Abstract

Temperature actions on metals and alloys usually stimulate the development of irreversible processes of structural evolution. Dilatometric hysteresis can be considered as the total effect of such processes. The elementary mechanisms affecting the sample size upon heating are known to be the thermal expansion of materials, the phase and structural transformations, the ductile flow under its own weight, and the creep stimulated by internal stresses. Each of these mechanisms has specific features, which are unavoidably reflected by the shape of the dilatometric curves in the corresponding temperature ranges. The thermal activation parameters of the mechanisms controlling the kinetics of the change in structural parameters and the development of the corresponding size effects have been determined by photometric analysis of structural images and directly from the dilatometric curves, and the results are discussed in this paper.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The structural mechanisms of physical processes in solids are of interest for two reasons: (1) their understanding opens ways for the development of processing technologies for improvement in mechanical characteristics of materials and (2) their knowledge allows one to refine the boundaries of the thermal stability of the structure of materials and their corresponding properties. Both factors are equally important for the reliable operation of technical equipment and systems. Materials can lose their properties under the action of operating conditions. The general definition of the stability of material structure and properties can be obtained by using a criterion such as the area enclosed by the curve of dilatometric hysteresis. Its shape contains information about the kinetics of the elementary processes, which contribute to the change in the sample size, and their comparative effectiveness in different temperature ranges. Such application of dilatometric analysis converts it into an indirect method of structural studies, which serves as a useful addition to direct structural methods. The information obtained from the dilatometric studies is of integral nature, it is recorded in the continuous regime, and it is known and extensive in volume. By contrast, when obtained by direct methods, such information is local, discrete, and limited in volume. The results of the direct and indirect methods of structural analysis can be correctly compared for the case where studies of identical types of samples are performed under identical experimental conditions. These requirements can be satisfied if the samples, after dilatometric experiments, are investigated by the method of photometric analysis of structural images (PhASI).

2 Experimental

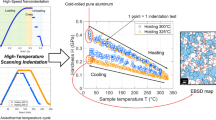

Cylindrical samples of 5 mm in diameter and 15 mm in length were prepared from the Al–14.6 %Zn alloy. Before the samples were put into the working cell of a DL-1500RH high-speed dilatometer, their lateral surfaces were photographed, and their images in digital code were introduced into the computer memory, where the spectrum of the brightness of visible light reflection was recorded. After the dilatometric experiment, the same surface of the sample was photographed again, its image was introduced into the computer, and the spectrum of the brightness of visible light reflection was recorded again. In this case, the photographic conditions and the regimes of the image editing during their introduction into the computer and subsequent analysis remained identical. It is known that the reflection and absorption of light by the surface of a material result from the interaction of photons with valence electrons. This interaction causes the alternating surface current, which creates an electromagnetic field in metallic bodies. The photons of this field are emitted by the surface of the material and recorded by a photoreceiver as the reflection spectrum of visible light [1, 2]. In this case, the character of the spectrum is determined by the chemical composition of the material surface and by its roughness. The thermal activation intensifies both the change in the surface chemical composition because of the diffusion of elements to the free surface and the change in the surface relief because of the escape of dislocations with the formation of surface steps. As a result, the mirror reflection of the initial surface becomes diffuse. The quantitative changes in the character of the visible light reflection of the surface are measured by a photometric analyzer of structural images PhASI, which compares the reflection brightness spectra of the same surface areas photographed before and after the dilatometric experiments [3, 4]. Figure 1 shows an example of the sample surface analysis before and after heating in the dilatometer.

The reflection brightness spectra are shown in the “spectral density of the reflection brightness—the corresponding value of the reflection brightness” coordinates. The following three characteristic brightness intervals can be resolved in a typical spectrum: (1) the interval of predominance of light absorption processes; (2) the interval surrounding the maximum of the reflection brightness; and (3) the interval of the predominance of light reflection processes. The interval with the increased absorption ability corresponds to the surface areas of increased roughness. As is shown by the experiments, the spectral density of the reflection brightness undergoes maximum changes in interval (1) of increased absorption. For this reason, the structure damageability of the material under thermal effects was quantitatively measured by the accepted parameter \(D_{s}\) determined by the formula,

where \(p(I_{b})\) is the average spectral density of the reflection brightness in brightness interval (1) before the dilatometric experiment, and \(p(I_{a})\) is the average density of the reflection brightness in the same brightness range, but after the dilatometric experiment. In parallel with the photometric studies of the surface condition, the registration of the dilatometric measurements was performed. The samples were heated to temperatures of 373 K, 473 K, 573 K, 673 K, 773 K, and 823 K at a rate of 5 K \(\cdot \) min\(^{-1}\) in a high-purity argon atmosphere.

