Abstract

The (p, ρ, T) behaviour of liquid 3,3,3-trifluoropropene (R-1243zf) was investigated in the temperature range from T = (203.23 to 293.72) K at pressures from p = (1.04 to 15.22) MPa utilizing a vibrating-tube densimeter. This work extends measurements of the refrigerant R-1243zf by 109 data points into the low-temperature and high-density region. A physically based and a polynomial model were used to calculate density from the measured values (temperature, pressure and oscillation period). The physically based model was used to present the densities while the polynomial model contributes to the estimate of their uncertainty. The combined expanded uncertainty (k = 2) of the experimental densities was estimated to be 1.7 kg·m−3. The reference equation of state of R-1243zf as implemented in NIST’s REFPROP 10.0 database deviates from the experimental data up to 2.0 %. To improve upon this representation, a genetic programming based symbolic regression approach was used to correlate data reported in the literature and measured in this work for liquid R-1243zf in the density range between (700 and 1240) kg·m−3. The new density correlation agrees with the experimental data within 0.2 %.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Implementation of international agreements such as the Montreal protocol aim to reduce the impact of emissions on the atmosphere. It was first adopted in 1987 to phase out the use of refrigerants with high ozone depletion potential (ODP) in favour for zero ODP hydrofluorocarbons (HFCs). More recently, the Kigali amendment (2016) had identified that HFCs have high global warming potentials (GWPs). It aims to phase down the production and consumption on HFCs by 85 % in the late 2040s. Accordingly, a new generation of zero ODP and low GWP refrigerants are now superseding HFCs.

One such refrigerant is 3,3,3-trifluoropropene (R-1243zf), a hydrofluoroolefin (HFO), which could be suitable as a replacement for 1,1,1,2-tetrafluoropropene (R-134a) in automotive and domestic refrigeration systems. R-1243zf has a GWP of 0.29 and an atmospheric lifetime of 8.7 days, significantly lower than those of R-134a, which has a GWP of 1300 and an atmospheric lifetime of 13.4 years [1]. Furthermore, its GWP is lower than of other HFOs such as, 1,2,2,2-tetrafluoroprop-1-ene (R-1234yf) [2], which has a GWP of 4. However, as a relatively new refrigerant, there are currently insufficient experimental data available to develop thermophysical property models for this fluid with the accuracy desired. Current pressure, density, and temperature (p, ρ, T) data sets for R-1243zf are limited to the temperature range from (253 to 430) K and a pressure range from (0.11 to 34.6) MPa, as shown in Table 1. The reference equation of state (EoS) of Akasaka [3] as implemented in NIST’s REFPROP 10.0 database [4] only makes predictions of density up to 1210 kg·m−3. The present work improves the current experimental density data situation of liquid R-1243zf in the temperature range between (203.23 and 293.72) K at pressures between (1.04 and 15.22) MPa, as shown in Fig. 1. Furthermore, an empirical density correlation for liquid R-1243zf is developed here to cover the density range from (700 to 1240) kg·m−3 and represent the experimental data mostly within their experimental uncertainty.

Pressure p and temperature T conditions of the experimental (p, ρ, T) data for R-1243zf reported in the literature ( Yin et al. [6],

Yin et al. [6],  Di Nicola et al. [8],

Di Nicola et al. [8],  Higashi and Sakoda [7] and

Higashi and Sakoda [7] and  Yang et al. [5]) and in this work (

Yang et al. [5]) and in this work ( ). The solid curve is the liquid–vapour-equilibrium curve and * denotes the critical point; both are obtained from REFPROP 10.0 [4]

). The solid curve is the liquid–vapour-equilibrium curve and * denotes the critical point; both are obtained from REFPROP 10.0 [4]

2 Experimental

2.1 Apparatus Description

A density measurement system based on a vibrating-tube densimeter (VTD) was set up to measure densities at temperatures between (203.23 and 333.16) K and pressures up to 15.22 MPa. The VTD technique is commonly used [9,10,11,12,13,14] for relatively accurate and fast density measurements. A schematic of the apparatus is shown in Fig. 2. The VTD (Anton Paar, Austria, type: DMA HPM) was housed inside a temperature-controlled environmental chamber (Weiss, Germany, type: WKL 100/70). For temperatures below 273.15 K, the chamber was constantly flushed with nitrogen to prevent water from the air freezing on the VTD. A syringe pump (Teledyne ISCO, USA, type: 260 D) was connected to the inlet of the VTD and used to pressurise the fluid sample. A pressure transducer (Keller, Switzerland, type: PA-21Y/800bar/81578.11) monitors the system pressure in parallel with the inlet. The outlet is connected to a venting manifold that includes a rotary vane vacuum pump (Vacuubrand, Germany, type: RZ 6).

