Abstract

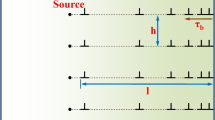

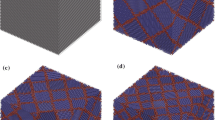

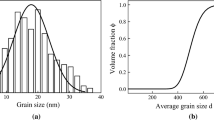

In this paper, the problem of crack propagation in the gradient nano-grained (GNG) metals is studied through extensive quasi-3D molecular dynamic (MD) simulations. Numerical samples of GNG copper with initial central crack are established and simulations of uniaxial deformation are carried out. The effect of the grain size gradient on the crack propagation is systematically investigated by comparing the propagation rates between the two tips of the central crack as well as by comparing the results of the GNG sample with those of uniform samples with different grain sizes. It is found that introduction of the grain size gradient can compromise the ability of the nano-grained metals to resist the crack propagation for grain size in inverse Hall–Petch regime. The crack tip profile, the stress, and the density of atoms of various defect structures were analyzed to gain insight into the synergistic interactions between the dislocation activity, the grain boundary mechanisms and the crack propagation. This work is intended to provide not only a mechanistic understanding of the fracture behavior of GNG metals, but also a guideline for ensuring the safety application of such advanced materials.

Similar content being viewed by others

References

Asadi E, Zaeem MA, Nouranian S, Baskes MI (2015) Two-phase solid–liquid coexistence of Ni, Cu, and Al by molecular dynamics simulations using the modified embedded-atom method. Acta Mater 86:169–181

Cao A, Wei Y (2007) Atomistic simulations of crack nucleation and intergranular fracture in bulk nanocrystalline nickel. Phys Rev B 76(2):024113

Cao P (2020) The strongest size in gradient nanograined metals. Nano Lett 20:1440–1446

Cao R, Qin Yu, Pan J, Lin Y, Sweet A, Li Yi, Ritchie RO (2020) On the exceptional damage-tolerance of gradient metallic materials. Mater Today 32:94–107

Chen AY, Li DF, Zhang JB, Liu F, Liu XR, Lu J (2011) Study of toughening mechanisms through the observations of crack propagation in nanostructured and layered metallic sheet. Mater Sci Eng A 528:8389–8395

Fang Q, Li Li, Li J, Hong Wu (2018) Strengthening mechanism of gradient nanostructured body-centred cubic iron film: From inverse Hall-Petch to classic Hall-Petch. Comput Mater Sci 152:236–242

Fang TH, Li WL, Tao NR, Lu K (2011) Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 331:1587–1590

Fang W, Xie H, Yin F, Li J, Khan DF, Fang Q (2016) Molecular dynamics simulation of grain boundary geometry on crack propagation of bi-crystal aluminum. Mater Sci Eng A 666:314–319

Farkas D (2007) Fracture resistance of nanocrystalline Ni. Metall Mater Trans A 38:2168–2173

Hasnaoui A, Van Swygenhoven H, Derlet PM (2003) Dimples on nanocrystalline fracture surfaces as evidence for shear plane formation. Science 300:1550–1552

Honeycutt JD, Andersen HC (1987) Molecular dynamics study of melting and freezing of small Lennard-Jones clusters. J Phys Chem 91:4950–4963

Huang HW, Wang ZB, Lu J, Lu K (2015) Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer. Acta Mater 87:150–160

Jing LJ, Pan QS, Lu L (2020) Effect of volume fraction of gradient nanograined layer on low-cycle fatigue behavior of Cu. Adv Eng Mater 22(1):1900554

Kedharnath A, Panwar AS, Kapoor R (2017) Molecular dynamics simulation of the interaction of a nano-scale crack with grain boundaries in α-Fe. Comput Mater Sci 137:85–99

Li J, Zhang Q, Huang R, Li X, Gao H (2020a) Towards understanding the structure–property relationships of heterogeneous-structured materials. Scr Mater 186:304–311

Li J, Weng GJ, Chen S, Xiaolei Wu (2017) On strain hardening mechanism in gradient nanostructures. Int J Plast 88:89–107

Li X, Lei Lu, Li J, Zhang X, Gao H (2020b) Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat Rev Mater 5:706–723

