Note 11-1 [19] or Technical Note 9-2 [20], broadening the field of application of the SSR. In conclusion, it is important to highlight that the ASTM C1549 method is applicable solely to diffuse reflective materials. There is a variation of the method for directional reflective materials, ASTM C1864, which has not yet been investigated. The possible interaction between samples and coating, both with directional reflection, will be the subject of specific studies following this research.

Data Availability

Data are available on request.

Notes

The Devices & Services is, to date, the sole source of supply of the apparatus, as reported in the ASTM C1549.

References

A. Hashem, S.R. Leanna, H. Akbari, L.S. Rose, Urban surfaces and heat island mitigation potentials. J. Hum. Environ. Syst. 11, 85–101 (2008)

L. Howard, The climate of London, deduced from meteorological observations made at different places in the neighborhood of the metropolis. Geogr. J. 132, 84 (1966). https://doi.org/10.2307/1793062

T.R. Oke, G. Mills, A. Christen, J.A. Voogt, Urban heat island. Urban Climate (2017). https://doi.org/10.1080/01431169208904271

J.A. Voogt, T.R. Oke, Thermal remote sensing of urban climates. Remote Sens. Environ. 86, 370–384 (2003). https://doi.org/10.1016/S0034-4257(03)00079-8

H. Akbari, C. Cartalis, D. Kolokotsa, A. Muscio, A.L. Pisello, F. Rossi, M. Santamouris, A. Synnefa, N.H. Wong, M. Zinzi, Local climate change and urban heat island mitigation techniques—the state of the art. J. Civ. Eng. Manag. 22, 1–16 (2016). https://doi.org/10.3846/13923730.2015.1111934

M. Sleiman, G. Ban-Weiss, H.E. Gilbert, D. François, P. Berdahl, T.W. Kirchstetter, R. Levinson, Soiling of building envelope surfaces and its effect on solar reflectance—part I: analysis of roofing product databases. Solar Energy Mater. Solar Cells 95, 3385–3399 (2011). https://doi.org/10.1016/j.solmat.2011.08.002

H. Akbari, R. Levinson, S. Stern, Procedure for measuring the solar reflectance of flat or curved roofing assemblies. Solar Energy 82, 648–655 (2008). https://doi.org/10.1016/j.solener.2008.01.001

Cool Roof Rating Council: Ansi/crrc s100 (2016) —standard test methods for determining radiative properties of materials. Standard test methods, Cool Roof Rating Council, Portland, OR, USA (2016)

European Cool Roof Council: product rating manual. European Cool Roof Council, Brussels, Belgium. European Cool Roof Council (2014)

ASTM International PA, W.C.: Astm e903-20 standard test method for solar absorptance, reflectance, and transmittance of materials using integrating spheres (03), 1–9 (2020) https://doi.org/10.1520/E0903-20.2

ASTM International PA, W.C.: Astm c1549-16 (2022) standard test method for determination of solar reflectance near ambient temperature using a portable solar reflectometer. Annu. Book ASTM Stand 16(C), 1–6 (2021) https://doi.org/10.1520/C1549-16R22.Copyright

ASTM International PA, W.C.: Astm e1918-21 standard test method for measuring solar reflectance of horizontal and low-sloped surfaces in the field (i(Reapproved 2015)), 18–20 (2016) https://doi.org/10.1520/E1918-21.2

R. Levinson, H. Akbari, P. Berdahl, Measuring solar reflectance-part I: defining a metric that accurately predicts solar heat gain. Solar Energy 84, 1717–1744 (2010). https://doi.org/10.1016/j.solener.2010.04.018

ASTM International PA, W.C.: Astm e891 - 87 standard tables for terrestrial direct normal solar spectral irradiance for air mass 1.5. Annual Book of ASTM Standards (06(Reapproved)), 1–6 (1994)

ASTM International PA, W.C.: Astm g173-03 standard tables for reference solar spectral irradiances: Direct normal and hemispherical on 37\(^\circ\) tilted surface. Annual Book of ASTM Standards (03(Reapproved)), 1–21 (2013) https://doi.org/10.1520/G0173-03R20.2

D &S: D &s technical note 09-1: Solar spectrum reflectometer version 6.0 version. Technical report (2009)

CRRC: CRRC-1—product rating program manual. CRRC (2018)

R. Levinson, H. Akbari, P. Berdahl, Measuring solar reflectance—part II: review of practical methods. Solar Energy 84, 1745–1759 (2010). https://doi.org/10.1016/j.solener.2010.04.017

D &S: Technical note 11-1: SSR-ER reflectance measurements for large radius cylindrical surfaces. Technical report (2010)

D &S: A proposed correction to reflectance measurements of profiled surfaces surfaces. Technical report (2009)

D &S: Technical note 84-2: Emissometer adapter model ae-ad1. Technical report (1984)

D &S: Technical note 78-2: Emissometer model AE—accuracy and calibration of standards. Technical report (1978)

D &S: Technical note 11-2: Model AE1 emittance measurements using a port adapter, model AE-ADP. Technical report (2011)

Buildings Performance Institute Europe (BPIE): Europe’s buildings under the microscope (2011). Buildings Performance Institute Europe

ISO 11664-1 colorimetry–Part 1: CIE standard colorimetric observers. ISO

C. Ferrari, A. Libbra, A. Muscio, C. Siligardi, Influence of the irradiance spectrum on solar reflectance measurements. Adv. Build. Energy Res. 7, 244–253 (2013). https://doi.org/10.1080/17512549.2013.865563

C. Ferrari, A. Muscio, C. Siligardi, Development of a solar-reflective ceramic tile ready for industrialization. Procedia Eng. 169, 400–407 (2016). https://doi.org/10.1016/j.proeng.2016.10.049

Acknowledgements

Project funded under the National Recovery and Resilience Plan (NRRP), Mission 04 Component 2 Investment 1.5—NextGenerationEU, Call for tender n. 3277 dated 30/12/2021, Award Number: 0001052 dated 23/06/2022

Funding

Open access funding provided by Università degli Studi di Modena e Reggio Emilia within the CRUI-CARE Agreement. Project funded under the National Recovery and Resilience Plan (NRRP), Mission 04 Component 2 Investment 1.5 - NextGenerationEU, Call for tender n. 3277 dated 30/12/2021, Award Number: 0001052 dated 23/06/2022

Author information

Authors and Affiliations

Contributions

The authors contributed equally to this work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Code Availability

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Selected Papers of the 22nd European Conference on Thermophysical Properties.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ferrari, C., Morselli, N. & Muscio, A. Solar Spectrum Reflectometer Measurements on Profiled and Small Samples: Design and Testing of Adapters. Int J Thermophys 45, 42 (2024). https://doi.org/10.1007/s10765-024-03342-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-024-03342-2