Abstract

In the frame of severe accident modeling, the knowledge of the so-called-corium thermophysical properties is crucial to obtain reliable simulation. In this work, an aerodynamic levitation technique was used to measure simultaneously surface tension, density and viscosity of liquid zirconia, one phase of corium, at temperature ranging from melting point 2 715 °C to 2 900 °C using acoustic excitation. The volume estimation, initially based on the hypothesis of a spherical shape for the sample, was improved with the use of a second camera placed on top of the sample. This enabled a more precise determination of the volume to estimate density. An original post-treatment method was developed to obtain the surface tension by taking into account multimodal oscillation frequencies. The viscosity may be slightly overestimated due to the multimode oscillation. Measurement uncertainties are estimated based on propagation law for the three thermophysical properties considered.

Similar content being viewed by others

Data Availability

Data and materials will be provided on request.

References

M. Pellegrini, K. Dolganov, L.E. Herranz, H. Bonneville, D. Luxat, M. Sonnenkalb, J. Ishikawa, J.H. Song, R.O. Gauntt, L.F. Moguel, F. Payot, Y. Nishi, Nucl. Technol. 196, 198 (2016). https://doi.org/10.13182/NT16-63

M. Pellegrini and al., in Nureth-19 Int. Top. Mtg. Nucl. React. Thermal Hydraulics (Brussels, 2022).

P. Piluso, M. Adorni, G. Azarian, K.-H. Bang, S. Basu, and M. Buck, Status Report on Ex-Vessel Steam Explosion: EVSE (NEA-OCDE, 2017).

J. Delacroix, C. Journeau, P. Piluso, Front. Energy Res. (2022). https://doi.org/10.3389/fenrg.2022.883972

S. Ozawa, S. Takahashi, S. Suzuki, H. Sugawara, H. Fukuyama, Jpn. J. Appl. Phys. 50, 11RD05 (2011). https://doi.org/10.1143/JJAP.50.11RD05

Y. Su, M. Mohr, R.K. Wunderlich, X. Wang, Q. Cao, D. Zhang, Y. Yang, H.-J. Fecht, J.-Z. Jiang, J. Mol. Liq. 298, 111992 (2020). https://doi.org/10.1016/j.molliq.2019.111992

H. Yoo, C. Park, S. Jeon, S. Lee, G.W. Lee, Metrologia 52, 677 (2015). https://doi.org/10.1088/0026-1394/52/5/677

Y. Ohishi, K. Kurokawa, Y. Sun, H. Muta, J. Nucl. Mater. 528, 151873 (2020). https://doi.org/10.1016/j.jnucmat.2019.151873

H. Oda, C. Koyama, M. Ohshio, H. Saruwatari, T. Ishikiwa, Int. J. Microgravity Sci. Appl. 37, 370302 (2020). https://doi.org/10.15011/ijmsa.37.3.370302

D. Grishchenko, P. Piluso, HTHP 40, 127 (2011)

D.L. Price, High-Temperature Levitated Materials (Cambridge University Press, Cambridge, 2010)

D. Langstaff, M. Gunn, G.N. Greaves, A. Marsing, F. Kargl, Rev. Sci. Instrum. 84, 124901 (2013). https://doi.org/10.1063/1.4832115

D. Manara, C. Ronchi, M. Sheindlin, M. Lewis, M. Brykin, J. Nucl. Mater. 342, 148 (2005). https://doi.org/10.1016/j.jnucmat.2005.04.002

I.C. Sommerville, W.S. Raw, J. Am. Leather Chem. Assoc. 44, 784 (1949)

P. Hofmann, S.J.L. Hagen, G. Schanz, A. Skokan, Nucl. Technol. 87, 327 (1989). https://doi.org/10.13182/NT-TMI2-146

S. Kohara, J. Akola, L. Patrikeev, M. Ropo, K. Ohara, M. Itou, A. Fujiwara, J. Yahiro, J.T. Okada, T. Ishikawa, A. Mizuno, A. Masuno, Y. Watanabe, T. Usuki, Nat. Commun. 5, 5892 (2014). https://doi.org/10.1038/ncomms6892

T. Kondo, H. Muta, K. Kurosaki, F. Kargl, A. Yamaji, M. Furuya, Y. Ohishi, Heliyon 5, e02049 (2019). https://doi.org/10.1016/j.heliyon.2019.e02049

W.K. Kim, J.H. Shim, M. Kaviany, J. Nucl. Mater. 491, 126 (2017). https://doi.org/10.1016/j.jnucmat.2017.04.030

O.L.G. Alderman, C.J. Benmore, J.K.R. Weber, L.B. Skinner, A.J. Tamalonis, S. Sendelbach, A. Hebden, M.A. Williamson, Sci. Rep. 8, 2434 (2018). https://doi.org/10.1038/s41598-018-20817-z

T. Kondo, H. Muta, Y. Ohishi, J. Nucl. Sci. Technol. 57, 889 (2020). https://doi.org/10.1080/00223131.2020.1736681

E. Cheremisina, Z. Zhang, E. de Bilbao, J. Schenk, Ceram. Int. 49, 4460 (2023). https://doi.org/10.1016/j.ceramint.2022.09.332

S.J. McCormack, A. Tamalonis, R.J.K. Weber, W.M. Kriven, Rev. Sci. Instrum. 90, 015109 (2019). https://doi.org/10.1063/1.5055738

