Abstract

The miniaturized Mössbauer-spectrometer (MIMOS II), originally devised by Göstar Klingelhöfer, is further developed by the Renz group at the Leibniz University Hanover in cooperation with the Hanover University of Applied Sciences and Arts. A new processing unit with a two-dimensional (2D) data acquisition was developed by M. Jahns. The advantage of this data acquisition is that no thresholds need to be set before the measurement. The energy of each photon is determined and stored with the velocity of the drive. After the measurement, the relevant area can be selected for the Mössbauer spectrum. Now we have expanded the evaluation unit with a power supply for a MIMOS drive and a MIMOS PIN detector. So we have a very compact MIMOS transmissions measurement setup. With this setup it is possible to process the signals of two detectors serially. Currently we are working on a parallel signal processing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Conventionally, the relevant energy range for measuring Mössbauer spectra is limited with thresholds [1]. This requires the setting of these before the measurement. When changing the detector system, or when changing the observed energy range, a calibration measurement for the thresholds is required. Furthermore, classically only one energy range is investigated [1]. With our two dimensional (2D) approach, not only the photons from a previously defined energy range are measured, but all photons are stored with their respective energy and the velocity of the Mössbauer drive [2]. From the resulting 2D spectrum, the Mössbauer spectrum can then be obtained after the measurement. In the case of the iron-57, the spectra of the 6.4 keV and 14.4 keV (classical) can be obtained in parallel, see Fig. 1. Since an energy spectrum is also recorded for each measurement, it would be possible to use the evaluation unit with a suitable excitation source for X ray fluorescence measurements.

2 Measurement Setup and Results

2.1 Old Setup

A schematic overview of the previous measurement setup is shown in Fig. 2. For example, our processing unit can be operated with a gas detector setup (proportional counter + shaper-amplifier) from the “WissEl” company and can also provide the triangular signal for a “WissEl” drive unit. Each component requires its own power supply. Until now, the MIMOS detector [3] could also be used with our processing unit but only with an additional external power supply.

2.2 New setup

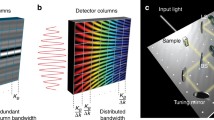

The experimental setup was expanded with a separate power supply for a MIMOS drive [3] and a MIMOS detector, so that it is now possible to measure directly with the processing unit without a separate power supply. The schematic measurement setup is shown in Fig. 3.

This results in a compact transmission measurement setup. A picture of the setup is shown in Fig. 4. In the upper part, the MIMOS drive and MIMOS detector can be seen below the new processing unit.

The setup was tested by measuring an α-iron foil (0.02 mm) with a cobalt-57 source in a rhodium matrix at 293 K. It was measured for 24 h. Then, the Mössbauer spectra in the energy ranges of 6.4 keV (1) and 14.4 keV (2) were extracted from the energy spectrum shown in Fig. 5.

Energy spectrum of the test measurement (setup from Fig. 3) with the marked energy regions 6.4 keV (1) and 14.4 keV (2)

Afterwards, the Mössbauer spectra were calibrated, folded and fitted (lorentzian site analysis) with the program „Recoil “. The resulting Mössbauer spectra with fits are shown in Fig. 6.

Mössbauer spectra with fits of the test measurement (setup from Fig. 3) from the energy regions 6.4 keV (left) and 14.4 keV (right)

The Mössbauer parameters [1] for the 6.4 keV | 14.4 keV spectra of the fits are as follows:

-

Center Shift CS = -0.0001(61) | 0.00065(90) mm/s

-

Quadrupole Splitting QS = 0.0004(61) | -0.00016(90) mm/s

-

Magnetic Splitting MS = 32.973(49) | 32.9653(72) T

-

Area A = -21000(1100) | 143600(1100) counts·mm/s

-

Half Width at Half Maximum w3 = 0.144(23) | 0.1369(34) mm/s

-

A1/A3 = 2.48(30) | 2.501(46)

