Abstract

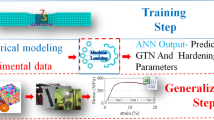

The Gurson–Tvergaard–Needleman (GTN) damage model is widely used to predict ductile failure initiation and propagation. However, the material-dependent parameters can show a significant spread when determined for the same steel grade material. Different calibration procedures and optimisation processes cause a significant variation in the obtained parameter values. Furthermore, there is no clear consensus on which parameters require calibration. In this study, the influence of the material-dependent parameters used to model the dynamic ductile fracture behaviour of X70 grade pipeline steel is investigated. A sensitivity analysis is performed on a finite element model of a Charpy V-Notch (CVN) specimen. Seven GTN model parameters are considered in a total of 70 simulations. A feedforward back-propagating artificial neural network (ANN) is constructed and trained using data obtained through the numerical simulations. A connected weights (CW) algorithm allows to determine the relative influence of each parameter on the fracture energy. It was observed that the void growth acceleration factor plays an important role with respect to the parameter influences. Remarkably, the mean nucleation strain, \( \varepsilon_{N} \) has the highest relative importance whilst the critical void volume fraction, \( f_{c} \)—which is considered as a crucial damage parameter—showed the smallest influence when the acceleration factor is low. On the contrary, when considering a high acceleration factor, \( f_{c} \) becomes the most influential parameter. Based on the obtained importance for each parameter, it is suggested that parameters \( f_{0} \), \( f_{c} \), \( f_{F} \), and \( f_{N} \) should be selected for calibration in each individual application. Finally, the applied machine learning approach is used to predict the fracture energy for a given set of damage parameters for X70 grade steel. It is observed that the trained neural network is able to provide a satisfactory approximation of the CVN fracture energy.

Similar content being viewed by others

Abbreviations

- AN:

-

Axisymmetric notched

- ANN:

-

Artificial neural network

- AI:

-

Artificial intelligence

- BTCM:

-

Battelle two curve method

- CMOD:

-

Crack mouth opening displacement

- CTOD:

-

Crack tip opening displacement

- CVN:

-

Charpy V-notch

- CW:

-

Connected weights

- DWTT:

-

Drop weight tear test

- G–T:

-

Gurson–Tvergaard

- GTN:

-

Gurson–Tvergaard–Needleman

- MSE:

-

Mean square error

- PE:

-

Predicted energy

- PS:

-

Parameter set

- RI:

-

Relative importance

- SENT:

-

Single edge notch test

- TE:

-

Target energy

- \( f \) :

-

Void volume fraction

- \( f* \) :

-

Effective void volume fraction

- \( \dot{f} \) :

-

Evolution of void volume fraction

- \( f_{0} \) :

-

Initial void volume fraction

- \( f_{c} \) :

-

Critical void volume fraction

- \( f_{F} \) :

-

Void volume fraction at failure

- \( f_{N} \) :

-

Void volume fraction of void nucleating particles

- \( \kappa \) :

-

Void growth acceleration factor

- \( n \) :

-

Strain hardening exponent

- \( q_{1} \), \( q_{2} \), \( q_{3} \) :

-

Constitutive GTN damage parameters

- \( s_{N} \) :

-

Standard deviation nucleation strain

- \( w_{xy} \) :

-

Connection weight between input and hidden neuron

- \( w_{yz} \) :

-

Connection weight between hidden and output neuron

- \( D \), \( p \) :

-

Cowper–Symonds coefficients

- \( E \) :

-

Young’s modulus

- \( J \) :

-

Fracture energy

- \( K \) :

-

Strength coefficient

- \( R \) :

-

Ratio of dynamic yield stress to static yield stress

- \( \varepsilon_{N} \) :

-

Mean value of nucleation strain

- \( \varepsilon^{pl} \) :

-

Plastic strain

- \( \bar{\varepsilon }^{pl} \) :