B. Glorieux, F. Millot, J.C. Rifflet, Int. J. Thermophys. 23, 1249 (2002). https://doi.org/10.1023/A:1019848405502

T. Ishikawa, P.-F. Paradis, S. Yoda, Rev. Sci. Instrum. 72, 2490 (2001). https://doi.org/10.1063/1.1368861

J. Canny, IEEE Trans. Pattern Anal. Machine Intell. (1986). https://doi.org/10.1109/TPAMI.1986.4767851

J.W.S. Rayleigh, Proc. R. Soc. Lond. 29, 71 (1879). https://doi.org/10.1098/rspl.1879.0015

S. Hakamada, A. Nakamura, M. Watanabe, F. Kargl, Int. J. Microgravity Sci. Appl. 34, 340403 (2017). https://doi.org/10.15011/ijmsa.34.4_340403

P.V.R. Suryanarayana, Y. Bayazitoglu, Phys. Fluids A 3, 967 (1991). https://doi.org/10.1063/1.857974

D.L. Cummings, D.A. Blackburn, J. Fluid. Mech. 224, 395 (1991). https://doi.org/10.1017/S0022112091001817

F. Millot, J.C. Rifflet, G. Wille, V. Sarou-Kanian, B. Glorieux, J. Am. Ceram. Soc. 85, 187 (2002). https://doi.org/10.1111/j.1151-2916.2002.tb00064.x

G. Wille, F. Millot, J.C. Rifflet, Int. J. Thermophys. 23, 1197 (2002). https://doi.org/10.1023/A:1019888119614

V. Sarou-Kanian, F. Millot, J.C. Rifflet, Int. J. Thermophys. 24, 277 (2003). https://doi.org/10.1023/A:1022466319501

F. Millot, V. Sarou-Kanian, J.-C. Rifflet, B. Vinet, Mater. Sci. Eng. A 495, 8 (2008). https://doi.org/10.1016/j.msea.2007.10.108

H. Lamb, Proc. Lond. Math. Soc. S1–13, 51 (1881). https://doi.org/10.1112/plms/s1-13.1.51

JCGM_100, Evaluation of measurement data — Guide to the expression of uncertainty in measurement (2008). https://www.bipm.org/documents/20126/2071204/JCGM_100_2008_E.pdf/cb0ef43f-baa5-11cf-3f85-4dcd86f77bd6

N. Metropolis, S. Ulam, J. Am. Stat. Assoc. 44, 335 (1949). https://doi.org/10.1080/01621459.1949.10483310

S.V. Ushakov, A. Shvarev, T. Alexeev, D. Kapush, A. Navrotsky, J. Am. Ceram. Soc. 100, 754 (2017). https://doi.org/10.1111/jace.14594

V. Sarou-Kanian, J.-C. Rifflet, F. Millot, Ninth International Workshop on Subsecond Thermophysics (Austria, Graz, 2010), pp.249–261

J. C. Delabrouille, Surfusion de Quelques Métaux et Alliages (Faculté des sciences de Paris, Paris, 1969).

T. Kondo, H. Muta, Y. Ohishi, HTHP 00, 1 (2019)

H.G. Kim, J. Choe, T. Inoue, S. Ozawa, J. Lee, Metall. Mater. Trans. B 47, 2079 (2016). https://doi.org/10.1007/s11663-016-0712-z

J. Delacroix, P. Piluso, N. Chikhi, O. Asserin, D. Borel, A. Brosse, S. Cadiou, Steel Res. Int. 93, 2100624 (2022). https://doi.org/10.1002/srin.202100624

T. Iida, R.I.L. Guthrie, The Physical Properties of Liquid Metals (Oxford University Press, Oxford, 1988)

Acknowledgements

This work was supported by the cross-cutting basic research Program (RTA Program) of the CEA Energy Division.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

CD, ZZ and EdB carried out the experiments. CD has written the main part of the article. EdB, JD and PP have added some contributions, and reviewed the present article in a collegial manner.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: High-Speed Camera Calibration: Detailed Parameters and Results

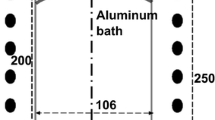

The calibration of the high-speed camera also allowed to define satisfying parameters (size of the drop, gas flow) to optimize the levitation and reduce the standard deviation on measured diameters. For each steel ball, several gas flow were used and the width and the height of the drop were obtained with their standard deviation by using the Python script (Table

4). Standard deviation was smaller for the biggest diameter, but it was not chosen because the drop with a higher mass is subjected to deformation in its lower part; thus the recommended diameter is around 2 mm for the sample. The standard deviation is always higher on the height, as this diameter is partially extrapolated due to the top of the nozzle hiding the lower part of the drop. Increasing the gas flow enables to see a bigger part of the sample with the high-speed camera, but it may also destabilize the drop and complicates the measurement of its thermophysical properties.

Appendix 2: Raw Data for the Three Thermophysical Properties Measured

The raw data and their uncertainties for the density, the surface tension, and the viscosity measured in this work are given Tables

5,

6 and

7, respectively.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Denier, C., Zhang, Z., de Bilbao, E. et al. Thermophysical Properties of Liquid Zirconia Measured by Aerodynamic Levitation at High Temperature. Int J Thermophys 44, 127 (2023). https://doi.org/10.1007/s10765-023-03230-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-023-03230-1