Mineral oxide fibers of various chemical compositions are reviewed: aluminosilicate, alumina, silica, biosoluble, fibers made from zirconium oxide, and others. Methods for manufacturing discrete and continuous fibers are given, such as spinning fibers from melts, sol-gel technology, spinning from solutions of metal salts, and others. The physicochemical characteristics of mineral fibers are described and their applications are indicated, such as thermal insulation up to 1150 or 1000°C and high temperature filtration for aluminosilicate and biosoluble fibers; thermal insulation up to 1600 or 2000°C, and reinforcement of composites used in the aerospace and defense industries for alumina fibers and fibers based on zirconium dioxide, and so on. Manufacturers of mineral oxide-containing fibers and products based on them in and outside of Russia are indicated.

Similar content being viewed by others

References

GOST 31913–2011 (EN ISO 9229:2007). Heat-Insulating Materials and Products. Terms and Definitions [in Russian], Standartinform, Moscow (2013).

B. Claus and D. Schwaller, “Modern aspects of ceramic fiber development,” Adv. Sci. Technol., 50, 1 – 8 (2006).

T. F. Cooke, “Inorganic fibers: A literature review,” J. Am. Ceram. Soc., 74(12), 2959 – 2978 (1991).

I. M. Afanasov and B. I. Lazoryak, High-Temperature Ceramic Fibers, Textbook on Composite Nanomaterials [in Russian], Izd. MGU im. M V. Lomonosov, Moscow (2010).

Zircar Zickonia, Inc.: [Electronic resource]; URL: https://www.zircarzirconia.com/ (date of access: 09/25/2021).

J. Chen and X.Wang, “Fabrication and characterization of novel excellent thermal-protection Gd2Zr2O7 /ZrO2 composite ceramic fibers with different proportions of Gd2Zr2O7,” Ceram. Int., 46(15), 24029 – 24037 (2020).

J. W. Chen, X. Q. Wang, and Y. S. Xie, “Preparation and fine thermal insulation performance of Gd2Zr2O7 /ZrO2 composite fibers,” Ceram. Int., 46(2), 1615 – 1620 (2020).

Yu. A. Balinova and G. Yu. Lyulukina, “Zirconium dioxide fibers: production, properties and prospects for application,” in: Modern High-Temperature Fibrous Heat and Sound Insulating Materials: All-Russian Sci.-Tech. Conf., Moscow, 7 Dec. 2017 [in Russian], FSUE VIAM, Moscow (2017), pp. 15 – 30.

S. Shi, K. Yuan, and C. Xu, “Electrospun fabrication, excellent high-temperature thermal insulation and alkali resistance performance of calcium zirconate fiber,” Ceram. Int., 44(12), 14013 – 14019 (2018).

M. Rahman, F. Tajabadi, and L. Shooshtari, “Nanoparticulate hollow TiO2 fibers as light scatterers in dye-sensitized solar cells: layer-by-layer self-assembly parameters and mechanism,” Chem. Phys. Chem., 12(5), 966 – 973 (2011).

M. Kh. Animian, N. Taghavinia, and A. Irajizad, “Highly porous TiO2 nanofibers with a fractal structure,” Nanotechnology, 17(2), 520 – 525 (2006).

J. Wang, X. An, and Y. Yu, “Er-doped titanium dioxide/silicon dioxide fibers with enhanced photodegradation performance,” Micro & Nano Lett., 13(3), 297 – 301 (2018).

D. Su, L.Wang, and K. Liang, “Silicon oxycarbide/titanium dioxide fibers with wrinkle-like surface by electrospinning,” Mater. Lett., 172, 202 – 206 (2016).

L. Zheng, Z. C. Yu, and K. K. Yuan, “Fabrication, heat-treatment and formation mechanism of MgO fiber using propionic acid as ligand,” Ceram. Int., 43(2), 2004 – 2011 (2017).

G. Kordas, “Sol-gel preparation of MgO fibers,” J. Mater. Chem., No. 5, 1157 – 1160 (2000).

X. Lin, B. Liu, and X.Wang, “Large scale fabrication of magnesium oxide fibers for high temperature thermal structure applications,” Ceram. Int., 43(1), 1455 – 1459 (2017).

