Abstract

Time and cost estimation of tunneling projects is usually performed in a deterministic manner. However, because the deterministic approach is not capable of dealing with uncertainty, probabilistic methods have been developed over the years to better account for this problem. Three models of this type are the Decision Aids for Tunneling (DAT) and two models developed at KTH Royal Institute of Technology and the Czech Technical University in Prague. To conduct a probabilistic time and cost estimation, it is important to understand and account for not only the uncertain factors that affect the project time and cost but also the involved parties’ different interests and contractual responsibilities. This paper develops a risk model for the specific purpose of time and cost estimation of tunneling projects. In light of this model, the practical application of the three probabilistic models is discussed from a risk-aware decision-maker’s perspective. The acquired insights can be helpful in increasing the experts’ risk-awareness in modeling time and cost of tunneling projects.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

During the planning phase of tunneling projects, time and cost are key factors in the decision-making process. These factors are typically estimated by experts using their experience from similar projects in the past. However, such estimations are often not sufficiently accurate. In many cases, the actual cost or time exceeds the estimate, which puts the sound management of huge amounts of public resources (or private, in some cases) in jeopardy. In the case of project costs, this situation is traditionally described using the terms cost overrun or cost escalation. Cost overrun is the exceedance of the original cost estimation. This phenomenon occurs in many of transport infrastructure projects (including tunneling projects) around the world, and has been common over the last 70 years (Skamris and Flyvbjerg 1997; Flyvbjerg et al. 2002, 2003; Cantarelli et al. 2012; Huo et al. 2018). According to Flyvbjerg (2006) the main cause of cost overruns are optimism bias and strategic misrepresentation where the technical reasons are not considered important. However, this conclusion has been criticized by recent studies, which conclude that technical reasons are in fact important (Miranda Sarmento and Renneboog 2017; Love and Ahiaga-Dagbui 2018; Gao and Touran 2020; Mohammadi 2021).

The estimation of time and cost is considered essential in tunneling project planning. The time and cost required for construction work are commonly estimated in a deterministic manner (Špačková et al. 2013a), but the deterministic approach is incapable of properly capturing the existing uncertainty. In comparison, probabilistic estimates of tunneling time and cost can help in understanding uncertainties and risks and lead to more reliable estimations (Reilly and Brown 2004; Guan et al. 2014; Naghadehi et al. 2016).

Optimal management of resources allocated for tunneling projects necessitates management of the uncertainty in time and cost estimates. A proper approach to the subject could potentially save significant amounts of public resources, and probabilistic approaches can be useful in managing the prevailing uncertainty. For example, by presenting time and cost estimates as a distribution with relevant probabilities, the decision-maker achieves a broader view of the risks involved in the decision. As a tunnel project generally has two contractual parties—a client and a contractor—decision-makers on both sides can favor applying probabilistic time and cost estimation approaches; nevertheless, the two parties have different interests and therefore different needs in terms of application.

There are essentially four aspects of a decision maker’s use of a probabilistic time and cost estimation tool:

-

(1)

The establishment of a probabilistic geological model providing the estimated probabilities of meeting different types of geological features and disruptive events along the tunnel route;

-

(2)

The establishment of a time and cost model that provides the total time and cost for a tunnel excavated through possible geological features;

-

(3)

The modification of the analysis considering the client’s or contractor’s risk ownership, as determined by the contract (e.g., a contractor’s analysis for bid preparation does not need to consider conditions and events for which the client, according to the contract, will compensate additionally in time and cost);

-

(4)

The application of the tool for budget estimation or scheduling optimization purposes.

Successful time and cost estimation requires a deep understanding of all the different underlying aspects that affect tunneling time and cost, covering not only the uncertain geological setting but also the variability in work processes and involved parties’ different interests and contractual responsibilities. Having such insight about the nature of the time and cost estimation problem would benefit both practicing engineers using the probabilistic models and researchers improving upon them.

In this paper we therefore discuss three existing probabilistic time and cost estimation models for tunnels from a risk-aware decision-maker’s perspective. The models are Decision Aids for Tunneling (DAT), developed by Einstein et al. (1992), a model developed by Isaksson and Stille (2005) at KTH Royal Institute of Technology (henceforth the KTH model), and a model developed by Špačková (2012) at the Czech Technical University in Prague (henceforth the CTU model). The scientific contribution of this paper lies in providing a theoretical basis for the practical application of such models. First, we further developed the risk model for tunnel projects that has been developed at KTH Royal Institute of Technology over recent decades (e.g. Sturk 1998; Stille 2017; Mohammadi and Spross 2023). The probabilistic models and their practical application are then discussed in light of the risk model.

