Abstract

In our previous work (J Chem Eng Data 2021, 66(3):1385–1398), a residual entropy scaling (RES) approach was developed to link viscosity to residual entropy [a thermodynamic property calculated with an equation of state (EoS)] using a simple polynomial equation for refrigerants. Here, we present an extension of this approach to a much wider range of fluids: all pure fluids and their mixtures whose reference EoS and experimental viscosity data are available. A total of 84 877 experimental points for 124 pure fluids and 351 mixtures are collected from 1846 references. The investigated pure fluids contain a wide variety of fluids from light gases with quantum effects at low temperatures to dense fluids and fluids with strong intermolecular association. More than 68.2 % (corresponding to the standard deviation) of the evaluated experimental data agree with the RES model within 3.2 % and 8.0 % for pure fluids and mixtures, respectively. Compared to the recommended models implemented in the REFPROP 10.0 software (the state-of-the-art for thermophysical property calculation), if the dilute gas viscosity is calculated in the same way, our RES approach yields similar statistical agreement with the experimental data while having a much simpler formulation and fewer parameters. To use our RES model, a software package written in Python is provided in the supporting information.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

According to the laws of thermodynamics, with an equation of state (EoS, typically a Helmholtz-energy equation or a pressure-explicit function with the independent variables temperature and density), and an equation for the isobaric heat capacity of the ideal gas, all thermodynamic properties (density, entropy, enthalpy, speed of sound, etc.) of a pure fluid can be calculated. After decades of development, the commonly used reference thermophysical property software packages (such as REFPROP 10.0 [1], TREND 5.0 [2] and CoolProp 6.4.1 [3]) include such reference multi-parameter EoS. These reference EoS were fitted to comprehensive and evaluated experimental data, and some of them have accuracies that only few experimental techniques can achieve, e.g., the EoS of Span et al. [4] for nitrogen yields a relative uncertainty of less than 0.02 % in density at atmospheric conditions. Nowadays, some of the most accurate reference EoS (e.g., Span et al. [4] for nitrogen, Wagner and Pruß [5] for water) are used to calibrate new experimental setups, and new experimental data are compared with these accurate reference EoS before publication. Nonetheless, transport properties (such as viscosity, thermal conductivity, and self-diffusion coefficient), are significantly less investigated in terms of both modeling and measurements than thermodynamic properties represented by the accurate reference EoS. Calculating a transport property requires independent equations and the typical calculation uncertainty (k = 2) is on the order of 5 % or higher.

In our previous work [6], a residual entropy scaling (RES) approach was developed to link the viscosity of pure refrigerant fluids to the residual entropy (a thermodynamic property obtained from an EoS) using a simple polynomial equation with four global parameters and a fluid-specific scaling factor for each pure fluid. In that work, this RES approach yields similar statistical agreement with evaluated experimental data as the recommended models in the REFPROP 10.0, the state-of-the-art for thermophysical property calculation. With the aim of linking viscosity to the accurate reference EoS for additional pure fluids, this work will extend the RES approach to all pure fluids whose reference EoS are available in REFPROP 10.0 and whose experimental viscosity data are available to us. In total, 124 pure fluids are investigated in this work, and some of them, e.g., hydrogen, water, and n-decane, have significantly different thermophysical properties than those of refrigerants. Thus, the simple polynomial equation with 4 global parameters developed in the previous work [6] cannot be used to accurately describe all the 124 pure fluids. A major task in this work is to classify these pure fluids into different groups and obtain global parameters for each group. Subsequently, a mixture model is proposed and compared to experimental data. For this purpose, a comprehensive literature search was carried out. Experimental data of 351 binary mixtures were obtained among the 7626 (= 123 × 124/2) possible pairs using the ThermoData Engine (TDE) database version 10 [7], and data of 4 multi-component mixtures were collected from peer-reviewed publications [8, 9]. This work aims to present an alternative reference viscosity model for fluids of industrial importance and the model will be implemented in the TREND software package [2, 10].

2 Theoretical Background

The RES approach expresses transport properties in terms of thermodynamic properties, which can be obtained directly from an EoS. Various approaches based on RES have been proposed and verified for viscosity of the Lennard–Jones (L–J) fluid [11] and hundreds of real fluids (e.g., hydrocarbons [12,13,14] refrigerants [6, 15,16,17], or other commonly used fluids [18, 19]), as well as thermal conductivity of some real fluids [17, 20,21,22,23,24]. Generalized RES approaches for viscosity of more than 100 pure fluids have been developed by Lötgering-Lin et al. [19] and Dehlouz et al. [25]. Here the approach developed in our previous work [6] is extended and the mixing rule is slightly modified.

The fluid viscosity η is calculated as the sum of the dilute gas viscosity ηρ0(T) and the residual part ηres(sr):

The dilute gas viscosity ηρ0(T) at temperature T of a pure fluid is calculated with the Chapman–Enskog [26] solution of the Boltzmann transport equation, assuming the interactions between molecules can be roughly captured by those of L–J particles with 12–6 potential:

where m, in units of kg is the mass of one molecule; kB = 1.380 649 × 10−23 J·K−1 is the Boltzmann constant; σ is the collision diameter of the L–J particle; and Ω(2,2)* is the reduced collision integral obtained by integrating the possible approach trajectories of the particles. Neufeld et al. [27] gives an empirical correlation of Ω(2,2)* as a function of temperature as:

where T* = kBT/ε is the dimensionless temperature, and ε/kB is the reduced L–J pair-potential energy. The non-polynomial terms are neglected in this work as REFPROP 10.0 [1] does. The L–J parameters (σ and ε) in this work were obtained from REFPROP 10.0 as listed in Table S1 in the Supporting Information (SI).