M. Macias, A. Chacko, and J. P. Ferraris, “Electrospun mesoporous metal oxide fibers,” Micropor. Mesopor. Mater., 86(1 – 3), 1 – 13 (2005).

W. S. Liu and T. P. Perng, “Ta2O5 hollow fiber composed of internal interconnected mesoporous nanotubes and its enhanced photochemical H2 evolution,” Int. J. Hydrogen Energy, 44(33), 17688 – 17696 (2002).

J. Y. Cheong, D. Y. Youn, and C. Kim, “Ag-coated one-dimensional orthorhombic Nb2O5 fibers as high performance electrodes for lithium storage,” Electrochim. Acta, 269, 388 – 396 (2018).

W. Sahle, S. Krantz, and B. Christensson, “Preliminary data on hard metal workers exposure to tungsten oxide fibers,” Sci. Total Envir., 191(1 – 2), 153 – 167 (1996).

A. M. Shestakov, M. A. Khaskov, and O. Yu. Sorokin, “Inorganic fibers based on organosilicon polymer precursors for high-temperature-resistant composite materials (review),” Kompozit. Mater.: Tr. VIAM, No. 1(73), 74 – 91 (2019).

Z. Ryu, J. Zheng, and M. Wang, “Preparation and characterization of silicon carbide fibers from activated carbon fibers,” Carbon, 40(5), 715 – 720 (2002).

K. Okamura, M. Sato, and Y. Hasegawa, “Silicon nitride fibers and silicon oxynitride fibers obtained by the nitridation of polycarbosilan,” Ceram. Int., 13(1), 55 – 61 (1987).

X. Sun, H. T. Liu, and H. F. Cheng, “Oxidation behavior of silicon nitride fibers obtained from polycarbosilane fibers via electron beam irradiation curing,” RSC Adv., No. 75, 47833 – 47839 (2017).

E. M. Dianov, K. M. Golant, and R. R. Khrapko, “Low-hydrogen silicon oxynitride optical fibers prepared by SPCVD,” J. Lightwave Technol., 13(7), 1471 – 1474 (1995).

Joseph E. Blaze Jr., High-Temperature Alumina Silica Fibers and Method of Manufacture (1970).

“Shinnikka Thermal Ceramics Corporation. Ceramic fiber and the development of insulating technology,” Nipon Steel Tech. Rep., No. 98, 110 – 115 (2008).

M. Kim., H. Ko, and T. Kwon, “Development of novel refractory ceramic continuous fibers of fly ash and comparison of mechanical properties with those of E-glass fibers using the Weibull distribution,” Ceram. Int., 46(9), 13255 – 13262 (2020).

D. Schawaller, B. Clauss, and M. R. Buchmeiser, “Ceramic filament fibers: A review,” Macromolecular Mater. Eng., 297(6), 502 – 522 (2012).

Yu. A. Balinova and T. A. Kirienko, “Continuous high-temperature oxide fibers for heat-shielding, heat-insulating, and composite materials,” Vse Mater., Entsikl. Istochniki, No. 4, 24 – 29 (2012).

M. Yang, X. Luo, and J. Yi, “A novel way to fabricate fibrous mullite ceramic using sol-gel vacuum impregnation,” Ceram. Int., 44(11), 12664 – 12669 (2018).

Karl A. Karst and Harold G. Sowman, Non-Frangible Alumina- Silica Fibers, Pat. US4047965A (1977).

C. J. Brinker and G. W. Scherer, Sol-Gel Science: The Physics and Chemistry of Sol-Gel Processing, Academic Press, San Diego (1990).

Y. Zhang, Y. Ding, and Y. Li, “Mullite fibers prepared by sol-gel method using aluminum chloride, aluminum isopropoxide, and tetraethylorthosilicate,” Mater. Manuf. Proc., 26(4), 649 – 653 (2011).

Yangrui Gao, Wensheng Liu, and Xiaolei Son, “Preparation, characterization, and mechanical properties of continuous mullite fibers derived from the diphasic sol-gel route,” J. Sol-Gel Sci. Technol., No. 92, 75 – 83 (2019).

Kong Qingrong, “Spinnable sol prepared by NHSG method used for mullite continuous fiber,” Key Eng. Mater., 680, 111 – 114 (2016).