Li X, Wei Y, Yang W, Gao H (2009) Competing grain-boundary-and dislocation-mediated mechanisms in plastic strain recovery in nanocrystalline aluminum. Proc Natl Acad Sci USA 106:16108–16113

Li Z, Yang F (2017) Grain rotations during uniaxial deformation of gradient nano-grained metals using crystal plasticity finite element simulations. Extreme Mech Lett 16:41–48

Lin Y, Qin Yu, Pan J, Duan F, Ritchie RO, Li Yi (2020) On the impact toughness of gradient-structured metals. Acta Mater 193:125–137

Ma Z, Liu J, Wang G, Wang H, Wei Y, Gao H (2016) Strength gradient enhances fatigue resistance of steels. Sci Rep 6:22156

Mishin Y, Mehl MJ, Papaconstantopoulos DA, Voter AF, Kress JD (2001) Structural stability and lattice defects in copper: Ab initio, tight-binding, and embedded-atom calculations. Phys Rev B 63(22):224106

Pan Q, Lu L (2020) Improved fatigue resistance of gradient nanograined metallic materials: suppress strain localization and damage accumulation. Sc Mater 187:301–306

Schäfer J, Albe K (2012) Competing deformation mechanisms in nanocrystalline metals and alloys: coupled motion versus grain boundary sliding. Acta Mater 60:6076–6085

Singh A, Tang L, Dao M, Lu L, Suresh S (2011) Fracture toughness and fatigue crack growth characteristics of nanotwinned copper. Acta Mater 59:2437–2446

Stukowski A (2010) Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model Simul Mater Sci Eng 18(1):015012

Stukowski A, Bulatov VV, Arsenlis A (2012) Automated identification and indexing of dislocations in crystal interfaces. Model Simul Mater Sci Eng 20(8):085007

Wang P, Yang X, Tian X (2015) Fracture behavior of precracked nanocrystalline materials with grain size gradients. J Mater Res 30:709–716

Wang Y, Yang G, Wang W, Wang X, Li Q, Wei Y (2017) Optimal stress and deformation partition in gradient materials for better strength and tensile ductility: a numerical investigation. Sci Rep 7:10954

Wang Y, Yuan L, Zhang S, Sun C, Wang W, Yang G, Li Q, Wei Y (2019) The influence of combined gradient structure with residual stress on crack-growth behavior in medium carbon steel. Eng Fract Mech 209:369–381

Wu X, Jiang P, Chen L, Yuan F, Zhu YT (2014) Extraordinary strain hardening by gradient structure. Proc Natl Acad Sci USA 111:7197–7201

Yang F, Yang W (2009) Crack growth versus blunting in nanocrystalline metals with extremely small grain size. J Mech Phys Solids 57:305–324

Yang L, Tao NR, Lu K, Lu L (2013) Enhanced fatigue resistance of Cu with a gradient nanograined surface layer. Scr Mater 68:801–804

Yang M, Pan Y, Yuan F, Zhu Y, Xiaolei Wu (2016) Back stress strengthening and strain hardening in gradient structure. Mater Res Lett 4:145–151

Yuan F, Wu X (2013) Atomistic scale fracture behaviours in hierarchically nanotwinned metals. Philos Mag 93:3248–3259

Zeng Z, Li X, Dongsheng Xu, Lei Lu, Gao H, Zhu T (2016) Gradient plasticity in gradient nano-grained metals. Extreme Mech Letters 8:213–219

Zhou P, Zhou J, Zhixiong Ye Xu, Hong HH, Wenjin Xu (2016) Effect of grain size and misorientation angle on fatigue crack growth of nanocrystalline materials. Mater Sci Eng A 663:1–7

Zhu Y, Wu X (2019) Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater Res Lett 7:393–98

Acknowledgements

The authors acknowledge the support from National Natural Science Foundation of China (11772231) and Shanghai Supercomputer Center.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Yang, F., Zhang, X. et al. Crack propagation in gradient nano-grained metals with extremely small grain size based on molecular dynamic simulations. Int J Fract 233, 71–83 (2022). https://doi.org/10.1007/s10704-021-00610-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-021-00610-2