Abstract

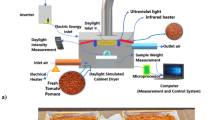

In recent years, the growth of the solar energy photovoltaic industry has greatly promoted the development of polysilicon. However, there has been little research into the slurry by-products of polysilicon production. In this paper the thermal performance of polysilicon slurry was studied in an industrial drying process with a twin-screw horizontal intermittent dryer. By dividing the drying process into several subunits, the parameters of each unit could be regarded as constant in that period. The time-dependent changes in parameters including temperature, specific heat and evaporation enthalpy were plotted. An equation for the change in the heat transfer coefficient over time was calculated based on heat transfer equations. The concept of a distribution coefficient was introduced to reflect the influence of stirring on the heat transfer area. The distribution coefficient ranged from 1.2 to 1.7 and was obtained with the fluid simulation software FLUENT, which simplified the calculation of heat transfer area during the drying process. These experimental data can be used to guide the study of polysilicon slurry drying and optimize the design of dryers for industrial processes.

Similar content being viewed by others

Abbreviations

- Q :

-

Heat (J)

- K :

-

Heat transfer coefficient (W\(\cdot \hbox {m}^{-2}\cdot \hbox {K}\))

- A :

-

Heat transfer area \((\hbox {m}^{2})\)

- c:

-

Specific heat of solid slug (kJ \(\cdot \) kg\(^{-1}\) \(\cdot {^{\circ }}\)C)

- \(\Delta H\) :

-

Evaporation enthalpy (kJ \(\cdot \) kg\(^{-1}\))

- \(A_\mathrm{work}\) :

-

Working area of dryer \((\hbox {m}^{2})\)

- \(A_\mathrm{rest}\) :

-

Resting area of dryer \((\hbox {m}^{2})\)

- \(A _\mathrm{barrel}\) :

-

Area of barrel \((\hbox {m}^{2})\)

- \(A _\mathrm{head}\) :

-

Area of heat \((\hbox {m}^{2})\)

- \(\Delta t_\mathrm{m}\) :

-

Arithmetic (logarithmic) mean temperature difference (\({^{\circ }}\)C)

- \(Q_\mathrm{sensible }\) :

-

Sensible heat (J)

- \(Q_\mathrm{latent }\) :

-

Latent heat (J)

- d :

-

Diameter of dryer (mm)

- L :

-

Length of dryer (mm)

- h :

-

Height of fullness (mm)

- \(\alpha \) :

-

Central angle of slurry cross section (\({^{\circ }})\)

- \(\xi \) :

-

Distribution coefficient

References

X.P. Bo, Chem. Ind. 26, 7 (2008)

W.O. Filtvedt, A. Holt, Sol. Energy Mat. Sol. C. 107, 188 (2012)

X.L. Niu, L.C. Cai, F.C. He, Heibei. Ind. Sci. Technol. 32, 5 (2014)

D.A. Seifert, M.F. Browning, Proc. Energy Metal. Miner. 218, 78 (1982)

H. Dalaker, M. Syvertsen, E. Ovrelid, Conference Record of the IEEE Photovoltaic Specialists Conference (2010), pp. 2157–2161

J.T. Heath, C.S. Jiang, H.R. Moutinho, San Francisco, CA 25, 30 (2010)

H. Xie, Guangdong Chem. Ind. 38, 1 (2011)

Y. Tao, Guizhou. Chem. Ind. 34, 3 (2009)

D.H. Li, TianJin University (2012)

H.J. Zeng, XinJiang. Chem. Ind. 35, 2 (2008)

H.S. Kim, M.S. Shin, D.S. Jang, E.S. Na, J. Environ. Sci. Health A 40, 1 (2012)

F.T. Ademiluyi, M.F.N. Abowei, Y.T. Puyate, Dry. Technol. 28, 550 (2010)

P.S.T. Sai, Dry. Technol. 31, 213 (2013)

E.N. Gnezdov, Stro. Mater. 6, 14 (2005)

S.B. Mabrouk, B. Khiari, M. Sassi, Appl. Therm. Eng. 26, 17 (2006)

C.J. Chai, Chemical Fluid Flow and Heat Transfer, 3rd edn. (Chemical Industry Press, Beijing, China, 2007)

S.S. Waje, B.N. Thorat, A.S. Dry, Technol. 24, 3 (2007)

T.E. Tan, Principle of Process Engineering, 2nd edn. (Chemical Industry Press, Beijing, China, 2007)

Z.M. Wang, TianJin University (2012)

K.L. Shao, Jiangsu Ind. 1, 49 (1991)

G.X. Li, S. Fu, Y. Liu, Energ. Convers. Manage. 50, 7 (2009)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Ma, D., Liu, Y. et al. Experimental Study of Heat Transfer Performance of Polysilicon Slurry Drying Process. Int J Thermophys 37, 120 (2016). https://doi.org/10.1007/s10765-016-2130-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-016-2130-5