Abstract

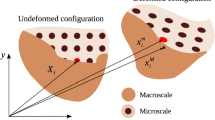

This paper presents a finite-strain homogenization model for the macroscopic behavior of porous polycrystals containing pressurized pores that are randomly distributed in a polycrystalline matrix. The porous polycrystal is modeled as a three-scale composite, where the pore size is taken to be much larger than the grain size, and the grains are described by single-crystal viscoplasticity. The instantaneous macroscopic response and corresponding field statistics in the material are determined using a generalization of the recently developed iterated second-order homogenization method, which employs the effective behavior of a linear comparison composite to estimate that of the nonlinear composite by means of a suitably designed variational approximation. Moreover, consistent evolution laws are derived for the pore pressure, pore geometry, and the underlying texture for the polycrystalline matrix. The model is then used to investigate porous ice polycrystals under a wide range of loading conditions. It is found that the pore pressure evolution has a strong effect on the material’s response under compressive loadings. More specifically, the macroscopic response of the porous polycrystals can be categorized into three different regimes: (i) a texture-controlled regime at low triaxialities, where the materials behave like solid polycrystals; (ii) a porosity-controlled regime at high triaxialities, where the materials behave like porous untextured materials; and (iii) a transition regime at intermediate triaxialities, where the materials exhibit a more complex behavior. This work highlights the importance of accounting for the interplay between porosity and matrix texture evolution in describing the constitutive response of porous polycrystals undergoing finite deformations.

Similar content being viewed by others

References

Agoras M, Ponte Castañeda P (2013) Iterated linear comparison bounds for viscoplastic porous materials with “ellipsoidal” microstructures. J Mech Phys Solids 61(3):701–725. https://doi.org/10.1016/j.jmps.2012.11.003

Agoras M, Ponte Castañeda P (2014) Anisotropic finite-strain models for porous viscoplastic materials with microstructure evolution. Int J Solids Struct 51(5):981–1002. https://doi.org/10.1016/j.ijsolstr.2013.11.025

Alley RB, Fitzpatrick JJ (1999) Conditions for bubble elongation in cold ice-sheet ice. J Glaciol 45(149):147–153

Aravas N, Ponte Castañeda P (2004) Numerical methods for porous metals with deformation-induced anisotropy. Comput Methods Appl Mech Eng 193(33–38):3767–3805. https://doi.org/10.1016/j.cma.2004.02.009

Ashby M, Duval P (1985) The creep of polycrystalline ice. Cold Reg Sci Technol 11(3):285–300

Bachmann F, Hielscher R, Schaeben H (2010) Texture analysis with mtex-free and open source software toolbox. Solid State Phenomena 160:63–68

Barrioz P, Hure J, Tanguy B (2019) Effect of dislocation channeling on void growth to coalescence in fcc crystals. Mater Sci Eng A 749:255–270

Benzerga AA, Besson J (2001) Plastic potentials for anisotropic porous solids. Eur J Mech A 20(3):397–434

Benzerga AA, Leblond JB (2010) Ductile fracture by void growth to coalescence. In: Stepehne PA et al (eds) Advances in applied mechanics. Elsevier, Amsterdam, pp 169–305

Benzerga AA, Leblond JB, Needleman A, Tvergaard V (2016) Ductile failure modeling. Int J Fract 201(1):29–80

Castelnau O, Duval P, Lebensohn RA, Canova GR (1996) Viscoplastic modeling of texture development in polycrystalline ice with a self-consistent approach: comparison with bound estimates. J Geophys Res 101(B6):13851–13868

Chino Y, Dunand DC (2008) Directionally freeze-cast titanium foam with aligned, elongated pores. Acta Mater 56(1):105–113

Danas K, Aravas N (2012) Numerical modeling of elasto-plastic porous materials with void shape effects at finite deformations. Compos B Eng 43(6):2544–2559