-

Equivalent plastic strain

- \( \dot{\varepsilon }^{pl} \) :

-

Plastic strain rate

- \( \dot{\varepsilon }_{kk}^{pl} \) :

-

Rate of plastic volume change

- \( \varepsilon_{m}^{pl} \) :

-

Equivalent plastic strain

- \( \nu \) :

-

Poisson ration

- \( \sigma_{eq} \) :

-

Equivalent stress

- \( \sigma_{hyd} \) :

-

Hydrostatic stress

- \( \sigma_{yld} \) :

-

Yield stress

- \( \bar{\sigma }\left( {\bar{\varepsilon }^{pl} } \right) \) :

-

Flow curve

- \( \varPhi \) :

-

Flow potential

References

Abbassi F, Belhadj T, Mistou S, Zghal A (2012) Parameter identification of a mechanical ductile damage using artificial neural networks in sheet metal forming. Mater Des 45:605–615

Abendroth M, Kuna M (2006) Identification of ductile damage and fracture parameters from the small punch test using neural networks. Eng Fract Mech 73:710–725

ASTM International (2018) ASTM E23-18: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International, West Conshohocken

Banabic, D.: Determination of GTN parameters from uniaxial tests. In: Multiscale Modelling in Sheet Metal Forming, pp 142–143. Springer (2016)

Besson J (2010) Continuum models of ductile fracture: a review. Int J Damage Mech 19:3–52

Brinnel V, Langenberg J, Kordtomeikel F, Di Y, Münstermann S (2015) Numerical derivation of strain-based criteria for ductile failure: discussions on sensitivity and validity. Eng Fract Mech 148:421–440

Brocks W, Sun DZ, Honig A (1995) Verification of the transferability of micromechanical parameters by cell model calculation with visco-plastic materials. Int J Plast 11:971–989

Chen Y, Lambert S (2003) Analysis of ductile tearing of pipeline-steel in single edge notch tension specimen. Int J Fract 124:179–199

Chen Y, Lambert S (2005) Numerical modeling of ductile tearing for semi-elliptical surface cracks in wide plates. Int J Press Vessels Pip 82:417–426

Chu CC, Needleman A (1980) Void nucleation effects in biaxially streched sheets. J Eng Mater Technol 3(102):249–256

Cosham A, Andrews RM, Schmidt T (2019) The EPRG Recommendation for Crack Arrest Toughness for Line Pipe Steel. European Pipeline Research Group, Duisburg

Cricri G (2013) A consistent use of the Gurson-Tvergaard-Needleman damage model for the R-curve calculation. Fratt. Integr. Strutt. 24:161–174

Dassault Systèmes: ABAQUS Documentation, Providence, United States (2019)

Demofonti, G., Mannucci, G., Di Vito, L.F., Aristotile, R., Di Biaggio, M., Malatesta, G., Harris, D., Harrison, P.L.: Ultra-high-strength pipeline prototyping for natural gas transmission DEMOPIPE. In: Research Programme of the Research Fund for Coal and Steel RDT (2005)

Duffy, A.R.: Full scale studies. In: A.G.A. Symposium on Line Pipe Research, Cat. No. L30 075 (1966)

Eiber, R.J.: Fracture propagation. In: A.G.A 4th Symposium on Line Pipe Research, Cat. No. L30 075 (1969)

Faleskog J, Gao X, Shih CF (1998) Cell model for nonlinear fracture analysis—I. Micromechanics calibration. Int J Fract 89:355–373

Fearnehough GD (1974) Fracture propagation control in gas pipelines: a survey of relevant studies. Int J Press Vessels Pip 2(4):257–282

Franklin AG (1969) Comparison between quantitative microscope and chemical methods for assessment of non-metallic inclusions. J. Iron Steel Inst. 207:181–186

Gnana-Sheela K, Deepa SN (2013) Review on methods to fix number of hidden neurons in neural networks. Math. Probl. Eng. 2013:6

