Abstract

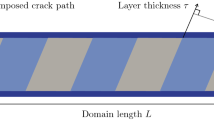

The relative potency of common toughening mechanisms is explored for layered solids and particulate solids, with an emphasis on crack multiplication and plasticity. First, the enhancement in toughness due to a parallel array of cracks in an elastic solid is explored, and the stability of co-operative cracking is quantified. Second, the degree of synergistic toughening is determined for combined crack penetration and crack kinking at the tip of a macroscopic, mode I crack; specifically, the asymptotic problem of self-similar crack advance (penetration mode) versus \(90^{\circ }\) symmetric kinking is considered for an isotropic, homogeneous solid with weak interfaces. Each interface is treated as a cohesive zone of finite strength and toughness. Third, the degree of toughening associated with crack multiplication is assessed for a particulate solid comprising isotropic elastic grains of hexagonal shape, bonded by cohesive zones of finite strength and toughness. The study concludes with the prediction of R-curves for a mode I crack in a multi-layer stack of elastic and elastic–plastic solids. A detailed comparison of the potency of the above mechanisms and their practical application are given. In broad terms, crack tip kinking can be highly potent, whereas multiple cracking is difficult to activate under quasi-static conditions. Plastic dissipation can give a significant toughening in multi-layers especially at the nanoscale.

Similar content being viewed by others

Notes

The dimension of the square finite elements near the crack tips has been fixed to 1/20th the vertical distance between the semi-infinite cracks.

Recall that \(\phi <0\) implies upwards kinking, whereas \(\phi >0\) will give downwards kinking, as explained by Lo (1978).

We note in passing that the limit \(R_0 /d\ll 1\) corresponds to an elastic–brittle solid. We anticipate that the degree of toughening associated with the deviations in crack path are comparable to that determined for the choice \(R_0 /d=1\).

References

Bertoldi K, Bigoni D, Drugan WJ (2008) Nacre: an orthotropic and bimodular elastic material. Compos Sci Technol 68:1363–1375

Cao HC, Evans AG (1991) On crack extension in ductile/brittle laminates. Acta Metall Mater 39:2997–3005

Chan KS, He M-Y, Hutchinson JW (1993) Cracking and stress redistribution in ceramic layered composites. Mater Sci Eng A 167:57–64

Cocks ACF, Ashby MF (1980) Intergranular fracture during power-law creep under multiaxial stresses. Metal Sci 14:395–402

Cocks ACF, Ashby MF (1982) Creep fracture by coupled power-law creep and diffusion under multiaxial stress. Metal Sci 16:465–474

Cocks ACF, Pan J (1993) Void growth ahead of a dominant crack in a material which deforms by Coble creep. Int J Fract 60:249–265

Currey JD (1977) Mechanical properties of mother of pearl in tension. Proc R Soc Lond B 196:443–463

Dean RH, Hutchinson JW (1980) Quasi-static crack growth in small-scale yielding. In: Fracture mechanichs. Proceedings of the twelfth national symposium of fracture mechanics, ASTM STP 700, American Society for Testing and Materials, pp 383–405

de la Osa R, Estevez R, Olagnon C, Chevalier J, Vignoud L, Tallaron C (2009) Cohesive zone model and slow crack growth in ceramic polycrystals. Int J Fract 158:157–167

Evans AG, Faber KT (1984) Crack-growth resistance of microcracking brittle materials. J Am Ceram Soc 67:255–260

Espinosa HD, Juster AL, Latourte FJ, Loh OY, Gregoire D, Zavattieri PD (2011) Tablet-level origin of toughening in abalone shells and translation to synthetic composite materials. Nat Commun 2:1–9

Freund LB (1998) Dynamic fracture mechanics. Cambridge University Press, Cambridge

Frost HJ, Ashby MF (1982) Deformation mechanism maps. The plasticity and creep of metals and ceramics. Pergamon Press, New York

Gao H, Ji B, Jäger IL, Arzt E, Fratzl P (2003) Materials become insensitive to flaws at the nanoscale: lesson from nature. Proc Natl Acad Sci USA 100:5597–5600

Gao H (2006) Application of fracture mechanics concepts to hierarchical biomechanics of bone and bone-like materials. Int J Fract 138:101–137

Gordon JE (1968) The new science of strong materials: or why you don’t fall through the floor. Penguin Books, London

He M-Y, Hutchinson JW (1989a) Crack deflection at an interface between dissimilar elastic materials. Int J Solid Struct 25:1053–1067

He M-Y, Hutchinson JW (1989b) Kinking of a crack out of an interface. J Appl Mech 56:270–278

He M-Y, Heredia FE, Wissuchek DJ, Shaw MC, Evans AG (1993) The mechanics of crack growth in layered materials. Acta Metall Mater 41:1223–1228

He M-Y, Wu B, Suo Z (1994) Notch-sensitivity and shear bands in brittle matrix composites. Acta Metall Mater 42:3065–3070

Hull D, Clyne TW (1996) An introduction to composite materials. Cambridge University Press, Cambridge