Das S, Ponte Castañeda P (2019) A multiphase homogenization model for the viscoplastic response of intact sea ice: the effect of porosity and crystallographic texture. Int J Multiscale Comput Eng 17:2. https://doi.org/10.1615/IntJMultCompEng.2019029125

Duval P, Ashby M, Anderman I (1983) Rate-controlling processes in the creep of polycrystalline ice. J Phys Chem 87(21):4066–4074

Fegyveresi JM, Alley RB, Voigt DE, Fitzpatrick JJ, Wilen LA (2019) Instruments and methods: a case study of ice core bubbles as strain indicators. Ann Glaciol 60(78):8–19

Gologanu M, Leblond JB, Devaux J (1993) Approximate models for ductile metals containing non-spherical voids—case of axisymmetric prolate ellipsoidal cavities. J Mech Phys Solids 41(11):1723–1754

Gow AJ (1968) Bubbles and bubble pressures in antarctic glacier ice. J Glaciol 7(50):167–182

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I–yield criteria and flow rules for porous ductile media. J Appl Mech 99:2–15

Ha S, Kim K (2010) Void growth and coalescence in fcc single crystals. Int J Mech Sci 52(7):863–873

Han X, Besson J, Forest S, Tanguy B, Bugat S (2013) A yield function for single crystals containing voids. Int J Solids Struct 50(14–15):2115–2131

Hershey A (1954) The elasticity of an isotropic aggregate of anisotropic cubic crystals. J Appl Mech 21(3):236–240

Hooke RL, Hudleston PJ (1978) Origin of foliation in glaciers. J Glaciol 20(83):285–299

Hudleston PJ (2015) Structures and fabrics in glacial ice: a review. J Struct Geol 81:1–27

Hure J (2019) A coalescence criterion for porous single crystals. J Mech Phys Solids 124:505–525

Hutchinson JW (1976) Bounds and self-consistent estimates for creep of polycrystalline materials. Proc R Soc Lond A 348(1652):101–127

Idiart MI, Ponte Castañeda P (2007) Field statistics in nonlinear composites. I. Theory. Proc R Soc Lond A 463(2077):183–202. https://doi.org/10.1098/rspa.2006.1756

Kailasam M, Ponte Castañeda P (1998) A general constitutive theory for linear and nonlinear particulate media with microstructure evolution. J Mech Phys Solids 46(3):427–465. https://doi.org/10.1016/S0022-5096(97)00095-1

Kailasam M, Ponte Castañeda P, Willis J (1997) The effect of particle size, shape, distribution and their evolution on the constitutive response of nonlinearly viscous composites. i. theory. Proc R Soc Lond A 355(1730):1835–1852. https://doi.org/10.1098/rsta.1997.0092

Kashibe S, Une K, Nogita K (1993) Formation and growth of intragranular fission gas bubbles in uo2 fuels with burnup of 6–83 gwd/t. J Nucl Mater 206:22–34

Keralavarma S, Benzerga A (2010) A constitutive model for plastically anisotropic solids with non-spherical voids. J Mech Phys Solids 58(6):874–901

Kröner E (1958) Berechnung der elastischen konstanten des vielkristalls aus den konstanten des einkristalls. Zeitschrift für Physik 151(4):504–518

Lahellec N, Suquet P (2013) Effective response and field statistics in elasto-plastic and elasto-viscoplastic composites under radial and non-radial loadings. Int J Plast 42:1–30

Lebensohn RA, Cazacu O (2012) Effect of single-crystal plastic deformation mechanisms on the dilatational plastic response of porous polycrystals. Int J Solids Struct 49(26):3838–3852

Lebensohn RA, Idiart MI, Ponte Castañeda P, Vincent PG (2011) Dilatational viscoplasticity of polycrystalline solids with intergranular cavities. Philos Magn 91(22):3038–3067. https://doi.org/10.1080/14786435.2011.561811

Lebensohn RA, Escobedo JP, Cerreta EK, Dennis-Koller D, Bronkhorst CA, Bingert JF (2013) Modeling void growth in polycrystalline materials. Acta Mater 61(18):6918–6932

