Abstract

The paper describes the metrological characterization of the highly stable Pt-40%Rh/Pt-6%Rh thermocouples to determine their reference function in the temperature range between 0 °C and 1769 °C. The preparation of the Pt-40%Rh/Pt-6%Rh thermocouples is described, as well as the measurement procedures and the measurement results of comparison and fixed point measurements for the determination of the reference function with low uncertainties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The current state of the art for contact thermometry measurements between about 1000 °C and 1600 °C includes the known platinum/rhodium alloyed thermocouples, Type R (Pt-13%Rh vs. Pt), Type S (Pt-10%Rh vs. Pt), and Type B (Pt-30%Rh vs. Pt-6%Rh). Their advantage is that they can be used at very high temperatures up to about 1750 °C (Types R and S) and up to about 1820 °C (Type B), but at temperatures above about 1200 °C additional drifts occurs mainly due to the increase in thermoelectric inhomogeneity. This degradation requires their regular calibration, especially when highly accurate measurements are required. Furthermore, pure platinum tends to accelerate in grain growth at high temperatures, which affects the mechanical stability of the thermoelements. To the authors’ knowledge the selection of Pt–Rh alloys in common use (i.e. Type R, S, B [1] and Land-Jewell [2]) have not been subjected to optimization [3]. Recent investigation showed that the high temperature thermoelectric stability of Pt–Rh alloy wires improves with the mass fraction of Rh [4]. If significant contamination of the wires is not taken into account, the most important factor governing thermoelectric stability and homogeneity of Pt–Rh wires is probably oxide vapor transport processes [5,6,7,8]. In the frame of the EMPIR project EMPRESS [9] a model to relate the electromotive force (emf) drift rate of Pt–Rh thermoelements to dS/dc, i.e. the sensitivity of the Seebeck coefficient, S, to rhodium mass fraction, c, the optimal composition of the pair of Pt–Rh wires that minimizes thermoelectric drift was determined [10]. The model has been applied to four multi-wire thermocouples each comprising 5 or 7 Pt–Rh wires of different composition. Three of them were exposed to different temperatures of approximately 1324 °C and 1492 °C, i.e. the melting points of the Co–C and Pd–C high temperature fixed points [11, 12], respectively. One thermocouple was exposed to a series of temperatures between 1315 °C and 1450 °C. As a result of this long-term study (up to 6000 h), an optimal low drift combination of two thermoelements was identified: the Pt-40%Rh vs. Pt-6%Rh thermocouple. The performance was significantly better than the conventional types and therefore are expected to have better performance. In order to facilitate the widespread use of this new Pt-40%Rh vs. Pt-6%Rh thermocouple type, its emf-temperature reference function has been established by different National Metrology Institutes (NMIs).

This paper describes the determination of the emf-temperature reference function for Pt-40%Rh vs. Pt-6%Rh thermocouples and is structured as follows: Sect. 2 describes the preparation of the thermocouples, Sect. 3 presents details of the experimental procedure and in Sect. 4 the measurement data are summarized. The construction of the emf-temperature reference function is described in Sect. 5, and its uncertainty in Sect. 6.

2 Preparation of Thermocouples

The Pt-40%Rh and Pt-6%Rh thermoelements used to construct a total of 11 thermocouples were manufactured by Johnson Matthey (UK) and distributed to the participating institutes. The thermocouple wires had a diameter of 0.5 mm and had been taken from the same batch, respectively. The thermocouples were constructed and thermoelectrically stabilized at PTB (3 + 1 (for DTI)), NPL (2 + 1 (for UL)), CEM (2), CMI (1), and TUBITAK (1) according to the following procedure:

-

Cleaning of the thermoelements (pure ethanol and distilled water)

-

Electrical anneal of each thermoelement at 1300 °C for 4 h in air

-

Assembling of the thermoelements in a twin-bore sheath (diameter ≥ 4 mm, length: ≥ 600 mm)

-

Furnace anneal of the thermocouple at 1350 °C for at least 200 h in air to improve the thermoelectric stability

