Abstract

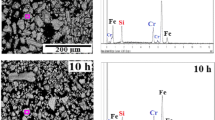

Full use of experimental measurements obtained by the mean of the X-ray diffraction technique and the Rietveld refinement has been implemented to study the effects of the addition of Si on the microstructural evolution of the Fe–Co–Ni alloy prepared by using a planetary ball mill (Fritsch P7). For this purpose, the mixtures of powders prepared have the general formula Fe60-xCo25Ni15Six (x = 0, 5, 10, 20, and 30 at.%). The related structures and microstructures were characterized by scanning electron microscopy, energy-dispersive X-ray spectroscopy, and X-ray diffraction. Microstructural parameters were determined by the Rietveld fitting of the X-ray Diffraction patterns. The systematical discussions about microstructures, including morphology, phase structure, lattice parameter, crystallite size, and lattice strain, were carried out. It was found that for the sample without Si, the allotropic transition hcp-Co to fcc-Co was identified, while the presence of Si metalloid may stabilize the hcp-Co phase during milling. Several solid solutions as well as bcc-Fe(Co), bcc-Fe(Co, Ni,Si), and fcc-Ni(Si) were refined. As a consequence of the Si additions, intense refinement of the microstructure (D ~ 10 nm; ε = 1.25%) and an amorphous phase were obtained for 30%Si after 100 h milling, namely that the Si has segregated in the grain boundaries and may increase the structural hardening and brittleness of the particles. The resulting nanostructure state is related to the concept of dislocations.

Similar content being viewed by others

Data Availability

All the data and materials are available by the authors.

References

Koch CC, Cavin OB, Mckamey CG, Scarbrough JO (1983) Appl Phys Lett 43:1017–1019

Yavari AR, Desre PJ, Banameur T (1992) Phys Rev Lett 68:235

Uenishi K, Koba ayashi KF, Nasu S, Hatano H, Ishibara KN, Shingu PH, Metallk Z (1992) 83:132

Kuyama J, Inui H, Imaoka S, Ishihara KN, Shinhu P (1991) Jpn J Appl Phys 30:L854

Suryanarayana C (2001) Prog Mater Sci 46:1

Sherif El-Eskandarany M (2001) Mechanical alloying for fabrication of advanced engineering materials. Noyes Publications/William Andrew Publishing, Norwich, NY

Suryanarayana C, Koch CC (1999). In: Suryanarayana C (ed) Non-equilibrium Processing of Materials. Pergamon, New York, pp 313–344

McHenry ME, Willard MA, Laughlin DE (2000) J Appl Phys 87:7091–7096

Bai FS, Dong YQ, Xie L, Li Q, He AN, Jia XJ, Li JW, Wang XM (2021) J Mater Sci 56:9254–9262

Hasiak M, Laszcz A, Zak A, Kaleta J (2019) Acta Phys Pol A 135:284–287

Wang G, Liu M, Wang L, Liu H (2019) Mater Express 9:686–689

Shafi K, Gedanken A, Prozorov R, Revesz A, Lendvai J (2000) J Mater Res;15(2):332e7

Rathi A, Meka VM, Jayaraman TV (2019) J Magn Magn Mater;469:467e82

Jartych E (2011) J Magn Magn Mater;323:209e16

Yuping D, Yahong Z, Tongmin W, Shuchao G, Xin L, Xingjun L (2014) Mater Sci Eng B, 185: 86e93

Jayaraman TV, Rathi A, Thotakura GV (2019) Intermetallics 113:106583

Jayaraman TV, Rathi A, Thotakura GV (2020) Intermetallics 119:106715

Jayaraman TV, Rathi A, Thotakura GV (2019) J Magn Magn Mater 489:165466

Solanki V, Lebedev OI, Seikh MdM, Mahato NK, Raveau B, Kundu AK (2016) J Magn Magn Mater;420:39e44

Yanai T, Shiraishi K, Akiyoshi T, Azuma K, Watanabe Y, Ohgai T, Morimura T, Nakano M (2016) H. Fukunaga. AIP Adv 6:055917