2.2 Model of VTD

A physical model developed by May et al. [15] was used to relate the oscillation period τ of the VTD to the density of the fluid ρ inside the vibrating tube by

where t is the fluid temperature relative to a reference temperature T0 = 273.15 K, i.e., t = T − 273.15 K, and p is the fluid pressure in MPa. The remaining parameters are determined through calibration and correspond to physical qualities of the apparatus. The tubing material density ρM is found through the manufacturer datasheet. Vacuum measurements are used to fit the vacuum resonance period at the reference temperature τ00, the linear temperature response coefficient of the spring constant ετ1, and the quadratic temperature response coefficient of the spring constant ετ2. Finally, the geometric sensitivity factor of the evacuated tube at the reference temperature S00, the pressure response coefficient of the spring constant βτ, the linear temperature response coefficient of tube volume αV, and the pressure response coefficient of tube volume βV, are all fit to calibration measurements with reference fluids [in the present work: nitrogen, water, carbon dioxide, difluoromethane (R32)].

A simplified version of the model of Outcalt and McLinden [16] proposed by Yang et al. [10] was also used to relate the oscillation period τ and the fluid density ρ as:

Here, the apparatus parameters A(p, T) and B(p, T) are:

where parameters c0, c1, c2 are determined by correlating experimental (T, τ) measurements with the evacuated vibrating tube to the equation:

and the remaining parameters are obtained from measurements with reference fluids.

2.3 Experimental Materials

The experimental materials are described in Table 2. The reference fluids (nitrogen, water, carbon dioxide, R32) and R-1243zf were transferred to the isolated and evacuated syringe pump directly from the gas cylinder obtained from the providers without further purification. Tap water was first deionised through a water purifier (IBIS Technology, resistivity > 18 MΩ·cm), then the water was degassed in a glass bottle using a vacuum pump, and a Cole–Parmer StableTemp magnetic stirrer at room temperature to agitate the water. Finally, it was transferred to a syringe pump by opening the top of the container to atmosphere and drawing water from the bottom of the bottle.

2.4 Measurement Procedure

Prior to sample transfer from the syringe pump and to the VTD, the VTD was evacuated and flushed with the sample fluid in 15-min intervals at least 3 times. Then, the syringe pump and the VTD were isolated from the exhaust and vacuum pump. The sample was then transferred to fill the vibrating tube at the planned measurement pressure.

Measurements were conducted along isotherms for all the samples. The VTD required at least 6 h to reach thermal equilibrium after a temperature change, due to the poor heat transfer between the air in the environmental chamber and VTD. For a pressure change, equilibrium was achieved after 15 min. Equilibrium was taken to have been reached when fluctuations in temperature were less than 0.01 K, pressure less than 0.01 MPa and oscillation period less than 0.02 μs over a 1 min period. After stabilisation, the measurement period commenced where 1-min averaged measurements (T, p, τ) were recorded for 2 h. Finally, each measurement period was averaged for further data analysis.

3 Results

3.1 Calibration

Calibration measurements were carried out with the cell of the VTD evacuated and filled with reference fluids; the results are listed in Tables 3 and 4, respectively. The physically based model developed by May et al. [15] is advantageous as it does not require extensive calibration measurements. The vacuum data set in Table 3 was used to fit parameters τ00, ετ1, and ετ2 in May’s model through Eq. 6:

The pure fluid data in Table 4 was used to fit the remaining four parameters of the model of May et al. [15], with bounds for physical values: S00 was unconstrained, βτ was constrained between (− 0.95 × ·10−5 and 1.2 × ·10−5) MPa−1 as provided in May et al. [15], αV was constrained between (30 × ·10−6 and 60 × ·10−6) K−1 for typical steel volumetric coefficient of thermal expansion values, and βV was required to be greater than 0 MPa−1.