-

A2/A3 = 1.87(24) | 1.790(36)

-

w1/w3 = 1.27(21) | 1.273(33)

-

w2/w3 = 1.06(19) | 1.114(31)

The fits show the expected values. The CS and QS should be 0.00 mm/s for α-iron. [1] The MS should be around 33.0 T at 298 K [4]. Smaller deviations can be explained by material differences. The natural half width at half maximum is 0.098 mm/s. Depending on the sample and the setup, the values are slightly higher. The signal ratio for optimal absorber thickness is 3–2-1. The ratios are slightly smaller, which may be due to the thickness of the iron foil [1].

With the processing unit it is now also easily possible to combine the MIMOS drive with another detector system, for example with a silicon drift detector (SDD). A SDD has a much better energy resolution so the 6.4 keV and 14.4 keV energy regions can be better separated. The amplified and shaped signal of the SDD is fed directly to the board. The voltage supply of the SDD and the shaper are then external again. The schematic setup with the SDD is shown in Fig. 7.

The setup was also tested by measuring an α-iron foil (0.02 mm) with a cobalt-57 source in a rhodium matrix at 293 K. It was measured for 24 h. Then, the Mössbauer spectra in the energy ranges of 6.4 keV (1) and 14.4 keV (2) were extracted from the energy spectrum shown in Fig. 8.

Energy spectrum of the test measurement (MIMOS drive + SDD, setup from Fig. 7) with the marked energy regions 6.4 keV (1) and 14.4 keV (2)

Afterwards, the Mössbauer spectra were calibrated, folded and fitted (lorentzian site analysis) with the program “Recoil”. The resulting Mössbauer spectra with fits are shown in Fig. 9.

Mössbauer spectra with fits of the test measurement (MIMOS drive + SDD, setup from Fig. 7) from the energy regions 6.4 keV (left) and 14.4 keV (right)

The Mössbauer parameters [1] for the 6.4 keV | 14.4 keV spectra of the fits are as follows:

-

Center Shift CS = 0.0008(11) | -0.00007(56) mm/s

-

Quadrupole Splitting QS = -0.0006(11) | -0.00019(56) mm/s

-

Magnetic Splitting MS = 32.9455(85) | 32.9479(42) T

-

Area A = -123100(1200) | 191400(1000) counts·mm/s

-

Half Width at Half Maximum w3 = 0.1348(44) | 0.1314(24) mm/s

-

A1/A3 = 2.513(62) | 2.516(34)

-

A2/A3 = 1.787(48) | 1.787(26)

-

w1/w3 = 1.134(39) | 1.123(21)

-

w2/w3 = 1.076(41) | 1.061(22)

The fits show the expected values. The CS and QS should be 0.00 mm/s for α-iron. [1] The MS should be around 33.0 T at 298 K [4]. Smaller deviations can be explained by material differences. The natural half width at half maximum is 0.098 mm/s. Depending on the sample and the setup, the values are slightly higher. The signal ratio for optimal absorber thickness is 3–2-1. The ratios are slightly smaller, which may be due to the thickness of the iron foil [1].

Furthermore, it is now possible to use the MIMOS detector directly with another drive, for example a „WissEl “ drive, since a separate power supply for the detector is no longer required. The schematic setup with the SDD is shown in Fig. 10.

The setup was also tested by measuring an α-iron foil (0.02 mm) with a cobalt-57 source in a rhodium matrix at 293 K. It was measured for 24 h. Then, the Mössbauer spectra in the energy ranges of 6.4 keV (1) and 14.4 keV (2) were extracted from the energy spectrum shown in Fig. 11.

Energy spectrum of the test measurement (WissEL drive + MIMOS detector, setup from Fig. 10) with the marked energy regions 6.4 keV (1) and 14.4 keV (2)

Afterwards, the Mössbauer spectra were calibrated, folded and fitted (lorentzian site analysis) with the program „Recoil “. The resulting Mössbauer spectra with fits are shown in Fig. 12.