Csik A, Vad K, Toth-Kadar E, Péter L (2009) Electrochem Commun 11:1289e91

Toneguzzo P, Viau G, Acher O, Guillet F, Bruneton E, Fievet-Vincent F, Fievet F (2000) J Mater Sci 35, 3767e84

Yang X, Liu J, Cui X, Jin G, Liu Z, Chen Y, Feng X (2019) J Phys Chem Solid, 130:210e6

Zhang Y, Ma R, Feng S, Cheng L, Davies PA, Yu P (2020) J Magn Magn Mater 497:165982

Lutterotti L (2000) MAUD CPD Newsletter. IUCr. 24

Khajepour M, Sharafi S (2012) Powder Technol 232:124–133

Chen YL, Hu YH, Hsieh CA, Yeh JW, Chen SK (2009) J Alloys Compd 481:768–775

Porter DA, Easterling KE (1992) Phase Transformations in Metals and Alloys, 2nd edn. Springer, Berlin, Germany

Fu Z, Chen W, Chen Z, Wen H, Lavernia EJ (2014) Mater Sci Eng A 619:137–145

Huang J, Wu Y, Ye H, Lu K (1995) Mater 6:723–726

Cardellini F, Mazzone G (1993) Philos Mag A 67:1289–1300

Alleg S, Azzaza S, Bensalem R, Suñol JJ, Khene S, Fillion G (2009) J Alloys Compd 482:86–89

Takeuchi A, Inoue A (2005) Mater Trans 46:2817–2829

Willard MA, Huang M-Q, Laughlin DE, McHenry ME (1999) Journal of Applied Physics, 85:4421–4423

Kane SN, Gupta A, Gercsi Z, Mazaleyrat F, Varga LK (2005) J Magn Magn Mater 292:447–452

Bhoi B, Srinivas V, Singh V (2010) J Alloy Compd 496:423–428

Rzychon T, Rodak K (2007) J of Mater Sci and Eng 28:605–608

Mhadhbi M, Khitouni M, Escoda L, Suñol JJ (2010) Mater Lett 64:1802–1805

Zhao YH, Sheng HW, Lu K (2001) Acta Mater 49(2):365–375

Zhao YH, Zhang K, Lu K (1997) Phys Rev B 56(22):14322–14329

Zhao YH, Lu K, Zhang K (2002) Phys Rev B 66(8):085404

Mohamed FA (2003) Acta Mater 51:4107–4119

Kalita MPC, Perumal A, Srinivasan A (2008) J Magn Magn Mater 320:2780–2783

Williamson GK, Smallman RE, (1995) Phil Mag 1, 34

Noyan IC, Cohen JB (1987) Springer-Verlag New York Inc.

Author information

Authors and Affiliations

Contributions

N. Khitouni and R. Daly designed the study and performed the experiments of structure analysis. N. Khitouni, R. Daly, and L. Escoda performed the experiments, designed the figures, and explained the microstructural evolutions. J. Sunol and M. Khitouni supervised and drafted the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Declarations

As the corresponding author, M. Khitouni, hereby confirm on behalf of all authors that:

(i) This manuscript has not been published, was not, and is not being submitted to any other journal. If presented at a conference, the conference is identified. If published in conference proceedings, substantial justification for re-publication must be presented.

(ii) All necessary permissions for publication were secured prior to submission of the manuscript.

The authors declare that they have no known personal relationships that could have appeared to influence the work reported in this paper.

Consent to Participate

As the corresponding author, M. Khitouni, hereby confirm on behalf of all authors that: All authors listed have made a significant contribution to the research reported and have read and approved the submitted manuscript, and furthermore, all those who made substantive contributions to this work have been included in the author list.

Consent for Publication

All authors listed accept the publication in this journal.

Competing Interests

The authors declare no competing interests.

Conflict of Interest

The authors declare that they have no known competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khitouni, N., Daly, R., Suñol, JJ. et al. Effect of Silicon Additions on Structural and Microstructural Properties of Nanostructured FeCoNi Alloy Prepared by High-Energy Ball Milling. Silicon 15, 1977–1986 (2023). https://doi.org/10.1007/s12633-022-02156-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02156-x