Abstract

In this paper a theoretical analysis of crack initiation and propagation conditions in a bonded specimen loaded under pure mode II condition is proposed. The end-loaded-split (ELS) test response is evaluated using a semi-analytical model where the adherends are modeled as two deformable Timoshenko beams and considering non-linear behaviour of the adhesive. Bi-linear elastic-plastic, elastic-softening and trapezoidal adhesive layer shear behaviours (ALSBs) have been implemented and studied. From the results we observed that the load–displacement curve does not permit accurate evaluation of the adhesive layer shear behaviour. An alternative procedure consisting of analyzing the strain energy release rate versus shear displacement at the crack tip is proposed for data reduction of ELS test results.

Similar content being viewed by others

References

A GA (2013) The Phenomena of Rupture and Flow in Solids, in: Encyclopedia of Tribology, Springer, Boston, pp. 1570–1573. https://doi.org/10.1007/978-0-387-92897-5_259

Alfredsson K (2004) On the instantaneous energy release rate of the end-notch flexure adhesive joint specimen. Int J Solids Struct 41(16–17):4787–4807. https://doi.org/10.1016/j.ijsolstr.2004.03.008

Bidaud P, Créac’hcadec R, Thévenet D, Cognard J-Y, Jousset P (2015) A prediction method of the behavior of adhesively bonded structures under cyclic shear loading based on a characterization of the viscous aspects of the adhesive in an assembly. J Adhes 91(9):701–724. https://doi.org/10.1080/00218464.2014.963840

Blackman B, Kinloch A, Paraschi M (2005) The determination of the mode II adhesive fracture resistance, GIIC, of structural adhesive joints: an effective crack length approach. Eng Fracture Mech 72:877–897. https://doi.org/10.1016/j.engfracmech.2004.08.007

Blackman BRK, Brunner AJ, Williams JG (2006) Mode II fracture testing of composites: a new look at an old problem. Eng Fract Mech 73(16):2443–2455. https://doi.org/10.1016/j.engfracmech.2006.05.022

Blaysat B, Hoefnagels J, Lubineau G, Alfano M, Geers M (2015) Interface debonding characterization by image correlation integrated with Double Cantilever Beam kinematics. Int J Solids Struct 55:79–91. https://doi.org/10.1016/j.ijsolstr.2014.06.012

Budzik M, Jumel J (2017) Inverse end loaded split test configuration for stable mode II crack propagation in bonded joint: macroscopic analysis—effective crack length approach. Int J Fract 207(1):27–39. https://doi.org/10.1007/s10704-017-0216-0

Cricrì G (2019) Cohesive law identification of adhesive layers subject to shear load: an exact inverse solution. Int J Solids Struct 158:150–164. https://doi.org/10.1016/j.ijsolstr.2018.09.001

Davies P, Blackman BRK, Brunner AJ (1998) Standard test methods for delamination resistance of composite materials: current status. Appl Compos Mater 5(6):345–364. https://doi.org/10.1023/A:1008869811626

de Morais AB, de Moura MFSF (2006) Evaluation of initiation criteria used in interlaminar fracture tests. Eng Fract Mech 73(16):2264–2276. https://doi.org/10.1016/j.engfracmech.2006.05.003

Gorman J, Thouless M (2019) The use of digital-image correlation to investigate the cohesive zone in a double-cantilever beam, with comparisons to numerical and analytical models. J Mech Phys Solids 123:315–331. https://doi.org/10.1016/j.jmps.2018.08.013

Hardy George F (1989) A review of: “adhesion and adhesives: science and technology, by A. J. Kinloch, Chapman and Hall, London and New York, 1987, 28(2-3):199–200. https://doi.org/10.1080/00218468908030882

Hashemi S, Kinloch AJ, Williams JG (1990) The analysis of interlaminar fracture in uniaxial fibre–polymer composites. Proc R Soc Lond Ser A Math Phys Sci 427(1872):173–199

Kanninen M (1974) A dynamic analysis of unstable crack propagation and arrest in the DCB test specimen. Int J Fract 10(3):415–430. https://doi.org/10.1007/BF00035502

Khoramishad H, Hamzenejad M, Ashofteh RS (2016) Characterizing cohesive zone model using a mixed-mode direct method. Eng Fract Mech 153:175–189. https://doi.org/10.1016/j.engfracmech.2015.10.045

Leffler K, Alfredsson KS, Stigh U (2007) Shear behaviour of adhesive layers. Int J Solids Struct 44(2):530–545. https://doi.org/10.1016/j.ijsolstr.2006.04.036

Liljedahl C, Crocombe A, Wahab M, Ashcroft I (2006) Damage modelling of adhesively bonded joints. Int J Fract 141(1–2):147–161. https://doi.org/10.1007/s10704-006-0072-9

Pérez-Galmés M, Renart J, Sarrado C, Rodríguez-Bellido A, Costa J (2016) A data reduction method based on the J-integral to obtain the interlaminar fracture toughness in a mode II end-loaded split (ELS) test. Compos Part A 90:670–677. https://doi.org/10.1016/j.compositesa.2016.08.020

