Abstract

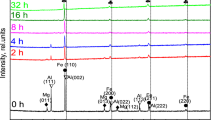

A coarse-grained sigma phase Fe48.1V51.9 was ground in argon in a vibratory mill in the presence of a small but steady air supply. The oxygen content increases regularly at a rate of about 0.25 at.%/h. During the first 140 h of milling, the sigma phase transforms into a heterogeneous bcc alpha phase because of a preferential oxidation of the sole vanadium atoms into V2O3. At that milling time, the average composition of the remaining bcc alloy is ~Fe80V20. Mössbauer spectroscopy shows too the presence of an amorphous phase. For longer milling times, ternary Fe–V–O spinel phases do form.

Similar content being viewed by others

References

Kubaschewski, O.: Iron-binary phase diagrams, pp. 160–164. Springer, Berlin (1982)

Villars, P., Calvert, L.D.: Pearson’s handbook of crystallographic data for intermetallic phases. In: American Physical Society for Metals, pp. 2246. Metals Park, OH (1991)

Bakker, H., Zhou, G.F., Yang, H.: Mechanically driven disorder and phase transformations in alloys. Prog. Mater. Sci. 39, 159–241 (1995)

Yang, H., Bakker, H.: Formation of amorphous and metastable phases from the sigma phase by ball milling. Mater. Sci. Eng., A. 181/182, 1207–1211 (1994)

Suryanaryana, C.: Mechanical alloying and milling. Prog. Mater. Sci. 46, 1–184 (2001)

Fultz, B., Le Caer, G., Matteazzi, P.: Mechanical alloying of Fe and V powders: intermixing and amorphous phase formation. J. Mater. Res. 4(6), 1450–1455 (1989)

Lanote, L., Matteazzi, P.: Influence of grinding on magnetic properties of Fe–V and Fe powders. J. Magn. Magn. Mater. 88, 58–62 (1990)

Fukunaga, T., Mori, M., Misawa, M., Mizutani, U.: Structural observation of metastable phases prepared by MA in V–M(=Fe, Cu) systems. Mat. Sci. Forum 88–90, 663–670 (1992)

Rawers, J., Doan, R.C., Slavens, G., Govier, D., Siple, J.: Effects of mechanical alloying of iron alloys in a gaseous nitrogen atmosphere. J. Mater. Synth. Process. 1, 75–84, (1993)

Rawers, J., Govier, D., Cook, D.: bct-Fe formation during mechanical processing of bcc-Fe powder. Scr. Metall. Mater. 32, 1319–1324 (1993)

Koyano, T., Chatani, K., Fukunaga, T., Mizutani, U.: Magnetic properties of Fe–V powders produced by mechanical alloying. Mat. Science and Engineering A181/A182, 1277–1280 (1994)

Rawers, J., Cook, D., Kim, T.: X-ray diffraction and Mossbauer characterization of attrition-milled nanostructured iron and iron–nitrogen powders. Philos. Mag., A. 78, 965–977 (1998)

Le Caër, G., Ziller, T., Delcroix, P., Bellouard, C.: Mixing of iron with various metals by high-energy ball milling of elemental powder mixtures. Hyperfine Interact. 130, 45–70 (2000)

Ziller, T., Le Caër, G., Isnard, O., Cenedese, P., Fultz, B.: Metastable and transient states of chemical ordering in Fe–V nanocrystalline alloys. Phys. Rev. B 65, 024204 (2002) (14 p)

Kataoka, N., Sumiyama, K., Nakamura, Y.: Metastable crystalline and amorphous Fe–V alloys produced by vapor quenching. Trans. Jpn. Inst. Met. 27, 823–829 (1986)

Ziller, T.: Étude du Mélange à l’ État Solide lors de la Mécanosynthèse d’alliages Fe–X (X=Cr, Mn, V, Mo) et étude de la mise en ordere d’alliages Fe–V élaborés par cette technique. Ph.D. Thesis, Nancy (2000)

Williamson, G., Hall, W.H.: X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1, 22–31 (1952)

Le Caër, G., Dubois, J.M.: Evaluation of hyperfine parameter distributions from overlapped Mössbauer spectra of amorphous alloys. J. Phys. E 12, 1083–1090 (1979)

Seki, J.I., Hagiwara, M., Suzuki, T.: Metastable order–disorder transition and sigma phase formation in Fe–V binary alloys. J. Mater. Sci. 14, 2404–2410 (1979)

Le Caër, G., Brand, R.A.: General models for the distributions of electric field gradients in disordered solids. J. Phys., Condens. Matter. 10, 10715–10774 (1998)

Shiga, M., Nakamura, Y.: Effect of local environment on formation of local moments in bcc Fe–V alloys: Mössbauer study. J. Phys. F. Met. Phys. 81, 177–190 (1978)

Dubiel, S.M., Zinn, W.: Influence of V on the Fe site spin and charge densities in BCC-iron. J. Magn. Magn. Mater. 37, 237–245 (1983)

Krause, J.C., Schaf, J., da Costa, M.I. Jr, Paduani, C.: Effect of composition and short-range order on the magnetic moments of Fe in Fe1 − x V x alloys. Phys. Rev. B 61, 6196–6204 (2000)

Fu, C.L., Krčmar, M., Painter, G.S., Chen, X.Q.: Vacancy mechanism of high oxygen solubility and nucleation of stable oxygen-enriched clusters in Fe. Phys. Rev. Lett. 99, 225502 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Costa, B.F.O., Le Caër, G. & Malaman, B. Evolution of a FeV sigma phase ball-milled in a mixture of argon and air. Hyperfine Interact 183, 67–73 (2008). https://doi.org/10.1007/s10751-008-9760-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10751-008-9760-3