As introduced by Bell [12, 18], the residual part of viscosity ηres(sr) can be calculated with:

Here, ρN, in units of m−3, is the number density; sr in units of J·mol−1·K−1 is the molar residual entropy, defined as the difference between the real fluid entropy and the ideal gas entropy at the same temperature and density; and R = 8.31 446 261 815 324 J·mol−1·K−1 is the molar gas constant [28]. In this work, the number density ρN and molar residual entropy sr were calculated with the reference EoS implemented in REFPROP 10.0 [1] using the python CoolProp package 6.4.1 [3] as an interface. The reference EoS for each pure fluid is listed in Table S2 in the SI. The plus-scaled dimensionless residual viscosity \({\eta }_{\mathrm{res}}^{+}\) is related to the plus-scaled dimensionless residual entropy s+ using the following polynomial equations

or

Equation 6 is for a pure fluid with fluid-specific fitted parameter nk (k = 1, 2, 3, 4), and Eq. 7 is for a group of pure fluids with global fitted parameters ngk (k = 1, 2, 3, 4) and a fluid-specific scaling factor ξ for each pure fluid.

To extend the RES model to mixtures, a predictive mixing rule is adopted. The dilute gas viscosity ηρ0,mix is calculated with the approximation of Wilke [29]:

with

where xi is the mole fraction of component i and mi is the mass of one molecule of component i. The mole fraction weighted average mmix of the components is used to replace the effective mass of one particle m in Eq. 4:

Attempts to use a mass fraction weighted average result in a negligible statistical difference. Then, in contract to our previous work [6], the mole fraction weighted average coefficient nk,mix is utilised to substitute the parameters nk in Eq. 6, i.e.,

where nk,i (k = 1, 2, 3, 4) are fitted nk parameters of component i. It is important to note that, only if a pure fluid does not have fluid-specific fitted parameters, the nk (k = 1, 2, 3, 4) are replaced by ng1/ξ, ng2/ξ1.5, ng3/ξ2, and ng4/ξ2.5, respectively.

3 Results

3.1 Data Collection and Selection

In total, 51 841 experimental (T, p, η) values of 124 pure fluids and 33 036 experimental (x, T, p, η) values of 351 mixtures were collected. These experimental data were obtained from approximately 1846 literature sources, detailed citations of which are provided in the Supporting Information—Detailed Plots and References (SI-DPR). The same method as in our previous work [6, 24] to correct a small portion of data from the TDE database (less than 0.1 %, mainly due to mistakes in data transfer from original sources to the database), and the same filters to sort out inappropriate data were carried out. A summary of the numbers of literature sources and the numbers of values screened out by each filter for each pure fluid and each mixture are listed in Tables S3 and S4 in the SI, respectively. In total, 6.2 % of pure fluid and 8.9 % of mixture data were filtered out. The temperature, pressure (and composition for mixture) ranges of the evaluated data are summarized in both tables as well. For reproducibility, all experimental data except for those exceeding limits of the reference EoSs (one of the filters) are illustrated in \({\eta }_{\mathrm{res}}^{+}\) vs. s+ plots in 124 figures for pure fluids and 351 figures in mixtures in the SI-DPR. The \({\eta }_{\mathrm{res}}^{+}\) vs. s+ points of most pure fluids collapse into a single curve, along with some noise due to the poor quality of certain experimental data. However, for fluids with quantum effects at low temperatures, such as hydrogen, deuterium (D2), and helium, the \({\eta }_{\mathrm{res}}^{+}\) vs. s+ points do not collapse well. This implies a limitation of the current RES approach: it does not work well for quantum fluids. In additions, one could expect that the RES model would not work for superfluids (e.g., He-4 at 2.17 K), whose viscosity is zero.

3.2 Correlation for Pure Fluids

In the first step, the fluid-specific nk parameters in Eq. 6 were obtained for those pure fluids with a sufficient quantity and good quality of experimental data in both liquid and gas phases. The results are listed in Table 1. The method to fit the nk parameters as well as the global ng,k parameters to be discussed below is described in our previous work [6]. Then, the classification of the 124 pure fluids was carried out to achieve an ultimate goal: the RES model with the global ng,k parameters and the fluid-specific scaling factor ξ yields the best statistical agreement with experimental data for each pure fluid while the number of groups was kept as small as possible.