The fitted parameters of models of May et al. [15] and Yang et al. [10] are listed in Table 5, and the deviations of the measured data from the reference equations of state (EoS, Span et al. [17] for nitrogen, Wagner and Pruβ [18] for water, Span and Wagner [19] for carbon dioxide and Tillner-Roth and Yokozeki [20] for R32) are plotted in Fig. 3. The values of the calibration parameters are close to the ones used by May et al. [15] and Jiao et al. [11] for the identical VTD.

Deviations of experimental densities ρexp of nitrogen ( ), water (

), water ( ), carbon dioxide (◊), and R32 (

), carbon dioxide (◊), and R32 ( ) from densities ρcalc calculated with the reference equation of state (nitrogen [17], water [18], carbon dioxide [19] and R32 [20]). Experimental densities in plots (a) and (b) were calculated with the model of May et al. [15], and plots (c) and (d) calculated with model by Yang et al. [10]

) from densities ρcalc calculated with the reference equation of state (nitrogen [17], water [18], carbon dioxide [19] and R32 [20]). Experimental densities in plots (a) and (b) were calculated with the model of May et al. [15], and plots (c) and (d) calculated with model by Yang et al. [10]

3.2 Measurements of R-1243zf

Density measurements of R-1243zf were carried out along ten isotherms from (203.23 to 293.72) K and at pressures from (1.04 to 15.22) MPa. To check the repeatability, the low-pressure measurements for each isotherm were measured again after all isotherms were complete. Moreover, some final repeat measurements at pressures of (1, 9 and 15) MPa for temperatures of (203.15, 233.15, 273.15, and 293.15) K were conducted again after the initial measurement campaign was complete. This results in a total of 109 (p, ρ, T) data, which are reported in Table 6, and the relative deviations from the reference EoS of R-1243zf [3] as implemented in NIST’s REFPROP 10.0 database [4] are plotted in Fig. 4.

Relative deviations of the experimental densities ρexp for R-1243zf from densities calculated ρcalc using the reference equation of state [3]. Experimental densities from this work ( ) and literature: Yin et al. [6] (

) and literature: Yin et al. [6] ( ), Di Nicola et al. [8] (

), Di Nicola et al. [8] ( ) and Higashi and Sakoda [7] (

) and Higashi and Sakoda [7] ( ). The expanded uncertainty of this work is plotted for two points, the lower density point is from the example in Table 7. (a) Gas and liquid phase densities, and (b) liquid density range

). The expanded uncertainty of this work is plotted for two points, the lower density point is from the example in Table 7. (a) Gas and liquid phase densities, and (b) liquid density range

Relative deviations for the liquid density range are plotted in panel (b) of Fig. 4. Experimental densities of both Di Nicola et al. [8] and this work begin to deviate from the EoS at around 1100 kg·m−3, continuing up to a maximum relative deviation of 1 % at 1220 kg·m−3. A further 6 points up to a density of 1237 kg·m−3 were not shown on the plot as the EoS implemented in REFPROP 10.0 [3] fails to estimate densities above 1210 kg·m−3 at T = 203 K. Thus, R-1243zf density predictions would benefit from a preliminary correlation with the new data until sufficient data is available to revise the reference EoS [3].

3.3 Uncertainty Analysis

The combined uncertainty in density measurements was determined according to the “Guide to the Expression of Uncertainty in Measurement” using the method proposed by Sampson et al. [9], with the uncertainty contributions shown in Table 7. The combined expanded uncertainty in density Uc(ρ) was calculated with:

Here, the contributions Umeas(ρ), UEoS(ρ), Ucal(ρ), Umodel(ρ) and Ucomp(ρ) are uncertainties attributable to the (T, p, τ) measurements, the EoS of the reference fluids, the measured density deviations from reference equations of state of the reference fluids, the model for the VTD, and impurities in the sample, respectively. The estimation of each uncertainty term is described as follows with the measurement at T = 293.20 K and p = 1.11 MPa taken as an example.