-

Repeated measurements of the thermocouple emf during furnace anneal at the freezing point of copper as a check of its thermoelectric stability after about 10 and 50 h and then in steps of about 50 h. The emf difference between the last two measurements at the freezing point of copper should be less than 0.5 µV (≈50 mK) indicating sufficient thermoelectric stability

-

Check of the thermoelectric homogeneity in a liquid bath at 400 °C or in a suitable furnace at a temperature not higher than 550 °C after the furnace annealing at 1350 ºC and after achieving the requested thermoelectric stability

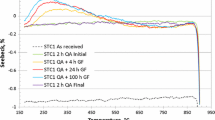

The results for measuring the initial thermoelectric stability of the thermocouples at the freezing point of copper (1084.62 °C) are shown in Fig. 1. With the exception of the thermocouple CMI-01, all thermocouples achieved the mentioned stability criterion (difference lower than 0.5 µV between two consecutive measurements at Cu fixed point) after (200–440) h annealing at 1350 °C. Also remarkable is the agreement of the measured thermoelectric voltages of all thermocouples at the Cu freezing point within a temperature equivalent of about 1 K.

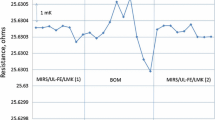

The Pt-40%Rh vs. Pt-6%Rh thermocouples PTB E2-18-02 and NPL TC1 were sent to DTI and UL respectively, to perform the measurements there. The other thermocouples were used at the manufacturer laboratories for the determination of the emf-temperature reference function. With the thermocouple PTB E2-18-05, long-term tests were carried out at 1350 °C and 1400 °C with repeated checks of its thermoelectric voltage at the freezing temperature of copper (1084.62 °C). The results of the emf measurements at the freezing point of Cu point are presented in Fig. 2. The combined uncertainty of the measurements (k = 1) was 1.1 µV. They revealed an exceptionally high thermoelectric stability of the thermocouple E2-18-05. After about 550 h, the thermoelectric voltage at the Cu point remained stable within ± 0.5 µV, which corresponds to a temperature equivalent of about ± 50 mK. During the next 500 h of annealing at 1350 °C, the emf at the copper point increased by approx. 0.4 µV, which corresponds to a drift rate of + (7–8) mK per 100 h. In the further annealing process at 1350 °C, a drift rate of about + 3 mK·100 h−1 was obtained. The increase of the ageing temperature from 1350 °C to 1400 °C after about 2690 h was accompanied with a slight decrease in the emf at the Cu point by about 0.5 µV. The calibration furnace used for the measurements at the freezing point of Cu failed after about 4000 h annealing time of the thermocouple PTB E2-18-05. The different temperature profile of the second furnace used to check the emf at the freezing point of copper caused a further slightly negative drop of the emf by about 0.6 µV. By correcting this effect, the emf at the freezing point of copper remained stable within about ± 0.5 µV. These results of the thermoelectric stability are used in Sect. 6 as one uncertainty contribution to calculate the uncertainty of the reference function.

3 Experimental Procedure

All the measurements to determine the emf-temperature reference function of Pt-40%Rh vs. Pt-6%Rh thermocouples are traceable to the International Temperature Scale of 1990 (ITS-90) [13]. Two types of measurements were performed. The first type was performed in isothermal enclosures where the reference temperature is determined by calibrated standard thermometers, (comparison method) and the second type at fixed points of the ITS-90. Both methods were collected in the temperature range between 0 °C and 1769 °C. The measurements were performed at increasing temperatures to avoid the influence of possible high temperature irreversible structural changes of the thermoelements on the properties of the reference function in the lower temperature range (T < 1100 °C). The following general principles were applied:

-

The comparison measurements provide the most data points and were therefore considered as the key task for the determination of the reference function

-

Fixed point measurements were carried out mainly to check the thermoelectric stability of the Pt-40%Rh vs. Pt-6%Rh thermocouples during the measurements by comparison, but were also used to determine the reference function

-

Repeated homogeneity tests of the Pt-40%Rh vs. Pt-6%Rh thermocouples were performed