This paper is structured as follows. Section 2 gives a brief overview of the three estimation models. Section 3 explains the risk model. Section 4 discusses the application of the estimation models in light of the risk model, and Sect. 5 presents concluding remarks. The frequently used Successive Principle (Lichtenberg 2000) is not considered in this paper for two reasons: it does not provide a proper probability distribution of time and cost, and it uses a top-down method to break down and analyze the project activities, whereas the other three models use a bottom-up method.

2 Estimation Models

2.1 Decision Aids for Tunneling (DAT)

Einstein et al. (1992) developed DAT at the Massachusetts Institute of Technology (MIT) and École Polytechnique Fédérale de Lausanne (EPFL). It consists of three main modules: geology, construction, and resources. The DAT tool facilitates the tunneling time and cost estimation, together with required resources such as construction material. Probabilistic geological/geotechnical profiles along the tunnel route are provided through geological description. Information obtained through geological exploration and subjective estimates made by experts are the input parameters that DAT uses to construct the profiles indicating the probabilities of particular geologic conditions occurring at a particular tunnel location (Fig. 1). Specifically, the average length of geological parameters and the probabilities of their transition are predicted by using a Markov chain, which means that the state of each subsequent geological condition depends on the state of the current geology and not on previous states (Einstein et al. 1999; Einstein 2004). The geological conditions are represented by several parameters that can take a range of values, and the effect of all parameters is accounted for by dividing their combinations into the ground classes. In each ground class different construction methods in terms of their unit activities are required, and these are referred to as construction classes.

a Probabilistic ground-class profile along the tunnel route (Gi represents ground classes) b a time–cost scattergram (Reprinted from Einstein et al. (1996) with permission from ASCE)

The construction process is simulated through ground class profiles using the software’s construction simulation component. This means that the ground classes are related to the construction classes in terms of the time and cost required. In the DAT application, parameters such as tunnel cross-section, primary and final support, as well as the excavation method most applicable to each ground class are combined to define different construction classes. Since the ground classes along the tunnel route change repeatedly, different construction classes are usually applied to complete any given tunnel, and since there are many possible ground class profiles predicted for the tunnel route at this stage, the DAT software applies a Monte Carlo procedure to simulate the construction process. First, the construction simulation is run for one random ground class profile, resulting in a time and cost, which is shown by each point in Fig. 1. Then, this procedure is repeated on the other geological profiles, and the complete time–cost scattergram shown in Fig. 1 emerges (Halabe 1996; Einstein et al. 1999; Einstein 2004).

The DAT can be used in different phases of tunneling, and the level of input depends on the project phase. It has been proposed to modify the tool to allow for the refinement of predictions via Bayesian updating, using conditions observed during the construction process (see, for example, Haas and Einstein 2002; Min et al. 2005). Min et al. (2003, 2008) used the DAT for a tunnel constructed by the drill & blast method. Analysis of the changes in tunneling technology effects’ on time and cost for micro-tunneling and tunneling with a full-face tunnel boring machine (TBM) was facilitated via simulations using DAT (Sinfield and Einstein 1996). The DAT can also be used for resource scheduling and planning as well as planning the handling of excavated material (Ritter et al. 2013; Min and Einstein 2016). Moreover, the DAT were also extended to be used for the time and cost estimation of wellbore drilling for engineered geothermal systems (Yost et al. 2015), viaducts, cuts, and embankments (Moret and Einstein 2016), as well as large-scale cavern construction projects (Zhe et al. 2015; Maruvanchery et al. 2020).

2.2 The KTH Model

This model was developed by Isaksson and Stille (2005) at KTH Royal Institute of Technology. In this model the inverse of the advance rate—i.e., the time and cost it takes to excavate a unit length of tunnel using a particular construction class (h/m)—is used as a basis for mathematical calculations. This concept is labeled production effort.

The first step in this estimation model specifies probable states of geological and hydrogeological conditions along the planned tunnel route. Then the tunnel route is divided into a number of geotechnical zones with more or less similar geological conditions, in which the same construction class is expected to be used. The total time (T) and cost (C) are expressed as the sum of normal and exceptional times and costs (TN, CN, TE, and CE), where the exceptional times and costs are caused by the occurrence of disruptive events (in the original model, the term undesirable events is used). Dividing the total tunnel length into nzone geotechnical zones of different characteristics,

where Lu is the length of the uth geotechnical zone, and zα is the cost variable related to one of the nα = 3 cost types: time-dependent, quantity-dependent, and fixed costs. The expression \(g_{u} \left[ {{\mathbf{x}}\left( l \right)} \right]\) is the production effort and is a function of the set of geotechnical characteristics (x) relevant for construction time and cost in zone u, where ndis is the number of types of disruptive events, and TE,i and CE,i are the time delay and imposed cost due to the occurrence of the disruptive event type i.