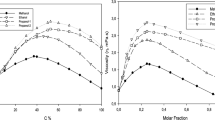

Ultimately, the 124 pure fluids were classified into eight groups, as given in Table 1 and illustrated in Fig. 1. From groups 1 to 8, the fluids are mainly but not exactly: (1-LG) light gases with quantum effects at low temperatures, mainly hydrogen and its spin isomers and helium; (2-G) gaseous fluids, e.g., the noble gases; (3-LHC) a majority of light hydrocarbons and halogenated hydrocarbons (refrigerants); (4-B) fluids with benzene rings and similar fluids; (5-MHC) medium hydrocarbons and similar fluids; (6-HHC) heavy hydrocarbons and dense fluids; (7-LA) fluids with light intermolecular association among molecules like methanol; (8-SA) fluids with strong intermolecular association among molecules, such as water. Group 3-LHC is intentionally preferred as it contains the largest number of fluids and we prefer to have a global parameter set for as many pure fluids as possible. The global ng,k parameters for each group are listed in Table 2; the fluid-specific scaling factors in each group are given in Table 1 and illustrated in Fig. 1. Experimental data of each group collapse into the individual global \({\eta }_{\mathrm{res}}^{+}\) vs. s+ curves as shown in Fig. 2; more details can be found in Fig. S3 in the SI.

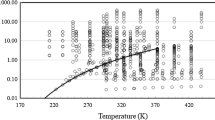

Scaling factor ξ. The denominator s+crit is the plus-scaled dimensionless residual entropy at the critical point calculated with REFPROP 10.0 [1] for each pure fluid. The number at the top right of each box indicates the group number. The vertical dashed dotted line denotes ξ/s+crit = 0.7. Values for group one hydrogen: 1.6, helium: 5.4, and deuterium (D2): 1.9

Values of ηres+ as a function of s+/ξ for each group of pure fluids, where is ηres+ the plus-scaled dimensionless residual viscosity, s+ is the plus-scaled residual entropy, and ξ is the scaling factor. The curves are calculated with the global ngk parameters. All groups are shown at the bottom; at the top, each group is individually illustrated but stacked by powers of 20 and with group number labeled

According to Fig. 1, there is a relation between ξ and s+crit, the plus-scaled dimensionless residual entropy at the critical point. For example, ξ/s+crit is roughly a value of 0.7 in group 3, and for a group with heavier components, the value of ξ/s+crit decreases. This factor is in good agreement with the scaling shown by Bell [13, 30]. Adopting the classification and the rough value of ξ/s+crit, the RES model could serve as a fully predictive model for other chemically similar pure fluids.

A summary of the relative deviations of the experimental viscosity ηexp from values ηRES calculated with the RES model is shown in Fig. 3, and more details are given in Fig. S4 in the SI. For clarity, more detailed plots are provided in 124 figures in the SI-DPR. It is important to note again, fluid-specific nk parameters are preferred in all calculations in this work and only if they are not available in Table 1, global parameters ngk are used. As a result, more than 68.2 % of the experimental data agree with the RES model within 3.2 % (corresponding to the standard deviation). For better reproducibility of this work, a Python package for viscosity calculation using the RES approach is provided in the SI, and sample viscosity calculations for each pure fluid are listed in Table S5 in the SI.

Relative deviations of the experimental viscosity ηexp from values ηRES calculated with the RES model. The short line indicates the average relative deviation; the shape shows the distribution of the relative deviation; and the colors are for a clear illustration only. Fluid-specific nk parameters are preferred, and only if they are not available in Table 1, global parameters ngk/ξ are used

Here we defined average relative deviation (ARD) and average of the absolute value of relative deviation (AARD) of the experimental values ηexp from the model calculations ηRES as:

where N is the total number of the experimental data points for a given fluid. The values of ARD and AARD denote the systematic offset and scatter, respectively, of the experimental data from the model. The ARD for each pure fluid are shown in Fig. 3 and the AARD are listed in Table S3 in the SI. Ideally, ARD should be approximately zero for pure fluids as the RES model for pure fluids is anchored to the experimental data. However, considering the existence of low-quality data and the possible uncertainties due to the modeling of the dilute gas, the absolute value of ARD for only 91 and 113 of the 124 pure fluids are less than 1.0 % and 2.0 %, respectively. For those with larger ARD, there are either only gas phase data available (e.g., R116, R161, and krypton), conflicting datasets (see the gourd-shaped pattern for isopentane, ammonia, and acetylene in Fig. 3), obviously inaccurate dilute gas viscosity calculation (xenon and butane, deviation plots not converge around zero at zero s+ limit, see the figures in the SI-DPR), or very few experimental data available (5 data only for cyclopropane). For pure fluids for which more than 1000 experimental data points are available, the absolute ARD values are generally less than 1.0 % and all are less than 2.0 %.

We compared the performance of the RES model with the recommended model of each pure fluid implemented in the REFPROP 10.0, short for REFPROP-models. The REFPROP-models are 41 reference correlations [31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66] for 43 pure fluids, the extended corresponding states (ECS) model [67,68,69] for 77 pure fluids, and the friction theory model [47, 70] for 3 pure fluids; details are documented in Table S2 in the SI. There is no viscosity model for NF3 in REFPROP 10.0. The REFPROP-models fail in the calculation of very few experimental data (less than 0.38 %, exceeding the model limit, see more details in Table S3 in the SI) at the given temperature and pressure. Detailed plots of the relative deviations of the experimental viscosity ηexp from values ηREFPROP calculated with the REFPROP-models for each experimental point are provided in 124 figures in the SI-DPR. The AARD from the experimental data to the RES model and the REFPROP-models are listed in Table S3 in the SI. The RES model yields smaller or equal AARD (i.e., smaller scatter) for 55 pure fluids out of 124 fluids compared to the REFPROP-models; this value becomes 61 out of 124 if the dilute gas viscosity in the RES model is calculated in the same way as the REFPROP-models do (achieved by setting pressure zero using the recommended models in REFPROP).