3 Results and Discussion

For quantitative estimation of the effect of temperature on the structure and properties of materials, we used the effective process time in the form proposed by Dorn [5] for the generalized representation of aluminum creep curves. Dorn showed that the results of creep tests of a series of aluminum samples at different levels of applied stresses lie on the same creep curve if they are represented as a function of the effective process time:

where \(t\) is the chronometric process time, \(Q\) is the activation energy of the self-diffusion of aluminum, and \(R\) is the universal gas constant. Dorn’s formula, Eq. 2, is suitable for the description of heat-activated processes occurring at high temperatures under isothermal conditions. The dilatometric experiments are performed upon heating at a constant rate to a predetermined temperature. Heating can be followed by isothermal holding at this temperature. The subsequent cooling occurs in a free or programmed regime. According to Dorn, the effective process time allows for the actions of both the intensive factor \(T\) and the extensive factor \(t\) on the material. Since the exponential term in Eq. 2 is the probability of thermal fluctuations sufficient for the events of the self-diffusion of aluminum atoms, the effective process time can be considered as the real time of the creep process. The dilatometric experiments in the present investigation were analyzed with the assumption that Dorn’s formula is applicable for the description of heat-activated processes at any temperatures, if the activation energy for self-diffusion in it is replaced by the effective activation energy for the processes occurring at the corresponding temperatures. Earlier, we used it to describe the dilatometric curve portion corresponding to the isothermal holding of the sample heated to a specified temperature [6, 7]. It was established that plastic deformations at this stage can be analytically described by the equation,

where \(\varepsilon _\mathrm{{o}}\) is the sample deformation at the end of the heating stage; \(t\) is the chronometric time from the beginning of heating; \(\Delta G\) is the difference in Gibbs free energies at the highest point of the energy barrier and at its base (its value is the same as that of the effective activation energy, i.e., it was assumed that \(U = \Delta G\)); and \(k\) is the Boltzmann constant. If we consider the heating stage as a sequence of isothermal stages, each occurring at a selected temperature, which is the sum of the temperature of the foregoing stage and the temperature jump determined by the heating rate, and describe the deformation for each elementary stage by Eq. 3, then after simple, but cumbersome calculations we obtain the following equation for the activation energy:

where the indices at variables \(t\) and \(T\) (\(i\), \(i + 1\), \(i + 2\), \(i + 3\)) are four sequential dilatometric data in each experiment. Equation 4 contains one indeterminate implicitly, and it can be solved only numerically. Using the data of dilatometric measurements and being assigned by the accuracy of calculations, we obtained the activation energies for all temperatures of the experiments. We developed a special computer program for these calculations. Using this program, we can assign the step of the change in the activation energy and obtain the number of solutions, which turn Eq. 4 into the identity for each activation energy at a given accuracy. The ratio of this number of solutions to the total number of attempts to obtain its solution by the substitution of the entire set of dilatometric data was considered as the probability to reveal the corresponding activation energy. Obtaining the full set of the activation energies and the corresponding probabilities, we carried out the renormalization of probabilities, subordinating it to the condition that the complete sum of the preliminarily calculated probabilities is equal to one. The program completely processed the results of the performed experiments, if the assigned step of activation energy was at least 0.05 eV. The program automatically found the boundaries of the stages of heating, isothermal holding, and cooling and calculated the activation energies for each stage separately. For checking, the results of the computer calculations executed in the automatic regime were doubled by calculations by the program “Excel” directly according to Eq. 4. The verifying calculations were performed with an activation energy step of 0.5 eV. The average activation energy for each stage of the dilatometric curve was obtained by the formula,

where m is the total number of activation energy values at this stage. Figures 2 and 3 show examples of typical statistical distribution curves of activation energy calculated from the results of dilatometric measurements by the above procedure.

The activation energies calculated by this procedure for the Al–14.6 %Zn alloy from the entire series of dilatometric experiments in a temperature range of 373 K to 823 K are given in Table 1. Note that the proposed procedure has some advantages over the currently used procedure for the determination of the activation energies on the basis of the theory of absolute reaction rates (TARR) [8]. The new method rests on the assumption about the constancy of the pre-exponential factor in a substantially smaller temperature interval (2 K to 5 K) than that used in TARR and is based on a substantially larger volume of experimental measurements (up to a thousand at each stage). It is applicable for studies upon isothermal heating, quasi-static heating at a constant heating rate, and at arbitrary heating and cooling regimes. The processing of the results of dilatometric experiments is fully automated.

The obtained values of the activation energy are in satisfactory agreement with literature data on heat-activated processes in aluminum and its alloys [9].