Leblond J, Perrin G, Suquet P (1994) Exact results and approximate models for porous viscoplastic solids. Int J Plast 10(3):213–235

Liu Y (2003) Macroscopic behavior, field fluctuations and texture evolution in viscoplastic polycrystals. Ph.D. thesis, University of Pennsylvania

Liu Y, Gilormini P, Ponte Castañeda P (2005) Homogenization estimates for texture evolution in halite. Tectonophysics 406(3–4):179–195. https://doi.org/10.1016/j.tecto.2005.06.007

Llorens MG, Griera A, Steinbach F, Bons PD, Gomez-Rivas E, Jansen D, Roessiger J, Lebensohn RA, Weikusat I (2017) Dynamic recrystallization during deformation of polycrystalline ice: insights from numerical simulations. Philos Trans R Soc A 375(2086):20150346

Lösönen L (2000) On the behaviour of intragranular fission gas in uo2fuel. J Nucl Mater 280:56–72

Madou K, Leblond JB (2012) A gurson-type criterion for porous ductile solids containing arbitrary ellipsoidal voids–i: limit-analysis of some representative cell. J Mech Phys Solids 60(5):1020–1036

Mandel J (1972) Plasticité et viscoplasticité. cism udine courses and lectures. no 97

Mbiakop A, Constantinescu A, Danas K (2015) An analytical model for porous single crystals with ellipsoidal voids. J Mech Phys Solids 84:436–467

Michel J, Suquet P (1992) The constitutive law of nonlinear viscous and porous materials. J Mech Phys Solids 40(4):783–812

Monchiet V, Cazacu O, Charkaluk E, Kondo D (2008) Macroscopic yield criteria for plastic anisotropic materials containing spheroidal voids. Int J Plast 24(7):1158–1189

Morin L, Leblond JB, Kondo D (2015) A gurson-type criterion for plastically anisotropic solids containing arbitrary ellipsoidal voids. Int J Solids Struct 77:86–101

Moulinec H, Suquet P (1994) A fast numerical method for computing the linear and nonlinear mechanical properties of composites. Comptes rendus de l’Académie des sciences Série II, Mécanique, physique, chimie, astronomie 318(11):1417–1423

Moulinec H, Suquet P (1998) A numerical method for computing the overall response of nonlinear composites with complex microstructure. Comput Methods Appl Mech Eng 157(1–2):69–94

Murray N, Dunand DC (2004) Effect of thermal history on the superplastic expansion of argon-filled pores in titanium: part i kinetics and microstructure. Acta Mater 52(8):2269–2278

Nahshon K, Hutchinson J (2008) Modification of the gurson model for shear failure. Eur J Mech A 27(1):1

Nebozhyn M, Gilormini P, Ponte Castañeda P (2001) Variational self-consistent estimates for cubic viscoplastic polycrystals: the effects of grain anisotropy and shape. J Mech Phys Solids 49(2):313–340. https://doi.org/10.1016/S0022-5096(00)00037-5

Needleman A (1972) Void growth in an elastic-plastic medium. J Appl Mech 39:964–970

Nielsen KL, Dahl J, Tvergaard V (2012) Collapse and coalescence of spherical voids subject to intense shearing: studied in full 3d. Int J Fract 177(2):97–108

Ogden RW (1997) Non-linear elastic deformations. Courier Corporation, North Chelmsford

Ohno H, Lipenkov VY, Hondoh T (2010) Formation of air clathrate hydrates in polar ice sheets: heterogeneous nucleation induced by micro-inclusions. J Glaciol 56(199):917–921

Ponte Castañeda P (1999) Nonlinear polycrystals with microstructure evolution. In: proceedings of the 9th international symposium. continuum models and discrete systems. World Scientific Publishing Co, pp 22–28

Ponte Castañeda P (1991) The effective mechanical properties of nonlinear isotropic composites. J Mech Phys Solids 39(1):45–71. https://doi.org/10.1016/0022-5096(91)90030-R

