Abstract

Instabilities in thermally-driven crack growth in thin glass plates have been observed in experiments that slowly immerse a hot, pre-notched glass slide into a cold bath. We show that a nonlocal model of thermomechanical brittle fracture with minimal input parameters can predict the entire phase diagram of fracture measured in experiments for the low immersion speed regime. Geometrical restrictions to crack growth commonly found in other approaches are absent here. We discuss a method for determining the appropriate size of the peridynamic horizon based on a data point around a separating line between crack-type zones in the experimental phase diagram. Once the nonlocal size is smaller than the length-scale introduced by the thermal gradient, the computational results show that no fracture criterion is needed beyond Griffith’s criterion to capture the observed instabilities. The combination of thermal gradients and competing contraction forces on the two sides of the crack are behind the observed crack path instabilities. Elastic (velocity) vortices of material points show how and why the cracks develop along the observed paths. Our results demonstrate that thermally-driven fracture in brittle materials can be predicted with accuracy. We anticipate that this model will lead to design protocols for controlled fracture in brittle materials relevant in materials science and advanced manufacturing.

Similar content being viewed by others

References

Bobaru F, Duangpanya M (2010) The peridynamic formulation for transient heat conduction. Int J Heat Mass Transf 53:4047–4059. https://doi.org/10.1016/j.ijheatmasstransfer.2010.05.024

Bobaru F, Duangpanya M (2012) A peridynamic formulation for transient heat conduction in bodies with evolving discontinuities. J Comput Phys 231:2764–2785. https://doi.org/10.1016/j.jcp.2011.12.017

Bobaru F, Hu W (2012) The meaning, selection, and use of the peridynamic horizon and its relation to crack branching in brittle materials. Int J Fract 176:215–222. https://doi.org/10.1007/s10704-012-9725-z

Bobaru F, Zhang G (2015) Why do cracks branch? A peridynamic investigation of dynamic brittle fracture. Int J Fract 196:59–98. https://doi.org/10.1007/s10704-015-0056-8

Bobaru F, Zhang G (2016) Crack branching in dynamic brittle fracture. In: Bobaru F, Foster JT, Geubelle PH, Silling SA (eds) Handbook of peridynamic modeling. CRC Press, Taylor and Francis Group, pp 245–316

Bouchbinder E, Hentschel HGE, Procaccia I (2003) Dynamical instabilities of quasistatic crack propagation under thermal stress. Phys Rev E Stat Nonlinear Soft Matter Phys 68:36601. https://doi.org/10.1103/PhysRevE.68.036601

Bourdin B (2007) Numerical implementation of the variational brittle fracture formulation. In: Combescure A, Belytschko T, de Borst R (eds) IUTAM symposium on discretization methods for evolving discontinuities. Springer, pp 381–394

Cabral B, Leedom LC (1993) Imaging vector fields using line integral convolution. In: Proceedings of the 20th annual conference on computer graphics and interactive techniques—SIGGRAPH ’93. ACM Press, New York, NY, USA, pp 263–270

Chen Z, Bakenhus D, Bobaru F (2016) A constructive peridynamic kernel for elasticity. Comput Methods Appl Mech Eng 311:356–373. https://doi.org/10.1016/j.cma.2016.08.012

Corson F, Adda-Bedia M, Henry H, Katzav E (2009) Thermal fracture as a framework for quasi-static crack propagation. Int J Fract 158:1–14. https://doi.org/10.1007/s10704-009-9361-4

Cotterell B, Rice JR (1980) Slightly curved or kinked cracks. Int J Fract 16:155–169. https://doi.org/10.1007/BF00012619

Dipasquale D, Zaccariotto M, Galvanetto U (2014) Crack propagation with adaptive grid refinement in 2D peridynamics. Int J Fract 190:1–22. https://doi.org/10.1007/s10704-014-9970-4

Ferney BD, Devary MR, Hsia KJ, Needleman A (1999) Oscillatory crack growth in glass. Scr Mater 41:275–281. https://doi.org/10.1016/S1359-6462(99)00161-X

Ha YD, Bobaru F (2010) Studies of dynamic crack propagation and crack branching with peridynamics. Int J Fract 162:229–244. https://doi.org/10.1007/s10704-010-9442-4

Hayakawa Y (1994) Numerical study of oscillatory crack propagation through a two-dimensional crystal. Phys Rev E 49:1804–1807. https://doi.org/10.1103/PhysRevE.49.R1804

Hu W, Ha YD, Bobaru F, Silling SA (2012) The formulation and computation of the nonlocal J-integral in bond-based peridynamics. Int J Fract 176:195–206. https://doi.org/10.1007/s10704-012-9745-8