As mentioned above, the thermal activation analysis of the dilatometric data was added by the thermal activation analysis of the structural evolution on the surface of the alloy samples controlled by photometric measurements subjected to dilatometric studies. For each sample, photometric measurements similar to those shown in Fig. 1 have been performed after the dilatometric studies. Assuming the spectral density of the brightness of visible light reflection in the first interval of the spectrum to be directly proportional to the effective time of the process at the stage of isothermal holding, we calculated the activation energy of the structure evolution of the alloy according to Eq. 6, which was obtained on the basis of this assumption. No corrections, allowing for the thermal effects at the heating and cooling stages, were introduced;

where \(p_{i}(I)\) is the average spectral density of the reflection brightness. Figure 4 shows the temperature dependence of the activation energy of structural evolution processes in the alloy.

In the figure, we can resolve three temperature intervals, which differ in the behavior of the dependence. At temperatures below 523 K, the dependence \(U=f(T)\) is virtually horizontal, and the activation energy for the structural evolution processes is zero. This means that the heat-activated deformation of samples in this region is of a thermal expansion character, and the structural transformations are virtually negligible. The boundaries of the second interval coincide with temperatures 523 K and 688 K, i.e., 523 K \(<\) TII \(<\) 688 K, and the values of the activation energies lie in the negative region. This can be explained by the development of the recovery processes, which occur with energy release. Finally, the third interval, which lies in the region at \(T>688\) K, is characterized by processes of structural evolution with changes in the grain structure and the phase composition of the alloy as a result of first-order phase transformations. The characteristic temperatures of the Al–14.6 %Zn alloy according to the data of the photometric analysis of the dilatometric samples and the Al–Zn phase diagram are given in Table 2.

The data given in Table 2 allow us to establish that \(T_{2}\) is the temperature of the \(\alpha \rightarrow (\alpha +\beta )\) phase transformation, \(T_{3}\) is the temperature of the solidification of the liquid phase, and \(T_{1}\) corresponds to the beginning of recovery.

4 Conclusions

-

(1)

A new method of thermal activation analysis of thermal deformations according to the data of dilatometric studies is developed. The method was experimentally verified on the Al–14.6 %Zn alloy, and the obtained results are close to literature data for pure aluminum and its low alloys.

-

(2)

The activation energies for the processes of the structural evolution in the alloy are obtained by the method of the surface photometric analysis of the samples used in the dilatometric experiments. For the high-temperature field, the results of the determination of the activation energy by both methods are in good agreement.

-

(3)

An extremum corresponding to phase transformation in the Al–Zn system has been revealed in the temperature dependence of the activation energy for structural evolution processes, which were measured by the photometric method.

References

V.I. Ginsburg, U.I. Goldberg, V.A. Golovkos, Light Scattering Near Phase Transition (Nauka, Moscow, 1990), p. 414

A. Beiser, Perspectives of Modern Physics, Int. edn. (McGraw-Hill Inc., New York, 1969)

V.A. Yermishkin, D.P. Murat, V.V. Podbelskiy, Informatsionnye Tekhnologii 11, 65 (2007)

V.A. Yermishkin, D.P. Murat, V.V. Podbel’skiy, Avtomatizatsiya i Sovremennye Tekhnologii 2, 11 (2008)

J.E. Dorn, The spectrum of activation energies for creep, in Creep and Recovery (American Society for Metals, Materials Park, OH, 1957), pp. 225–283

N.A. Minina, V.A. Yermishkin, Yu.D. Lepeshkin, N.L. Fedotov, Fizika i Khimiya Obrabotki Materialov 3, 18 (2009)

I.I. Novikov, V.A. Yermishkin, N.A. Minina, D.P. Murat, Photometric diagnostics of phase transitions, thermophysical properties of substances and materials, in Transactions of Russian Conference on the Thermophysical Properties of Substances, 2008 (Interkontakt Nauka, Moscow. 2009), pp. 85–92

F. Garofalo, Fundamentals of Creep and Creep-Rupture in Metals (Macmillan, New York, 1965)

A.N. Orlov, Yu.V. Trushin, Energy of Point Defects in Metals (Energiya-Atomizdat, Moscow, 1983)

N.P. Lyakishev (ed.), Phase Diagrams of Binary Metallic Alloys. Reference Book (Mashinistroenie, Moscow, 1996), p. 991

Acknowledgments

The work is supported by the Russian Foundation for Basic Research (Grant Nos. 07-08-00381a; 09-08-00562a).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Minina, N.A., Yermishkin, V.A. & Novikov, I.I. Structural Mechanisms of Dilatometric Processes. Int J Thermophys 34, 2152–2159 (2013). https://doi.org/10.1007/s10765-013-1537-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10765-013-1537-5