Abstract

Stress reduction factor (λ) is an important component in the two-dimensional (2D) analysis of tunnel using convergence–confinement method (CCM). So far, however, there has been little discussion about effective parameters on λ. The aim of this study was to evaluate what the effect of constitutive model and determining method of λ is on CCM application in circular tunnel in shallow depth. For this purpose, at first, a series of parametric studies were carried out in different circular tunnel radius and depth. Parameters calibration of each constitutive model was carried out by triaxial simulation using finite difference method (FLAC). The results showed significant impact of constitutive model on λ in tunnel walls. The effects of constitutive model on λ were reduced by increasing depth, radius and distance from tunnel face. Then a comparison of the 2D analysis using CCM to in situ monitoring data of Lyon–Vaise tunnel was carried out. To this aim, two different constitutive models (CJS2 and Mohr–Coulomb) and various determining method of λ (direct and indirect method) were used. The results represented that λ obtained via indirect method cause more precise results. CJS2 constitutive model enable the convergence–confinement method to more accurate prediction of tunnel behavior than Mohr–Coulomb.

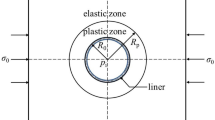

Reproduced with permission from Bernat et al. (1999)

Reproduced with permission from Bernat et al. (1999)

Similar content being viewed by others

References

Alejano LR et al (2009) Ground reaction curves for tunnels excavated in different quality rock masses showing several types of post-failure behaviour. Tunn Undergr Space Technol 24(6):689–705

Alejano LR, Rodríguez-Dono A, Veiga M (2012) Plastic radii and longitudinal deformation profiles of tunnels excavated in strain-softening rock masses. Tunn Undergr Space Technol 30:169–182

Amet JC, Guibert G, Schwenzfeier A (1996) Shield-experience on line D extension Lyon metro. In: Proceedings of the North American tunneling 96, Washington, pp 27–33

Benmebarek S et al (1998) Auscultation et modélisation numérique du processus de creusement à l’aide d’un tunnelier. Géotechnique 48(6):801–818

Bernat S, Cambou B (1998) Soil-structure interaction in shield tunnelling in soft soil. Comput Geotech 22(3):221–242

Bernat S, Cambou B, Dubois P (1999) Assessing a soft soil tunnelling numerical model using field data. Géotechnique 49(4):427–452

Cai Y et al (2015) An analytical model considering interaction behavior of grouted rock bolts for convergence–confinement method in tunneling design. Int J Rock Mech Min Sci 76:112–126

Cambou B, Jafari K (1988) Modèle de comportement des sols non cohérents. Rev Fr Geotech 44:43–55

Carranza-Torres C, Fairhurst C (2000) Application of the convergence–confinement method of tunnel design to rock masses that satisfy the Hoek–Brown failure criterion. Tunn Undergr Space Technol 15(2):187–213

Chen R, Tonon F (2010) Closed-form solutions for a circular tunnel in elastic-brittle-plastic ground with the original and generalized Hoek–Brown failure criteria. Rock Mech Rock Eng 44(2):169–178

Chou WI, Bobet A (2002) Predictions of ground deformations in shallow tunnels in clay. Tunn Undergr Space Technol 17(1):3–19

Corbetta F, Bernaud D, Nguyen Minh D (1991) Contribution à la méthode convergence–confinement par le principe de la similitude. Rev Fr Géotech 54:5–11

Cui L et al (2015) A numerical procedure for the fictitious support pressure in the application of the convergence–confinement method for circular tunnel design. Int J Rock Mech Min Sci 78:336–349

Dias D (2011) Convergence–confinement approach for designing tunnel face reinforcement by horizontal bolting. Tunn Undergr Space Technol 26(4):517–523

Do N-A, Dias D, Oreste P (2014) Three-dimensional numerical simulation of mechanized twin stacked tunnels in soft ground. J Zhejiang Univ SCIENCE A 15(11):896–913

Eisenstein Z, Branco P (1991) Convergence–confinement method in shallow tunnels. Tunn Undergr Space Technol 6(3):343–346

Fairhurst C, Carranza-Torres C (2002) Closing the circle. In: Labuz J, Bentler J (eds) Proceedings of the 50th annual geotechnical engineering conference. St. Paul, Minnesota, February 22, 2002. University of Minnesota (Available for downloading at The Fairhurst’s Files, www.itascainternational.com)

Fang Q et al (2013) Ground reaction curves for deep circular tunnels considering the effect of ground reinforcement. Int J Rock Mech Min Sci 60:401–412

Gesta P et al (1980) Tunnel stability by convergence–confinement method. Undergr Space 4(4):225–232

González-Nicieza C et al (2008) Influence of the depth and shape of a tunnel in the application of the convergence–confinement method. Tunn Undergr Space Technol 23(1):25–37

Houhou M, Emeriault F, Vanoudheusden E (2016) Three-dimensional back-analysis of an instrumented shallow tunnel excavated by a conventional method. Geotechn Geol Eng 34:1101–1117