M. M. A. Zadehn, M. Keyanpour-Rad, and T. Ebadzadeh, “Synthesis of mullite nanofibers by electrospinning of solutions containing different proportions of polyvinyl butyral,” J. Mater. Sci. Eng., 39(8), 9079 – 9084 (2013).

H. Tan, Y. Ding, and J. Yang, “Mullite fibers preparation by aqueous sol-gel process and activation energy of mullitizatio,” J. Alloys Compd., 492(1 – 2), 396 – 401 (2010).

H. Tan, Y. Ding, and J. Yang, “Mullite fibers prepared from an inorganic sol-gel precursor,” J. Sol-Gel Sci. Technol., 53(2), 378 – 383 (2009).

H. B. Tan, “Mullite fiber preparation by extrusion method using alumina sol as binder,” Mater. Technol., 26(2), 76 – 79 (2011). DOI: https://doi.org/10.1179/175355510x12856832934188

Z. Chen, Z. Zhang, and C. Tsai, “Electrospun mullite fibers from the sol-gel precursor,” J. Sol-Gel Sci. Technol., 74(1), 208 – 219 (2014).

Y. Ishii, H. Sakai, and H. Murata, “A new electrospinning method to control the number and a diameter of uniaxially aligned polymer fiber,” Mater. Lett., 62(19), 3370 – 3372 (2008).

L. D. Maxim and M. J. Utell, “Aluminosilicate fibers,” in: Encyclopedia of Toxicology, Dec. (2014), pp. 156 – 160.

V. V. Samoylenko, V. V. Firsov, and O. S. Tatarintseva, “On the issue of assessing the heat resistance of aluminosilicate fiber,” Polzunovskii Vest. 1(4), 213 – 217 (2016).

V. E. Soshkin and M. V. Kumarin, “Technologies for the production and use of high-temperature refractory materials and products based on aluminosilicate fibers and inorganic binders,” Liteishchik Rossii, No. 3, 21 – 23 (2014).

Sukholozhskii Refractory Plant [Electronic resource]; URL: http://slsoz.ru (date of access: 08/10/2021).

BFAI LLC [Electronic resource]; URL: https://bfai.ru (date of access: 08/11/2021).

Rath [Electronic resource]; URL: https://www.rathgroup.com/ru (date of access: 08/12/2021).

Research and Production Enterprise Izomat CJSC [Electronic resource]; URL: https://www.izomat.ru (date of access: 08/13/2021).

Home. Unifrax [Electronic resource]; URL: https://www.unifrax.com (date of access: 08/12/2021).

3M/ Nextel/ Ceramic Fibers and Textiles: Technical Reference Guide, 3M Advanced Materials Division, 3M Center, St. Paul (2021).

Luyang Energy-saving Materials Co., Ltd [Electronic resource]; URL: https://www.luyangwool. com (date of access:08/12/2021).

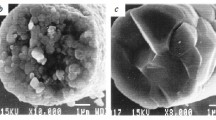

B. L. Krasnyi, A. B. Krasnyi, and M. N. Korolev, “Innovative integrated solutions for the purification of waste gasses in ferrous metallurgy. Technical solutions for cleaning high-temperature gas flows,” Chernaya Metall., Byull. Sci., Tech., Economic Inform., No. 77(2), 200 – 208 (2021).

G. Elliott, “Developments of Cerafil/filter elements in environmental emission technology for aluminum refineries,” in: Proc. 7th International Alumina Quality Workshop (2005), pp. 258 – 263.

J. Humalaki, Mechanical Characterization of Fibrous Ceramic Filter Elements, Master of Science Thesis (2013). URL: https://trepo.tuni.fi/bitstream/handle/123456789/21791/Humalam %C3 %A4ki.pdf?sequence=3&isAllowed=y (date of access 08.12.2021).

FilterRath [Electronic resource]; URL: https://www.rathgroup.com/ru/products/vacuum-formed-products/filtrath (date of access: 08/12/2021).

Glosfume [Electronic resource]; URL: http://www.glosfume.com (date of access: 08/12/2021).

Rath Integrates BWF’s Ceramic Hot Gas Filter Cartridge Production in Meissen Facility (2020). URL: https://www.filtsep.com/power-generation/news/rathbwfs-ceramichot-gas-filter-cartridge/ (date of access 18/10/2021).