Pérez-Galmés M, Renart J, Sarrado C, Costa J (2018) Suitable specimen dimensions for the determination of mode II fracture toughness of bonded joints by means of the ELS test. Eng Fract Mech 202:350–362. https://doi.org/10.1016/j.engfracmech.2018.07.039

Rice JR (1968) A path independent integral and the approximate analysis of strain concentration by Notches and Cracks. J Appl Mech 35(2):379–386. https://doi.org/10.1115/1.3601206

Sorensen B, Jacobsen T (2003) Determination of cohesive laws by the J integral approach. Eng Fract Mech 70(14):1841–1858. https://doi.org/10.1016/S0013-7944(03)00127-9

Wu C, Huang R, Liechti K (2019) Simultaneous extraction of tensile and shear interactions at interfaces. J Mech Phys Solids 125:225–254. https://doi.org/10.1016/j.jmps.2018.12.004

Zhang J, Wang J, Yuan Z, Jia H (2018) Effect of the cohesive law shape on the modelling of adhesive joints bonded with brittle and ductile adhesives. Int J Adhes Adhes 85:37–43. https://doi.org/10.1016/j.ijadhadh.2018.05.017

Zineb T.Ben, Sedrakian A, Billoet J (2003) An original pure bending device with large displacements and rotations for static and fatigue tests of composite structures. Compos B Eng 34(5):447–458. https://doi.org/10.1016/S1359-8368(03)00017-9

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Compliance assessment

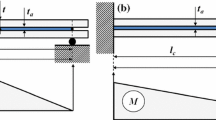

The classical beam theory does not take into account the adhesive layer compliance. The specimen is seen as Timoshenko beams under flexure caused by applied load P. Specimen dimensions are seen in Fig. 1.

The Griffith’s energy balance gives the Strain Energy Release Rate \(\mu \) (SERR) as:

To obtain the compliance C(a), the whole specimen potential energy \(W_e\) is integrated:

T is the transverse force and M the bending moment. \(S_{eff}\) and \(I_{eff}\) are respectively effective area and effective quadratic bending moment of the part of the specimen concerned. \(\kappa \) is the beam shear correction factor \(\kappa =5/6\), E and G are respectively Young’s and Coulomb’s modulus of the adherends. Considering the specimen as a 2t thickness beam along the bonded length \(l_c\) connected to two t thickness beams in parallel along the crack length a (all beams width is w), we have:

We then find the whole specimen compliance as a function of the crack length a and the expression for the SERR:

Appendix B: Full derivation of constitutive equations

According to Timoshenko beam theory, the constitutive equations linking local forces to the displacements are:

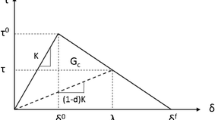

where \(I = wt^3/12\) is the quadratic bending moment of one adherend cross section, \(\kappa \) is the beam shear correction factor \(\kappa =5/6\), G is the shear modulus of the adherends, \(S=wt\) is the area of one adherend cross section. The local static equilibrium (see Fig. 4) is described with the following equations:

where \(\uptau (x)\) is the shear stress along the adhesive. The shear strain \(\gamma \) is (see Fig. 4):

We obtain the shear stress distribution from Eqs. (29) to (35) depending on the Adhesive Layer Shear Behaviour (ALSB).

Shear stress for the elastic regime can be defined as:

Combining Eqs. (29) to (36) leads to a third order differential equation:

The solution to this equation in \(\uptau (x)\) is:

with

where X varies in the interval \([-l_e;-(l_1+l_2)]\). X, \(l_1\), \(l_2\) are defined in Fig. 6. \(\uptau _m\) is the mean shear stress. To obtain general expression for the local forces N(x), T(x), M(x) and the displacements u(x), v(x) and the rotation \(\varphi (x)\), \(\uptau (x)\) is replaced by its expression in Eqs. (29) to (34) finding:

where \(N_0\), \(M_0\), \(u_0\), \(\varphi _0\) and \(v_0\) are integration constants. In the case of softening or hardening behaviour, shape of the ALSB is defined by a local tangent modulus \(G_t^2 \ne 0\). A similar third order differential equation is obtained:

Leading to a similar stress distribution:

with

where X varies in the interval \([-l_2;0]\). \(l_2\) being the length of the damaged zone as described in Fig. 6. \(X=0\) corresponds to the crack tip position. \(\lambda _{\uptau }^2\) is the characteristic wave number that controls the extent of the process zone. \(\uptau _2\) is the shear stress along the damaged region of the adhesive developped during the softening or hardening stage. As for the elastic stage, \(\uptau _2\) is replaced by its expression in Eqs. (29) to (34) which gives similar expressions to Eqs. (40) to (45).

In the case of a trapezoidal ALSB, a perfectly plastic behaviour is considered where the local tangent modulus is equal to 0. Shear stress for this regime can be defined as:

After solving a second order differential equation, local forces and displacements can therefore be described as:

where in this trapezoidal case, X varies in the interval \([-(l_1+l_2);-l_2]\).