The uncertainty in density due to the measurements was calculated according to:

Here, the expanded uncertainty (k = 2) for the temperature measurements, U(T), is 0.20 K, for the pressure measurements, U(p), is 0.034 MPa, and for the oscillation period, U(τ), is 0.004 μs, which was estimated based on the fluctuations observed during measurements. Uncertainty in temperature measurement was estimated conservatively by considering the accuracy of the thermometer’s calibration and fluctuations observed during the density measurement. Uncertainty in pressure measurement was estimated considering the calibration (against a Paroscientific Series 3000 transducer, full range 13.8 MPa) and the drifting over time.

Terms on the right side of Eq. 8 were estimated through a sensitivity analysis. For example, the contributions of the (∂ρ/∂T)p,τ·U(T) term was estimated by taking the deviation between the original density calculation, and the density recalculated with the temperature uncertainty value added to the temperature measurement. The maximum absolute deviation was selected to be the value of (∂ρ/∂T)p,τ·U(T), being 0.896 kg·m−3. A similar analysis was carried out for the pressure term, found to be 0.003 kg·m−3, and for the oscillation period term, found to be 0.005 kg·m−3. The resulting uncertainty contribution due to the measurements Umeas(ρ) is 0.896 kg·m−3.

In the calibration measurement range, the relative expanded uncertainty (k = 2) in density for each of the reference EoS are 0.001 % for water [18], 0.05 % for carbon dioxide [19], 0.05 % for R32 [20], and 0.02 % for nitrogen [17]. Here, the uncertainty attributed to the EoS was taken to be the maximum of these as UEoS(ρ)/ρ = 0.05 %. According to Fig. 3, the calibrated measurements deviated from the reference EoS within a boundary of 0.60 kg m−3. Assuming a normal distribution of the deviations, the uncertainty attributed to the calibration Ucal(ρ) was estimated to be 0.42 kg m−3 (= 0.60 kg m−3/\(\sqrt{2}\)). The model contribution to uncertainty Umodel(ρ) of 0.553 kg·m−3 was found by taking the maximum absolute deviation in the measured R-1243zf density calculated from the (p, T, τ) data using the equations of May et al. [15] and Yang et al. [10]. The impurities in the R-1243zf sample were unknown; we simply assumed that R1234yf, R1234ze(E) or R1234ze(Z), which have similar molecular formula, are the trace impurity. The maximum absolute deviation between pure R-1243zf density and density with 0.004 mol fraction (k = 2) impurity, both calculated using REFPROP 10.0 [4], was used as the estimated uncertainty in composition. An R1234ze(Z) impurity produced the largest deviation and so Ucomp(ρ) was assigned a value of 1.11 kg·m−3. In summary according to Eq. 7, the combined expanded uncertainty Uc(ρ) (k = 2) was estimated to be 1.7 kg·m−3.

3.4 Correlation Equation

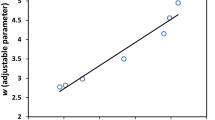

Similar to previous studies [9, 10, 14], a Schilling-type equation [21] was used to correlate the liquid R-1243zf density from (p, ρ, T) data of this work and literature [7, 8], using the software tool of DataModeler 9.5 [22]. The functional form is:

where σ = (T/T0 − 1) is the reduced temperature, relative to T0 = 150 K, π = (p/p0 + 1) is the reduced pressure, relative to p0 = 100 MPa, and ρ0 = 900 kg·m−3 is the reference density. There was a trade-off between the root-mean-squared error and complexity of the fitted equation. Six terms (N = 6) were the least number of parameters that could fit Eq. 9 so that the error fell within the uncertainty of the measurements of this work. Coefficients ni, and exponents ti and pi were fit for the ith term using the DataModeler 9.5 [22] software and are listed in Table 8. The resulting equation for density predicted through DataModeler 9.5 [22], ρDM, is shown in Eq. 10. It is applicable over the temperature range from (203 to 368) K and densities from (700 to 1240) kg·m−3, and to validate the equation a temperature of 293.10 K and pressure of 1.11 MPa will result in a density of 995.88 kg·m−3.