In the case of estimating time, the production effort (Q) is the number of working hours per unit length for the activities on the critical path. Two types of Q have to be considered when estimating the cost, i.e. quantity-dependent and time-dependent. The Q in a given construction class is mainly affected by a set of geotechnical characteristics (x). An example of the stochastic relationship between Q and a single geotechnical characteristic (xi) is shown in Fig. 2. The production effort is categorized into three classes (poor, fair, and good) by the subjective assessment of experts. These categories are called production classes. Figure 2 illustrates the utilization of triangular distributions to represent uncertainty in the production effort of each production class. Experts assign the minimum, most likely, and maximum production efforts (duration per unit length of tunnel) within each class, drawing upon their expertise or data from previous comparable projects. These assigned values are then utilized within the model framework to calculate the overall time and cost. The important issue in assessing production classes is to define the range or group of geotechnical characteristics corresponding to a certain production class.

An example of the relation between a single geotechnical characteristic (xi) and production effort (Q), illustrating production effort in each production class (PC), where the triangles show how the minimum, most likely, and maximum values of production effort can be modelled by triangular distributions within each class. The dashed lines represent the theoretical relationship between Q and xi (based on Isaksson 2002)

The KTH model also takes the robustness of the tunneling method into consideration: when variation in the magnitude of a certain geotechnical characteristic has only negligible effects on the capacity of the tunneling method, the method is robust with respect to that geotechnical characteristic. However, to increase robustness, different tunneling methods would require different robustness-increasing measures (Isaksson 2002; Isaksson and Stille 2005). For instance, grouting is a robustness-increasing measure in good quality rock mass where a significant amount of groundwater inflow is expected. Moreover, foam can be added when using an Earth Pressure Balance (EPB) tunneling machine if the ground is found to have high permeability. In Fig. 3, an illustrative example of the modeling results for tunneling time is presented. The KTH model is utilized to estimate the tunneling time for a tunnel with a length of 2700 m. The histogram demonstrates the distribution of total tunneling time obtained through Monte Carlo simulation with a sample size of 100,000. Similar distributions for total tunneling cost are obtained. This model can be used in all phases of a tunnel project, including the construction phase, where the results can be refined using any real data obtained.

2.3 The CTU Model

This model was developed by Špačková (2012) at the Czech Technical University in Prague. A Poisson distribution is used to describe the number of disruptive events (which this model labels failures) that can occur while excavating a tunnel of length L. Therefore, the probability of a \(N_{{\text{F}}} = k\) number of disruptive events is:

where L = [L1, Li, …, \(L_{{n_{Z} }}\)] is the total tunnel length divided into \(n_{Z}\) zones, H is a discrete random variable called Human Factor, \(n_{H}\) is the number of states of the variable H, and λij is the failure rate within the ith zone with length Li for H in state j. Hence, \({{\varvec{\uplambda}}}\) is a matrix describing the failure rate per unit length of tunnel, defined as:

where the rows indicate the number of zones comprising the tunnel and the columns represent different states of the parameter human factor.

A time delay or financial loss are types of damage caused by the occurrence of disruptive events. The total delay brought about by tunnel construction failures can be quantified as:

where Di is the time increase caused by the ith failure, and NF is the number of failures. The Di and DTOT are both continuous random variables (Špačková 2012; Špačková et al. 2013b).

Tunnel construction performance is modeled using a dynamic Bayesian network (DBN), as shown in Fig. 4. A construction round of length ∆l (a segment in the original model) in the tunnel is represented by a slice in the DBN model. The same round length ∆l is used for all slices. Within a segment, all variables are treated spatially as constants, meaning that the construction process and geotechnical conditions do not vary within a segment (Špačková 2012; Špačková et al. 2013c). The slice lengths are also considered constant throughout the construction process, which means that geotechnical conditions can only change when entering a new slice in the model (Špačková and Straub 2011). Any event that causes a delay longer than the threshold value of 15 days is categorized as an extraordinary event, and events that cause less than 15 days of delay are categorized as small disturbances (Špačková 2012). Špačková et al. (2013a) concluded that the mean and variance of the observed unit time is significantly influenced by the occurrence of small disturbances, but they noted that most experts would not consider the effect of these events. Špačková et al. (2013a) took the effect of these disturbances into account.

Generic DBN model used for the tunnel construction process. Here, ∆l is the length of construction rounds, GCi is the geological condition in the ith round, CPi is the construction time and cost for the ith round, EEi is the disruptive events in the ith construction round, Tcu,i is the sum of duration of i rounds, Ccu,i is the sum of costs of i rounds. Tcu,I and Ccu,I are the total time and cost of construction, and Cover,I is the final cost of the project which is obtained by adding overhead costs to total cost of construction (Reprinted from Špačková et al. (2013c) with permission from Elsevier)