Ponte Castañeda P (2012) Bounds for nonlinear composites via iterated homogenization. J Mech Phys Solids 60(9):1583–1604. https://doi.org/10.1016/j.jmps.2012.05.004

Ponte Castañeda P (2015) Fully optimized second-order variational estimates for the macroscopic response and field statistics in viscoplastic crystalline composites. Proc R Soc A 471(2184):20150665. https://doi.org/10.1098/rspa.2015.0665

Ponte Castañeda P, Suquet P (1998) Nonlinear composites. Adv Appl Mech 34:171–302. https://doi.org/10.1016/S0065-2156(08)70321-1

Ponte Castañeda P, Willis J (1995) The effect of spatial distribution on the effective behavior of composite materials and cracked media. J Mech Phys Solids 43(12):1919–1951. https://doi.org/10.1016/0022-5096(95)00058-Q

Ponte Castañeda P, Zaidman M (1994) Constitutive models for porous materials with evolving microstructure. J Mech Phys Solids 42(9):1459–1497. https://doi.org/10.1016/0022-5096(94)90005-1

Qi C, Prior DJ, Craw L, Fan S, Llorens MG, Griera A, Negrini M, Bons PD, Goldsby DL (2019) Crystallographic preferred orientations of ice deformed in direct-shear experiments at low temperatures. Cryosphere 13(1):351–371

Ramos Nervi JE, Idiart MI (2015) Bounding the plastic strength of polycrystalline voided solids by linear-comparison homogenization techniques. Proc R Soc A 471(2183):20150380

Smyshlyaev V, Willis J (1998) A ‘non-local’variational approach to the elastic energy minimalization of martensitic polycrystals. Proc R Soc Lond Ser A 454(1974):1573–1613

Song D, Ponte Castañeda P (2017a) A finite-strain homogenization model for viscoplastic porous single crystals: I-theory. J Mech Phys Solids 107:560–579. https://doi.org/10.1016/j.jmps.2017.06.008

Song D, Ponte Castañeda P (2017b) A finite-strain homogenization model for viscoplastic porous single crystals: II-applications. J Mech Phys Solids 107:580–602. https://doi.org/10.1016/j.jmps.2017.06.003

Song D, Ponte Castañeda P (2017c) Macroscopic response of strongly anisotropic porous viscoplastic single crystals and applications to ice. Extreme Mech Lett 10:41–49. https://doi.org/10.1016/j.eml.2016.10.001

Song D, Ponte Castañeda P (2018a) A multi-scale homogenization model for fine-grained porous viscoplastic polycrystals: I-finite-strain theory. J Mech Phys Solids 115:102–122. https://doi.org/10.1016/j.jmps.2018.03.001

Song D, Ponte Castañeda P (2018b) A multi-scale homogenization model for fine-grained porous viscoplastic polycrystals: II-applications to fcc and hcp materials. J Mech Phys Solids 115:77–101. https://doi.org/10.1016/j.jmps.2018.03.002

Song D, Agoras M, Ponte Castañeda P (2015) The evolution of pore shape and orientation in plastically deforming metals: implications for macroscopic response and shear localization. Mech Mater 90:47–68. https://doi.org/10.1016/j.mechmat.2015.01.011

Srivastava A, Needleman A (2015) Effect of crystal orientation on porosity evolution in a creeping single crystal. Mech Mater 90:10–29

Suquet P, Moulinec H, Castelnau O, Montagnat M, Lahellec N, Grennerat F, Duval P, Brenner R (2012) Multi-scale modeling of the mechanical behavior of polycrystalline ice under transient creep. Procedia IUTAM 3:76–90

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17(4):389–407

Vincent PG, Monerie Y, Suquet P (2009a) Porous materials with two populations of voids under internal pressure: I. Instantaneous constitutive relations. Int J Solids Struct 46(3–4):480–506

Vincent PG, Monerie Y, Suquet P (2009b) Porous materials with two populations of voids under internal pressure: II. Growth and coalescence of voids. Int J Solids Struct 46(3–4):507–526