Deviations in density of the new correlation to the experimental data from this work and literature [7, 8] are displayed in Fig. 5. Measurements from this work are within 0.17 % of the correlation, and are much less than the 0.98 % maximum deviation to the reference EoS [3] in Fig. 4b. Similarly, density measurements made near the critical point by Higashi and Sakoda [7] which have a relative deviation of 1.12 % from the fundamental EoS [3] deviate by 0.99 % from the new correlation. However, measurements by Di Nicola et al. [8] deviate up to 0.26 % from Eq. 10, which is larger than their 0.09 % deviation from the EoS [3]. Excluding the measurements of Higashi and Sakoda [7] near the critical point, the maximum deviation of the new correlation is 2.27 kg·m−3, which is much smaller than the reference EoS [3] at 11.8 kg·m−3 for the prediction of R-1243zf liquid densities.

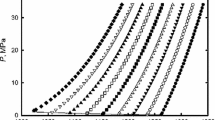

A further breakdown of the (p, ρ, T) data from this work and the deviation from the new correlation is shown in Fig. 6. Figure 6a shows the measured densities at different pressures for each isotherm and the model as given in Eq. 10. The relative deviation of the measured isotherms from the model are displayed in Fig. 6b against pressure. Deviations range up to 0.17 % for the 293 K isotherm and the remainder of the isotherms are within 0.11 %. Thus, the correlation of this work provides more accurate predictions of liquid densities at and above 1210 kg·m−3 than the existing EoS.

(a) Density ρexp measured along each isotherm, 203 K ( ), 213 K (

), 213 K ( ), 223 K (

), 223 K ( ), 233 K (

), 233 K ( ), 243 K (

), 243 K ( ), 253 K (

), 253 K ( ), 263 K (

), 263 K ( ), 273 K (+), 283 K (

), 273 K (+), 283 K ( ), 293 K (

), 293 K ( ), varies with pressure p. The solid lines represent the correlation of Eq. 10. (b) Relative deviations between measured density and density ρDM calculated from the correlation of Eq. 10

), varies with pressure p. The solid lines represent the correlation of Eq. 10. (b) Relative deviations between measured density and density ρDM calculated from the correlation of Eq. 10

4 Conclusions

In this work, we investigated the (p, ρ, T) behaviour of liquid R-1243zf over a temperature range from (203.23 to 293.72) K and pressures from (1.04 to 15.22) MPa. Measurements were performed using a high-pressure VTD. The combined expanded uncertainty (k = 2) in the experimental density was estimated to be 1.7 kg·m−3 with contributions from measurement uncertainties, as well as uncertainties from calibration, reference fluid EoS, VTD density model, and pure fluid impurities. The experimental data and literature data above 700 kg·m−3 were regressed to a Schilling-type equation using DataModeler 9.5. This correlation provides better predictions, within 0.2 % of experimental data, than the current reference EoS for liquid density R-1243zf at and above 1210 kg·m−3. Further measurements of density, particularly near the critical region would be useful prior to the development of an improved fundamental EoS for R-1243zf.

Data Availability

A Supplementary File is available containing all data in Table 6 (in csv format).

References

S. González, E. Jiménez, B. Ballesteros, E. Martínez, J. Albaladejo, Environ. Sci. Pollut. Res. (2015). https://doi.org/10.1007/s11356-014-3426-2

M.O. McLinden, A.F. Kazakov, J. Steven Brown, P.A. Domanski, Int. J. Refrig. (2014). https://doi.org/10.1016/j.ijrefrig.2013.09.032

R. Akasaka, Sci. Technol. Built Environ. (2016). https://doi.org/10.1080/23744731.2016.1208000

E.W. Lemmon, I.H. Bell, M.L. Huber, M.O. McLinden (2018). https://doi.org/10.18434/T4/1502528