B. L. Krasnii, V. G. Kiselev, V. P. Tarasovskii, and V. V. Bondar’, “Device for the manufacture of products with a fibrous structure, Pat. RU2307702C1, No. 2307702,” Byull. Izobr. Polezn. Modeli, No. 28 (2007), dec. 04.04.2006, publ.10.10.2007.

R. F. Allen, Filter Elevent, Pat. US 2008/0314012 (2008).

J. F. Zievers, Hot Gas Filter, Pat. US 4968467 (1990).

T. Carius, M. Dunkel, and H.-J. Imminger, Filter Candle with Mineral Additive, Pat. US 2017/0333819A1 (2017).

Kennet, B. Miller, Asastair Mcintype, JasonWeir, Herve Lhote, and Mauricio Munhoz De Souza, Filter Element and Method for Making the Same, Pat. US 2017/0333819 A1 (2017).

J. Chandradass and M. Balasubramanian, “Effect of magnesium oxide on sol-gel spun alumina and alumina-zirconia fibers,” J. Europ. Ceram. Soc., 26(13), 2611 – 2617 (2006).

N. M. Varrik, A. M. Zimichev, and A. V. Sumin, “Obtaining continuous fibers based on aluminum oxide with the addition of silicon oxide and zirconium,” Chem. Fibers, No. 6, 22 – 29 (2019).

P. Zhang, X. Jiao, and D. Chen, “Fabrication of electrospun Al2O3 fibers with CaO–SiO2 additive,” Mater. Lett., 91, 23 – 26 (2013).

L. Li, X. Liu, and G. Wang, “Research progress of ultrafine alumina fiber prepared by sol-gel method: A review,” Chem. Eng. J., 421, Pt 2 (2020); URL: https://doi.org/10.1016/j.cej.2020.127744 (date of access 09.24.2021).

G. I. Shcherbakova, T. L. Apukhtina, N. S. Krivtsova, et al., “Method for obtaining modified aluminum oxide fibers, Pat. RU2716621C1, No. 2716621,” Byull. Izobr. Polezn. Modeli, No. 8 (2020), dec. 10/22/2018, publ. 03/13/2020.

I. S. Martakov, P. V. Krivoshapkin, M. A. Torlopov, and E. F. Krivoshapkina, “Influence of the supramolecular structure of cellulose on the morphology of aluminum oxide fibers obtained by the sol-gel method,” Khim. v Interesakh Ustoich. Razv., No. 22, 145 – 151 (2014).

I. S. Martakov, M. A. Torlopov, and E. F. Krivoshapkina, “The use of cellulose in the production of ceramic fibrous materials by the template method,” in: Scientific and Applications Conf. Prof.-Teacher Staff at the Syktyvkar Forest Institute Based on the Results of Scientific Research Performed in 2015 [in Russian], Syktyvkar (2016), pp. 312 – 313.

I. S. Martakov, Morphology and Properties of Aluminum and Titanium Oxides Obtained by Template Synthesis Using Cellulose and Its Derivatives, Author’s Abstract of Candidate’s Thesis [in Russian], Institute of Chemistry, Komi Scientific Center, Ural Branch of the Russian Academy of Sciences, Syktyvkar (2017).

C. Cui, M. He, and B. Hu, “Membrane solid phase microextraction with alumina hollow fiber on line coupled with ICP – OES for the determination of trace copper, manganese and nickel in environmental water samples,” J. Hazardous Mater., 187(1 – 3), 379 – 385 (2011).

B. A. Krajina, A. C. Proctor, and A. P. Schoen, “Biotemplated synthesis of inorganic materials: An emerging paradigm for nanomaterial synthesis inspired by nature,” Prog. Mater. Sci., 91, 1 – 23 (2018).

S. Yang, Y. Sun, and Z. Jia, “Fabrication and characterization of alumina fiber by anodic oxidation and chemical dissolution processes,” Ceram. Int., 45(10), 12727 – 12733 (2019).

Y. Zhang, Y. Ding, Li., “Synthesis and characterization of polyvinyl butyral – Al(NO3)3 composite sol used for alumina based fibers,” J. Sol-Gel Sci. Technol., 49, 385 – 390 (2009).

