Abstract

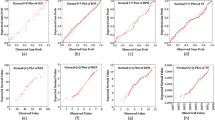

This paper presents an extended multifactorial fuzzy evaluation of hard rock tunnel boring machine performance. Several modifications have been applied to an earlier work of the authors team in 2009 to capture better prediction capabilities of TBM penetrability modeling. In this new work, five linguistic categories, ranging from “Very Poor” to “Very Good”, have been considered to represent penetrability classes which are described by Sigmoidal fuzzy membership functions to consider the relationship between machine’s rate of penetration and the ground characteristics including intact rock and rock mass properties. A comprehensive database of a total of 151 tunnel sections was employed for this purpose. Also, several experts from different fields of tunneling have been asked to evaluate the criteria using fuzzy Delphi analytical hierarchy process technique instead of relying upon the authors’ knowledge and expertise. The results have been verified by comparisons to the actual field penetration data as well as the results of other predictive models from the literature, showing a very good conformity between measurements and predictions of this research compared to all the previous models. It proves not only the superiority of the utilized methodology, but also its field applicability in future tunneling projects in similar geological conditions.

Similar content being viewed by others

References

Acaroglu O, Ozdemir L, Asbury B (2008) A fuzzy logic model to predict specific energy requirement for TBM performance prediction. Tunn Undergr Space Technol 23(5):600–608. https://doi.org/10.1016/j.tust.2007.11.003

Adoko AC, Gokceoglu C, Yagiz S (2017) Bayesian prediction of TBM penetration rate in rock mass. Eng Geol. https://doi.org/10.1016/j.enggeo.2017.06.014

Alber M (1996) Prediction of penetration and utilization for hard rock TBMs. In: ISRM international symposium Eurock’96. pp 721–725

Alvarez Grima M, Bruines PA, Verhoef PNW (2000) Modeling tunnel boring machine performance by neuro-fuzzy methods. Tunn Undergr Space Technol 15(3):259–269. https://doi.org/10.1016/S0886-7798(00)00055-9

Armaghani DJ, Mohamad ET, Narayanasamy MS, Narita N, Yagiz S (2017) Development of hybrid intelligent models for predicting TBM penetration rate in hard rock condition. Tunn Undergr Space Technol 63:29–43. https://doi.org/10.1016/j.tust.2016.12.009

Baglio S, Fortuna L, Graziani S, Muscato G (1994) Membership function shape and the dynamic behaviour of fuzzy systems. Int J Adapt Control Signal Process 8(4):369–377. https://doi.org/10.1002/acs.4480080406

Barton N (2000) TBM tunnelling in jointed and faulted rock. Balkema, Rotterdam

Benardos A, Kaliampakos DC (2004) Modelling TBM performance with artificial neural networks. Tunn Undergr Space Technol 2(19):597–605

Benato A, Oreste P (2015) Prediction of penetration per revolution in TBM tunneling as a function of intact rock and rock mass characteristics. Int J Rock Mech Min Sci 74:119–127. https://doi.org/10.1016/j.ijrmms.2014.12.007

Bruland A (1998) Hard rock tunnel boring. Norwegian Institute of Technology (NTNU), Trondheim

Bruland A (1999) Hard rock tunnel boring: advance rate and cutter wear. Norwegian Institute of Technology (NTNU), Trondheim

Delisio A, Zhao J (2014) A new model for TBM performance prediction in blocky rock conditions. Tunn Undergr Space Technol 43:440–452. https://doi.org/10.1016/j.tust.2014.06.004

Delisio A, Zhao J, Einstein HH (2013) Analysis and prediction of TBM performance in blocky rock conditions at the Lötschberg base tunnel. Tunn Undergr Space Technol 33:131–142. https://doi.org/10.1016/j.tust.2012.06.015

Dollinger GL, Handewith HJ, Breeds CD (1998) Use of the punch test for estimating TBM performance. Tunn Undergr Space Technol 13(4):403–408. https://doi.org/10.1016/S0886-7798(98)00083-2

Dubois D, Prade H (1986) Weighted minimum and maximum operations in fuzzy set theory. Inf Sci 39(2):205–210. https://doi.org/10.1016/0020-0255(86)90035-6

Farmer IW, Glossop NH (1980) Mechanics of disc cutter penetration. Tunn Tunn Int 12:22–25