Z. Yang, A. Valtz, C. Coquelet, J. Wu, J. Lu, Int. J. Refrig. (2022). https://doi.org/10.1016/j.ijrefrig.2022.03.027

J. Yin, J. Ke, G. Zhao, S. Ma, Int. J. Refrig. (2020). https://doi.org/10.1016/j.ijrefrig.2020.04.021

Y. Higashi, N. Sakoda, J. Chem. Eng. Data (2018). https://doi.org/10.1021/acs.jced.8b00452

G. Di Nicola, J. Steven Brown, L. Fedele, M. Securo, S. Bobbo, C. Zilio, Int. J. Refrig. (2013). https://doi.org/10.1016/j.ijrefrig.2013.08.004

C.C. Sampson, X. Yang, J. Xu, M. Richter, J. Chem. Thermodyn. (2019). https://doi.org/10.1016/j.jct.2018.10.016

X. Yang, C.C. Sampson, O. Frotscher, M. Richter, J. Chem. Thermodyn. (2020). https://doi.org/10.1016/j.jct.2020.106054

F. Jiao, S.Z.S. Al Ghafri, T.J. Hughes, E.F. May, J. Mol. Liq. (2020). https://doi.org/10.1016/j.molliq.2020.113219

A. Arami-Niya, X. Xiao, S.Z.S. Al Ghafri, F. Jiao, M. Khamphasith, E. Sadeghi Pouya, M.S. Sadaghiani, X. Yang, T. Tsuji, Y. Tanaka, Y. Seiki, E.F. May, Int. J. Refrig. (2020). https://doi.org/10.1016/j.ijrefrig.2020.05.009

S.Z. Al Ghafri, D. Rowland, M. Akhfash, A. Arami-Niya, M. Khamphasith, X. Xiao, T. Tsuji, Y. Tanaka, Y. Seiki, E.F. May, T.J. Hughes, Int. J. Refrig. (2019). https://doi.org/10.1016/j.ijrefrig.2018.10.027

C.W. Scholz, O. Frotscher, S. Pohl, R. Span, M. Richter, Ind. Eng. Chem. Res. (2021). https://doi.org/10.1021/acs.iecr.0c06248

E.F. May, W.J. Tay, M. Nania, A. Aleji, S. Al-Ghafri, J.P. Martin Trusler, Rev. Sci. Instrum. (2014). https://doi.org/10.1063/1.4894469

S.L. Outcalt, M.O. McLinden, Ind. Eng. Chem. Res. (2007). https://doi.org/10.1021/ie070791e

R. Span, E.W. Lemmon, R.T. Jacobsen, W. Wagner, A. Yokozeki, J. Phys. Chem. Ref. Data (2000). https://doi.org/10.1063/1.1349047

W. Wagner, A. Pruß, J. Phys. Chem. Ref. Data (2002). https://doi.org/10.1063/1.1461829

R. Span, W. Wagner, J. Phys. Chem. Ref. Data (1996). https://doi.org/10.1063/1.555991

R. Tillner-Roth, A. Yokozeki, J. Phys. Chem. Ref. Data (1997). https://doi.org/10.1063/1.556002

G. Schilling, R. Kleinrahm, W. Wagner, J. Chem. Thermodyn. (2008). https://doi.org/10.1016/j.jct.2008.02.020

Evolved Analytics LLC, DataModeler 9.5 (Evolved Analytics LLC, 2022). https://evolved-analytics.com

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. L.T. was supported by a UWA UPA Scholarship co-funded by the FSR Research Group and a FEnEx CRC Top Up Scholarship.

Author information

Authors and Affiliations

Contributions

Conceptualization: XY, EM; Methodology: LT, OF, XY, FJ; Formal analysis and investigation: LT, OF, FJ, XY, EM; Writing—original draft preparation: LT; Writing—review and editing: OF, XY, MR, PS, EM; Funding acquisition: EM, PS; Supervision: MR, PS, EM.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tenardi, L.D., Frotscher, O., Yang, X. et al. Measurement and Correlation of the (p, ρ, T) Behaviour of Liquid R-1243zf at Temperatures from (203 to 293) K and Pressures up to 15 MPa. Int J Thermophys 44, 14 (2023). https://doi.org/10.1007/s10765-022-03120-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-022-03120-y

this work,

this work,  Di Nicola et al. [

Di Nicola et al. [ Higashi and Sakoda [

Higashi and Sakoda [