Additional comparisons were made to the RES approach developed by Lötgering-Lin et al. [19], where the residual entropy is calculated with the PCP-SAFT EoS [71]. The calculations with the PCP-SAFT EoS were carried out with the TREND 5.0 package [2] and the model parameters were obtained from the supporting information of Lötgering-Lin et al. [19]. The generalized RES approach developed by Dehlouz et al. [25] was not compared here as their approach is not yet developed for mixtures and the needed I-PC-SAFT EoS [72] or tc-PR cubic EoS [73] are not available to us. There are 35 pure fluids for which all three models (the REFPROP-models are considered as one model here) can be applied. For a fair comparison, approximately 6 % of the evaluated experimental data were further filtered out; these are mainly near the phase boundaries as the PCP-SAFT EoS predicts different phase boundaries than the multi-parameter reference EoS. Relative deviations of the experimental data from the three models are statistically shown in Fig. 4 and detailed plots are given in Fig. S4-4 in the SI. The ARD for the 35 fluids are shown in Fig. 4 and the AARD are listed in Table S6 in the SI. Our RES model yields the smallest AARD (i.e., smallest scatter) for 11 pure fluids while that for model of Lötgering-Lin et al. [19] is best for 3 fluids. According to Table S6, it is obvious that viscosity values calculated with Lötgering-Lin et al. model for ethanol and methanol (group 7) significantly deviate from experimental data (19.0 % and 44.2 %, respectively) and the other two models. This somehow supports their statement about their model: “almost all mixtures containing either methanol or ethanol are not well represented” [19]. It might attribute to the imperfection of their approach in linking viscosity and residual entropy for these two fluids, as the residual entropy calculated with both PCP-SAFT and the reference multi-parameter EoS generally agree with each other within 5 %.

Relative deviations of the experimental viscosity ηexp of pure fluids from values ηRES calculated with the RES model, REFPROP-models and model of Lötgering-Lin et al. [19]. The short line indicates the average relative deviation; the shape shows the distribution of the relative deviation; and the colors are for a clear illustration only. Relative deviations of the experimental data of ethanol and methanol from Lötgering-Lin et al. model generally exceed the figure limits

3.3 Prediction for Mixtures

For mixtures, a predictive mixing rule was used, see Sect. 2. More than 68.2 % of the evaluated experimental data agree with the RES model within 8 %. A summary is provided in Fig. 5 showing the ARD (systematic offset) and AARD (scatter) from the experimental data to the RES model for binaries among two groups. For binaries from the same group, the absolute value of ARD is generally less than 2 %; in particular, the ARD is only − 0.4 % for binaries within group 3 (4856 experimental data). For binaries from different groups, some are very good, e.g., 1982 data from groups 1 and 2 having an ARD of − 1.2 %, while some are relatively poor, e.g., 3368 data from groups 7 and 8 with an ARD of 17 %. There seems to be problems in the EoS for the residual entropy calculations of binaries from groups 7 and 8 (e.g., Ethanol + Water), as will be discussed in the next paragraph, the REFPROP-models which also rely on the EoS fails in most of the calculations for binaries from groups 7 and 8. Regarding asymmetric mixtures of industrial interest, such as refrigerants with lubricants (respectively in group 3 and possibly group 6), and hydrogen with heavy hydrocarbon (groups 1 and 5 or 6) [74], very few experimental data are available. Therefore, Fig. 5 reveals an AARD clearly beyond 10 % for groups 3 and 6, and for groups 1 and 5 or 6, the AARD cannot be calculated (no data available).

Statistical summary of the relative deviation of the experimental data from model calculations for binary mixtures. Top line: all evaluated experimental data; bottom line: evaluated experimental data were further filtered for the calculations using the REFPROP-models. ARD average relative deviation, AARD average of the absolute value of relative deviation, of the experimental values from the model calculations. Please note, for those without available data, ARD and ARRD are given a value of 0.0

We first compared the performance of the RES model and REFPROP-models in mixture prediction. Sample viscosity calculations using both RES model and REFPROP-models for each group pairs are listed in Table S7 in the SI. Please note, there are up to four additional binary interaction parameters for each binary in the ECS model (the most commonly adopted model in REFPROP-models), and these parameters are fitted to the available experimental data or otherwise are set to zero. Table S4 in the SI indicates which binary mixtures have binary interaction parameters fitted in the ECS model. The REFPROP-models fail to calculate 21 % of the evaluated experimental data at the given temperature and pressure, mainly belonging to binaries including groups 7 and 8, see details in Table S4. After removing these data, statistical results compared to the experimental data are shown in the bottom line of Fig. 5 and listed in Table S4 in the SI. More detailed plots are illustrated in 351 figures in the SI-DPR for each mixture. According to Table S4, the RES model yields lower AARD (scatter) for 161 mixtures out of all 351 mixtures; this value is 185 out of 351 if the dilute gas viscosity in the RES model is calculated in the same way as the REFPROP-models do. According to Fig. 5, the RES model yields lower AARD (scatter) for 12 group pairs out of 18 group pairs where experimental data are available.