H. Zhang, Y. Hang, and Y. Qin, “Synthesis and characterization of sol-gel derived continuous spinning alumina based fibers with silica nano-powders,” J. Europ. Ceram. Soc., 34(2), 465 – 473 (2014).

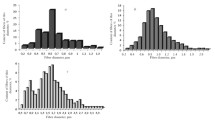

T. S. Natarajan and P. Bhargava, “Influence of spinning parameters on synthesis of alumina fibers by centrifugal spinning,” Ceram. Int., 44(10), 11644 – 11649 (2018).

M. Akia, D. Capitanachi, and M. Martinez, “Development and optimization of alumina fine fibers utilizing a centrifugal spinning process,” Micropor. Mesopor. Mater., 262, 175 – 181 (2018).

J. H. Roque-Ruiz, N. A. Medellin-Castillo, and S. Y. Reyes-Lopez, “Fabrication of α-alumina fibers by sol-gel and electrospinning of aluminum nitrate precursor solution,” Results in Physics, 12, 193 – 204 (2019).

C. Li,W. Liu, and T. Luo, “Effect of formic-acid–to–acetic–acid ratio on the structure and spinnability of aqueous aluminum sol of alumina fiber,” Ceram. Int., 47(18), 26034 – 26041 (2021).

K. Taewan and L. Kiyoung, “Formation of anodic Al oxide nanofibers on Al3104 alloy substrate in pyrophosphoric acid,” J. Korean Electrochem. Soc., 1(24), 7 – 12 (2021).

M. Chatterjee, M. Naskar, and P. Chakrabarty, “Sol-gel alumina fiber mats for high-temperature applications,” Mater. Lett., 57(1), 87 – 93 (2002).

P. V. Krivoshapkin, Obtaining and Physical and Mechanical Properties of Materials Based on Nanodispersed Oxides of Aluminum and Iron (III), Author’s Abstract of Candidate’s Thesis [in Russian], Institute of Chemistry, Komi Scientific Center, Ural Branch of the Russian Academy of Sciences, Syktyvkar (2016).

P. P. Faikov, K. S. Zamarenskikh, N. A. Popova, N. A. Fedosova, E. V. Zharikov, and E. M. Kol’tsova, “Ceramic composite material and method of its preparation, Pat. RU2517146 No. 2517146,” Byull. Izobr. Polezn. Modeli, No. 15 (2014), dec.02.07.2012, publ. May 27 (2014).

N. M. Varrik, Yu. A. Ivakhnenko, and V. G. Maksimov, “Oxide-oxide composite materials for gas turbine engines (review),” Tr. VIAM, No. 8 (2014); URL: http://viam-works.ru/ru/articles? art id=694 (date of access: 09/15/2021).

J. Zhang, K. Xiong, Z. Sun, “Strength degradation of aluminum fiber: Irreversible phase transition after high temperature treatment,” Ceram. Int., 47(17), 24582 – 24588 (2021).

M. Sreejith and R. S. Rajeev, “Fiber reinforced composites for aerospace and sports applications,” in: Fiber Reinforced Composites (2021), pp. 821 – 859.

D. N. Awang Chee and A. F. Ismail, “Dual-function ZIF-8 membrane supported on alumina hollow fiber membrane for copper(II) removal,” J. Env. Chem. Eng., 9(4), 105343 (2021). https://doi.org/10.1016/j.jece.2021.105343

D. N. Awang Chee, A. F. Ismail, and F. Aziz, “The influence of alumina particle size on the properties and performance of alumina hollow fiber as support membrane for protein separation,” Separation and Purification Technol., 250, 117147 (2020). https://doi.org/10.1016/j.seppur.2020.117147

Y. R. Chen, L. H. Chen, and C. H. Chen, “Hydrophobic alumina hollow fiber membranes for sucrose concentration by vacuum membrane distillation,” J. Membrane Sci., 555, 250 – 257 (2018).

D. L. Trimm and C. W. Lam, “The combustion of methane on platinum-alumina fiber catalysts-I: Kinetics and mechanism,” Chem. Eng. Sci., 35(6), 1405 – 1413 (1980).