A simple optimisation procedure is used to simulate the mechanical response of an ELS specimen. Indeed, the whole specimen is represented with segments connected together where shear stress distribution are given by relations (38) and (47). Considering displacements and cohesive forces along the adherend, the parameters to be identified are the lengths of each segment (\(l_e\),\(l_1\),\(l_2\)). This procedure is illustrated in algorithms 1 in the case of a bilinear ALSB with the following boundary conditions (see Fig. 6):

-

Boundary condition considering the specimen clamped at its left end: \(u(0) = 0\), \(v(0) = 0\) and \(\varphi (0) = 0\).

-

At crack tip, \(N_2(l_e+l_2) = 0\) and \(M_2(l_e+l_2) = Pa/2\) since there is no loaded adhesive. The specimen behaves like a simple beam under flexure.

-

Continuity conditions between elastic region and damaged region (see Fig. 6): \(u(l_e)=u_2(l_e)\), \(v(l_e)=v_2(l_e)\), \(\varphi (l_e)=\varphi _2(l_e)\), \(N(l_e)=N_2(l_e)\), \(M(l_e)=M_2(l_e)\).

-

Fully developed FPZ condition: \(\uptau _2(l_e)=\uptau _{max}\).

-

Shear stress condition: \(\uptau =\uptau _{max}\).

-

Compatibility conditions: u(x) and \(\varphi (x)\) are replaced by their expression (Eqs. 43 and 44) in Eq. 36. Then identification between shear stress distribution (see Eq. 38) and shear stress as a function of shear strain (see Eq. 36) gives:

$$\begin{aligned} \tau _m= & {} cste \end{aligned}$$(55)$$\begin{aligned} \uptau _m= & {} 2\frac{G_a}{t_a}\left[ \left( \frac{1}{ES}\left[ w\uptau _m\frac{X^2}{2}+N_0 X\right] +u_0\right) \right. \nonumber \\&+\left. \frac{t}{2}\left( \frac{1}{EI}\left[ -\frac{PX^2}{2}+\uptau _m\frac{tw}{2}\frac{X^2}{2}+M_0 X\right] +\varphi _0\right) \right] \nonumber \\ \end{aligned}$$(56)Polynomial terms in Eq. 56 must be equal to zero because \(\uptau _m=cste\), so we obtain:

$$\begin{aligned} \uptau _m= & {} \frac{P}{wt} \frac{St^2}{4I + St^2} \end{aligned}$$(57)$$\begin{aligned} M_0= & {} -\frac{2I}{tS} N_0 \end{aligned}$$(58)$$\begin{aligned} \uptau _m= & {} 2\frac{G_a}{t_a} \left[ u_0 + \frac{t}{2}\varphi _0 \right] \end{aligned}$$(59)

Algorithm 1 describes how local forces and displacement are obtained for the elastic, FPZ development and crack propagation regimes for a bilinear ALSB. More over, it describes how the maximum length for the process zone is obtained: multiple lengths are tested until shear strain goes over maximum shear strain (\(\gamma _2\)). For each length of process zone, local forces and displacements are obtained. Similarly, during crack propagation regime, for each crack length a tested, quantities are calculated, especially shear strain. If shear strain is included in an interval \([\gamma _{max}-\varepsilon ,\gamma _{max}+\varepsilon ]\), crack propagates (crack length a rises). \(\varepsilon \) is the precision expected with respect to the ALSB parameters. Moreover, it permits the semi-analytical model to converge to a solution. If shear strain is not in the interval, size of the FPZ \(l_{FPZ}\) has to be adjusted. In the case of bi-linear ALSB, \(l_{FPZ} = l_2\). In the case of trapezoidal ALSB, \(l_{FPZ} = l_1 + l_2\).

Getting the local forces and displacements describes crack propagation along the adhesive layer as a function of the applied load. Shear stress and strain are obtained and can be correlated with the adhesive layer shear behaviour. These quantities depends on the geometrical and ALSB parameters.

Appendix C: Approximate solution

The shear stress distribution is:

\(\uptau _m\) is the mean shear stress. X, \(l_e\), \(l_1\), \(l_2\) are described in Fig. 6. Assuming non interacting large gradient regions at both bondline edge, the boundary condition at the crack tip edge \(X=0\) reduced to:

\(N_0\), \(M_0\) are integration constants. With compatibility conditions obtained with the method described in Appendix B:

We obtain:

So near crack tip region (\(B=0\)):

and near clamping region with \(\uptau (X=-l_e)=0\)

Replacing Eq. (69) in classical constitutive equations, we obtain:

with \(\varphi (X=-l_e)=0\)

near crack tip

\(\varphi _r\) is the root rotation coeeficient.

The same procedure is applied to determine the root deflection coefficient \(v_r\):

with \(v(X=-l_e)=0\)

near crack tip

Rights and permissions

About this article

Cite this article

Bertrand, J., Jumel, J., Renart, J. et al. Theoretical assessment of ELS test data reduction technique using virtual testing. Int J Fract 229, 195–213 (2021). https://doi.org/10.1007/s10704-021-00549-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-021-00549-4