We then added the model of Lötgering-Lin et al. [19] into the comparison. Considering that there are only 35 pure fluids for which all three models (the REFPROP-models are considered as one model here) can be applied for, the binary mixtures were narrowed down to only 158. For a fairer comparison, approximately 2.8 % of the evaluated experimental data at or near phase boundaries was further filtered out as the PCP-SAFT and the multi-parameter reference EoS predict different phase boundaries. The statistical summary of the comparison from experimental data to the three models are listed in Table S8 of the SI and illustrated for some mixtures in Fig. 6; more similar figures and detailed plots are given in Fig. S5 in the SI. According to Table S8, our RES model, the REFPROP-models, and the model of Lötgering-Lin et al. [19] have the best agreement with experimental data for 56, 69 and 33 mixtures, respectively. It is interesting to note that, for some binary mixtures, such as n-pentane + toluene, nonane + n-pentane, n-hexane + p-xylene, and decane + p-xylene (see figures in the SI-DPR) experimental data in the liquid phase have similar deviations with all three models, i.e., the models agree with each other while the experimental data deviate.

Relative deviations of the experimental viscosity ηexp of selected mixtures from values ηRES calculated with the RES model, REFPROP-models and model of Lötgering-Lin et al. [19]. The short line indicates the average relative deviation; the shape shows the distribution of the relative deviation; and the colors are for a clear illustration only

4 Conclusion, Discussion and Future Work

In this work, we present a simple but accurate RES approach for all 124 pure fluids whose reference EoS (implemented in REFPROP) and experimental viscosity data are available in the literature. This RES approach links viscosity to the residual entropy using a simple polynomial equation. More than 68.2 % (corresponding to the standard deviation) of the evaluated experimental data agree with the RES model within 3.2 % for pure fluids. The pure fluids are classified into eight groups, and fluids with similar physical properties are roughly in the same group. Experimental data of each group collapse into a global residual viscosity vs. scaled residual entropy curve. There is a relation between the fluid-specific scaling factor and the plus-scaled dimensionless residual entropy at the critical point. According to this and adopting the classification, the RES model could serve as a fully predictive model for other pure fluids. To use our RES model, a software package written in Python is provided; besides please note: fluid-specific fitted parameters should be used, and only if they are not available in Table 1, global fitted parameters are used.

Compared to the recommended models implemented in REFPROP 10.0, the state-of-the-art for thermophysical property calculation, the RES model yields smaller or equal average of the AARD from the experimental data for 55 pure fluids out of 124 fluids. If the dilute gas viscosity in the RES model is calculated in the same way as the REFPROP models do, this value becomes 61 out of 124. A sensitivity analysis shows that, for example, a 1.0 % change in the residual entropy yields 0.02 % and 1.0 % changes in the calculated viscosity in the gas and liquid phases, respectively. Therefore, future developments in the reference EoS, which improve the accuracy in the residual entropy calculation, should significantly improve the accuracy of the RES model, mainly in the liquid phase.

With a predictive mixing rule, more than 68.2 % of the evaluated experimental mixture data agree with the RES model within 8 %. More sophisticated mixing rules for each group pair might achieve better predictions, which would be our future work. Nonetheless, if dilute gas viscosity is calculated in the same way, the RES approach yields similar statistical agreement with the experimental data as the REFPROP-models, while the RES approach has much simpler formulation and fewer parameters.

Regarding future work, considering that the RES approach links viscosity to an EoS with a simple polynomial global equation and requires no extra parameters for mixtures, one could expect that it has great advantages (less complexity and faster calculation) in industrial applications, such as thermo-economic analysis for refrigerant and organic Rankine cycles. Under certain circumstances, if only liquid viscosity is considered (e.g., as is typical for lubricant oils which are more likely in group 6) only one extra parameter (the fluid-specific scaling factor) is needed to obtain a reliable viscosity value if an EoS is available. Therefore, interesting future work will be the exploration of the application of the developed RES model to industrial applications. Besides, in order to achieve a much faster calculation and much easier access to industry, suitable cubic EoS could be evaluated for each pure fluid.

Our next target is to explore the application of our RES approach to a specific group of asymmetric mixtures: light component refrigerants in group 3 mixed with heavy component lubricants which might belong to group 6. Accurate models of these mixtures are extremely important in developing next generation refrigerant systems, however, modeling viscosity of asymmetric mixtures remains a major challenge nowadays [74]. Modeling thermophysical properties of lubricants is demanding itself as commercially available lubricants are all mixtures with components and compositions barely possible to be determined accurately. Traditional thermophysical modeling approaches cannot be used for such lubricants, because these models are generally developed for pure fluids or mixtures with known components and compositions. To tackle this challenge, a novel approach should be developed: assuming each lubricant as a pseudo-pure fluid, characterizing each lubricant with fluid constants (e.g., critical temperature, critical pressure, fluid-specific scaling factor for viscosity, etc.), determining these fluid constants with minimal amount of experiments, and combining this approach to our current RES method.

Data Availability

1. Python package for residual entropy scaling model calculation.

2. A Supporting Information document including:

[Table of names, group and constants of pure fluids].