Vincent PG, Suquet P, Monerie Y, Moulinec H (2014a) Effective flow surface of porous materials with two populations of voids under internal pressure: I. A GTN model. Int J Plast 56:45–73

Vincent PG, Suquet P, Monerie Y, Moulinec H (2014b) Effective flow surface of porous materials with two populations of voids under internal pressure: II. Full-field simulations. Int J Plast 56:74–98

Willis J (1977) Bounds and self-consistent estimates for the overall properties of anisotropic composites. J Mech Phys Solids 25(3):185–202

Willis JR (1981) Variational and related methods for the overall properties of composites. In: Stephane PA et al (eds) Advances in applied mechanics. Elsevier, Amsterdam, pp 1–78

Willis J (1991) On methods for bounding the overall properties of nonlinear composites. J Mech Phys Solids 39(1):73–86

Yerra S, Tekog C, Scheyvaerts F, Delannay L, Van Houtte P, Pardoen T et al (2010) Void growth and coalescence in single crystals. Int J Solids Struct 47(7–8):1016–1029

Acknowledgements

This material is based upon research supported by the Office of Naval Research under Award Number N00014-17-1-2076.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Homogenization problems for a porous composite with pressurized pores and a porous composite with vacuous pores

In this appendix, we show that the effective behavior and field statistics for porous polycrystals with pressurized pores can be determined from those for porous polycrystals with vacuous pores (\(P=0\)), provided that the macroscopic stress is appropriately modified, as discussed in Sect. 3.1. As will be seen below, this is a direct consequence of the incompressibility of the matrix phase. Thus, we will provide a demonstration in the more general context of porous materials with an incompressible viscoplastic matrix.

Here we consider an RVE \({\varOmega }\) consisting of pressurized pores randomly distributed in an incompressible, viscoplastic matrix. We assume that the matrix and pores occupy, respectively, the spatial domains \({\varOmega }^{(1)}\) and \({\varOmega }^{(2)}\), and that the pores are subjected to an internal pressure P. In the following, we will make use of the symbols \(\left\langle \cdot \right\rangle \) and \(\langle \cdot \rangle ^{(q)}\) (\(q=1,2\)) to denote the volume averages of fields over \({\varOmega }\) and \({\varOmega }^{(q)}\), respectively.

The constitutive response for the matrix can be described by a stress potential \(u^{(1)}({{\varvec{\sigma }}})\equiv \psi ({\varvec{\sigma }}_{d})\) (\({\varvec{\sigma }}_{d}\) denotes the deviatoric stress), so that

where \(\mathbf{D }\) is the strain rate satisfying the incompressibility constraint \(\mathrm{tr}(\mathbf{D })=0\). On the other hand, the constitutive behavior for the pressurized pores can be characterized by a stress potential \(u^{(2)}({\varvec{\sigma }})\), such that \(u^{(2)}({\varvec{\sigma }})=0\) if \({\varvec{\sigma }}=-P\mathbf{I }\), while \(u^{(2)}({\varvec{\sigma }})=\infty \) otherwise, as has been discussed in Section 2.2.2.

In order to determine the homogenized response of the porous composite for a prescribed macroscopic stress \({\overline{{\varvec{\sigma }}}}\) (note that \({\overline{{\varvec{\sigma }}}}=\langle {\varvec{\sigma }}\rangle \)), we need to solve the following boundary value problem for the velocity field \(\mathbf{v}\):

keeping in mind that \({\varvec{\sigma }}\) depends on \(\mathbf{v}\) through the constitutive relation (39), while \(\partial {\varOmega }\) and \(\partial {\varOmega }^{(2)}\) denote, respectively, the boundaries of \({\varOmega }\) and \({\varOmega }^{(2)}\). After solving (40), the effective stress potential \({\widetilde{u}}({\overline{{\varvec{\sigma }}}};P)\) for the porous composite can be determined by computing the average of the local stress potential via

where \(f=V^{(2)}/V\) is the porosity, with \(V^{(2)}=|{\varOmega }^{(2)}|\) and \(V=|{\varOmega }|\) denoting the total volumes of the pores and the RVE, respectively.