Hutchinson JW (1987) Crack tip shielding by micro-cracking in brittle solids. Acta Metall Mater 35:1605–1619

Jackson AP, Vincent JFV, Turner RM (1988) The mechanical design of nacre. Proc R Soc Lond B 234:415–440

Jackson AP, Vincent JFV, Turner RM (1990) Comparison of nacre with other ceramic composites. J Mater Sci 25:3173–3178

Jang D, Li X, Gao H, Greer JR (2012) Deformation mechanisms in nanotwinned metal nano pillars. Nat Nanotechnol 7:594–601

Kaim Y, Onck PR, van der Giessen E (2004) Simulations of crack meandering and crack branching in intergranular creep fracture. In: Advanced fracture mechanics for life and safety assessments. Proceedings of the 15th European Conference on Fracture, ECF15

Kaim Y, Onck PR, van der Giessen E (2005) The topology of fracture surfaces in intergranular creep fracture. In: Proceedings of the 11th international conference on fracture 2005, ICF11, pp 3090–3095

Kelly A (1973) Strong solids. Clarendon Press, Oxford

Kreher W, Pompe W (1981) Increased fracture toughness of ceramics by energy-dissipative mechanisms. J Mater Sci 16:694–706

Lawn BR, Wilshaw TR (1975) Fracture of brittle solids. Cambridge University Press, Cambridge

Lin A, Meyers MA (2005) Growth and structure in abalone shell. Mater Sci Eng A 390:27–41

Lo KK (1978) Analysis of branched cracks. J Appl Mech 45:797–802

Lubliner J (1990) Plasticity theory. Pearson Education, Upper Saddle River, NJ

Needleman A, Rice JR (1980) Plastic creep flow effects in the diffusive cavitation of grain boundaries. Acta Metall Mater 28:1315–1332

Pan J, Cocks ACF (1993) The effect of grain-size on the stress and velocity fields ahead of a crack in a material which deforms by Coble creep. Int J Fract 60:121–134

Rice JR (1979) Plastic creep flow processes in fracture at elevated temperature. In: Time dependent fracture of materials at elevated temperature. U.S. Department of Energy Report CONF 790236 UC-25, pp 130–145

Rose LRF (1986) Microcrack interaction with a main crack. Int J Fract 31:233–242

Rühle M, Evans AG, McMeeking RM, Charalambides PG, Hutchinson JW (1987) Microcrack toughening in aluminia/zirconia. Acta Metall Mater 35:2701–2710

Shabir Z, Van der Giessen E, Duarte CA, Simone A (2011) The role of cohesive properties on intergranular crack propagation in brittle polycrystals. Model Simul Mater Sci Eng 19:1–21

Shao Y, Zhao H-P, Feng X-Q, Gao H (2012) Discontinuous crack-bridging model for fracture toughness analysis of nacre. J Mech Phys Solids 60:1400–1419

Shaw MC, Clyne TW, Cocks ACF, Fleck NA, Pateras SK (1996) Cracking patterns in metal-ceramic laminates: effects of plasticity. J Mech Phys Solids 44:801–821

Shum DKM, Hutchinson JW (1990) On toughening by microcracks. Mech Mater 9:83–91

Suo Z, Shih C, Varias AG (1993) A theory for cleavage cracking in the presence of plastic flow. Acta Metall Mater 41:1551–1557

Tvergaard V, Hutchinson JW (1992) The relation between crack growth resistance and fracture process parameters in elastic-plastic solids. J Mech Phys Solids 40:1377–1397

Tvergaard V (1997) Cleavage crack growth resistance due to plastic flow around a near-tip dislocation-free region. J Mech Phys Solids 45:1007–1023

Wang RZ, Suo Z, Evans AG, Yao N, Aksay IA (2001) Deformation mechanisms in nacre. J Mater Res 16:2485–2493

Xu X-P, Needleman A (1994) Numerical simulations of fast crack growth in brittle solids. J Mech Phys Solids 42:1397–1434

Youa Z, Lib X, Guic L, Lua Q, Zhuc T, Gao H, Lua L (2013) Plastic anisotropy and associated deformation mechanisms in nanotwinned metals. Acta Mater 61:217–227

Zhang Z, Zhang Y-W, Gao H (2011) On optimal hierarchy of load-bearing biological materials. Proc R Soc Lond B 278:519–525

Zhu T, Gao H (2012) Plastic deformation mechanism in nanotwinned metals: an insight from molecular dynamics and mechanistic modeling. Scr Mater 66:843–848

Acknowledgments

The authors are grateful to DARPA for their financial support through Grant W91CRB-10-1-005 titled “A micro-cellular solids approach to thermo-structural materials with controlled architecture”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Noselli, G., Deshpande, V.S. & Fleck, N.A. An analysis of competing toughening mechanisms in layered and particulate solids. Int J Fract 183, 241–258 (2013). https://doi.org/10.1007/s10704-013-9890-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-013-9890-8