Mössbauer spectra with fits of the test measurement (WissEL drive + MIMOS detector, setup from Fig. 10) from the energy regions 6.4 keV (left) and 14.4 keV (right)

The Mössbauer parameters [1] for the 6.4 keV | 14.4 keV spectra of the fits are as follows:

-

Center Shift CS = 0.0026(45) | 0.0004(10) mm/s

-

Quadrupole Splitting QS = 0.0011(45) |—0.0008(10) mm/s

-

Magnetic Splitting MS = 32.927(34) | 32.9504(77) T

-

Area A = -23340(960) | 130900(1200) counts·mm/s

-

Half Width at Half Maximum w3 = 0.143(19) | 0.1620(44) mm/s

-

A1/A3 = 2.76(27) | 2.431(50)

-

A2/A3 = 1.98(21) | 1.745(39)

-

w1/w3 = 1.19(16) | 1.076(31)

-

w2/w3 = 1.13(16) | 1.025(32)

The fits show the expected values. The CS and QS should be 0.00 mm/s for α-iron. [1] The MS should be around 33.0 T at 298 K [4]. Smaller deviations can be explained by material differences. The natural half width at half maximum is 0.098 mm/s. Depending on the sample and the setup, the values are slightly higher. The signal ratio for optimal absorber thickness is 3–2-1. The ratios are slightly smaller, which may be due to the thickness of the iron foil [1].

3 Conclusion

By upgrading our 2D processing unit with a power supply for a MIMOS detector and MIMOS drive, we have obtained a very small and at the same time flexible transmission measurement setup. The setup can be used with MIMOS detector and e.g. „WissEl “ drive, as well as with MIMOS drive and e.g. silicon drift detector or gas detector.

Data availability

The data and materials are available from the corresponding author upon reasonable request.

References

Gütlich, P., Bill, E., Trautwein, A.X.: Mössbauer Spectroscopy and Transition Metal Chemistry, 1st edn. Springer-Verlag, Berlin Heidelberg, Heidelberg, Germany (2011)

Jahns, M., Pawlak, J., Klimke, S., Sindelar, R., Schrewe, U., Patzke, R., Renz, F.: Nucl. Inst. Methods Phys. Res. A 1031, 166529 (2022)

Klingelhöfer, G., Fegley, B., Morris, R.V., Kankeleit, E., Held, P., Evlanov, E., Priloutskii, O.: Planet. Space Sci. 44(11), 1277–1288 (1996)

Violet, C.E., Pipkorn, D.N.: J. Appl. Phys. 42, 4339–4342 (1971)

Acknowledgements

The authors would like to thank Hannover School for Nanotechnology (HSN), Leibniz University Hanover (LUH), Laboratory of Nanotechnology and Quantum Engineering (LNQE) and Hochschule Hannover – University of Applied Sciences and Arts (HsH). The authors would also like to thank the German Aerospace Center (DLR) and the UMB-II project.

Funding

Open Access funding enabled and organized by Projekt DEAL. This work was financially supported by the Hannover School for Nanotechnology (HSN), the German Aerospace Center (DLR) and the UMB-II project.

Author information

Authors and Affiliations

Contributions

J.P. wrote main manuscript text, prepared figures, worked on the experimantal setup, made measurements. M.B. wrote manuscript text, made measurements, reviewed the manuscript. M.J. worked on the experimantal setup, reviewed the manuscript. F.B. reviewed the manuscript. R.S, F.R. and R.P supervised the work, reviewed the manuscript.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pawlak, J., Beyki, M., Jahns, M. et al. 2D data processing with MIMOS II. Hyperfine Interact 244, 20 (2023). https://doi.org/10.1007/s10751-023-01833-6

Accepted:

Published:

DOI: https://doi.org/10.1007/s10751-023-01833-6