[Table of reference equation of state and the recommended viscosity model in REFPROP 10.0].

[Table for statistics of the experimental values of pure fluids].

[Table for statistical experimental data summary of fluid mixtures].

[Table for sample viscosity calculations of pure substances with the REFPROP 10.0 and the RES model].

[Table for comparisons of the deviations from experimental data to the three ‘models’].

[Table for sample viscosity calculations of binaries with the recommended models in REFPROP 10.0 and the RES model].

[Table for statistics of the comparison from experimental data to three models for mixtures].

[Figures for viscosity as a function of residual entropy for each group].

[Figures for relative deviation from experimental data of pure fluids to model predictions].

[Figures for relative deviation from experimental data of fluid mixtures to model predictions].

[Detail plots and the reference list of the whole experimental data source].

3. A Supporting Information document containing detailed plots and references of all collected experimental data.

References

E.W. Lemmon, I.H. Bell, M.L. Huber, M.O. McLinden, NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0 (National Institute of Standards and Technology, Gaithersburg, 2018)

R. Span, R. Beckmüller, S. Hielscher, A. Jäger, E. Mickoleit, T. Neumann, S. Pohl, TREND. Thermodynamic Reference and Engineering Data 5.0 (Lehrstuhl für Thermodynamik, Ruhr-Universität Bochum, Bochum, 2020)

I.H. Bell, J. Wronski, S. Quoilin, V. Lemort, Ind. Eng. Chem. Res. 53, 2498 (2014). https://doi.org/10.1021/ie4033999

R. Span, E.W. Lemmon, R.T. Jacobsen, W. Wagner, A. Yokozeki, J. Phys. Chem. Ref. Data 29, 1361 (2000). https://doi.org/10.1063/1.1349047

W. Wagner, A. Pruß, J. Phys. Chem. Ref. Data 31, 387 (2002). https://doi.org/10.1063/1.1461829

X. Yang, X. Xiao, E.F. May, I.H. Bell, J. Chem. Eng. Data 66, 1385 (2021). https://doi.org/10.1021/acs.jced.0c01009

M. Frenkel, R.D. Chirico, V. Diky, X. Yan, Q. Dong, C. Muzny, J. Chem. Inf. Model. 45, 816 (2005). https://doi.org/10.1021/ci050067b

S.Z.S. Al Ghafri, M. Akhfash, T.J. Hughes, X. Xiao, X. Yang, E.F. May, Fuel Process. Technol. 223, 106984 (2021). https://doi.org/10.1016/j.fuproc.2021.106984

X. Yang, A. Arami-Niya, X. Xiao, D. Kim, S.Z.S. Al Ghafri, T. Tsuji, Y. Tanaka, Y. Seiki, E.F. May, J. Chem. Eng. Data 65, 4252 (2020). https://doi.org/10.1021/acs.jced.0c00228

R. Span, R. Beckmüller, A. Jäger, E. Mickoleit, T. Neumann, S. Pohl, B. Semrau, M. Thol, TREND. Thermodynamic Reference and Engineering Data 6.0 (Lehrstuhl für Thermodynamik, Ruhr-Universität Bochum, Bochum, 2022)

I.H. Bell, R. Messerly, M. Thol, L. Costigliola, J.C. Dyre, J. Phys. Chem. B 123, 6345 (2019). https://doi.org/10.1021/acs.jpcb.9b05808

I.H. Bell, J. Chem. Eng. Data 65, 3203 (2020). https://doi.org/10.1021/acs.jced.0c00209

I.H. Bell, J. Chem. Eng. Data 65, 5606 (2020). https://doi.org/10.1021/acs.jced.0c00749

M. Binti Mohd Taib, J.P.M. Trusler, J. Chem. Phys. 152, 164104 (2020). https://doi.org/10.1063/5.0002242

H. Liu, F. Yang, Z. Yang, Y. Duan, J. Mol. Liq. 308, 113027 (2020). https://doi.org/10.1016/j.molliq.2020.113027

I.H. Bell, A. Laesecke, in 16th International Refrigeration and Air Conditioning Conference at Purdue, 11–14 July 2016

X. Wang, E. Wright, N. Gao, Y. Li, J. Therm. Sci. (2020). https://doi.org/10.1007/s11630-020-1383-2

I.H. Bell, Proc. Natl Acad. Sci. USA 116, 4070 (2019). https://doi.org/10.1073/pnas.1815943116

O. Lötgering-Lin, M. Fischer, M. Hopp, J. Gross, Ind. Eng. Chem. Res. 57, 4095 (2018). https://doi.org/10.1021/acs.iecr.7b04871

H. Liu, F. Yang, X. Yang, Z. Yang, Y. Duan, J. Mol. Liq. 330, 115612 (2021). https://doi.org/10.1016/j.molliq.2021.115612

W.A. Fouad, J. Chem. Eng. Data 65, 5688 (2020). https://doi.org/10.1021/acs.jced.0c00682