Making use of the change of variables (Vincent et al. 2009a)

we have from (40) that

On closer inspection, we realize that (43) defines the corresponding boundary value problem for a porous composite with the exact same substructure and matrix, but with vacuous pores, for a prescribed macroscopic stress \({\overline{{\varvec{\sigma }}}}^{*}=\langle {\varvec{\sigma }}^{*}\rangle ={\overline{{\varvec{\sigma }}}}+P\mathbf{I }\). Making use of the fact that \(u^{(1)}({\varvec{\sigma }}) = u^{(1)}({\varvec{\sigma }}^{*})\), together with expression (41), it is straightforward to verify that \({\widetilde{u}}({\overline{{\varvec{\sigma }}}};P) = {\widetilde{u}}({\overline{{\varvec{\sigma }}}}^*,0)\), from which equations (10) and (11) in Section 3.1 follow. In addition, it can be easily shown that the field statistics in the porous composite with pressurized pores can be obtained from those in the porous composite with vacuous pores. In particular, we have that

where use has been made of (42). In the above equation, \({\mathbb {C}}^{(1)}(\cdot )\) denotes the fluctuation covariance tensor for a given quantity in the matrix phase, e.g., \({\mathbb {C}}^{(1)}({\varvec{\sigma }})=\langle {\varvec{\sigma }}\otimes {\varvec{\sigma }}\rangle ^{(1)}-\langle {\varvec{\sigma }}\rangle ^{(1)}\otimes \langle {\varvec{\sigma }}\rangle ^{(1)}\).

Additio nally, because the matrix is incompressible and insensitive to the hydrostatic stress (see (39)), it is easy to verify that the local velocity field, along with the local strain-rate and spin fields, obtained by solving (40) are identical to those obtained by solving (43), that is \(\mathbf{v} = \mathbf{v}^{*}\), \(\mathbf{D} = \mathbf{D}^{*}\) and \(\mathbf{W} = \mathbf{W}^{*}\). It then follows that

Similarly, the corresponding relations for the spin field and the slip rates over different slip systems can be written in forms completely analogous to (45).

Furthermore, making use of the divergence theorem, it can be shown that the average strain-rate and spin fields over the pores can be determined from the velocity field on the pore boundaries (Gurson 1977). For example, we have that

Since the velocity fields obtained by solving (40) and (43) are identical, we also have the result that

Evolution law for the pore pressure

In this Appendix, we derive the evolution law (22) for the average pore pressure. Let us denote the initial volumes of the RVE and pores by \(V_{I}\) and \(V_{I}^{(2)}\), respectively, while denote the current volumes of the RVE and pores by V and \(V^{(2)}\), respectively. Furthermore, we denote the initial and current (average) pore pressures by \(P_{I}\) and P, respectively.

As discussed in Section 3.2.1, we assume that the product of the average pore pressure with the total pore volume remains unchanged, so that for any given state

Taking the derivative of (48) with respect to time, we have that

Making use of (48) in (49), and after some manipulations, we arrive at

Because the matrix phase of the porous composite is incompressible, the volume change of the composite equals the volume change of the pores (i.e., \({\dot{V}}={\dot{V}}^{(2)}\)). Thus, we have that

where use has been made of the facts that \({\dot{V}}/V={\overline{D}}_{kk}\), and \(V^{(2)} = fV\) (f is the porosity in the current state of the RVE). Substituting (51) into (50), we arrive at equation (22).

Rights and permissions

About this article

Cite this article

Das, S., Song, D. & Ponte Castañeda, P. Macroscopic response and microstructure evolution in viscoplastic polycrystals with pressurized pores. Int J Fract 230, 43–70 (2021). https://doi.org/10.1007/s10704-020-00500-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-020-00500-z