Hu W, Wang Y, Yu J et al (2013) Impact damage on a thin glass plate with a thin polycarbonate backing. Int J Impact Eng 62:152–165. https://doi.org/10.1016/j.ijimpeng.2013.07.001

Hussain AKMF (1986) Coherent structures and turbulence. J Fluid Mech 173:303. https://doi.org/10.1017/S0022112086001192

Kilic B, Madenci E (2009) Prediction of crack paths in a quenched glass plate by using peridynamic theory. Int J Fract 156:165–177. https://doi.org/10.1007/s10704-009-9355-2

Kilic B, Madenci E (2010) Peridynamic theory for thermomechanical analysis. IEEE Trans Adv Packag 33:97–105. https://doi.org/10.1109/TADVP.2009.2029079

Marder M (1994) Instability of a crack in a heated strip. Phys Rev E 49:51–55. https://doi.org/10.1103/PhysRevE.49.R51

Menouillard T, Belytschko T (2011) Analysis and computations of oscillating crack propagation in a heated strip. Int J Fract 167:57–70. https://doi.org/10.1007/s10704-010-9519-0

Pham VB, Bahr HA, Bahr U et al (2008) Global bifurcation criterion for oscillatory crack path instability. Phys Rev E Stat Nonlinear Soft Matter Phys 77:1–10. https://doi.org/10.1103/PhysRevE.77.066114

Ronsin O, Heslot F, Perrin B (1995) Experimental study of quasistatic brittle crack propagation. Phys Rev Lett 75:2352–2355. https://doi.org/10.1103/PhysRevLett.75.2352

Ronsin O, Perrin B (1998) Dynamics of quasistatic directional crack growth. Phys Rev E 58:7878–7886. https://doi.org/10.1103/PhysRevE.58.7878

Sakaue K, Yoneyama S, Kikuta H, Takashi M (2008) Evaluating crack tip stress field in a thin glass plate under thermal load. Eng Fract Mech 75:1015–1026. https://doi.org/10.1016/j.engfracmech.2007.04.025

Sakaue K, Yoneyama S, Takashi M (2009) Study on crack propagation behavior in a quenched glass plate. Eng Fract Mech 76:2011–2024. https://doi.org/10.1016/j.engfracmech.2009.05.008

Shewchuk JR (1994) An introduction to the conjugate gradient method without the agonizing pain. Technical Report CMUCS-TR-94-125, Carnegie Mellon University

Shilko EV, Psakhie SG (2014) Theoretical study of peculiarities of unstable longitudinal shear crack growth in sub-Rayleigh and supershear regimes. In: International conference on physical mesomechan, pp 571–574

Silling SA, Askari E (2005) A meshfree method based on the peridynamic model of solid mechanics. Comput Struct 83:1526–1535. https://doi.org/10.1016/j.compstruc.2004.11.026

Silling SA, Lehoucq RB (2010) Peridynamic theory of solid mechanics. In: Advances in applied mechanics, pp 73–168. https://doi.org/10.1016/S0065-2156(10)44002-8

Strogatz SH (2001) Nonlinear dynamics and chaos: with applications to physics, biology, chemistry and engineering. Westview Press, Boulder

Tian X, Du Q (2013) Analysis and comparison of different approximations to nonlocal diffusion and linear peridynamic equations. SIAM J Numer Anal 51:3458–3482. https://doi.org/10.1137/13091631X

van Wijk JJ (2002) Image based flow visualization. ACM Trans Graph 21:745–754. https://doi.org/10.1145/566654.566646

Yang B, Ravi-Chandar K (2001) Crack path instabilities in a quenched glass plate. J Mech Phys Solids 49:91–130. https://doi.org/10.1016/S0022-5096(00)00022-3

Yoneyama S, Sakaue K (2014) Experimental-numerical hybrid stress analysis for a curving crack in a thin glass plate under thermal load. Eng Fract Mech 131:514–524. https://doi.org/10.1016/j.engfracmech.2014.09.007

Yoneyama S, Sakaue K, Kikuta H, Takashi M (2008) Observation of stress field around an oscillating crack tip in a quenched thin glass plate. Exp Mech 48:367–374. https://doi.org/10.1007/s11340-007-9078-0

Yuse A, Sano M (1993) Transition between crack patterns in quenched glass plates. Nature 362:329–331. https://doi.org/10.1016/S0167-2789(97)00011-0

Yuse A, Sano M (1997) Instabilities of quasi-static crack patterns in quenched glass plates. Phys D Nonlinear Phenom 108:365–378. https://doi.org/10.1016/S0167-2789(97)00011-0

Zhang G, Le Q, Loghin A et al (2016) Validation of a peridynamic model for fatigue cracking. Eng Fract Mech 162:76–94. https://doi.org/10.1016/j.engfracmech.2016.05.008