M. Hopp, J. Gross, Ind. Eng. Chem. Res. 56, 4527 (2017). https://doi.org/10.1021/acs.iecr.6b04289

M. Hopp, J. Mele, R. Hellmann, J. Gross, Ind. Eng. Chem. Res. 58, 18432 (2019). https://doi.org/10.1021/acs.iecr.9b03998

X. Yang, D. Kim, E.F. May, I.H. Bell, Ind. Eng. Chem. Res. 60, 13052 (2021). https://doi.org/10.1021/acs.iecr.1c02154

A. Dehlouz, R. Privat, G. Galliero, M. Bonnissel, J.-N. Jaubert, Ind. Eng. Chem. Res. 60, 12719 (2021). https://doi.org/10.1021/acs.iecr.1c01386

J.O. Hirschfelder, C.F. Curtiss, R.B. Bird, M.G. Mayer, Molecular Theory of Gases and Liquids (Wiley, New York, 1964)

P.D. Neufeld, A.R. Janzen, R.A. Aziz, J. Chem. Phys. 57, 1100 (1972). https://doi.org/10.1063/1.1678363

E. Tiesinga, P.J. Mohr, D.B. Newell, B.N. Taylor, J. Phys. Chem. Ref. Data 50, 033105 (2021). https://doi.org/10.1063/5.0064853

C.R. Wilke, J. Chem. Phys. 18, 517 (1950). https://doi.org/10.1063/1.1747673

I.H. Bell, S. Delage-Santacreu, H. Hoang, G. Galliero, J. Phys. Chem. Lett. 12, 6411 (2021). https://doi.org/10.1021/acs.jpclett.1c01594

S.A. Monogenidou, M.J. Assael, M.L. Huber, J. Phys. Chem. Ref. Data 47, 023102 (2018). https://doi.org/10.1063/1.5036724

E.W. Lemmon, R.T. Jacobsen, Int. J. Thermophys. 25, 21 (2004). https://doi.org/10.1023/B:IJOT.0000022327.04529.f3

S. Avgeri, M.J. Assael, M.L. Huber, R.A. Perkins, J. Phys. Chem. Ref. Data 43, 033103 (2014). https://doi.org/10.1063/1.4892935

S. Herrmann, E. Vogel, J. Phys. Chem. Ref. Data 47, 013104 (2018). https://doi.org/10.1063/1.5020802

M.J. Assael, T.B. Papalas, M.L. Huber, J. Phys. Chem. Ref. Data 46, 033103 (2017). https://doi.org/10.1063/1.4996885

M.L. Huber, A. Laesecke, R. Perkins, Energy Fuels 18, 968 (2004). https://doi.org/10.1021/ef034109e

X.Y. Meng, Y.K. Sun, F.L. Cao, J.T. Wu, V. Vesovic, J. Phys. Chem. Ref. Data 47, 033102 (2018). https://doi.org/10.1063/1.5039595

A. Laesecke, C.D. Muzny, J. Phys. Chem. Ref. Data 46, 013107 (2017). https://doi.org/10.1063/1.4977429

U. Tariq, A.R.B. Jusoh, N. Riesco, V. Vesovic, J. Phys. Chem. Ref. Data 43, 033101 (2014). https://doi.org/10.1063/1.4891103

C.D. Muzny, M.L. Huber, A.F. Kazakov, J. Chem. Eng. Data 58, 969 (2013). https://doi.org/10.1021/je301273j

M.L. Huber, A. Laesecke, H.W. Xiang, Fluid Phase Equilib. 228–229, 401 (2005). https://doi.org/10.1016/j.fluid.2005.03.008

X. Meng, J. Zhang, J.T. Wu, Z.-G. Liu, J. Chem. Eng. Data 57, 988 (2012). https://doi.org/10.1021/je201297j

X.Y. Meng, F.L. Cao, J.T. Wu, V. Vesovic, J. Phys. Chem. Ref. Data 46, 013101 (2017). https://doi.org/10.1063/1.4973501

E. Vogel, R. Span, S. Herrmann, J. Phys. Chem. Ref. Data 44, 043101 (2015). https://doi.org/10.1063/1.4930838

S.B. Kiselev, J.F. Ely, I.M. Abdulagatov, M.L. Huber, Ind. Eng. Chem. Res. 44, 6916 (2005). https://doi.org/10.1021/ie050010e

P.M. Holland, B.E. Eaton, H.J.M. Hanley, J. Phys. Chem. Ref. Data 12, 917 (1983). https://doi.org/10.1063/1.555701

K.A.G. Schmidt, S.E. Quiñones-Cisneros, J.J. Carroll, B. Kvamme, Energy Fuels 22, 3424 (2008). https://doi.org/10.1021/ef700701h

V. Arp, R. McCarty, D. Friend, Thermophysical Properties of Helium-4 from 0.8 to 1500 K with Pressures to 2000 MPa. Technical Note 1334 (NIST, Boulder, 1998)

E.K. Michailidou, M.J. Assael, M.L. Huber, I.M. Abdulagatov, R.A. Perkins, J. Phys. Chem. Ref. Data 43, 023103 (2014). https://doi.org/10.1063/1.4875930

E.K. Michailidou, M.J. Assael, M.L. Huber, R.A. Perkins, J. Phys. Chem. Ref. Data 42, 033104 (2013). https://doi.org/10.1063/1.4818980

E. Vogel, C. Küchenmeister, E. Bich, Int. J. Thermophys. 21, 343 (2000). https://doi.org/10.1023/A:1006623310780

H.W. Xiang, A. Laesecke, M.L. Huber, J. Phys. Chem. Ref. Data 35, 1597 (2006). https://doi.org/10.1063/1.2360605