Itasca F (2002) Fast Lagrangian analysis of continua. Version 4.0 user’s guide, Itasca Consulting Group Inc., Thrasher Square East, p 708

Karakus M (2007) Appraising the methods accounting for 3D tunnelling effects in 2D plane strain FE analysis. Tunn Undergr Space Technol 22(1):47–56

Karakus M, Fowell RJ (2003) Effects of different tunnel face advance excavation on the settlement by FEM. Tunn Undergr Space Technol 18(5):513–523

Koukoutas SP, Sofianos AI (2015) Settlements due to single and twin tube urban EPB shield tunnelling. Geotech Geol Eng 33(3):487–510

Lombardi G (1980) Some comments on the convergence–confinement method. Undergr Space 4(4):249–258

Maleki M, Mousivand M (2014) Safety evaluation of shallow tunnel based on elastoplastic–viscoplastic analysis. Sci Iran Trans A Civ Eng 21(5):1480–1491

Maleki M, Cambou B, Dubujet P (2000) Modelisation hierarchisee du comportement des sols. Rev Fr Genie Civ 4:895–928

Maleki M et al (2011) An equivalent beam model for the analysis of tunnel-building interaction. Tunn Undergr Space Technol 26(4):524–533

Mitaim S, Detournay E (2005) Determination of ground reaction curve for hyperbolic soil model using the hodograph method. Can Geotech J 42(3):964–968

Ng C, Lee G (2005) Three-dimensional ground settlements and stress-transfer mechanisms due to open-face tunnelling. Can Geotech J 42(4):1015–1029

Panet M (1995) Le calcul des tunnels par la méthode convergence–confinement. Presses ENPC

Panet M (2001) Recommendations on the convergence-confinement method. AFTES report, version, 1, pp 1–11

Panet M, Guenot A (1983) Analysis of convergence behind the face of a tunnel: Tunnelling 82. In: Proceedings of the 3rd international symposium, Brighton, 7–11 June 1982, P197–204. IMM, Publ London, 1982. In International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts. Pergamon

Potts D, Zdravkovic L (2001) Finite element analysis in geotechnical engineering: application, vol 2. Thomas Telford, London, p 427

Rowe R, Lo K, Kack G (1983) A method of estimating surface settlement above tunnels constructed in soft ground. Can Geotech J 20(1):11–22

Shin Y et al (2011) Interaction between tunnel supports and ground convergence—consideration of seepage forces. Int J Rock Mech Min Sci 48(3):394–405

Swoboda G, Marence M, Mader I (1994) Finite element modelling of tunnel excavation. Int J Eng Model 6:51–63

Vlachopoulos N, Diederichs M (2014) Appropriate uses and practical limitations of 2D numerical analysis of tunnels and tunnel support response. Geotech Geol Eng 32(2):469–488

Author information

Authors and Affiliations

Corresponding author

Appendix: Brief Representation of CJS2 Constitutive Model

Appendix: Brief Representation of CJS2 Constitutive Model

1.1 Elastic Mechanism

Elastic law of this model has been given as follow:

where \(\dot{s}_{ij}\) is second invariant of stress deviator tensor, \(\dot{I}_{1}\) is first invariant stress tensor, K and G are elastic shear and bulk modulus of material. K and G are a function of confine pressure as:

P a is reference pressure which equal to 100 kPa and \(K_{e}^{0}\), \(G_{e}^{0}\) and n are elastic parameters of model that can be determine by laboratory results.

1.2 Isotropic Plastic Mechanism

Yield surface in this mechanism is as follow:

Flow rule is associated in this mechanism.

where λ i is plastic modulus.

1.3 Deviatoric Plastic Mechanism

The failure surface can be expressed as follow:

where \(s_{II} = \sqrt {s_{ij} s_{ij} }\), R m is equivalent radius of failure surface, I 1c is cohesion parameter and h(θ) = (1 − γ cos3θ)1/6, θ is Lode angle and γ is constant model parameter.

Figure 19 shows plastic, characteristic and failure mechanism of CJS2 constitutive model in deviatoric space.

Reproduced with permission from Maleki and Mousivand (2014)

Presentation of different mechanism of CJS2 constitutive model; a and b deviatoric stress space.

Yield surface in this constitutive model is similar to failure surface as follow:

where \(R = \frac{{AR_{m} P}}{{R_{m} + AP}}\) is associated hardening of model, P and A are hardening variable and constant model parameter respectively. Failure mode occurs when the parameter P approach infinity. The characteristic surface separates the contractancy and dilatancy states in the stress space can be define as below:

where R c is equivalent radius of characteristic surface.

Rights and permissions

About this article

Cite this article

Mousivand, M., Maleki, M. Constitutive Models and Determining Methods Effects on Application of Convergence–Confinement Method in Underground Excavation. Geotech Geol Eng 36, 1707–1722 (2018). https://doi.org/10.1007/s10706-017-0426-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0426-2