The human factor (variable H) is a discrete random variable that represents human, organizational, and external factors that systematically influence construction time, which creates stochastic dependencies among performances in each segment (construction round). The human factor H has three possible states (j = 3): unfavorable, neutral, and favorable. Practically, a favorable state of H means better quality of organization of construction planning which indicates lower rate of occurrence of failures (disruptive events). The conditional probability of occurrence of k failures for a given H = j is described in Eqs. 2 and 3. However, this parameter cannot be measured directly prior to the start of construction. Thus, one can only deduce the parameter from the average performance over long sections of already-performed tunnel excavation (Špačková et al. 2013b; Špačková 2012). To investigate the effect of H on total time of tunneling, Tcum, Špačková (2012) compared two different realizations of the states of H as:

-

H(a): Pr(Hi = “unfavorable”) = 0.3, Pr(Hi = “neutral”) = 0.6, Pr(Hi = “favorable”) = 0.1

-

H(b): Pr(Hi = “unfavorable”) = 0.33, Pr(Hi = “neutral”) = 0.33, Pr(Hi = “favorable”) = 0.33

The results of estimation using the two realizations of parameter H as well as the estimation results without accounting for H are shown in Fig. 5. When combination H(a) is applied, the mean value of total time increases slightly, while H(b) causes no difference in the mean value. However, by applying these two scenarios, the standard deviation increases with respect to the neutral case, meaning that H affects the Tcum.

Prediction of total excavation time Tcum, for two a priori models of human factors, i.e. H(a) and H(b), and the case of a fixed human factor. The human factor (H) affects both the mean value and standard deviation of Tcum (based on Špačková 2012)

2.4 Main Differences Between the Models

All three models have three main modules: a geology module, a construction simulator, and disruptive events. The DAT and CTU models use a Markov Chain Monte Carlo (MCMC) process to predict geological conditions along the tunnel route. For this purpose, a large number of ground class profiles are established based on geological investigations. Each ground class profile represents one possible outcome of geological conditions along the tunnel route, for which the probability of occurrence for various geological conditions at each point along the tunnel route are specified. In the KTH model, the proportions of ground classes over the tunnel length are established, but their location is not specified. Modeling the proportions of ground classes as stochastic variables allows the uncertainty concerning the geological conditions to be accounted for, as recently discussed by Spross and Lidmar (2023). Notably, accurate estimation of the transition probability matrix for the MCMC process and the proportions of the ground class profiles is a challenging task for both model types, especially for complex geological settings. This is a key aspect for all the models, although no study has yet investigated the capability of these two approaches to model geological uncertainty representatively.

Another difference between the DAT and CTU models and KTH model lies in the assessment of input parameters for construction simulation. In the DAT and CTU models, the parameter advance rate is used as the basis for modeling construction simulation, while in the KTH model the inverse of the advance rate, i.e. the production effort, is the basis for construction simulation. While the assessment of advance rate and production effort is not different in practice, the calculation process becomes different, as discussed by Mohammadi et al. (2022).

Distinguished from the other two models, the CTU model uses the parameter human factor (H) to account for the effect of factors that systematically influence construction time. However, the status of the parameter H is unknown prior to the start of the construction phase.

3 Estimation Models in the Context of a Risk Model

3.1 Modeling Virtues

The desirable qualities of models are called modeling virtues or attributes. There are many modeling virtues such as generality and parameter precision that affect the suitability of a model. Nevertheless, scientists are unlikely to be able to construct models that account for all theoretical virtues simultaneously. This results in tradeoffs among the modeling virtues (Matthewson and Weisberg 2009). Therefore, model constructors must choose the best tradeoff for their purpose. In the case of time and cost estimation for tunneling projects, the main objective is to provide an accurate representation of the uncertainty about the actual final time and cost values. However, considering the high degree of complexity in tunneling projects, the scientific validation of such models is extremely challenging. Thus, a secondary desirable quality for the model would be to support decision-making that accounts for the considerable uncertainties that affect the project.

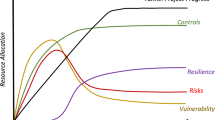

To achieve a model that accurately represents the uncertainty related to both geology and the time/cost model (aspects 1 and 2 listed in the Introduction), it is critical to understand the fundamental difference between epistemic uncertainty (caused by a lack of knowledge) and aleatory uncertainty (caused by randomness) (Der Kiureghian and Ditlevsen 2009). Knowledge gained should be reflected in a reduction of uncertainty, meaning that the modelling outcome should represent the current knowledge of geological conditions and actual variability in construction time and cost. Increased risk-awareness during planning and construction of tunnel projects will potentially result in a better representation of the uncertainty in time and cost estimations, which can in turn facilitate better management and allocation of public resources.