X. Zhou, K. Song, and Z Li, “The excellent catalyst support of Al2O3 fibers with needle-like mullite structure and HMF oxidation into FDCA over CuO/Al2O3 fibers,” Ceram. Int., 45(2), Pt 2, 2330 – 2337 (2018).

E. Cuenca, L. D’Ambrosio, and D. Lizunov, “Mechanical properties and self-healing capacity of ultra-high performance fiber-inforced concrete with alumina nano-fibers: tailoring ultra-high durability concrete for aggressive exposure scenarios,” Cement and Concrete Composites, 118, 103956 (2021). DOI: https://doi.org/10.1016/j.cemconcomp.2021.103

S. Muzenski, I. F. Vivian, and K. Sobolev, “Ultra-high strength cement-based composites designed with aluminum oxide nano-fibers,” Constr. Build. Mater., 220(1), 177 – 186 (2019).

A. Houston and T. Clyne, “Highly porous hybrid particle-fiber ceramic composite materials for use as diesel particulate filters,” J. Europ. Ceram. Soc., 40(2), 542 – 551 (2019).

A. Mathur and S. Chavan, “Exhaust filtration: Fiber based solutions in diesel exhaust filtration,” Filtration & Separation, 45(5), 32 – 35 (2008).

GOST R 56212–2014. Fiberglass. Silica Fiber, Materials, and Products Based on It, National Standard of the Russian Federation [in Russian], Standartinform, Moscow (2015).

X. Luan, X. Xu, and M. Li, “Design, preparation, and properties of a boron nitride coating of silica optical fiber for high temperature sensing applications,” J. Alloys Compd., 850, 156782 (2021). https://doi.org/10.1016/j.jallcom.2020.156782

NPO Stekloplastik: [Electronic resource]; URL: https://npo-stekloplastic.ru (date of access: 08/13/2021).

Y. Nakashima, M. Fukushima, and H. Hyuga, “Fiber template approach preparing towards one-dimensional silica nanostructure with rough surface,” Adv. Powder Technol., 32(4), 1099 – 1105 (2021).

S. S. Choi, S. G. Lee, and S. S. Im, “Silica nanofibers from electrospinning/sol-gel process,” J. Mater. Sci. Lett., 22(12),891 – 893 (2003).

A. C. Patel, S. Li, and C.Wang, “Electrospinning of porous silica nanofibers containing silver nanoparticles for catalytic applications,” Chem. Mater., 19(6), 1231 – 1238 (2007).

Y. Dong, C. Su, and X. Pan, “Density functional theory investigation on formation of nanoscale PbS materials and its fabrication in silica optical fiber via atomic layer deposition,” Opt. Fiber Technol., 58, 102257 (2020). https://doi.org/10.1016/j.yofte.2020.102257

G. Liu, F. Wang, and X. Guan, “Geometric and optical properties of Bi/Er co-doped silica optical fiber,” Opt. Mater., 107, 110030 (2020). https://doi.org/10.1016/j.optmat.2020.110030

Z. An, X. Hou, and P. Zhou, “A novel flexible, layered, recoverable SiO2 fiber skeleton and aerogel composites material prepared by papermaking process,” Ceram. Int., 47(9), 12963 – 12969 (2021).

Ekowool: [Electronic resource]; URL: http://www.ekowool.ru (date of access: 09/15/2021).

Polotsk-Glass Fiber JSC [Electronic resource]; URL: http://www.polotsk-psv.by (date of access: 09/15/2021).

K. D. Freeman and G. E. Jabb, “Modification of alkaline earth silicate fibers, Pat. No. 2416577 RF,” Byull. Izobr. Polezn. Modeli, No. 34 (2008), dec. 10.26.05, publ. 12.10.08.

X. Wang, H. Liu, and Z. Wang, “Effect of rare earth oxides on the properties of bio-soluble alkaline earth silicate fibers,” J. Rare Earths, 34(2), 203 – 207 (2016).

L. D. Maxim and M. J. Utell, “Aluminosilicate Fibers,” in: Encyclopedia of Toxicology (2014), Vol. 1, pp. 156 – 160.

M. J. Utell and L. C. Maxim, “Refractory ceramic fiber (RCF) toxicity and epidemiology: A review,” Inhalation Toxicology, 22(6), 500 – 521 (2010).

