Abstract

Temperature gradient type ESSO test is one of the most popular test methods for evaluating the brittle crack arrest toughness, \(K_{ca}\). However, test conditions which are specimen shape, tab plate shape, applied stress and temperature gradient affect \(K_{ca}\). This document reports effects of specimen geometries that are specimen width, tab plate length, tab plate thickness and tab plate width on \(K_{ca}\) evaluation. In addition, effects of applied stress and temperature gradient have also been investigated. Temperature gradient type ESSO tests are conducted at three different steel mills in Japan. Then, test conditions were varied and test results were compared. In the result, influence range of effect specimen width, tab plate thickness, applied stress and temperature gradient were demonstrated. The applicable range of specimen geometry, applied stress and temperature gradient were clarified and implemented to the brittle crack arrest standard.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Fracture control design is often applied for steel structures, such as cryogenic storage tanks, penstocks, etc. Brittle crack initiation is needed to prevent in those structures in principal. However, it is difficult to control the brittle fracture initiation on large scale steel structures completely even suitable fracture control design is applied because of various unexpected causes. Brittle crack arrestability of structural steels is essentially important for the integrity of large steel structures to prevent fatal accidents for some large structures whose damage may cause significant social loss. This double integrity concept which prevents both initiation and propagation of brittle fracture can decrease risk by brittle fracture dramatically.

However, there is no strictly described standard of brittle crack arrest toughness test of full thickness steel plate until Class NK published the standard \(K_{ca}\) test method which is temperature gradient type ESSO test (Class 2009). Temperature gradient type ESSO test is one of the most popular test methods for evaluating the brittle crack arrest toughness. However, the effects of test conditions are not always clearly investigated even standard \(K_{ca}\) test method of Class NK.

In this research, effect of the test specimen size, tab plate size, applied stress and temperature gradient were investigated. Additionally, validity range of test condition was introduced.

2 Effect of specimen width

2.1 Case of narrow width specimen

2.1.1 Testing conditions

Temperature gradient type ESSO tests are conducted for three kinds of specimen width. To investigate the narrow width, specimen width is even or less than 500 mm which is standard specimen width. Chemical compositions and mechanical properties of the steel used are shown in Tables 1 and 2.

Testing system is shown in Fig. 1. Test specimen width and other testing conditions are shown in Table 3.

2.1.2 Results

Test results described in Table 3 and Fig. 2 compares the Arrhenius plots of \(K_{ca}\) obtained from test specimens with a narrow width to those obtained from standard width. In the low temperature side where \(K_{ca}\) decreases, the values of \(K_{ca}\) obtained from test specimens with the width of 350–400 mm are slightly lower than those obtained from standard test specimens with the width of 500 mm.

2.1.3 Discussion

The reason of \(K_{ca}\) decreases at narrow width is that impact energy which is applied for initiating brittle crack increases the dynamic stress intensity factor, \(K_{d}\), in a short crack length (The Japan Welding Engineering Society 2014).

Considering that the results obtained from test specimens with a narrow width are on the safe side, and also considering the practicality of testing, the use of narrow width specimens is allowed. Since, however, too narrow test specimens are likely to give too low values of \(K_{ca}\), the lower limit of test specimen width is specified as 350 mm.

2.2 Case of wide width specimen

2.2.1 Testing conditions

Temperature gradient type ESSO tests are conducted for three kinds of specimen width. To investigate the wide width, specimen width is even or more than 500 mm which is standard specimen width. Chemical compositions and mechanical properties of the steel used are shown in Tables 4 and 5.

Figure 3 shows the testing system. Test specimen width and other testing conditions are shown in Table 6.

2.2.2 Results

Table 6 shows the test results and Fig. 4 shows the results comparing the values of arrest toughness obtained from test specimens with a width of 500–1000 mm made from the same material. The values of \(K_{ca}\) obtained from wide test specimens with the width of 700–1000 mm are almost the same as those obtained from standard width specimen.

2.2.3 Discussion

Case of using wide width specimen larger than 1000 mm, distance between loading pins shorter than 4 m has possibility to decrease K\(_{d}\) by stress reflection (The Japan Welding Engineering Society 2014). In addition, considering the practicality of testing, acceptable distance between loading pins is 4 m or less.

Considering that test specimens with a width up to at least 1000 mm have little effect on \(K_{ca}\) values, the upper limit of test specimen widths is specified as 1000 mm.

3 Effect of tab plates dimension

3.1 Various kind size of tab plate

3.1.1 Testing conditions

To verify the effect of tab plate size, various kind size of tab plate is used for temperature gradient type ESSO tests. 16 mm thick steel plate is used for specimen and the standard tab plate thickness is same thickness of test specimen. Chemical compositions and mechanical properties of the steel are shown in Tables 7 and 8.