3.2 The Risk Model

The risk model developed at KTH (e.g. Sturk 1998; Stille 2017; Mohammadi and Spross 2023) can be used for the identification and possible prevention of different types of damage in tunnel projects. This risk model includes the following components:

-

Initiating event: event that triggers a damage event

-

Risk domain: domain that contains hazard

-

Hazard: a weakness in the risk domain containing a threat of a potential damage

-

Warning bell: indication that a damage event might occur

-

Damage event: event that results in damage

-

Damage: the consequence of the occurrence of damage event, which is often expressed as time delay and financial loss

To apply the risk model for the identification of potential damage events that can result in damage, it is required to establish an application purpose and identify the relevant risk domains. Then the possible weaknesses in the risk domain with regard to the purpose of the application of the risk model must be identified, which in turn facilitates the identification of initiating events, warning bells, and damage events. For the purpose of tunneling time and cost estimation, we further developed the model and propose in this paper, based on our practical experience from tunnel projects, six risk domains:

-

geological condition along the tunnel route,

-

issues related to the detailed design of the project,

-

issues related to the contract,

-

competency of the client and contractor in performing their duties,

-

project economy, and

-

the condition of the machinery.

Thus, the total tunneling time (T) and cost (C) are essentially functions of these risk domains:

The competence has two components:

-

Client’s competence is the awareness, willingness to act, and capability to take actions to reduce or prevent the potential occurrence of the damage events throughout the project. Client’s competence includes, for example, decision-making concerning the amount of pre-investigations, selection of tunneling method and contractual format.

-

Contractor’s competence affects the planning and construction phases. In the planning phase the contractor’s competence is the ability to provide realistic estimations for bidding purposes as well as an understanding and preventing the contract ambiguities from causing damage. In the construction phase, it is the ability to account for the following aspects:

-

Time efficiency in the organization of construction work, e.g. minimizing idle time between unit activities.

-

Provision of construction material in the work face so that there is no disruption of the construction process due to a lack of material.

-

Regular and proper maintenance of the machinery to minimize the number of machinery breakdowns.

-

Observing the warning bells that indicate the future occurrence of a damage event, and a prompt reaction to prevent it from happening.

Figure 6 shows the risk model applied to tunneling time and cost estimation. Some examples of the components of the risk model are presented in Table 1; note that one hazard can belong to more than one risk domain.

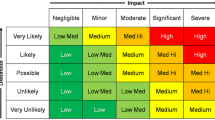

The damage in the time and cost estimation of tunneling projects can occur as either time delay, cost increase, or both. Delays and cost increases can be categorized as either minor or exceptional; the two categories are discussed further in Sects. 3.2.1 and 3.2.2.

3.2.1 Minor Delay and Minor Cost Increase

A damage event causing a minor delay or minor cost increase can happen while performing any unit activity, but such events do not cause considerable disruption to the total duration of the unit activity. Examples of such events include occasional cases of drill rods getting stuck in the rock, as well as the breakdown of a jumbo drill. Mohammadi (2021) lists more examples related to the drill & blast method. A minor delay is usually in the order of hours, and the associated cost increase is not significant for a single event. However, since the frequency of these events can be high (they can happen during all unit activities in all excavation rounds), they can have a considerable impact on the total time and cost.

3.2.2 Exceptional Delay and Cost Increase

A damage event causing an exceptional delay or exceptional cost increase is defined as an event that causes a significant disruption in the construction process. Examples of such disruptive events include tunnel collapses or excessive water ingress into the tunnel. Each disruptive event causes a considerable delay or cost increase, but they are normally rare.

4 Analysis of the Estimation Models

The way the estimation models consider three main uncertainties is discussed here with respect to the risk model and the user (client or contractor).

4.1 Geological Uncertainty

To gain a good estimation of the probabilities (proportions) of ground classes, experts need to have a good understanding of the influence of the risk domains on the estimation outcomes in all three estimation models. Experts usually assign the probabilities (proportions) of ground classes based on the information obtained from geological investigations. In this case, the prevailing uncertainty is of epistemic nature and can be reduced by obtaining more information about the geological condition of the tunnel route through geological investigations. However, it is not always financially viable to fully investigate the geological condition along the tunnel route, meaning that there can remain a considerable amount of uncertainty about the geological condition. In fact, the optimal amount of pre-investigations will depend on the purpose of analysis. A client is likely interested in estimating the total time and cost for both the budgeting and preparation of the geotechnical baseline report (GBR) to be used in the tendering. In deciding the amount of pre-investigations, the client needs to consider the contractual format as this determines the amount of geological risk owned by each party. The client’s decision on the amount of pre-investigation therefore affects the modelling results; hence, this issue is related to the risk domains of both geology and client’s competence.

On the other hand, a contractor would probably like to estimate time and cost only for the geological conditions that are specified as the contractor’s responsibility in the GBR. Thus, the contractor’s cost would be expected to be lower than the client’s, because the client is responsible for the geological condition beyond the geotechnical baselines. The ability to correctly interpret the GBR for modelling the geological uncertainty is therefore affected by the contractor’s competence.