Farrokh E, Rostami J, Laughton C (2012) Study of various models for estimation of penetration rate of hard rock TBMs. Tunn Undergr Space Technol 30:110–123

Frough O, Rostami J (2014) Analysis of TBM performance in two long mechanized tunnels, case history of Karaj water conveyance tunnel project lots 1 and 2 (Iran). In: Proceedings of the world tunnel congress 2014. Foz do Iguaçu, Brazil

Frough O, Torabi SR (2013) An application of rock engineering systems for estimating TBM downtimes. Eng Geol 157:112–123. https://doi.org/10.1016/j.enggeo.2013.02.003

Frough O, Torabi SR, Yagiz S (2015) Application of RMR for estimating rock-mass–related TBM utilization and performance parameters: a case study. Rock Mech Rock Eng 48(3):1305–1312. https://doi.org/10.1007/s00603-014-0619-4

Gao L, Li X (2015) Utilizing partial least square and support vector machine for TBM penetration rate prediction in hard rock conditions. J Cent South Univ 22(1):290–295. https://doi.org/10.1007/s11771-015-2520-z

Gehring K (1995) Leistungs- und Verschleissprognosen im maschinellen Tunnelbau. Felsbau 13:439–448

Ghasemi E, Yagiz S, Ataei M (2014) Predicting penetration rate of hard rock tunnel boring machine using fuzzy logic. Bull Eng Geol Env 73(1):23–35. https://doi.org/10.1007/s10064-013-0497-0

Gholamnejad J, Tayarani N (2010) Application of artificial neural networks to the prediction of tunnel boring machine penetration rate. Min Sci Technol (China) 20(5):727–733. https://doi.org/10.1016/S1674-5264(09)60271-4

Gong QM, Zhao J (2009) Development of a rock mass characteristics model for TBM penetration rate prediction. Int J Rock Mech Min Sci 46(1):8–18. https://doi.org/10.1016/j.ijrmms.2008.03.003

Gorzalczany MB (2002) Computational intelligence systems and applications. Springer, Berlin

Graham PC (1976) Rock exploration for machine manufacturers. Exploration for rock engineering, vol 1. A.A. Balkema, Rotterdam, pp 173–180

Hassanpour J, Rostami J, Khamehchiyan M, Bruland A (2009) Developing new equations for TBM performance prediction in carbonate-argillaceous rocks: a case history of Nowsood water conveyance tunnel. Geomech Geoeng 4(4):287–297. https://doi.org/10.1080/17486020903174303

Hassanpour J, Rostami J, Khamehchiyan M, Bruland A, Tavakoli HR (2010) TBM performance analysis in pyroclastic rocks: a case history of Karaj water conveyance tunnel. Rock Mech Rock Eng 43(4):427–445. https://doi.org/10.1007/s00603-009-0060-2

Hassanpour J, Rostami J, Zhao J (2011) A new hard rock TBM performance prediction model for project planning. Tunn Undergr Space Technol 26(5):595–603. https://doi.org/10.1016/j.tust.2011.04.004

Hassanpour J, Rostami J, Zhao J, Tarigh Azali S (2015) TBM performance and disc cutter wear prediction based on ten years experience of TBM tunnelling in Iran. Geomechanik Und Tunnelbau 8(3):239–247

Hassanpour J, Ghaedi Vanani AA, Rostami J, Cheshomi A (2016) Evaluation of common TBM performance prediction models based on field data from the second lot of Zagros water conveyance tunnel (ZWCT2). Tunn Undergr Space Technol 52:147–156. https://doi.org/10.1016/j.tust.2015.12.006

Jalali SME, Zare Naghadehi M (2013) Development of a new laboratory apparatus for the examination of the rotary-percussive penetration in tunnel boring machines. Tunn Undergr Space Technol 33:88–97

Jang JR, Sun C, Mizutani E (1997) Neuro-fuzzy and soft computing: a computational approach to learning and machine intelligence. Prentice-Hall International, Englewood Cliffs

Kaymak U (1998) Fuzzy decision making with control applications. Delft University of Technology, Delft

Khademi Hamidi J, Shahriar K, Rezai B, Rostami J (2010) Performance prediction of hard rock TBM using rock mass rating (RMR) system. Tunn Undergr Space Technol 25(4):333–345. https://doi.org/10.1016/j.tust.2010.01.008