F.L. Cao, X.Y. Meng, J.T. Wu, V. Vesovic, J. Phys. Chem. Ref. Data 45, 013103 (2016). https://doi.org/10.1063/1.4941241

F. L. Cao, X. Y. Meng, J. T. Wu, and V. Vesovic, J. Phys. Chem. Ref. Data 45, 023102 (2016). https://doi.org/10.1063/1.4945663

E. Vogel, C. Küchenmeister, E. Bich, A. Laesecke, J. Phys. Chem. Ref. Data 27, 947 (1998). https://doi.org/10.1063/1.556025

B. Balogun, N. Riesco, V. Vesovic, J. Phys. Chem. Ref. Data 44, 013103 (2015). https://doi.org/10.1063/1.4908048

Y. Tanaka, T. Sotani, Int. J. Thermophys. 17, 293 (1996). https://doi.org/10.1007/BF01443394

M.L. Huber, M.J. Assael, Int. J. Refrig. 71, 39 (2016). https://doi.org/10.1016/j.ijrefrig.2016.08.007

M.L. Huber, A. Laesecke, Ind. Eng. Chem. Res. 45, 4447 (2006). https://doi.org/10.1021/ie051367l

M.L. Huber, A. Laesecke, R.A. Perkins, Ind. Eng. Chem. Res. 42, 3163 (2003). https://doi.org/10.1021/ie0300880

Ch.M. Tsolakidou, M.J. Assael, M.L. Huber, R.A. Perkins, J. Phys. Chem. Ref. Data 46, 023103 (2017). https://doi.org/10.1063/1.4983027

Z. Shan, S.G. Penoncello, R.T. Jacobsen, A Generalized Model for Viscosity and Thermal Conductivity of Trifluoromethane (R-23) (American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., Atlanta, 2000)

R.A. Perkins, M.L. Huber, M.J. Assael, J. Chem. Eng. Data 61, 3286 (2016). https://doi.org/10.1021/acs.jced.6b00350

S.E. Quiñones-Cisneros, M.L. Huber, U.K. Deiters, J. Phys. Chem. Ref. Data 41, 023102 (2012). https://doi.org/10.1063/1.3702441

S. Avgeri, M.J. Assael, M.L. Huber, R.A. Perkins, J. Phys. Chem. Ref. Data 44, 033101 (2015). https://doi.org/10.1063/1.4926955

M.L. Huber, R.A. Perkins, A. Laesecke, D.G. Friend, J.V. Sengers, M.J. Assael, I.N. Metaxa, E. Vogel, R. Mareš, K. Miyagawa, J. Phys. Chem. Ref. Data 38, 101 (2009). https://doi.org/10.1063/1.3088050

J.C. Chichester, M.L. Huber, Documentation and Assessment of the Transport Property Model for Mixtures Implemented in NIST REFPROP (Version 8.0) (National Institute of Standards and Technology, Gaithersburg, 2008)

M.L. Huber, Models for Viscosity, Thermal Conductivity, and Surface Tension of Selected Pure Fluids as Implemented in REFPROP V10.0 (NIST, Gaithersburg, 2018)

M.L. Hubet, J.F. Ely, Fluid Phase Equilib. 80, 239 (1992). https://doi.org/10.1016/0378-3812(92)87071-T

S.E. Quiñones-Cisneros, U.K. Deiters, J. Phys. Chem. B 110, 12820 (2006). https://doi.org/10.1021/jp0618577

J. Gross, G. Sadowski, Ind. Eng. Chem. Res. 40, 1244 (2001). https://doi.org/10.1021/ie0003887

E. Moine, A. Piña-Martinez, J.-N. Jaubert, B. Sirjean, R. Privat, Ind. Eng. Chem. Res. 58, 20815 (2019). https://doi.org/10.1021/acs.iecr.9b04660

Y. Le Guennec, R. Privat, J.-N. Jaubert, Fluid Phase Equilib. 429, 301 (2016). https://doi.org/10.1016/j.fluid.2016.09.003

M. Thol, M. Richter, Int. J. Thermophys. 42, 161 (2021). https://doi.org/10.1007/s10765-021-02905-x

Funding

Open Access funding enabled and organized by Projekt DEAL. The realization of the project and the scientific work was supported by the German Federal Ministry of Education and Research on the basis of a decision by the German Bundestag (Funding Code 03SF0623A). The authors gratefully acknowledge this support and carry the full responsibility for the content of this paper.

Author information

Authors and Affiliations

Contributions

XY: Conceptualization, Methodology, Software, Validation, Formal analysis, Investigation, Writing—original draft, Visualization, Data curation. XX: Resources, Data curation, Writing—review and editing. MT: Validation, Writing—review and editing. MR: Resources, Writing—review and editing, Funding acquisition. IHB: Conceptualization, Methodology, Resources, Validation, Writing—review and editing, Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, X., Xiao, X., Thol, M. et al. Linking Viscosity to Equations of State Using Residual Entropy Scaling Theory. Int J Thermophys 43, 183 (2022). https://doi.org/10.1007/s10765-022-03096-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-022-03096-9