Before starting the measurements, the Pt-40%Rh vs. Pt-6%Rh thermocouples were annealed at 400 °C for 24 h so that all thermocouples were in the same thermoelectric state. The calibrations of the Pt-40%Rh vs. Pt-6%Rh thermocouples were performed step by step over different temperature ranges. The standard thermometers used for the comparison measurements as well as the thermocouples themselves were calibrated at fixed points initially, followed by two runs of comparison measurements in the respective temperature range, and a recalibration of the Pt-40%Rh vs. Pt-6%Rh thermocouples at the same fixed points as initially. At the end of each of the cycles the thermoelectric homogeneity of the Pt-40%Rh vs. Pt-6%Rh thermocouples was tested at 400 °C. The following temperature ranges were chosen:

-

(a)

0–400 °C (Fixed points: Ice-point, Ga, In, Sn, Zn. 2 cycles of comparison measurements with temperature steps of 25 °C in water bath + oil bath + salt bath or dry block calibrator. Fixed points: Ice-point, Ga, In, Sn, Zn)

-

(b)

400–1000/1100 °C (Fixed points: Al, Ag, Cu. 2 cycles of comparison measurements in salt bath and/or furnaces with temperature steps of (25–30) °C. Fixed points: Al, Ag, Cu). Due to the critical temperature range (500–950) °C with preferential rhodium oxidation, the Pt-40%Rh vs. Pt-6%Rh thermocouples were annealed for 4 h at 1100 °C (causes the dissociation of surface oxide layers) and 24 h at 400 °C (causes short-range-ordering effects), This annealing was performed after the initial fixed point measurements and before starting the first run of the comparison measurements. After finishing the first run of comparison measurements, the additional annealing procedure (4 h at 1100 °C and 24 h at 400 °C) of the thermocouples was repeated). Thereafter, the second run of comparison measurements was performed. At the end of the 2nd run, the thermocouples were annealed again for 4 h at 1100 °C and 24 h at 400 °C, before the Pt-40%Rh vs. Pt-6%Rh thermocouples were calibrated at fixed points as described above.

-

(c)

1000–1350 °C (Fixed points: Cu, Fe–C, Co–C or Ni–C. 2 cycles of comparison measurements at furnaces with temperature steps of (25–30) °C. Fixed points: Cu, Fe–C, Co–C or Ni–C)

-

(d)

Temperatures above 1350 °C (Fixed points: Pd–C, Pd, Rh–C, Pt. 2 cycles of comparison measurements at furnace with temperature steps of about 25 °C. Fixed points: Pd–C, Pd, Rh–C, Pt)

Table 1 summarizes information about the temperature ranges of the comparison measurements, the apparatus, and standard thermometers used in the different laboratories.

4 Experimental Results

According to the procedure described in Sect. 3 the ten Pt-40%Rh vs. Pt-6%Rh thermocouples were calibrated by comparison (25/30 °C steps) and at fixed points as summarized in Table 2.

For each of the 10 Pt-40%Rh vs. Pt-6%Rh thermocouples different numbers of temperature/emf pairs were obtained, between 21 (TUBITAK-01) and 77 (CEM-2018–1/2). The data of the thermocouples CEM-2018-1 and CEM-2018-2 covered the widest temperature range and the difference between them was smaller than the expanded uncertainty. As stated in [14], least squares fitting to determine the emf-temperature relationship of a thermocouple is valid only if all data are from one thermocouple or if the data are from a set of statistically indistinguishable thermocouples. Therefore, based on all data measured, the data of the CEM thermocouples were chosen for construction of the reference function.

The immersion profiles of the both CEM thermocouples measured at 400 °C in a vertical furnace demonstrated a good thermoelectric homogeneity as shown in Fig. 3. Maximum emf deviations over the length of homogeneous temperature in the furnace (about 20 cm) are lower than ± 1 µV, even after the thermocouples were exposed to the highest temperatures at the melting points of Rh–C (1657 °C) and of platinum (1769 °C).

The measurements of both CEM thermocouples at the fixed points showed a good agreement between them in their emf values within a temperature equivalent lower than 1 K. Only the emf values at the Rh–C eutectic fixed point revealed a difference of about 1.7 K between the two CEM thermocouples. Table 3 contains the mean thermoelectric voltages calculated from the emfs measured at the fixed points, before and after the comparison measurements were carried out in the individual temperature ranges (see Sect. 3). The related emf differences and temperature differences between the both CEM thermocouples are also presented.