Li HX, Yen VC (1995) Fuzzy sets and fuzzy decision making. CRC Press, Boca Raton

Liu Y, Chen C (2007) A new approach for application of rock mass classification on rock slope stability assessment. Eng Geol 89(1–2):129–143

Macias J (2016) Hard rock tunnel boring: performance predictions and cutter life assessments. Norwegian University of Sciences and Technology (NTNU), Trondheim

Mahdevari S, Shahriar K, Yagiz S, Akbarpour Shirazi M (2014) A support vector regression model for predicting tunnel boring machine penetration rates. Int J Rock Mech Min Sci 72:214–229. https://doi.org/10.1016/j.ijrmms.2014.09.012

Martins FF, Miranda TFS (2013) Prediction of hard rock TBM penetration rate based on data mining techniques. In: Proceedings of the 18th international conference on soil mechanics and geotechnical engineering. Paris, France, pp. 1751–1754

Mikaeil R, Zare Naghadehi M, Sereshki F (2009) Multifactorial fuzzy approach to the penetrability classification of TBM in hard rock conditions. Tunn Undergr Space Technol 24(5):500–505. https://doi.org/10.1016/j.tust.2008.12.007

Mohammadi SD, Torabi-Kaveh M, Bayati M (2015) Prediction of TBM penetration rate using intact and mass rock properties (case study: Zagros long tunnel, Iran). Arab J Geosci 8(6):3893–3904. https://doi.org/10.1007/s12517-014-1465-0

Namli M, Bilgin N (2017) A model to predict daily advance rates of EPB-TBMs in a complex geology in Istanbul. Tunn Undergr Space Technol 62:43–52

Oraee K, Salehi B (2013) Assessing prediction models of advance rate in tunnel boring machines-a case study in Iran. Arab J Geosci 6(2):481–489

Paltrinieri E, Sandrone F, Zhao J (2016) Analysis and estimation of gripper TBM performances in highly fractured and faulted rocks. Tunn Undergr Space Technol 52:44–61. https://doi.org/10.1016/j.tust.2015.11.017

Ramezanzadeh A (2005) Performance analysis and development of new models for performance prediction of hard rock TBMs in rock mass. INSA de Lyon, Villeurbanne

Ramezanzadeh A, Rostami J, Kastner R (2005) Influence of rock mass properties on performance of hard rock TBMs. RETC. In: RETC. Seattle, Washington, USA

Ramezanzadeh A, Rostami J, Tadic D (2008) Impact of rock mass characteristics on hard rock TBM performance. In: 13th Australian tunneling conference. Melbourne, Australia

Ribacchi R, Lembo Fazio A (2005) Influence of rock mass parameters on the performance of a TBM in a Gneissic formation (Varzo tunnel). Rock Mech Rock Eng 38(2):105–127

Ross TJ (2010) Fuzzy logic with engineering applications, 3rd edn. Wiley, New York

Rostami J (1997) Development of a force estimation model for rock fragmentation with disc cutters through theoretical modeling and physical measurement of crushed zone pressure. Colorado School of Mines, Golden

Rostami J, Ozdemir L (1993) A new model for performance prediction of hard rock TBM. In: Bowerman LD et al (eds) Proceedings of RETC. Boston, pp. 793–809

Salimi A, Faradonbeh RS, Monjezi M, Moormann C (2016a) TBM performance estimation using a classification and regression tree (CART) technique. Bull Eng Geol Env. https://doi.org/10.1007/s10064-016-0969-0

Salimi A, Rostami J, Moormann C, Delisio A (2016b) Application of non-linear regression analysis and artificial intelligence algorithms for performance prediction of hard rock TBMs. Tunn Undergr Space Technol 58:236–246. https://doi.org/10.1016/j.tust.2016.05.009

Sapigni M, Berti M, Bethaz E, Busillo A, Cardone G (2002) TBM performance estimation using rock mass classifications. Int J Rock Mech Min Sci 39(6):771–788. https://doi.org/10.1016/S1365-1609(02)00069-2

Shao C, Li X, Su H (2013) Performance prediction of hard rock TBM based on extreme learning machine. In: 6th international conference, ICIRA 2013. Busan, South Korea, pp. 409–416