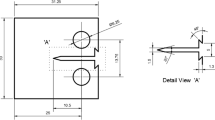

Testing system is shown in Fig. 5. Tab plate size and other testing conditions are shown in Table 9.

3.1.2 Results

Table 10 shows the test results and Fig. 6 shows the results of comparing the values of \(K_{ca}\) in various kind of tab size. In a range of tab plate thickness up to 1.5 times the test specimen thickness, the values of \(K_{ca}\) are almost the same independently of the tab plate thickness. On the other hand, in case of using wide width tab plate up to 2.0 times the test specimen width, the values of \(K_{ca}\) are almost the same that of 1.0 times the test specimen width. In addition, in a range of tab plate length up to 3.0 times the test specimen length, \(K_{ca}\) values are roughly in a line giving a linear Arrhenius plot of 1.0 times the test specimen length.

3.1.3 Discussion

In the case of thicker tab plate than test specimen, stress reflection at the boundary between specimen and tab plate affects on decrease of stress around crack tip (Kawabata et al. 2010).

As a result, the upper limit of tab plate thickness as 1.5 times the test specimen thickness is recommended.

Figure 6 also shows the measurement results of \(K_{ca}\) in the case of widening the tab plate width to 2.0 times the test specimen width. The results indicate that, in the case of tab plate widths in a range of 1.0–2.0 times the test specimen width, the tab plate width has no effect on the measured values of \(K_{ca}\). As a result, tab plate widths as 1.0–2.0 times the test specimen width are allowed.

Additionally, Fig. 6 shows the results of \(K_{ca}\) measurement for different tab plate lengths. The values of \(K_{ca}\) obtained using the same length as the test specimen width (500 mm) are roughly the same as those obtained using a long tab plate with a length 3.0 times the test specimen width (1500 mm) with a small load drop. From these results, tab plate lengths are determined considering that the valid values of \(K_{ca}\) can be measured with a small load drop when the tab plate length is equal to or larger than the test specimen width. The total length of the test specimen and the tab plates shall be larger than 3.0 times the test specimen width.

Pin chuck shapes are not specified in detail. Pin chucks have to have enough strength to hold applied loads. In principle, however, pin chuck widths are specified to be equal to or larger than the tab plate width so that stresses are uniformly transferred to the test specimen and the tab plates.

3.2 Case of thin tab plate

3.2.1 Testing conditions

In order to investigate the effect of thin tab plate, two kinds thickness of tab plate are used for an ESSO tests. 50mm thick steel plate is used for specimen. Chemical compositions and mechanical properties of the steel are shown in Tables 11 and 12.

Testing system is shown in Fig. 7. Tab plate thickness and other testing conditions are shown in Table 13.

3.2.2 Results

Table 14 shows the test results and Fig. 8 shows the values of \(K_{ca}\) obtained from thin tab plate specimen. For comparison, Fig. 8 also shows the values of \(K_{ca}\) obtained from thick tab plate specimen. The results indicate that the values of \(K_{ca}\) decrease when using thin tab plates.

3.2.3 Discussion

The reason \(K_{ca}\) decreases at thin tab plate that stress waves reflect to the tension side and act on the crack propagation area of the test specimen. As a result, lower \(K_{ca}\) values are estimated when using thin tab plates. Since the evaluation gives the results on the safe side, the use of thin tab plates is allowed considering the practicality of testing. However, too thin tab plates are likely to give too low values of \(K_{ca}\), the lower limit of tab plate thickness is specified as 0.8 times the test specimen thickness.

4 Effect of applied stress

4.1 Testing conditions

To verify the effect of applied stress, lots of temperature gradient type ESSO tests are conducted using high strength steel with a specified minimum yield stress of 320–460 N/mm\(^{2}\). Chemical compositions and mechanical properties of each steels used are shown in Tables 15 and 16. Width of all specimens is 500 mm.

Testing system is shown in Fig. 9. That of temperature gradient type ESSO test on Y32N80 steel is same as Fig. 3a. Test conditions are shown in Table 17.

4.2 Results

Table 17 shows the test results. The numbers which are described in the parentheses nearby plots in Fig. 10 show the ratios of applied stress to yield stress at room temperature. In the case of Fig. 10a, b, where all tests were conducted under the condition of an applied stress ratio of 0.5 or less, the data points are in a line giving a linear Arrhenius plot. On the other hand, in the case of Fig. 10c, the data points for an applied stress ratio of 0.673 were plotted higher than other data. Similarly in the cases of Fig. 10d, e, the data points for high applied stress ratios were plotted higher than other data.

4.3 Discussion

Increasing applied stress may increases the plastic zone a head of crack tip and leads to the decrease in crack driving force (Aihara et al. 2012). As a consequence, the \(K_{ca}\) for high applied stress ratios are plotted higher than other data.