4.2 Construction Variability

The second type of uncertainty concerns the variability in time and cost within the construction classes, meaning that the advance rate and associated costs (called production effort in the KTH model) have a remaining aleatory uncertainty even after the construction class has been determined. This uncertainty is due to the variability in unit activity time between rounds and is best described by lognormal or beta distributions (Moret and Einstein 2012). However, understanding and assigning the abstract parameters of these distributions are not easy for experts and can result in erroneous assessments, so triangular distributions are usually used, as they have been found to model the advance rate with acceptable accuracy.

For triangular distributions, the minimum, most likely, and maximum time or cost of constructing a certain segment of the tunnel (such as 1 or 5 m) are assigned by experts, based on the available information from past similar projects or the experts’ experience. Note that a client preparing a budget and a contractor preparing a bid hold a different amount of knowledge regarding the staff and machinery to be used, so the contractor should in theory assess narrower distributions for the construction variability. These estimations are challenging and in fact related to all six risk domains.

An important point in assessing time and cost in each construction class is to perform a work breakdown structure (WBS). This will facilitate more realistic modelling of the variability, as it usually is more tangible for the experts to assess the time of performing a unit activity (such as drilling, charging, etc.), than to try and assess directly the time of excavating a certain length of the tunnel. The DAT has the capability to break down any construction class into its unit activities (Sinfield and Einstein 1996). For the KTH model, Mohammadi et al. (2022) updated the application method to allow for such a breakdown into unit activities, while Isaksson and Stille (2005) originally assessed the production effort directly from a concept called production classes.

Some unit activities are conditional on other activities, meaning that a certain activity cannot be performed prior to completion of another activity. Typical examples are when the tunnel is excavated by top heading & bench excavation or when using multiple drift. Moreover, sharing certain machinery and personnel means that the respective time and cost of conditional activities are correlated. The conditionality and correlation between activities should be considered while assessing the advance rate. The effect of correlation on uncertainty is investigated by Moret and Einstein (2016); however, more research is required to model the effect of correlation and conditional activities on the other models.

Some aspects of machinery and contractor’s competence in the construction phase are conceptually captured by the human factor used in the CTU model (see Sect. 2.3), but the human factor does not explicitly model the four aspects of contractor competence in the construction phase (see Sect. 3.2), nor does it consider the effect of the machinery condition. Modelling these aspects explicitly could be helpful for project control purposes during the construction phase.

The assessed minimum, most likely, and maximum duration and cost of unit activities must be realistic in order to yield a reliable total time and cost of tunneling. During the construction phase, the distribution of actual duration and costs of the unit activities can be compared with the assessed values to ensure that the duration and cost of the unit activities were assessed accurately. Any discrepancy between the actual and assessed values can be associated with one or more risk domains. Identification of these discrepancies can be regarded as a warning bell in the context of the risk model.

4.3 Disruptive Events

Disruptive events can occur in all risk domains, but whether the model user should consider a specific disruptive event in a time and cost estimation depends on how the contract is formulated and the purpose of the estimation. A contractor needs to consider, for example, whether a GBR specifies that the risk of a certain geological hazard is owned by one’s own organization or the client, while the risk of machinery breakdown is always owned by the contractor. A contractor can also opt to transfer the risk of some disruptive events using an insurance. Regardless, disruptive events are challenging to assess because they are rare events with high consequences. The assessing experts can also consider assistance from other risk management tools such as fault and event trees (see e.g. Tidlund et al. 2023).

Some disruptive events belong to a single risk domain, while others are associated with more than one domain, competence typically being one of them. For example, geology is the single risk domain when severe squeezing happens due to encountering a weakness zone, whereas both geology and contractor’s competence affect when a collapse happens in a highly jointed rock mass due to improper or late installation of primary support.

Disruptive events are considered in all models but in different ways. In the DAT, the delays of various magnitudes can be added to each excavation round according to the expert’s assessment. The KTH model categorizes the disruptive events into 5 groups, though the events are assessed individually in terms of their probability and damage. The sum of these events constitutes the exceptional time (TE) and exceptional cost (CE), respectively. In the CTU model, the disruptive events are classified into small disturbances and main events differentiated by a threshold value of 15 days of delay.

5 Concluding Remarks

Based on proposed risk domains, we developed a risk model for tunneling time and cost estimation purposes. Understanding the risk model can increase the experts’ awareness about the prevailing uncertainty in the application of the probabilistic time and cost estimation models. In this context, three models (Decision Aids for Tunneling (DAT), the KTH model, and the CTU model) were analyzed in terms of how they handle the uncertainty. This examination discussed the influence of the risk domains on the assessment of the uncertainty of the models’ input parameters, specifically considering the client’s and contractor’s different needs and perspectives.