5 Construction of the emf-Temperature Reference Function

Two runs between 25 °C and 1550 °C in steps of about 25 K were measured with both CEM thermocouples. The mean values of four nominal emf measurements at each temperature were taken into account for the determination of the reference function. Additionally, the mean emfs measured at the fixed points of the ITS-90 listed in Table 3 were used with the exception of the emfs of the freezing point of Cu and the melting point of Co–C eutectic. These two emf values showed unexplained deviations from the fitting curves. It should be noted that the Rh–C (1657 °C) and the Pt (1769 °C) melting points were measured at PTB to extend the temperature range. In this way, in total 69 emf/temperature pairs were taken into account. The reference function is a weighted least squares polynomial fit with the form of Eq. 1 where the thermoelectric voltage emf is in µV and temperature t in °C (1):

Weights equal u–2, where u is the reported standard uncertainty of a particular measurement. Goodness of the fit is evaluated with the “root mean square” (rms) values due to error. Table 4 gives the rms values of different trial fits.

According to Table 4, the combination of a 6th degree polynomial below the temperature of the freezing point of Al (660,323 °C) and an 8th degree polynomial above the Al freezing point gives an adequately low rms value. Continuity is achieved by defining the proper starting point of the second polynomial with a very high weight value. The coefficients of the final reference function are listed in Table 5.

6 Uncertainty of the Reference Function

The uncertainties of the single emf data of the CEM thermocouples are summarized in Table 6 and discussed below. Table 6 contains the maximum uncertainty contributions ui in µV and in different temperature ranges, which were used to calculate the uncertainties of the single emf values.

The repeatability (Type A uncertainty) is the standard deviation of the emf-readings of the two CEM thermocouples. The stability of the isothermal enclosures (baths and furnaces) was estimated from the temperature fluctuations measured by one of the reference thermometers. The uncertainty of the reference thermometer calibration was calculated from their calibrations at fixed points. Their drifts are the differences of the readings before and after the comparison measurement runs at a fixed point of the corresponding temperature range. The homogeneity of the isothermal enclosure was evaluated, at each measurement point, by the difference between the two standard thermometers. The uncertainty of the electrical measurement includes the calibration uncertainty of the voltmeter used, its resolution and its drift. The voltmeter was calibrated every day and the 24 h stability specification of the manufacturer was chosen as the uncertainty contribution of the drift. The thermoelectric homogeneity emfhom of the thermocouples was measured at 400 ºC. This value was extrapolated to each temperature T according to Eq. 2:

A maximum emfhom(400 °C) value of 0.5 µV of was considered. The uncertainty due to the thermoelectric stability of the CEM thermocouples were calculated using the results of the long-term investigation of the Pt-40%Rh vs. Pt-6%Rh thermocouple, PTB E2-18-05, at 1350 °C (2686 h) and subsequently at 1400 °C (1815 h) with repeated checks of the thermoelectric voltage at the freezing point temperature of copper (1084.62 °C). After about 500 h, the thermoelectric voltage at the Cu point remained stable within ± 0.5 µV, which corresponds to a temperature equivalent of less than ± 50 mK. The value emfstab of 0.5 µV was used to calculate uncertainty contribution due to the thermoelectric stability at the different temperatures according to Eq. 3:

The expanded uncertainty (k = 2) of the reference function is the sum of the point by point expanded uncertainties of the single emf values and of the absolute fitting residuals. It can be roughly approximated with a 4th order polynomial (Fig. 4), which results in uncertainties that increase from about 2 µV at low temperatures up to about 450 °C, to 5 µV at 800 °C, to 10 µV at 1200 °C and to 37 µV at 1769 °C. This corresponds to temperature equivalents of approximately 0.4 K at 450 °C, 0.5 K at 800 °C, 0.8 K at 1200 °C and almost 3 K at 1769 °C. It should be noted, that the Seebeck coefficient at temperatures below about 250 °C is lower than 3 µV·K−1. This low thermoelectric sensitivity makes the usage of the Pt-40%Rh vs. Pt-6%Rh not useful at temperatures below 250 °C.