From the above results, the applied stress as 2/3 or less of the yield stress at room temperature is recommended. Applied stresses higher than the above are likely to give higher values of \(K_{ca}\). For information, this condition was obtained from the test results on high strength steel with a yield stress of 320–360 N/mm\(^{2}\) and a thickness of 30–80 mm. Since the appropriate range of applied stresses may depend on yield stresses and thicknesses, further study is needed.

5 Effect of temperature gradient

5.1 Testing conditions

Difference in temperature gradient affects formation of side ligaments of the arrest test specimen. Therefore arrest test results may affected by temperature gradient. In this chapter, the effect of temperature gradient is investigated.

Two normalized steels of 50 mm and 80 mm thickness are used. Chemical compositions and mechanical properties are shown in Tables 18 and 19.

Temperature gradient type ESSO tests are conducted at three different steel mills in Japan. An example of the testing system is shown in Fig. 11a. Testing conditions are shown in Table 20. Duplex ESSO test is also conducted, which can be understand as no temperature gradient test. The testing system is shown in Fig. 11b. Suitable embrittled plates and welding consumables, which have proper toughness in the test temperature, are used in the duplex ESSO tests for straight and fast propagation of brittle crack through running plate and welded joint.

5.2 Results

Test results are shown in Table 20, Figs. 12 and 13. \(K_{ca}\) values of larger temperature gradient condition show lower values than those of smaller temperature gradient condition in both N−1 and N−2. \(K_{ca}\) level estimated from results of duplex ESSO test is consistent with\( K_{ca}\) values of 0.25 \({^\circ }\)C/mm condition.

5.3 Discussion

Figures 12 and 13 indicate that \(K_{ca}\) value of 0.50 \({^\circ }\)C/mm condition may be too severe to evaluate the arrest in the actual structure which is usually under isothermal condition, i.e. without temperature gradient. From the above results, the temperature gradient as nearly equal 0.25 \({^\circ }\)C/mm is recommended.

6 Conclusion

In this report, some of the effects of test conditions on the \(K_{ca}\) value evaluated by temperature gradient type ESSO tests are investigated. Investigation is based on the many temperature gradient ESSO type tests results with 16–80 mm thick low carbon steel produced by three research groups in Japan.

Effect of applied stress on the results of arrest toughness tests. a Effect of applied stress on \(K_{ca}\) on Y36N30. b Effect of applied stress on \(K_{ca}\) on Y32N80. c Effect of applied stress on \(K_{ca}\) on Y36N50-1\(\sim \)4. d Effect of applied stress on \(K_{ca}\) on Y36N50-5\(\sim \)10. e Effect of applied stress on \(K_{ca}\) on Y36T30

This investigation gives the appropriate range of test conditions as follows.

-

The recommendation range of specimen width is 350–1000 mm. However, too narrow test specimens are likely to give too low values of \(K_{ca}\), While, to use wide width specimen have little effect on \(K_{ca}\) values.

-

The recommendation tab plate thickness is between from 0.8 times to 1.5 times the test specimen thickness. The recommendation tab plate width as 1.0–2.0 times the test specimen width affects little on the measured values of \(K_{ca}\).

-

The total length of the test specimen and the tab plates shall be larger than 3.0 times the test specimen width.

-

The recommendation range of applied stress is less than 2/3 times yield stress at room temperature.

-

The temperature gradient as nearly equal 0.25 \({^\circ }\)C/mm is recommended.

References

Aihara S, Shibanuma K, Watabe Y (2012) Development of numerical model for brittle crack propagation/arrest behaiviors (in Japanese). Jpn Soc Naval Archit Ocean Eng 16:109–120

Class NK (2009) Guidelines on brittle crack arrest design, pp 4–8

Kawabata T, Matsumoto K, Yajima H, Aihara S, Yoshinari H, Hirota K, Toyoda M, Kiyosue T, Inoue T, Hanada and T, Tani, (2010) Development of brittle crack arrest toughness \(K_{ca}\) test method—Brittle crack arrest design for ultra large container ships 2-. In: Proceedings of the 20th international offshore and polar engineering conference, Beijing 2010, pp 80–87

The Japan Welding Engineering Society (2014) Test method for brittle crack arrest toughness, \(K_{ca}\)

Acknowledgements

The authors would like to acknowledge Class NK, The Japan Welding Engineering Society and the various personal of joint research committee, who conducted various test, analyzed date and discussed the results.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Shimada, Y., Inoue, T., Kawabata, T. et al. Effect of specimen size, applied stress and temperature gradient on brittle crack arrest toughness test. Int J Fract 204, 245–260 (2017). https://doi.org/10.1007/s10704-016-0179-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-016-0179-6