As a final remark, we find it important to incorporate better ways to consider uncertainties in the time and cost estimation of tunneling projects in order to provide a basis for decision-making regarding tunnel investment. Spross et al. (2018, 2020) argued that risk-based approaches that rigorously consider geotechnical uncertainty facilitate better use of public resources in the design of underground structures. We believe the same to be true for the use of probabilistic time and cost estimation models. All the models analyzed in this paper aim to improve current time and cost estimations by using probabilistic methods. We believe that in the future such approaches will be as important to time and cost estimations as their counterparts have been for structural design.

Data availability

We did not use any data for this paper as we developed a conceptual model.

References

Cantarelli CC, Van Wee B, Molin EJ, Flyvbjerg B (2012) Different cost performance: different determinants?: the case of cost overruns in Dutch transport infrastructure projects. Transp Policy 22:88–95

Der Kiureghian A, Ditlevsen O (2009) Aleatory or epistemic? Does it matter? Struct Saf 31(2):105–112

Einstein HH (2004) Decision aids for tunneling: update. Transp Res Rec 1892(1):199–207

Einstein HH, Indermitte C, Sinfield J, Descoeudres FP, Dudt JP (1999) Decision aids for tunneling. Transp Res Rec 1656(1):6–13

Einstein HH, Dudt JP, Halabe VB, Descoeudres F (1992) Decision aids in tunneling; Principle and practical application. Monograph. Swiss Federation Office of Transportation.

Einstein HH, Halabe VB, Dudt JP, Descoeudres F (1996) Geologic uncertainties in tunneling. In: Uncertainty in the geologic environment: From theory to practice, ASCE, pp 239–253.

Flyvbjerg B (2006) From Nobel Prize to project management: getting risks right. Proj Manag J 37(3):5–15

Flyvbjerg B, Holm MS, Buhl S (2002) Underestimating costs in public works projects: error or lie? J Am Plann Assoc 68(3):279–295

Flyvbjerg B, Skamris Holm MK, Buhl SL (2003) How common and how large are cost overruns in transport infrastructure projects? Transp Rev 23(1):71–88

Gao N, Touran A (2020) Cost overruns and formal risk assessment program in US rail transit projects. J Construc Eng Manag 146(5):05020004

Guan Z, Deng T, Jiang Y, Zhao C, Huang H (2014) Probabilistic estimation of ground condition and construction cost for mountain tunnels. Tunn Undergr Space Technol 42:175–183

Haas C, Einstein HH (2002) Updating the decision aids for tunneling. J Constr Eng Manag 128(1):40–48

Halabe VB (1996) Resource modeling for DAT. PhD Thesis, Massachusetts Institute of Technology, Cambridge.

Huo T, Ren H, Cai W, Shen GQ, Liu B, Zhu M, Wu H (2018) Measurement and dependence analysis of cost overruns in megatransport infrastructure projects: case study in Hong Kong. J Constr Eng Manag 144(3):05018001

Isaksson T, Stille H (2005) Model for estimation of time and cost for tunnel projects based on risk evaluation. Rock Mech Rock Eng 38(5):373–398

Isaksson T (2002) Model for estimation of time and cost based on risk evaluation applied on tunnel projects. PhD Thesis, TRITA-JOB PHD 1003, KTH Royal Institute of Technology, Stockholm.

Lichtenberg S (2000) Proactive management of uncertainty using the successive principle: a practical way to manage opportunities and risks. Polyteknisk Press, Lyngby

Love PE, Ahiaga-Dagbui DD (2018) Debunking fake news in a post-truth era: the plausible untruths of cost underestimation in transport infrastructure projects. Transp Res Part A Policy Pract 113:357–368

Maruvanchery V, Zhe S, Robert TLK (2020) Early construction cost and time risk assessment and evaluation of large-scale underground cavern construction projects in Singapore. Undergr Space 5(1):53–70

Matthewson J, Weisberg M (2009) The structure of tradeoffs in model building. Synthese 170(1):169–190

Min S, Einstein HH (2016) Resource scheduling and planning for tunneling with a new resource model of the Decision Aids for Tunneling (DAT). Tunn Undergr Space Technol 51:212–225

Min SY, Einstein HH, Lee JS, Kim TK (2003) Application of decision aids for tunneling (DAT) to a drill & blast tunnel. KSCE J Civ Eng 7(5):619–628

Min SY, Einstein HH, Lee JS, Lee HS (2005) Application of the Decision Aids for Tunneling (DAT) to update excavation cost/time information. KSCE J Civ Eng 9(4):335–346

Min SY, Kim TK, Lee JS, Einstein HH (2008) Design and construction of a road tunnel in Korea including application of the decision aids for tunneling–a case study. Tunn Undergr Space Technol 23(2):91–102

Miranda Sarmento J, Renneboog L (2017) Cost overruns in public sector investment projects. Publ Works Manag Policy 22(2):140–64

Mohammadi M, Spross J, Stille H (2022) Probabilistic time estimation of tunneling projects: the Uri headrace tunnel. Rock Mech Rock Eng 56(1):703–717

Mohammadi M, Spross J (2023) Risk model for understanding uncertainty in time and cost estimation in tunneling phases. In: Proceedings of underground construction Prague 2023, Prague, Czech Republic, May 29–31, 2023.