7 Summary

Based on the results of comparison and fixed point measurements using two Pt-40%Rh/Pt-6%Rh thermocouples, a reference function in the temperature range between 0 °C and 1769 °C was determined for this new thermocouple type. The expanded uncertainty of this reference function between about 250 °C and 800 °C is about 0.5 K. It increases to about 1 K at 1350 °C, 1.6 K at 1550 °C, and 3 K at 1769 °C. The special feature of the Pt-40%Rh vs. Pt-6%Rh thermocouples is the fact that the composition of the thermocouple wires was based first time on an optimization which should guarantee only low drifts at high temperatures (T > 1100 °C). Therefore, the main application temperatures of this new thermocouple type are temperatures above 1100 °C where the high thermoelectric stability becomes particularly apparent.

References

R.M. Park, R.M. Carroll, P. Bliss, Manual on The Use of Thermocouples in Temperature Measurement, 4th edn. (American Society for Testing and Materials, Ann Arbor, MI, 1993)

R.E. Bedford, Reference tables for platinum-40% rhodium/platinum-20% rhodium thermocouples. Rev. Sci. Instrum. 36, 1571–1580 (1965)

P.A. Kinzie, Thermocouple Temperature Measurement (Wiley, New York, 1973)

F. Edler, P. Ederer, Thermoelectric homogeneity and stability of platinum-rhodium alloyed thermoelements of different compositions. AIP Conf. Proc. 1552, 532 (2013)

J.V. Pearce, Optimising platinum-rhodium thermocouple wire composition to minimise composition change due to evaporation of oxides. Johnson Matthey Technol. Rev. 60, 238–242 (2016)

J.C. Chaston, The oxidation of the platinum metals. Platin. Metals Rev. 19, 135 (1975)

C.B. Alcock, G.W. Hooper, Thermodynamics of the gaseous oxides of the platinum-group metals. Proc. R. Soc. 254, 551 (1960)

E.S. Webster, A.G. Greenen, J.V. Pearce, Measurement of the inhomogeneity in type B and Land-Jewell noble-metal thermocouples. Int. J. Thermophys. 37, 70 (2016)

J.V. Pearce, EMPRESS: a pan-European project to enhance manufacturing process efficiency through improved temperature control. Meas. Control 49, 252–255 (2016). https://doi.org/10.1177/0020294016656892

J.V. Pearce et al., A systematic investigation of the thermoelectric stability of Pt–Rh thermocouples between 1300 °C and 1500 °C. Metrologia 55, 558 (2018)

G. Machin, Twelve years of high temperature fixed point research: a review. AIP Conf. Proc. 1552, 305 (2013). https://doi.org/10.1063/1.4821383

R. Morice, F. Edler, J. Pearce, G. Machin, J. Fischer, J.R. Filtz, High-temperature fixed-point facilities for improved thermocouple calibration—Euromet project 857. Int. J. Thermophys. 29, 231–240 (2008)

H. Preston-Thomas, The International Temperature Scale of 1990 (ITS-90). Metrologia 27, 3–10 (1990)

G.W. Burns, D.C. Ripple, M. Battuello, Platinum versus palladium thermocouples: an emf-temperature reference function for the range 0 C to 1500 C. Metrologia 35, 761–780 (1998). https://doi.org/10.1088/0026-1394/35/5/6

Acknowledgements

The project 17IND04 EMPRESS 2 has received funding from the EMPIR program co-financed by the Participating States and from the European Union's Horizon 2020 research and innovation program. The research was also supported partially by the Ministry of Economic Development and Technology, Metrology Institute of the Republic of Slovenia, in scope of contract 6401-18/2008/70 for the national standard laboratory for the field of thermodynamic temperature and humidity.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Edler, F., Bojkovski, J., Garcia Izquerdo, C. et al. Pt-40%Rh Versus Pt-6%Rh Thermocouples: An emf-Temperature Reference Function for the Temperature Range 0 °C to 1769 °C. Int J Thermophys 42, 150 (2021). https://doi.org/10.1007/s10765-021-02895-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-021-02895-w