T. W. Hesterberg, G. Chase, and C. Axten, “Biopersistence of synthetic vitreous fibers and amosite asbestos in the rat lung following inhalation,” Toxicology Appl. Pharmacology, 151(2), 262 – 275 (1998).

X. T.Wang, C. Z. Luo, and B. G. Zhang, “Solution behavior of CaO–MgO–SiO2 system bio-soluble refractory ceramic fibers,” Key Eng. Mater., 336 – 338, 1556 – 1558 (2007).

X. Zhu, Y. Gu, andW. Ma, “Biomarkers for pulmonary inflammation and fibrosis and lung ventilation function in Chinese occupational refractory ceramic fibers-exposed workers,” Int. J. of Environmental Research and Public Health, 15(1), 42 (2017). DOI: https://doi.org/10.3390/ijerph15010042

G. E. Jubb and K. D. Freeman, “Salt-soluble inorganic fibers, Pat. No. 2303574 RF,” Byull. Izobr. Polezn. Modeli, No. 2 (2003), dec. 01.02.03, publ. 07.24.03.

Beijing SUPER International Trade Co., Ltd [Electronic resource]; URL: https://beijingsuper.ru (date of access:09/15/2021).

Altra®, Alsitra, Calsitra. Ultra-Light High Temperature Insulation Wool for Heat Insulation up to 1650°C [Electronic resource]; URL: http://www.nurzat.com.tr/assets/files/rath/products/htiw.pdf (accessed 09.15.2021).

G. E. Jubb and J. L. Martin, Fibers Resistant to High Temperatures, Soluble in Physiological Saline, Pat. 2247085 RF [in Russian], publ. 02/27/2005.

Lee Jin Hiuk, Seog In Sig, Lee Dzeung Dze, and Dzung Won Sik, “Composition for the manufacture of ceramic fiber and bio-soluble ceramic fiber obtained from it for heat-insulating material at high temperature, Pat. RU 2 580 846 C2. No. 2580846,” Byull. Izobr. Polezn. Modeli, No. 9 (2011), dec.12/14/10, publ. 01.09.11.

Z. Du, L. Guo, and T. Zheng, “Formation of core-shell structured calcium silicate fiber via sol-gel electrospinning and controlled calcinations,” Ceram. Int., 45(18), 23975 – 23983 (2019).

C. Xu, S. Shi, and S. Zhu, “Comparative study on electrospun magnesium silicate ceramic fibers fabricated through two synthesis routes,” Mater. Lett., 127837 (2020). https://doi.org/10.1016/j.matlet.2020.127837

C. Xu, S. Shi, and X. Wang, “Electrospun SiO2–MgO hybrid fibers for heavy metal removal: characterization and adsorption study of Pb(II) and Cu(II),” J. Hazardous Mater., 381, 120974 (2019). https://doi.org/10.1016/j.jhazmat.2019.120974

C. Xu, S. Shi, and Q. Dong, “Citric-acid-assisted sol-gel synthesis of mesoporous silicon-magnesium oxide ceramic fibers and their adsorption characteristics,” Ceram. Int., 46(8), 10105 – 10114 (2020).

E. N. Demin, I. D. Kashcheev, and V. K. Ivanov, “New high-temperature heat-insulating materials,” Novye Ogneupory, No. 10, 19 – 21 (2012).

D. A. Fernando, “Insulating plate from high-strength biosoluble inorganic fibers, Pat. No. 2011126262 RF,” Byull. Izobr. Polezn. Modeli, No. 4 (2010), dec. 12/29/2009; publ.07.08.10.

M. Boarnuya, Exhaust Gas Treatment Device, Pat. 2453713 RF [in Russian], publ. 06/20/2012.

Astrakhan Glass Fiber PJSC [Electronic resource]; URL: http://www.azsv.ru/ (date of access: 10/14/2021).

A. M. Zimichev and E. P. Solovieva, “Zirconium dioxide fiber for high-temperature applications (review),” Aviats. Mater. Tekhnol., No. 3, 55 – 61 (2014).