Acknowledgements

This work has been supported in part by grants from the AFOSR MURI Center for Material Failure Prediction Through Peridynamics, Grant Number FA9550-14-1-0073 (Program Managers Drs. James Fillerup, Ali Sayir, David Stargel, and Fariba Fahroo), and from the ONR Award #N00014-16-1-2173 (Program Manager William Nickerson). This work was completed utilizing the Holland Computing Center of the University of Nebraska, which receives support from the Nebraska Research Initiative.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (mp4 3217 KB)

Supplementary material 2 (mp4 3991 KB)

Supplementary material 3 (mp4 5342 KB)

Supplementary material 4 (mp4 3595 KB)

Supplementary material 5 (mp4 3973 KB)

Supplementary material 6 (mp4 10352 KB)

Supplementary material 7 (mp4 12690 KB)

Supplementary material 8 (mp4 12842 KB)

Supplementary material 9 (mp4 20691 KB)

Supplementary material 10 (mp4 12946 KB)

Supplementary material 11 (mp4 13611 KB)

Appendices

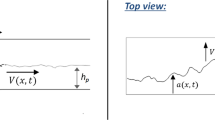

Appendix A1: Mathematical expression of the analytical thermal field

An analytical expression, shown in Fig. 1, that approximates the thermal field from the water bath, across the gap, and into the oven, is (see Bouchbinder et al. 2003, Pham et al. 2008):

where \(H=10\) mm (double of the gap length h) to have a transition of the temperature between three zones similar to that observed in the experiment (see Fig. 1 bottom panel), \(T_{0}\) the temperature of the cold water bath, \(T_{\mathrm {gap}}\) the temperature difference between water bath and oven, \(L_{D}\) = 1 mm the diffusion length, and x the coordinate along length direction with the origin \((x = 0)\) placed at the interface between the water bath and the gap.

Appendix A2: Temperature dependent fracture energy

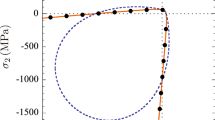

Experiments showed that the fracture energy decreases with the increase of the temperature at the crack tip (

dots and corresponding blue guideline in Fig. 12, digitizied from Fig. 11 in Ronsin and Perrin 1998). To take this effect into consideration in our simulation, the guideline is fitted using the equation:

where \(G_{\mathrm {0,max}}=3.8\, \mathrm {J/}\mathrm {m}^{\mathrm {2}}\) and \(G_{\mathrm {0,min}}=1.6\, \mathrm {J/}\mathrm {m}^{\mathrm {2}}\) correspond to the fracture energy at lower temperature limit temperature (\(T_{0}=30\, \mathrm {^{\circ }C})\) and at higher temperature limit, respectively. \(\beta =1/14\) is a fitting parameter. Equation A2 represents the experimental \(G_{\mathrm {0}}\)—T relation very well, for T above 45 \(\mathrm {^{\circ }C}\). A slight deviation below 45 \(\mathrm {^{\circ }C}\) has no impact on the crack growth because the crack tip never falls in this low temperature region.

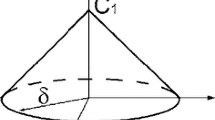

Appendix A3: \(\varvec{\delta }\)-convergence

Figure 13 shows the crack path at different horizon size \(\delta \) while other parameters are fixed: \(T_{\mathrm {gap}} = 135\) \(\mathrm {^{\circ }C}\), immersing velocity \(v = 0.05\) mm/s, plate width \(w = 15\,\hbox {mm}\), \(m=\delta /\Delta x=6\). On the physical phase diagram, the physical parameters place this case near the transition zone between growth of a straight crack and an oscillatory crack (see Fig. 6). Branching cracks are observed at \(\delta = 0.4\) and 0.3 mm, while oscillating crack is observed at \(\delta = 0.2\,\hbox {mm}\) and lower. The horizon size influences the amount of damage along the crack path. For a larger horizon, a larger amount of material is damaged and any small imbalance between the amounts of material on the sides of the crack path gets amplified more. As the horizon decreases, this imbalance approaches the physical, real imbalance, that leads to thermal strain larger on one side than the other, which consequently results in contraction forces that pull the crack from its straight path into an oscillatory one. (see discussion in Sect. 4.3). Notice that for the oscillating crack case, the wavelength appears to be relatively insensitive to the horizon size, while the starting point of oscillations slightly moves farther from the notch tip the smaller the horizon is.

Appendix A4: Elastic vortex and instability of crack growth for \({\varvec{v}} = 0.5\) mm/s

Rights and permissions

About this article

Cite this article

Xu, Z., Zhang, G., Chen, Z. et al. Elastic vortices and thermally-driven cracks in brittle materials with peridynamics. Int J Fract 209, 203–222 (2018). https://doi.org/10.1007/s10704-017-0256-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-017-0256-5