Mohammadi M (2021) Probabilistic time estimation in tunnel projects. Licentiate thesis, TRITA-ABE-DLT-2137, KTH Royal Institute of Technology, Stockholm.

Moret Y, Einstein HH (2012) Modeling correlations in rail line construction. J Constr Eng Manag 138(9):1075–1084

Moret Y, Einstein HH (2016) Construction cost and duration uncertainty model: application to high-speed rail line project. J Constr Eng Manag 142(10):05016010

Naghadehi MZ, Benardos A, Javdan R, Tavakoli H, Rojhani M (2016) The probabilistic time and cost risk analysis of a challenging part of an urban tunneling project. Tunn Undergr Space Technol 58:11–29

Reilly J, Brown J (2004) Management and control of cost and risk for tunneling and infrastructure projects. In: Proceedings of world tunnel congress and 13th ITA Assembly, Singapore, May 2004.

Ritter S, Einstein HH, Galler R (2013) Planning the handling of tunnel excavation material—a process of decision making under uncertainty. Tunn Undergr Space Technol 33:193–201

Sinfield JV, Einstein HH (1996) Evaluation of tunneling technology using the “decision aids for tunneling.” Tunn Undergr Space Technol 11(4):491–504

Skamris MK, Flyvbjerg B (1997) Inaccuracy of traffic forecasts and cost estimates on large transport projects. Transp Policy 4(3):141–146

Špačková O, Novotná E, Šejnoha M, Šejnoha J (2013b) Probabilistic models for tunnel construction risk assessment. Adv Eng Softw 62:72–84

Špačková O, Šejnoha J, Straub D (2013c) Probabilistic assessment of tunnel construction performance based on data. Tunn Undergr Space Technol 37:62–78

Špacková O, Straub D (2011) Probabilistic risk assessment of excavation performance in tunnel projects using Bayesian networks: a case study. In: Proceedings of the 3rd International Symposium on Geotechnical Safety and Risk, Munich, pp 651–60

Špačková O, Sejnoha J, Straub D (2013a) Tunnel construction time and costs estimates: from deteministic to probabilistic approaches. In: 12th international conference underground construction, 22–24 April, 2013a, Prague.

Špačková O (2012) Risk management of tunnel construction projects. Doctoral Thesis, Czech Technical University in Prague, Prague.

Spross J, Stille H, Johansson F, Palmström A (2018) On the need for a risk-based framework in Eurocode 7 to facilitate design of underground openings in rock. Rock Mech Rock Eng 51(8):2427–2431

Spross J, Stille H, Johansson F, Palmström A (2020) Principles of risk-based rock engineering design. Rock Mech Rock Eng 53:1129–1143. https://doi.org/10.1007/s00603-019-01962-x

Spross J, Lidmar J (2023) Dirichlet distribution for tunnel construction class proportions in probabilistic time and cost estimations. Accepted to Proceedings of Georisk 2023, 23–26 July, Arlington, VA.

Stille H (2017) Geological uncertainties in tunnelling-risk assessment and quality assurance. Sir Muir Wood lecture. In: ITA-AITES World Tunnel Congress. The International Tunnelling and Underground Space Association, Paris. https://about.ita-aites.org/publications/muir-wood-lecture/1515/muir-wood-lecture-2017

Sturk R (1998) Engineering geological information—its value and impact on tunnelling. PhD Thesis, TRITA-AMI PHD 1027, KTH Royal Institute of Technology, Stockholm.

Tidlund M, Spross J, Larsson S (2023) Observational method as risk management tool: the Hvalfjörður tunnel project, Iceland. Georisk Assessment Manage Risk Eng Syst Geohaz 17(2):346–360.

Yost K, Valentin A, Einstein HH (2015) Estimating cost and time of wellbore drilling for Engineered Geothermal Systems (EGS)–Considering uncertainties. Geothermics 53:85–99

Zhe S, Maruvanchery V, Tiong LK, Teo TY, Ng KW (2015) Dat modifications and its application in large-scale cavern construction. Tunn Undergr Space Technol 50:209–217

Funding

Open access funding provided by Royal Institute of Technology. This work was supported by Formas [Grant Number 2017-01218] and the Rock Engineering Research Foundation (BeFo) [Grant Number 400]. The research was conducted without the involvement of funding sources.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. The first draft of the manuscript was written by MM and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mohammadi, M., Spross, J. & Stille, H. Models to Analyze Risk in Time and Cost Estimation of Tunneling Projects. Geotech Geol Eng 42, 1445–1457 (2024). https://doi.org/10.1007/s10706-023-02627-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-023-02627-x