Gurland J, Plateau J (1963) The mechanism of ductile rupture of metals containing inclusions. Trans. ASM 56:442–454

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: Part I—yield criteria and flow rules for porous ductile media. J Eng Mater Technol 1(99):2–15

Hütter, G., Zybell, L.: Models describing void growth. In: Recent Trends in Fracture and Damage Mechanics, pp. 376–385. Springer (2016)

ISO (2019) ISO 3183:2019—Petroleum and Natural Gas Industries-Steel Pipe for Pipeline Transportation Systems. International Organization for Standardization, Geneva

Kami A, Mollaei Dariani B, Sorin-Comsa D, Banabic D, Sadough-Vanini A, Liewald M (2016) Calibration of GTN damage model parameters using hydraulic bulge test. Roman. J. Tech. Sci. Appl. Mech. 61:245–260

Kim, I.-J., Jang, Y.-C., Kim, C.-M., Kim, Y.-P., Jang, Y.-Y., Huh, N.-S.: Crack growth simulation of fracture toughness specimens using GTN (Gurson-Tvergaard-Needleman) model. In: Proceedings of KSME Spring Conference, Jeongseon-gun (2018)

Kim J, Gao X, Srivatsan S (2004) Modeling of void growth in ductile solids: effects of stress triaxiality and initial porosity. Eng Fract Mech 71:379–400

Kiran R, Khandelwal K (2013) Gurson model parameters for ductile fracture simulation in ASTM A992 steels. Fatigue Fract Eng Mater Struct 2(37):1–13

Kiran R, Khandelwal K (2014) Gurson model parameters for ductile fracture simulation in ASTM A992 steels. Fatigue Fract Eng Mater Struct 37:171–183

Levenberg K (1944) A method for the solution of certain non-linear problems in least squares. Q Appl Math 2(2):164–168

Li, H., Fu, M.: Calibration of the ductile fracture models. In: Deformation-Based Processing of Materials: Behavior, Performance, Modeling, and Control. Elsevier (2019)

Lian J, Sharaf M, Archie F, Münstermann S (2013) A hybrid approach for modelling of plasticity and failure behaviour of advanced high-strength steel sheets. Int J Damage Mech 22(2):188–218

Mannucci, G., Demofonti, G., Di Biagio, M.: X100—Fracture Initiation and Propagation. ECSC Report (2005)

Marquardt DW (1963) An algorithm for the least-squares estimation of nonlinear parameters. SLAM J. Appl. Math. 11(2):431–441

MathWorks: MATLAB release, Massachusetts, United States (2019a)

Maxey, W.A.: Fracture initiation, propagation and arrest. In: Proceedings of 5th Symposium on Line Pipe Research, Houston, USA (1974)

Nasiri S, Reza-Khosravani M, Weinberg K (2017) Fracture mechanics and mechanical fault detection by artificial intelligence methods: a review. Eng Fail Anal 81:270–293

Needleman A, Tvergaard V (1987) An analysis of ductile rupture modes at a crack tip. J Mech Phys Solids 2(35):151–183

Needleman A, Tvergaard V (1991) An analysis of dynamic ductile crack growth in a double edge cracked specimen. Int J Fract 49:41–67

Olden JD, Jackson DA (2002) Illuminating the “black box”: a randomization approach for understanding variable contributions in artificial neural networks. Ecol Model 154:135–150

Olden JD, Joy MK, Death RG (2004) An accurate comparison of methods for quantifying variable importance in artificial neural networks using simulated data. Ecol Model 178:389–397

Rahimidehgolan F, Majzoobi G, Alinejad F, Fathi Sola J (2017) Determination of the constants of GTN damage model using experiment, polynomial regression and Kriging methods. Appl. Sci. 11:1179–1199

Ramadevi R, Sheela RB, Prakash V (2012) Role of hidden neurons in an elman recurrent neural network in classification of cavitation signals. Int J Comput Appl 37(7):9–13