V. P. Gorelov, “High-temperature phase transitions in ZrO2,” Fiz. Tverd. Tela, 61(7), 1346 – 1351 (2019).

Bernard H. Hamling, Stabilized Tetragonal Zirconia Fibers and Textiles, Pat. US 3860529, Warwick, NY (1975).

C. Heuer, E. Storti, and T. Graule, “Electrospinning of Y2O3-and MgO-stabilized zirconia nanofibers and characterization of the evolving phase composition and morphology during thermal treatment,” Ceram. Int., 46(8), Pt B, 12001 – 12008 (2020).

V. V. Rodaev, S. S. Razlivalova, and A. I. Tyurin, “Microstructure and phase composition of yttria-stabilized zirconia nanofibers prepared by high-temperature calcination of electrospun zirconium acetylacetonate/yttrium nitrate/polyacrylonitrile fibers,” Fibers, 7(10), 82 (2019). https://doi.org/10.3390/fib7100082

K. Castkova, K. Maca, and J. Sekaninova, “Electrospinning and thermal treatment of yttria doped zirconia fibers,” Ceram. Int., 43(10), 7581 – 7587 (2017).

E. F. Funkenbusch,W. B. Lake, and T. T. Tran, Zirconium Oxides Fibers and Process for Preparation, Pat. US4937212 (1990).

K. Yuan, X. Jin, and Z. Yu, “Electrospun mesoporous zirconia ceramic fibers for catalyst supporting applications,” Ceram. Int., 44(1), 282 – 289 (2018).

L. Xu and H. K. Lee, “Zirconia hollow fiber: preparation, characterization, and microextraction application,” Analytical Chem., 79(14), 5241 – 5248 (2007).

J. L. Woodhead, Zirconium/Metal Oxides Fibers, Pat. US6790807 (2004).

H. Y. Liu, X. Q.. Hou, and X. Wang, “Fabrication of high-strength continuous zirconia fibers and their formation mechanism study,” J. Am. Ceram. Soc., 87(12), 2237 – 2241 (2004).

K. Castkova, K. Maca, and J. Sekaninova, “Electrospinning and thermal treatment of yttria doped zirconia fibers,” Ceram. Int., 43(10), 7581 – 7587 (2017).

Q. Dong, S. Shi, and Y. Xie, “Preparation of mesoporous zirconia ceramic fibers modified by dual surfactants and their phosphate adsorption characteristics,” Ceram. Int., 46(9), 14019 – 14029 (2020).

D. S. Rutman, Yu. S. Toprov, and S. Yu. Pliner, High Refractory Materials from Zirconium Dioxide [in Russian], Metallurgiya, Moscow (1985).

Y. Tang, Z. Liu, and K. Zhao, “Adsorption and separation properties of positively charged ZrO2 nanofibrous membranes fabricated by electrospinning,” RSC Adv., 7(67), 42505 – 42512 (2017).

A. Stanishevsky, R. Yager, and J. Tomaszewska, “Structure and mechanical properties of nanofibrous ZrO2 derived from alternating field electrospun precursors,” Ceram. Int., 45(15), 18672 – 18682 (2019).

L. Yin, J. Niu, and Z. Shen, “Preparation and photocatalytic activity of nanoporous zirconia electrospun fiber mats,” Mater. Lett., 65(19 – 20), 3131 – 3133 (2011).

E. Bódis, K. Molnar, and A. Mucsi, “Silicon nitride-based composites reinforced with zirconia nanofibers,” Ceram. Int., 43(18), 16811 – 16818 (2017).

R. Zhang, X. Hou, and C. Ye, “Fabrication and properties of fibrous porous mullite-zirconia fiber networks with a quasi-layered structure,” J. Europ. Ceram. Soc., 36(14), 3539 – 3544 (2016).

Anhui Harmony Crystal and New Material Co., Ltd. [Electronic resource]; URL: http://en.anhuihcm.com (date of access 09.13.2021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 1, pp. 39 – 50, January, 2022.

Rights and permissions

About this article

Cite this article

Krasnyi, B.L., Ikonnikov, K.I., Lemeshev, D.O. et al. Oxide-Containing Mineral Fibers: Types, Manufacturing Methods, Applications, and Producers (Review). Glass Ceram 79, 28–36 (2022). https://doi.org/10.1007/s10717-022-00448-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-022-00448-7