Simoes M, Kim T (2006) Fuzzy modeling approaches for the prediction of machine utilization in hard rock tunnel boring machines. In: Conference record of the 2006 IEEE industry applications conference forty-first IAS annual meeting, vol. 2. IEEE, pp. 947–954. https://doi.org/10.1109/IAS.2006.256639

Sousa JM, Kaymak U (2002) Fuzzy decision making in modeling and control. World Scientific, Singapore

Tutmez B, Kahraman S, Gunaydin O (2007) Multifactorial fuzzy approach to the sawability classification of building stones. Constr Build Mater 21(8):1672–1679. https://doi.org/10.1016/j.conbuildmat.2006.05.023

Yager RR (1978) Fuzzy decision making including unequal objectives. Fuzzy Sets Syst 1(2):87–95. https://doi.org/10.1016/0165-0114(78)90010-6

Yager RR (1980) On a general class of fuzzy connectives. Fuzzy Sets Syst 4(3):235–242. https://doi.org/10.1016/0165-0114(80)90013-5

Yagiz S (2002) Development of rock fracture and brittleness indices to quantify the effects of rock mass features and toughness in the CSM model basic penetration for hard rock tunneling machines. Colorado School of Mines, Golden

Yagiz S (2008) Utilizing rock mass properties for predicting TBM performance in hard rock condition. Tunn Undergr Space Technol 23(3):326–339. https://doi.org/10.1016/j.tust.2007.04.011

Yagiz S (2009) Assessment of brittleness using rock strength and density with punch penetration test. Tunn Undergr Space Technol 24(1):66–74. https://doi.org/10.1016/j.tust.2008.04.002

Yagiz S (2010) Comments on the article “multifactorial fuzzy approach to the penetrability classification of TBM in hard rock conditions” by R. Mikaeil, M. Zare Naghadehi and F. Sereshki [Tunneling and Underground Space Technology, 24 (2009) 500–505]. Tunn Undergr Space Technol. https://doi.org/10.1016/j.tust.2009.09.001

Yagiz S (2017) New equations for predicting the field penetration index of tunnel boring machines in fractured rock mass. Arab J Geosci 10(2):33. https://doi.org/10.1007/s12517-016-2811-1

Yagiz S, Karahan H (2011) Prediction of hard rock TBM penetration rate using particle swarm optimization. Int J Rock Mech Min Sci 48(3):427–433. https://doi.org/10.1016/j.ijrmms.2011.02.013

Yagiz S, Karahan H (2015) Application of various optimization techniques and comparison of their performances for predicting TBM penetration rate in rock mass. Int J Rock Mech Min Sci 80:308–315. https://doi.org/10.1016/j.ijrmms.2015.09.019

Yagiz S, Gokceoglu C, Sezer E, Iplikci S (2009) Application of two non-linear prediction tools to the estimation of tunnel boring machine performance. Eng Appl Artif Intell 22(4):808–814. https://doi.org/10.1016/j.engappai.2009.03.007

Yagiz S, Kim T, Frough O, Torabi SR (2013) A rock mass rating system for predicting TBM utilization. In: ISRM international symposium—EUROCK 2013: “rock mechanics for resources, energy and environment.” Wroclaw, Poland. International Society for Rock Mechanics (ISRM)

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353. https://doi.org/10.1016/S0019-9958(65)90241-X

Zare Naghadehi M, Ramezanzadeh A (2016) Models for estimation of TBM performance in granitic and mica gneiss hard rocks in a hydropower tunnel. Bull Eng Geol Env. https://doi.org/10.1007/s10064-016-0950-y

Zare Naghadehi M, Mikaeil R (2017) Optimization of tunnel boring machine (TBM) disc cutter spacing in jointed hard rock using a distinct element numerical simulation. Period Polytech Civ Eng 61(1):56–65

Zhao Z, Gong Q, Zhang Y, Zhao J (2007) Prediction model of tunnel boring machine performance by ensemble neural networks. Geomech Geoeng 2(2):123–128. https://doi.org/10.1080/17486020701377140

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mikaeil, R., Zare Naghadehi, M. & Ghadernejad, S. An Extended Multifactorial Fuzzy Prediction of Hard Rock TBM Penetrability. Geotech Geol Eng 36, 1779–1804 (2018). https://doi.org/10.1007/s10706-017-0432-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0432-4