Rivalin F, Besson J, Pineau A, Di Fant M (2001) Ductile tearing of pipeline-steel wide plates II. Modeling of in-plane crack propagation. Eng Fract Mech 68:347–364

Rosenblatt F (1958) The perceptron: a probabilistic model for information storage and organisation in the brain. Pschycol. Rev. 6(65):386–408

Russel S, Norvig P (1995) Artificial Intelligence: A Modern Approach. Pearson, London

Sayyed H (2008) Apportion of Charpy energy in API 5L grade X70 pipeline steel. Int J Press Vessels Pip 85:879–884

Sun DZ, Siegele D, Voss B, Schmitt W (1989) Application of local damage models to the numerical analysis of ductile rupture. Fatigue Fract Eng Mater Struct 2:210–212

Talemi R, Cooreman S, Van Hoecke D (2018) Finite element simulation of dynamic brittle fracture in pipeline steel: a XFEM-based cohesive zone approach. J. Mater. Des. Appl. 5(232):357–370

Thibaux, P., Van den Abeele, F.: Determination of crack initiation and propagation energy in instrumented Charpy V-notch impact tests by finite element simulations. In: Pipeline Technoogy Conference, Ostend (2009)

Turing AM (1950) Computing machinery and intelligence. Mind 49:433–460

Tvergaard V (1981) influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17:389–407

Tvergaard V (1982a) On localization in ductile materials containing spherical voids. Int J Fract 18:237–252

Tvergaard V (1982b) Influence of void nucleation on ductile shear fracture at a free surface. J Mech Phys Solids 6(30):399–425

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 1(32):157–169

Von Segger D (1993) CRC Standard Curves and Surfaces. CRC Press, Boca Raton

Wcislik, W.: Experimental determination of critical void volume fraction fF for the Gurson Tvergaard Needleman (GTN) model. In: 21st European Conference on Fracture, Catania, Italy (2016)

Xia L, Fong-Shih C, Hutchinson JW (1995) A computational approach to ductile crack growth under large scale yielding conditions. J Mech Phys Solids 3(43):389–413

Yeda L, Renqiang W, Bing Z, Tao F (2018) Application of GTN model in tensile fracture of pipeline steel. Key Eng Mater 777:451–456

Ying L, Liu W, Wang D, Hu P (2017) Parameter calibration of GTN damage model and formability analysis of 22MnB5 in hot forming process. J Mater Eng Perform 26(11):5155–5165

Zhang WW, Cong S (2016) Failure analysis of SUS304 sheet during hydro-bulging based on GTN ductile damage model. Int J Adv Manuf Technol 86:427–435

Zhang, P., Pereira, M., Rolfe, B., Wilkosz, D., Abeyrathna, B., Weiss, M.: A new strain-based method to determine GTN parameters for thin stainless steel foil. In: International Conference and Workshop on Numerical Simulation of 3D Sheet Metal Forming Processes, Tokyo (2018)

Zhang ZL, Thaulow C, Odegard J (2000) A complete Gurson model approach for ductile fracture. Eng Fract Mech 2(67):155–168

Zhu X-K (2015) State-of-the-art review of fracture control technology for modern and vintage gas transmission pipelines. Eng Fract Mech 148:260–280

Zhu, X.K., Leis, B.N.: CVN and DWTT energy methods for determining fracture arrest toughness of high strength pipeline steels. In: Proceedings of the 9th International Pipeline Conference, Calgary, Canada (2012)

Acknowledgements

The author gratefully acknowledges the support of the Research Foundation Flanders (FWO) via PhD fellowship grant 1SB6420N.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Paermentier, B., Debruyne, D. & Talemi, R. A machine learning based sensitivity analysis of the GTN damage parameters for dynamic fracture propagation in X70 pipeline steel. Int J Fract 227, 111–132 (2021). https://doi.org/10.1007/s10704-020-00499-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-020-00499-3